Abstract

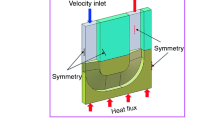

With the rapid development of circulating fluidized bed (CFB) technology in different fields, the disadvantages of conventional non-mechanical valves are becoming more apparent, and they are not suitable to be used in complex CFB systems. In this paper, a novel non-mechanical valve named the jet-control valve is presented which can avoid the fluidization of solid particles. The feasibility and performance characteristics of the new valve are investigated with a cold-model dual CFB. The results show that compared with the conventional non-mechanical valve, the jet-control valve can transfer solid particles steadily over a larger range, prevent artesian flow, and improve the leakage characteristics. The effects of the operating parameters and structural parameters on the minimum aeration velocity, solid flow rate, and maximum solid flow rate are studied. A two-valve model is proposed to explain the transport capacity of the valve for one jet pipe. A semi-theoretical expression is obtained based on the experimental data with a maximum deviation of 30% providing useful guide for scaling-up the design.

Similar content being viewed by others

References

Berruti F, Pugsley T, Godfroy L, et al. Hydrodynamics of circulating fluidized bed risers: A review. The Canadian Journal of Chemical Engineering. 1995, 73(10): 579–602.

Zhang Y, Wang Y, Cai L, et al. Dual bed pyrolysis gasification of coal: Process analysis and pilot test. Fuel. 2013, 112(0): 624–634.

Guan G, Fushimi C, Ishizuka M, et al. Flow behaviors in the downer of a large-scale triple-bed combined circulating fluidized bed system with high solids mass fluxes. Chemical Engineering Science. 2011, 66(18): 4212–4220.

Gong Z, Liu Z, Zhou T, et al. Combustion and NO emission of Shenmu char in a 2 MW circulating fluidized bed. Energy & Fuels. 2015, 29(2): 1219–1226.

Liu J, Zhu Z, Jiang H, et al. Gasification of Bituminous Coal in a Dual-Bed System at Different Air/Coal Ratios. Energy & Fuels. 2015, 29(2): 496–500.

Fan X, Lu Q, Na Y, et al. Experimental study on coal multi-generation in dual fluidized beds. Journal of Ther mal Science. 2007, 16(3): 277–282.

Bidwe A, Hawthorne C, Yu X, et al. Cold model study of a dual fluidized bed system for the gasification of solid fuels. Fuel. 2014,127(0): 151–160.

Gidaspow D, Lu H. Equation of state and radial distribution functions of FCC particles in a CFB. AIChE Journal. 1998, 44(2): 279–293.

Fan L, Lu Q, Na Y, et al. Experimental Investigation on Direct Reduction of Iron Ore Powder by Pulverized Coal in a Circulating Fluidized Bed The Chinese Journal of Process Engineering. 2011, 11(1): 91–96.

Basu P, Cheng L. An Analysis of Loop Seal Operations in a Circulating Fluidized Bed. Chemical Engineering Research and Design. 2000, 78(7): 991–998.

Geldart D, Jones P. The behaviour of L-valves with granular powders. Powder technology. 1991, 67(2): 163–174.

Knowlton T, Hirsan I, Leung L. The effect of aeration tap location on the performance of a J-valve. Proceedings of Second Engineering Foundation Conference on Fluidization, Cambridge, England, 1978. 128–133.

Terasaka K, Akashi S, Tsuge H. Development of a J-shaped pneumatic valve to control the solid particle circulation rate in a circulating fluidized bed. Powder technology. 2002, 126(1): 13–21.

Leung L, Chong Y, Lottes J. Operation of V valves for gas—solid flow. Powder Technology. 1987, 49(3): 271–276.

Basu P, Butler J. Studies on the operation of loop-seal in circulating fluidized bed boilers. Applied energy. 2009, 86(9): 1723–1731.

Wang P, Lu J, Xing W, et al. Impact of loop seal structure on gas solid flow in a CFB system. Powder Technology. 2014, 264(0): 177–183.

Liu X, Cui X, Sun G, et al. Buildup of high solids flux conveying flow by coupling a moving bed to the riser bottom. AIChE Journal. 2009, 55(9): 2477–2481.

Bischi A, Langørgen Ø, Bolland O. Double loop circulating fluidized bed reactor system for two reaction processes, based on pneumatically controlled divided loopseals and bottom extraction/lift. Powder Technology. 2013, 246(0): 51–62.

Yazdanpanah M, Forret A, Gauthier T, et al. An experimental investigation of loop-seal operation in an interconnected circulating fluidized bed system. Powder Technology. 2013, 237(0): 266–275.

Zhang J, Wu R, Zhang G, et al. Recent studies on chemical engineering fundamentals for fuel pyrolysis and gasification in dual fluidized bed. Industrial & Engineering Chemistry Research. 2013, 52(19): 6283–6302.

Chalermsinsuwan B, Gidaspow D, Piumsomboon P. Indepth system parameters of transition flow pattern between turbulent and fast fluidization regimes in high solid particle density circulating fluidized bed reactor. Powder Technology. 2014, 253(0): 522–536.

Smolders K, Baeyens J. The operation of L-valves to control standpipe flow. Advanced Powder Technology. 1995, 6(3): 163–176.

Dong L, Ji W, Zhao Z, et al. Elimination of stagnant particles from a N-valve with side aeration in circulating fluidized bed. Advanced Powder Technology. 2014,25(3): 1155–1161.

Saayman J, Xu M, Lim JC, et al. Gas leakage between reactors in a dual fluidized bed system. Powder Technology. 2014, 266(0): 196–202.

Yang W, Knowlton T. L-valve equations. Powder Technology. 1993, 77(1): 49–54.

Yu K. Experimental Study on Coal Gasification Process in Dual Circulating Fluidized Beds. Graduate University of Chinese Academy of Sciences, Beijing, China, 2012: 52

Zheng Z, Ma Z, Wang A. Study on flow characteristics of gas solid two phase flow in L valve. The Sixth National fluidized Conference. Wuhan, China, 1993.

Hu Y, Bao S. Experiment on the Adjusting Characteristics of a Pneumatic Distribution Valve. Boiler Technology. 2008, 39(4): 37–41.

Liu Q. Experimental study on coal pyrolysis-gasification processing in dual fluidized beds. Graduate University of Chinese Academy of Sciences, Beijing, China, 2009: 90

Beverloo W, Leniger HA, Van de Velde J. The flow of granular solids through orifices. Chemical Engineering Science. 1961, 15(0): 260–269.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jiang, H., Dong, P., Zhu, Z. et al. Pneumatic jet-control valve for dual circulating fluidized beds. J. Therm. Sci. 24, 574–582 (2015). https://doi.org/10.1007/s11630-015-0825-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-015-0825-8