Abstract

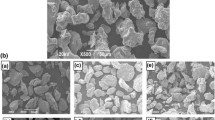

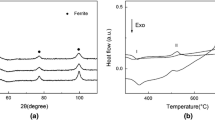

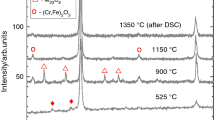

The microstructure and the strength of an iron mechanically milled with various amounts of oxygen (i.e., 0.2, 0.6, and 1.5 mass pct) were studied. The samples were subjected to a mechanical milling in an argon atmosphere for 100 hours followed by consolidating bar rolling to a total reduction of about 86 pct at 700 °C. The microstructure of the steels sensitively changed depending on the oxygen content, i.e., on the volume fraction of the oxide particles. The average grain size decreased from about 0.7 to 0.2 µm with an increase in the amount of oxygen. Moreover, the misorientation distributions of the grain boundaries were different in the samples with various amounts of oxygen. A relatively large fraction of low-angle boundaries arranged crosswise to the rolling axis was registered in the samples with 0.2 and 0.6 pct oxygen, while the near random distribution of the boundary misorientations was obtained in the specimens with 1.5 pct oxygen. The effect of dispersed particles on the structure evolution and the relationship between microstructures and some mechanical properties are discussed.

Similar content being viewed by others

References

F.J. Humphreys, P.B. Prangnell, J.R. Bowen, A. Gholinia, and C. Harris: Phil. Trans. R. Soc. London, 1999, vol. 357, pp. 1663–81.

R.Z. Valiev, R.K. Islamgaliev and I.V. Alexandrov: Progr. Mater. Sci., 2000, vol. 45, pp. 103–89.

Y. Kimura, S. Takaki, S. Suejima, R. Uemori, and H. Tamehiro: Iron Steel Inst. Jpn. Int., 1999, vol. 39, pp. 176–82.

Y. Sakai, M. Ohtaguchi, Y. Kimura, and K. Tsuzaki: in Ultrafine Grained Materials, R.S. Mishra, S.L. Semiatin, C. Suryanarayana, N.N. Thadhani, and T.C. Lowe, eds., TMS, Warrendale, PA, 2000, pp. 361–70.

D.B. Williams and C.B. Carter: Transmission Electron Microscopy, Plenum Press, New York, NY, 1996, pp. 289–300.

J.K. MacKenzie: Biometrika, 1958, vol. 45, pp. 229–40.

C.N. Reid: Deformation Geometry for Materials Scientists, Pergamon Press, Elmsford, NY, 1973, pp. 103–78.

L.F. Pease III: in Metals Handbook, ASM INTERNATIONAL Handbook Committee, ed., ASM INTERNATIONAL, Materials Park, OH, 1990, vol. 1, pp. 801–21.

Y. Kimura, H. Hidaka, and S. Takaki: Mater. Trans. JIM, 1999, vol. 40, pp. 1149–57.

E.O. Hall: Proc. Phys. Soc., 1951, vol. B64, pp. 747–53.

A. Belyakov, W. Gao, H. Miura, and T. Sakai: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2957–65.

A. Belyakov, T. Sakai, and H. Miura: Mater. Trans. JIM, 2000, vol. 41, pp. 476–84.

O.A. Kaibyshev: Superplasticity of Alloys, Intermetallics and Ceramics, Springler, Berlin, 1992, pp. 1–36.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Belyakov, A., Sakai, Y., Hara, T. et al. Effect of dispersed particles on microstructure evolved in iron under mechanical milling followed by consolidating rolling. Metall Mater Trans A 32, 1769–1776 (2001). https://doi.org/10.1007/s11661-001-0153-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0153-3