Abstract

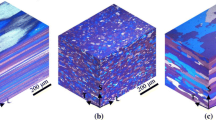

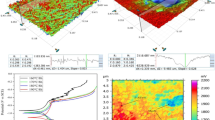

Isothermal time-temperature-localized corrosion-behavior curves were determined for the Al-1.8Li-2.70Cu-0.6Mg-0.3Zn alloy AF/C458, to understand the effect of slow or delayed quenching on localized corrosion susceptibility. Alloy samples were subject to a series of systematic interrupted quenching experiments conducted at temperatures ranging from 480 °C to 230 °C for times ranging from 5 to 1000 seconds. Individual samples were then exposed to an oxidizing aqueous chloride solution consisting of 57 g/L NaCl plus 10 mL/L H2O2 to induce localized attack. The localized corrosion mode was characterized by optical microscopy. Additionally, the microstructure of selected samples was characterized by transmission electron microscopy (TEM) to relate the corrosion mode and morphology to microstructural features. Results showed that only pitting attack was exhibited by samples subjected to isothermal treatment at temperatures greater than 430 °C. At temperatures ranging from 280 °C to 430 °C, isothermal treatment tended to induce susceptibility to intergranular attack (IGA) and intersubgranular attack (ISGA) for all treatment times investigated. For isothermal treatments at temperatures lower than 280 °C, only pitting was observed for treatment times less than about 30 seconds, while IGA and ISGA were observed for longer treatment times. Comparisons showed that the time-temperature domains for IGA and ISGA were virtually coincident. Based on this finding and the results from TEM characterization, IGA and ISGA appear to be related to the precipitation of a Zn-modified T 1 (Al2(Cu,Zn)Li) precipitate, which can occur both on low-angle and high-angle grain boundaries in this alloy. When the alloy is resistant to IGA and ISGA, the grain boundaries are decorated by θ′ (Al2Cu), and T B (Al7Cu4Li) phase particles, or subgrain boundaries are populated by a comparatively low density of T 1 precipitates. It is, therefore, speculated that θ′ and T B are more corrosion-resistant precipitate phases than T 1, and that a critical concentration of boundary T 1 must exist for IGA or ISGA to occur.

Similar content being viewed by others

References

P.S. Chen, A.K. Kuruvilla, T.W. Malone, and W.P. Stanton: J. Mater. Eng. Performance, 1998, vol. 7, pp. 682–90.

A.K. Hopkins, K.V. Jata, and R.J. Rioja: Mater. Sci. Forum, 1996, vol. 217–222, pp. 647–52.

V.K. Jain, K.V. Jata, R.J. Rioja, J.T. Morgan, and A.K. Hopkins: J. Mater. Proc. Technol., 1998, vol. 73, pp. 108–18.

“Workshop on the Characterization of Al-Li Alloy AF/C458,” a collection of slides, K. Jata, ed., Aluminum-Lithium Workshop, Wright Patterson AFB, Dayton, OH, 1998.

R.G. Buchheit, J.P. Moran, and G.E. Stoner: Corrosion, 1994, vol. 50, pp. 120–30.

W.L. Fink and L.A. Willey: Trans. AIME, 1948, vol. 175, pp. 414–27.

H.K. Hardy and J.M. Silcock: J. Inst. Met., 1955–56, vol. 84, pp. 423–30.

J.C. Huang and A.J. Ardell: Mater. Sci. Technol., 1987, vol. 3, pp. 176–88.

B. Noble and G.E. Thomson: Met. Sci. J., 1972, vol. 6, pp. 167–74.

R.G. Buchheit and G.E. Stoner: Al-Li Alloys V, MCE Publications, Ltd., Birmingham, United Kingdom, 1989, pp. 1347–56.

J.M. Silcock: J. Inst. Met., 1959–60, vol. 88, pp. 357–64.

N.J. Kim, J.M. Howe, and E.G. Boden: J. Phys., 1987, vol. 48 (9), C3, pp. 457–63.

JCPDS-ICDD, File 40-1158.

K. Schneider and M. von Heimendahl: Z. Metallkd., 1973, vol. 64, pp. 342–47.

H.M. Flower and P.J. Gregson: Mater. Sci. Technol., 1987, vol. 3, pp. 81–90.

R.G. Buchheit, J.P. Moran, and G.E. Stoner: Corrosion, 1990, vol. 46, pp. 610–16.

D. Mathur: Master’s Thesis, Ohio State University, Columbus, OH, 2000.

H.F. DeJong and J.H.M. Martens: Aluminium, 1985, vol. 61, pp. 416–20.

P. Niskanen, T.H. Sanders, Jr., M. Marek, and J.G. Rinker: Al-Li Alloys I, TMS-AIME, Warrendale, PA, 1981, pp. 347–76.

L. Christoudoulou, L. Struble, and J.R. Pickens: Al-Li Alloys II, Institute of Metals, London, 1984, pp. 561–80.

L.F. Mondolfo: Aluminum Alloys: Structure and Properties, Butterworth and Co., London, 1976, p. 502.

R.G. Buchheit: J. Electrochem. Soc., 1995, vol. 142, pp. 3394–96.

J.R. Galvele and S.M. DeMicheli: Corr. Sci., 1970, vol. 10, pp. 795–807.

R.C. Dorward: Mater. Sci. Eng., 1986, vol. 84, pp. 89–95.

E.I. Meletis: Mater. Sci. Technol., 1987, vol. 93, pp. 235–45.

T. Sheppard and N.C. Parson: Mater. Sci. Technol., 1987, vol. 3, pp. 345–52.

J.B. Lumsden and T.A. Allen: Corr. Sci., 1988, vol. 44, pp. 527–32.

L. Gan and E.I. Meletis: Mater. Sci. Forum, 2000, vols. 331–337, part 3, pp. 1619–24.

R.G. Buchheit, F.D. Wall, G.E. Stoner, and J.P. Moran: Corrosion, 1995, vol. 51, pp. 417–27.

C. Kumai, J. Kusiniski, G. Thomas, and T.M. Devine: Corrosion, 1989, vol. 45, pp. 294–302.

F.D. Wall and G.E. Stoner: Corr. Sci., 1997, vol. 39, pp. 835–53.

E.H. Hollingsworth and H.Y. Hunsicker: Metals Handbook, 9th ed., ASM International, Metals Park, OH, 1987, vol. 13, p. 584.

I.L. Muller and J.R. Galvele: Corr. Sci., 1977, vol. 17, pp. 995–1007.

S.F. Baumann and D.B. Williams: Al-Li Alloys II, TMS-AIME, Warrendale, PA, 1984, pp. 17–30.

J.R. Pickens, L.S. Kramer, T.J. Langen, F.H. Heubaum, and F.W. Gayle: Aluminum-Lithium Alloys VI, DGM Informationsgesellschaft mbH, Garmisch-Partenkirchen, Germany, 1992, pp. 357–62.

R.J. Kilmer and G.E. Stoner: Scripta Metall., 1991, vol. 25, pp. 243–48.

R.G. Buchheit, R.P. Grant, P.F. Hlava, B. McKenzie, and G.L. Zender: J. Electrochem. Soc., 1997, vol. 144, pp. 2621–28.

A.A. Csontos, B.M. Gable, A. Gaber, and E.A. Starke, Jr.: Mater. Sci. Forum, 2000, vols. 331–333, pp. 1333–40.

Atlas of Time Temperature Transformation Diagrams for Non-Ferrous Alloys, G.F. Vander Voort, ed., ASM INTERNATIONAL, Materials Park, OH, 1991, pp. 12–13.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kertz, J.E., Gouma, P.I. & Buchheit, R.G. Localized corrosion susceptibility of Al-Li-Cu-Mg-Zn alloy AF/C458 due to interrupted quenching from solutionizing temperature. Metall Mater Trans A 32, 2561–2573 (2001). https://doi.org/10.1007/s11661-001-0046-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0046-5