Abstract

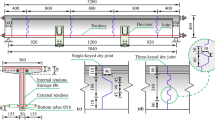

To evaluate various interlaminar bonding reinforcement techniques used for steel bridge decks, the UHPC surface was roughened with shot blasting (SB), transverse grooving (TG) and surface embedded stone (S), epoxy resin (E), epoxy asphalt (EA) and high viscosity high elasticity asphalt (HV) as interlayer bonding materials. In addition, a diagonal shear test was conducted using a self-designed diagonal shear jig. The effects of adhesive layer materials type, surface texture type, and different loading rates on the interlaminar bonding performance of UHPC/SMA combination specimens were investigated. The experimental study showed that the peak shear strength and shear modulus of the combined specimen decreased gradually with the decrease of thermosetting of the adhesive layer materials. The peak shear fracture energy of E was greater than that of HV and EA. The synergistic effect of the contact force generated by the roughing of the UHPC surface, the friction force, and the bonding force provided by the adhesive layer material can significantly improve the interlaminar shear performance of the assemblies. The power-law function of shear strength and shear modulus was proposed. The power-law model of peak shear strength and loading rate was verified. The shear strength and predicted shear strength satisfy the positive proportional functions with scale factors of 0.985, 1.015, 0.961, and 1.028, respectively.

Similar content being viewed by others

References

Hu S G. Research and Application of New Steel Bridge Deck Pavement Technology[C]. Proceedings of the Fourteenth Annual Conference of the National Urban Highway Association, 2005

Ding Q J. The Invention Relates to a Bridge Deck Paving Method[P]. CN104562888A, 2015–04-29, 2015

Jia X Y, Hu W, Zhu D. Investigation of Interlayer Shear Failure of Concrete Bridge Deck Asphalt Overlay Utilizing Shear Strength Envelopes[J]. Engineering Failure Analysis, 2021, 123: 105 278

Diakhaté M, Millien A, Petit C, et al. Experimental Investigation of Tack Coat Fatigue Performance: Towards an Improved Lifetime Assessment of Pavement Structure Interfaces[J]. Construction and Building Materials, 2011, 25(2): 1 123–1 133

Walubita L F, Fuentes L, Lee S I, et al. Comparative Evaluation of Five HMA Rutting-related Laboratory Test Methods Relative to Field Performance Data: DM, FN, RLPD, SPST, and HWTT[J]. Construction and Building Materials, 2019, 215: 737–753

Wang W B, Hu K, Feng S, et al. Shear Behavior of Hydraulic Asphalt Concrete at Different Temperatures and Strain Rates[J]. Construction and Building Materials, 2020, 230: 117 022

Zheng Q. Study on Improving Skid Resistance of Old Asphalt Pavement by Shot Blasting Technology[D]. Dalian: Daliann Maritime University, 2014

Ministry of Transport of China. Technical Guidelines for the Construction of Highway Cement Concrete Pavements[S]. JTG/T F30–2014, 2014

Sudarsanan N, Karpurapu R, Amrithalingam. An Investigation on the Interface Bond Strength of Geosynthetic-reinforced Asphalt Concrete Using the Leutner Shear Test[J]. Construction and Building Materials, 2018, 186: 423–437

Chen J S, Huang C C. Effect of Surface Characteristics on Bonding Properties of Bituminous Tack Coat[J]. Journal of the Transportation Research Board, 2010, 2180(1): 142–149

Wang L, Wu Z Y, Huang W B. Research on Interfacial Shear Characteristics of Crumb Rubber Modified Asphalt Concrete Bridge Deck Pavement Structure[J]. Procedia-Social and Behavioral Sciences, 2013, 96: 1 341–1 349

Yang K, Li R, Yu Y, et al. Evaluation of Interlayer Stability in Asphalt Pavements Based on Shear Fatigue Property[J]. Construction and Building Materials, 2020, 258: 119 628

Li J, Xia Y, Wang W P, et al. Bond Performances Between Asphalt Surface and UHPC of Ultra-high Performance Lightweight Composite Decks[J]. Journal of Hunan University, 2019, 46(5): 11–20

Shao X D, Qiu M H, Yan B F, et al. A Review on the Research and Application of Ultra-high Performance Concrete in Bridge Engineering Around the World[J]. Materials Review, 2017, 31(23): 33–43

Wang M. Prediction Study for Steel Bridge Asphalt Pavement Structural Damage[D]. Chongqing: Chongqing Jiaotong University, 2017

Huang Q B, Qian Z D, Chen L L, et al. Evaluation of Epoxy Asphalt Rubber with Silane Coupling Agent Used as a Tack Coat for Seasonally Frozen Orthotropic Steel Bridge Decks[J]. Construction and Building Materials, 2020, 241: 117 957

Walubita L F, Nyamuhokya T P, Komba J J, et al. Comparative Assessment of the Interlayer Shear-bond Strength of Geogrid Reinforcements in Hot-mix asphalt[J]. Construction and Building Materials, 2018, 191: 726–735

Canestrari F, Ferrotti G, Partl M N, et al. Advanced Testing and Characterization of Interlayer Shear Resistance[J]. Journal of the Transportation Research Board, 2005, 1929(1): 69–78

Tozzo C, D’Andrea A, Cozzani D, et al. Fatigue Investigation of the Interface Shear Performance in Asphalt Pavement[J]. Modern Applied Science, 2014, 8(2): 1–11

Fan X Y, Luo R. Experimental Study on the Crack Resistance of Typical Steel-bridge-deck Paving Materials[J]. Construction and Building Materials, 2021, 277: 122 315

Xu P J, Zhu X T, Cong P L, et al. Modification of Alkyl Group Terminated Hyperbranched Polyester on Paving Epoxy Asphalt[J]. Construction and Building Materials, 2018, 165: 295–302

Dong V D, Quynh-Anh T B, Dam D N, et al. Prediction of Interlayer Shear Strength of Double-layer Asphalt Using Novel Hybrid Artificial Intelligence Models of ANFIS and Metaheuristic Optimizations[J]. Construction and Building Materials, 2022, 323: 126 595

Wang J Y, Xiao F P, Chen, Z, et al. Application of Tack Coat in Pavement Engineering[J]. Construction and Building Materials, 2017, 152: 856–871

Ministry of Transport of China. Specifications for Design and Construction of Pavement on Highway Steel Deck Bridge[S]. JTG/T 3364–02-2019, 2019

Walubita L F, Faruk Abu NM, Fuentes L, et al. Using the Simple Punching Shear Test (SPST) for Evaluating the HMA Shear Properties and Predicting Field Rutting Performance[J]. Construction and Building Materials, 2019, 224: 920–929

Li J, Chen S Y, Huang C, et al. Correlation Between Static Properties and Fatigue Life of UHPC-SMA Layers[J]. Journal of Hunan University (Natural Science Edition), 2022, 49(03): 14–22

AMELIAN S, KIM Y R. Performance Assessment of Interlayer: with Different Tack Coats by Considering Loading Types and Failure Modes[J]. Journal of the Transportation Research Board, 2018, 2672(28): 1–9

Shen J A. Road Performance of Asphalt and Asphalt Mixtures[M]. Beijing: The People’s Communications Publishing House, 2001

Canestrari F, Roche C D L, Benedetto H D, et al. Advances in Interlaboratory Testing and Evaluation of Bituminous Materials[M]. Netherlands: Dordrecht, 2013

Abuaddous M, Canestrari F, Graziani A, et al. Influence of Specimen Dimension and Test Speed on the Shear Strength of Bituminous Interfaces[M]. Netherlands: Dordrecht, 2016

Funding

Funded by National Natural Science Foundation of China(Nos. U21A20149 and 51878003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, Q., Lei, Y., Zhang, G. et al. Interlaminar Bonding Performance of UHPC/SMA Based on Diagonal Shear Test. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 38, 97–108 (2023). https://doi.org/10.1007/s11595-023-2672-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-023-2672-1