Abstract

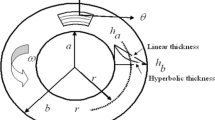

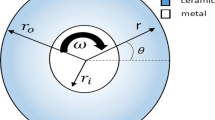

A mathematical model is developed to analyse creep in a variable thickness functionally graded rotating disc yielding according to Tresca criterion. The results obtained are compared with those estimated using von Mises criterion. The tangential and radial stresses, using Tresca criterion, are observed to be slightly higher, except those noticed near the inner and outer disc radii. The Tresca criterion yields lower values of effective stress as compared to Mises criterion. However, the Tresca criterion estimates higher values of strain rates in the disc as compared to Mises criterion, with maximum variation noticed at the inner radius. Thus, the FGM disc designed using Tresca yield criterion is more conservative than that designed according to von Mises criterion.

Similar content being viewed by others

References

Abdollahifar A, Nami MR (2014) Determination of dynamic stress intensity factor in FGM plates by MPLG method. Iran J Sci Technol Trans Mech Eng 38(M1+):181–194

Aboudi J, Pindera MJ, Arnold SM (1999) Higher-order theory for functionally graded materials. Compos B 30:777–832

Ali A, Bayat M, Sahari BB, Saleem M, Zaroog OS (2012) The effect of ceramic in combinations of two sigmoid functionally graded rotating disks with variable thickness. Sci Res Essays 7:2174–2188

Bayat M, Saleem M, Sahari BB, Hamouda AMS, Mahdi E (2005) Thermo elastic analysis of a functionally graded rotating disk with small and large deflections. Thin Wall Struct 45:677–691

Bayat M, Saleem M, Sahari BB, Hamouda AMS, Mahdi E (2008) Analysis of functionally graded rotating disks with variable thickness. Mech Res Commun 35:283–309

Bayat M, Sahari BB, Saleem M, Hamouda AMS, Reddy JN (2009a) Thermo elastic analysis of functionally graded rotating disks with temperature-dependent material properties: uniform and variable thickness. Int J Mech Mater Des 5:263–279

Bayat M, Sahari BB, Saleem M, Ali A, Wong SV (2009b) Thermo elastic solution of a functionally graded variable thickness rotating disc with bending based on the first-order shear deformation theory. Thin Wall Struct 47:568–582

Bayat M, Sahari BB, Saleem M, Dezvareh E, Mohazzab AH (2011) Analysis of functionally graded rotating disks with parabolic concave thickness applying an exponential function and the Mori-Tranka Scheme. IOP Conf Ser Mater Sci Eng 17

Belhocine A (2015) Thermomechanical stress analysis of vehicles gray cast brake. Iran J Sci Technol Trans Mech Eng 39(M1+):243–252

Bhowmick S, Misra D, Saha KN (2010) Variational formulation based analysis on growth of yield front in high speed rotating solid disks. Int J Eng Sci Techol 2:200–219

Burden RL, Faires JD (2011) Numerical analysis, 9th edn. Cengage Learning India Limited, Delhi, pp 20–21

Callioglu H, Sayer M, Demir E (2011) Stress analysis of functionally graded rotating discs under mechanical and thermal loads. Indian J Eng Mater Sci 18:111–118

Çallıoğlu H, Topcu M, Tarakcilar AR (2006) Elastic–plastic stress analysis of an orthotropic rotating disc. Int J Mech Sci 48:985–990

Damircheli M, Azadi M (2011) Temperature and thickness effects on thermal and mechanical stresses of rotating FG-disks. J Mech Sci Technol 25:827–836

Deepak D, Gupta VK, Dham AK (2010) Creep modeling of functionally graded rotating disc of variable thickness. J Mech Sci Technol 24:2221–2232

Dieter GE (1988) Mechanical metallurgy. McGraw Hill Book Company, New Delhi

Durodola JF, Attia O (2000) Deformation and stresses in FG rotating disks. Compos Sci Technol 60:987–995

Eraslan AN (2003) Elastic–plastic deformations of rotating variable thickness annular disks with free, pressurized and radially constrained boundary conditions. Int J Mech Sci 45:643–667

Eraslan AN, Orcan Y (2002) Elastic–plastic deformation of a rotating disk of exponentially varying thickness. Mech Mater 34:423–432

Farshi B, Jahed H, Mehrabian A (2004) Optimum design of inhomogeneous non-uniform rotating disks. Int J Comput Struct 82:773–779

Frank AD (1960) ISA dissertation. University of Pittsburgh

Gupta VK, Singh SB, Chandrawat HN, Ray S (2004) Steady state creep and material parameters in a rotating disc of Al–SiCp composite. Eur J Mech A/Solids 23:335–344

Gupta VK, Singh SB, Chandrawat HN, Ray S (2005) Modeling of creep behavior of a rotating disc in the presence of both composition and thermal gradients. J Eng Mater Technol 127:97–105

Guven U (1992) Elastic-plastic stresses in a rotating annular disk of variable thickness and variable density. Int J Mech Sci 34:133–138

Hassani A, Hojjati MH, Farrahi GH, Alashti RA (2012) Semi-exact solution for thermo-mechanical analysis of functionally graded elastic-strain hardening rotating disks. Commun Nonlinear Sci Numer Simul 17:3747–3762

Hojjati MH, Hassani A (2008) Theoretical and numerical analyses of rotating discs of non-uniform thickness and density. Int J Pressure Vessels Piping 85:694–700

Jahed H, Sherkatti S (2000) Thermoelastic analysis of inhomogeneous rotating disk with variable thickness. In: Proceedings of the EMAS Conference of Fatigue, Cambridge

Jahed H, Farshi B, Bidabadi J (2005) Minimum weight design of inhomogeneous rotating discs. Int J Pressure Vessels Piping 82:35–41

Khanna K, Gupta VK, Nigam SP (2015) Creep analysis of a variable thickness rotating FGM disc using Tresca criterion. Def Sci J 65:163–173

Kordkheili SAH, Naghdabadi R (2007) Thermoelastic analysis of a functionally graded rotating disk. Compos Struct 79:508–516

Laskaj M, Murphy B, Houngan K (1999) A project report on: Improving the efficiency of cooling the front disc brake on a V8 racing car, 22nd Oct. Monash University, Melbourne

Lee K (1999) Numerical prediction of brake fluid temperature rise during braking and heat soaking. SAE technical paper series 1999-01-0483, International congress and exposition, Detroit, Michigan, March 1–4, 1999, pp 1–9

Ma BM (1964) A power-function creep analysis for rotating solid disks having variable thickness and temperature. J Franklin Inst 277:593–612

Ma ZY, Tjong SC (2001) Creep deformation characteristics of discontinuously reinforced aluminum matrix composites. Compos Sci Technol 61:771–786

Nami MR, Janghorban M (2015) Free vibration of functionally graded size dependent nanoplates based on second order shear deformation theory using nonlocal elasticity theory. Iran J Sci Technol Trans Mech Eng 39(M1):15–28

Nie GJ, Batra RC (2010) Stress analysis and material tailoring in isotropic linear thermo elastic incompressible functionally graded rotating disks of variable thickness. Compos Struct 92:720–729

Orcan Y, Eraslan AN (2002) Elastic–plastic stresses in linearly hardening rotating solid disks of variable thickness. Mech Res Commun 29:269–281

Reddy JN, Wang CM, Kitipornchai S (1999) Axisymmetric bending of functionally graded circular and annular plates. Eur J Mech A/Solids 18:185–199

Townely CHA (1971) The use of computers in the creep analysis of power plant structures, advances in creep design. In: Smith AI, Nicolson AM (eds) Allied Science Publishers, London, pp 443–456

Vullo V, Vivio F (2008) Elastic stress analysis of non-linear variable thickness rotating disks subjected to thermal load and having variable density along the radius. Int J Solids Struct 45:5337–5355

Wahl AM (1962) Application of the modified bailey equations for creep under biaxial tension stress. Fourth U. S. national congress of applied mechanics, Berkeley, California

Wahl AM, Sankey GO, Manjoine MJ, Shoemaker E (1954) Creep test of rotating discs at elevated temperature and comparison with theory. J Appl Mech Trans ASME 21:225–235

You LH, Tang YY, Zhang JJ, Zheng CY (2000) Numerical analysis of elastic–plastic rotating disks with arbitrary variable thickness and density. Int J Solids Struct 37:7809–7820

Acknowledgements

The authors would like to express their sincere thanks to all the reviewers for their meticulous observations and comments, which helped in raising the standard of this research paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanna, K., Gupta, V.K. & Nigam, S.P. Modelling and Analysis of Creep in a Variable Thickness Rotating FGM Disc Using Tresca and von Mises Criteria. Iran J Sci Technol Trans Mech Eng 41, 109–119 (2017). https://doi.org/10.1007/s40997-016-0051-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-016-0051-3