Abstract

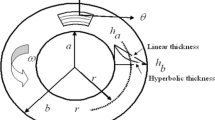

Steady-state creep response in a particle-reinforced isotropic functionally graded material (FGM) disc with linear variation of particle distribution along the radial distance has been investigated and compared with that of a disc containing the same amount of particle distributed uniformly. In view of the application of rotating discs in friction drives, turbines, and a number of other machine components, which are often exposed to elevated temperatures, weight saving without impairing the creep response may be a desirable goal. The disc under investigation is made of a composite containing silicon carbide particles in a matrix of 6061 aluminum alloy, and the steady-state creep response of the composite is described by Norton’s law. The material parameters of creep vary along the radial distance in the disc due to varying composition, and this variation has been estimated by regression fit of the available experimental data. The present analysis indicates that the tangetial stress increases due to increased density caused by a higher particle content in the region near the inner radius of the FGM disc. But it is more than compensated by the lowering of creep parameters due to increased particle content, and consequently, the steady-state creep rate decreases compared to those estimated in a disc with the same average particle content distributed uniformly. In the region near the outer radius, the tangential stress decreases and the creep parameters increase, both due to relatively lower particle content. But the resulting lower tangential stress is able to decrease the creep rate in this region overcoming the effect of increased creep parameters. Thus, for the assumed linear particle distributions in an isotropic rotating disc, the steady-state tangential and radial creep rates are smaller by almost an order of magnitude compared to those in an isotropic disc with uniform particle distribution.

Similar content being viewed by others

References

T.R. Jackson, H. Liu, N.M. Patrikalakis, E.M. Sachs, and M.J. Cima: Mater. Design, 1999, vol. 20, pp. 63–75.

Y. Fukui, N. Yamanka, and Y. Enokida: Proc. 2nd Int. Conf. on Composites Engineering (ICCE/2), [LA, Aug. 21–24, 1995, David Hui, ed.,] New Orleans, ICCE (International Community for Composites Engineering), New Orleans, LA, 1995, pp. 833–34.

D. Zhu and R.A. Miller: J. Mater. Res., 1999, vol. 14 (1), pp. 146–61.

R.L. Williamson, B.H. Rabin, and G.E. Byerly: Composites Eng., 1995, vol. 5 (7), pp. 851–63.

M.F. Ashby: HIP487: A Program for Constructing Hot Isostatic Pressing Diagrams, Cambridge University, Cambridge, United Kingdom, 1987.

S.B. Singh, S. Ray, R.K. Gupta, and N.S. Bhatnagar: Proc. Conf. on Mathematics and Its Application in Engineering Industry, University of Roorkee, Roorkee, India, Dec. 16–18, 1996.

S.B. Singh, R.K. Gupta, N.S. Bhatnagar, and S. Ray: Proc. COMPEAT-98, National Metallurgical Laboratory, Jamshedpur, India, 1998, pp. 83–102.

S.B. Singh: Ph.D. Thesis, University of Roorkee, Roorkee, India, 2000.

T.G. Nieh: Metall. Trans. A, 1984, vol. 15A, pp. 139–45.

A.B. Pandey, R.S. Mishra, and Y.R. Mahajan: Acta Metall. Mater., 1992, vol. 40 (8), pp. 2045–52.

R. von Mises: Technical Memorandum 88488, NASA, Washington, DC, 1986; translation of Mechanik der Festen Koerper im Plastisch-Deformablem Zustrand, Nachrichten von der Königlichen Gasellschaft der Wissenschaften, pp. 582–92.

A.M. Wahl, G.O. Sankey, M.J. Manjoine, and E. Shoemaker: J. Appl. Mech., 1954, vol. 21 (3), pp. 225–35.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Singh, S.B., Ray, S. Steady-state creep behavior in an isotropic functionally graded material rotating disc of Al-SiC composite. Metall Mater Trans A 32, 1679–1685 (2001). https://doi.org/10.1007/s11661-001-0146-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0146-2