Abstract

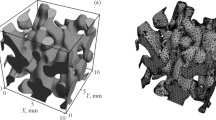

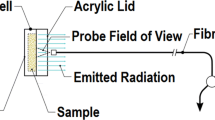

Recently developed sandwich structures consist of a porous metal core sandwiched between two fully dense face sheets. These structures are produced by pressurizing a metal powder compact with an inert gas prior to consolidation by hot isostatic pressing (“hipping”). After consolidating and hot rolling the compact to a sheet form, a high-temperature annealing step is used to expand the internally pressurized gas-filled micropores. This expansion results in a porous core sandwich structure with integrally bonded face sheets. Recent experimental studies[1] with a Ti-6Al-4V porous core sandwich have indicated that the expansion rate exhibits a maximum during thermal ramping to 920 °C but then continued to expand over many hours at a constant temperature. Significant grain growth also accompanied the expansion. A microstructure-dependent creep model has been developed for a body containing a distribution of spheroidal pores. The body’s constitutive behavior is described by microstructure-dependent creep potentials for dislocation (power law) and diffusion-accommodated grain-boundary sliding (DAGS). It has been used to simulate the expansion of Ti-6Al-4V sandwich structures subjected to thermal cycles similar to those studied experimentally. The simulated response compared well with experimental results. The model was then used to identify an attainable core porosity as a function of the initial gas pressure and initial core relative density at the completion of the expansion process step.

Similar content being viewed by others

References

D.T. Queheillalt, B.W. Choi, D.S. Schwartz, and H.N.G. Wadley: Metall. Mater. Trans. A, 2000, vol. 31A, p. 261.

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed., Cambridge University Press, Cambridge, United Kingdom, 1997.

D.S. Schwartz, D.S. Shih, R.L. Lederich, R.L. Martin, and D.A. Deuser: Porous and Cellular Materials for Structural Applications, Materials Research Society Symposia Proceedings, D.S. Schwartz, D.S. Shih, H.N.G. Wadley, and A.G. Evans, eds., Materials Research Society, Warrendale, PA, 1998, vol. 521, p. 225.

I. Jin, L.D. Kenny, and H. Sang: U.S. Patent No. 4,973,358, Nov. 27, 1990.

I. Jin, L.D. Kenny, and H. Sang: U.S. Patent No. 5,112,697, May 12, 1992.

I. Jin, L.D. Kenny, and H. Sang: U.S. Patent No. 5,221,324, June 22, 1993.

L.D. Kenny: U.S. Patent No. 5,281,251, June 25, 1994.

H. Sang, L.D. Kenny, and I. Jin: U.S. Patent No. 5,334,236, Aug. 2, 1994.

M. Thomas, L.D. Kenny, and H. Sang: U.S. Patent No. 5,622,542, Apr. 22, 1997.

J.C. Elliot: U.S. Patent No. 2,751,289, Oct. 8, 1951.

A.R. Valdo: U.S. Patent No. 3,756,303, Sept. 4, 1973.

L.M. Niebylski and C.P. Jarema: U.S. Patent No. 3,790,365, Feb. 5, 1974.

L.M. Niebylski, C.P. Jarema, and T.E. Lee: U.S. Patent No. 3,816,952, June 18, 1974.

L.M. Niebylski and C.P. Jarema: U.S. Patent No. 3,847,591, Nov. 12, 1974.

S.E. Speed: U.S. Patent No. 3,981,720, Sept. 21, 1976.

S. Akiyama, H. Ueno, K. Imagawa, A. Katahara, S. Nagata, K. Morimoto, T. Nishikawa, and M. Itoh: European Patent No. 210803A1, Feb. 4, 1987.

S. Akiyama, H. Ueno, K. Imagawa, A. Katahara, S. Nagata, K. Morimoto, T. Nishikawa, and M. Itoh: U.S. Patent No. 4,713,277, Dec. 15, 1987.

S. Akiyama, H. Ueno, K. Imagawa, A. Katahara, S. Nagata, K. Morimoto, T. Nishikawa, and M. Itoh: European Patent No. 210803B1, Sept. 20, 1989.

S. Morita and Y. Igarashi: U.S. Patent No. 5,462,612, Oct. 1, 1995.

T. Masusa and S. Kanbayashi: U.S. Patent No. 5,482,533, Jan. 9, 1996.

C.C. Yang, S.C. Chueh, K.C. Su, and T.H. Chion: U.S. Patent No. 5,632,319, May 27, 1997.

R.L. Landingham: U.S. Patent No. 4,560,621, Dec. 24, 1985.

J. Baumeister: DE Patent 4,018,360, 1991.

J. Baumeister and H. Schrader: U.S. Patent No. 5,151,246, Sept. 29, 1992.

H. Worz and H.P. Degisher: U.S. Patent No. 5,393,485, Feb. 28, 1995.

C.J. Yu, H.H. Eifert, J. Banhart, and J. Baumeister: Mater. Res. Innovat., 1998, vol. 2, p. 181.

V.I. Shapovalov and A.G. Timchenko: Fiz. Metall., 1993, vol. 76, p. 335.

V.I. Shapovalov: U.S. Patent No. 5,181,549, Jan. 26, 1993.

V.I. Shapovalov: MRS Bull., 1994, vol. 19 (4), p. 24.

M.W. Kearns: U.S. Patent No. 4,659,546, Apr. 21, 1987.

M.W. Kearns, P.A. Blenkinsop, A.C. Barber, and T.W. Farthing: Proc. 6th World Conf. on Titanium, Cannes, France, 1988, p. 667.

M.W. Kearns, P.A. Blenkinsop, A.C. Barber, and T.W. Farthing: Int. J. Powder Metall., 1988, vol. 24 (1), p. 59.

R.L. Martin and R.J. Lederich: Advances in Powder Metallurgy: Proc. 1991 Powder Metallurgy Conf. Exp., Powder Metallurgy Industries Federation, Princeton, NJ, 1991, p. 361.

R.L. Martin: U.S. Patent No. 5,564,064, Oct. 8, 1996.

M.F. Ashby: Materials Selection in Mechanical Design, Pergamon, Oxford, United Kingdom, 1992.

F.R. Shanley: Weight-Strength Analysis of Aircraft Structures, Dover, New York, NY, 1960.

R. Vancheeswaren, D.M. Elzey, and H.N.G. Wadley: Acta Mater., 1996, vol. 44 (6), p. 2175.

R. Vancheeswaren, D.G. Meyer, and H.N.G. Wadley: Acta Mater., 1997, vol. 45 (10), p. 4001.

R. Vancheeswaren, D.M. Elzey, J.M. Kunze, and H.N.G. Wadley: Mater. Sci. Eng. A, 1998, vol. 244 p. 49.

R. Vancheeswaren and H.N.G. Wadley: Mater. Sci. Eng. A, 1998, vol. 244, p. 58.

M.F. Ashby: Mater. Sci. Technol., 1992, vol. 8 (2), p. 102.

E. Arzt, M.F. Ashby, and K.E. Easterling: Metall. Trans. A, 1983, vol. 14A pp. 211–21.

D.M. Elzey and H.N.G. Wadley: Acta Metall. Mater., 1993, vol. 41 (8), p. 2297 (references within).

B.J. Lee and M.E. Mear: J. Mech. Phys. Solids, 1992, vol. 40 (8), p. 1805.

J.M. Duva and P.D. Crow: Acta Metall. Mater., 1992, vol. 40 (1), p. 31.

J.M. Duva and P.D. Crow: Mech. Mater., 1994, vol. 17 (1), p. 25.

M.F. Ashby and R.A. Verall: Acta Metall., 1973, vol. 21 (2), p. 149.

F.R.N. Nabarro: The Physics of Creep: Creep and Creep Resistant Alloys, Taylor & Francis, London, 1995.

J. Cadek: Creep of Metallic Materials, Elsevier, New York, NY, 1988.

R.W. Evans and B. Wilshire: Creep of Metals and Alloys, Institute of Metals, London, 1985.

J.P. Poirier: Creep of Crystals: High-Temperature Deformation Processes in Metals, Ceramics, and Minerals, Cambridge University Press, Cambridge, United Kingdom, 1985.

H.E. Evans: Mechanisms of Creep Fracture, Elsevier, New York, NY, 1984.

D.S. Wilkinson and M.F. Ashby: Acta Metall., 1975, vol. 23 (11) p. 1277.

A.C.F. Cocks: J. Mech. Phys. Solids, 1989, vol. 37, p. 693.

P. Ponte Castaneda: J. Mech. Phys. Solids, 1991, vol. 39 p. 45.

P. Sofronis and R.M. McMeeking: J. Appl. Mech., 1992, vol. 59 (2) p. S88.

Y. Liu, H.N.G. Wadley, and J.M. Duva: Acta Metall. Mater., 1994, vol. 42 (7) p. 2247.

J.M. Warren and H.N.G. Wadley: Acta Metall. Mater., 1995, vol. 43 (7) p. 2773.

J.E. Burke and D. Turnbull: Progr. Met. Phys., 1952, vol. 3 p. 220.

M. Hillert: Acta Metall., 1965, vol. 13 p. 227.

MATLAB™, The Math Works, Inc., Natick, MA, www.mathworks.com.

B. Budiansky, J.W. Hutchinson, and S. Slutsky: in Mechanics of Solids, H.G. Hopkins and M.J. Sewell, eds., Pergamon Press, Oxford, United Kingdom, 1982, p. 13.

D.S. Schwartz: Boeing Company, St. Louis, MO, private communication, 1998.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vancheeswaram, R., Queheillalt, D.T., Elzey, D.M. et al. Simulation of the creep expansion of porous sandwich structures. Metall Mater Trans A 32, 1813–1821 (2001). https://doi.org/10.1007/s11661-001-0157-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0157-z