Abstract

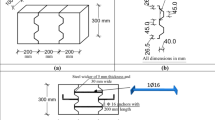

In this study, ultrahigh-performance concrete (UHPC) was utilized in precast segmental beams to reduce the self-weight, shorten the construction time, and improve the performance and durability of bridges. Owing to the discontinuity in the joints, shear behavior plays a critical role in the overall structural performance of precast UHPC segmental beams (PUSBs). Therefore, four dry-jointed segmental specimens along with one monolithic specimen were designed and tested under a two-point concentrated load with various joint types, shear span-to-depth ratios (λ), and numbers of shear keys. Two types of shear failure modes were observed in the tests: shear compression failure of the web (λ = 1.44 and 2.56) and local shear failure of the flanges at the joint (λ = 3.67). The shear capacity, stiffness, and cracking load of the dry-jointed segmental specimens were lower than those of the monolithic specimen, and the single-keyed specimen exhibited better shear behavior than the three-keyed specimen. Increasing λ decreased the shear strength and stiffness of the segmental beams and considerably affected their failure modes and crack distributions. Additionally, four UHPC design codes were evaluated for their accuracy in estimating the shear strength of the specimens, and a simplified strut-and-tie model was developed to predict the shear strength of externally pre-stressed PUSBs. Finally, several design recommendations were proposed. This study is expected to facilitate the research and application of PUSBs.

Similar content being viewed by others

Data availability

All data, models, or code generated or used during the study appear in the published article.

References

Hao H, Bi K, Chen W, Pham TM, Li J. Towards next generation design of sustainable, durable, multi-hazard resistant, resilient, and smart civil engineering structures. Eng Stuct. 2023;277:115477.

Fang S, Li L, Luo Z, Fang Z, Huang D, Liu F, Wang H, Xiong Z. Novel FRP interlocking multi-spiral reinforced-seawater sea-sand concrete square columns with longitudinal hybrid FRP–steel bars: monotonic and cyclic axial compressive behaviours. Compos Struct. 2023;305:116487.

Ye M, Li L, Yoo DY, Wang L, Li H, Zhou C. Shear performance of prestressed composite beams with ultra-high-performance concrete and corrugated steel webs under different loading conditions. Thin-Walled Struct. 2023;186:110675.

Zhou M, Lu W, Song J, Lee GC. Application of ultra-high performance concrete in bridge engineering. Constr Build Mater. 2018;186:1256–67.

Graybeal BA, Brühwiler E, Kim B, Toutlemonde F, Voo YL, Zaghi A. International perspective on UHPC in bridge engineering. J Bridge Eng. 2020;25(11):04020094–101.

Xue J, Briseghella B, Huang F, Nuti C, Tabatabai H, Chen B. Review of ultra-high performance concrete and its application in bridge engineering. Constr Build Mater. 2020;260:119844.

Du J, Meng W, Khayat KH, Bao Y, Guo P, Lyu Z, Wang H. New development of ultra-high-performance concrete (UHPC). Compos B Eng. 2021;224:109220.

Ye M, Li L, Hu F, Wang L, Shao X. UHPC-based precast large-cantilevered thin-walled bent caps: design and experiments. Eng Stuct. 2022;272:114909.

Li H, Li L, Fan X, Ye M, Shao X, Yi L. Experimental and numerical investigation on the flexural behavior of a large-scale prestressed UHPC T-Shaped girder. Eng Stuct. 2022;272:115027.

Graybeal BA, Material property characterization of ultra-high performance concrete. US department of transportation, Federal Highway Administration, 2006;pp. 1–188.

Yoo DY, Lee JH, Yoon YS. Effect of fiber content on mechanical and fracture properties of ultra high performance fiber reinforced cementitious composites. Compos Struct. 2013;106:742–53.

Yu R, Spiesz P, Brouwers HJH. Mix design and properties assessment of Ultra-high performance fibre reinforced concrete (UHPFRC). Cem Concr Res. 2014;56:29–39.

Yoo DY, Park JJ, Kim SW, Yoon YS. Early age setting, shrinkage and tensile characteristics of ultra high performance fiber reinforced concrete. Constr Build Mater. 2013;41:427–38.

Yoo DY, Min KH, Lee JH, Yoon YS. Shrinkage and cracking of restrained ultra-high-performance fiber-reinforced concrete slabs at early age. Constr Build Mater. 2014;73:357–65.

Wille K, El-Tawil S, Naaman AE. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem Concr Compos. 2014;48:53–66.

Yoo DY, Banthia N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: a review. Cem Concr Compos. 2016;73:267–80.

Meng W, Khayat KH. Improving flexural performance of ultra-high-performance concrete by rheology control of suspending mortar. Compos B Eng. 2017;117:26–34.

Li J, Wu Z, Shi C, Yuan Q, Zhang Z. Durability of ultra-high performance concrete–A review. Constr Build Mater. 2020;255:119296.

Ye M, Li L, Pei B, Yoo DY, Li H. Shear behavior of externally prestressed ultra-high-performance concrete (UHPC) T-beams without stirrups. Eng Struct. 2023;288:116217.

Voo YL, Poon WK, Foster SJ. Shear strength of steel fiber-reinforced ultrahigh- performance concrete beams without stirrups. J Struct Eng. 2010;136(11):1393–400.

Yang IH, Joh C, Kim BS. Structural behavior of ultra high performance concrete beams subjected to bending. Eng Struct. 2010;32(11):3478–87.

Ye M, Li L, Hu F, Shao X, Tang J. Flexural behavior of a fully prefabricated lightweight UHPC bent cap. J Bridge Eng. 2020;25(10):04020085.

Li H, Li L, Yoo DY, Ye M, Zhou C, Shao X. Experimental and theoretical investigation of the shear lag effect in the novel non-prismatic prestressed CSW–UHPC composite box girders. Archiv Civ Mech Eng. 2023;23:132.

Zhou C, Wang J, Jia W, Fang Z. Torsional behavior of ultra-high performance concrete (UHPC) rectangular beams without steel reinforcement: Experimental investigation and theoretical analysis. Compos Struct. 2022;299:116022.

Fang S, Zhang S, Cao Z, Zhao G, Fang Z, Ma Y, Jiang H. Effects of stud aspect ratio and cover thickness on push-out performance of thin full-depth precast UHPC slabs with grouped short studs: Experimental evaluation and design considerations. J Build Eng. 2023;67:105910.

Fang Z, Hu L, Jiang H, Fang S, Zhao G, Ma Y. Shear performance of high-strength friction-grip bolted shear connector in prefabricated steel–UHPC composite beams: Finite element modelling and parametric study. Case Stud Constr Mat. 2023;18:e01860.

Liu T, Wang Z, Guo J, Wang J. Shear strength of dry joints in precast UHPC segmental bridges: experimental and theoretical research. J Bridge Eng. 2019;24(1):04018100–1.

Hu Y, Qiu J, Li Z, Wang J, Tao Y. Shear strength prediction method of the UHPC keyed dry joint considering the bridging effect of steel fibers. Eng Struct. 2022;255:113937.

Ye M, Li L, Yoo DY, Li H, Shao X, Zhou C. Mechanistic understanding of precast UHPC segmental beams with external tendons and epoxy joints subject to combined bending and shear. Eng Struct. 2023;280:115698.

Ahmed GH, Aziz OQ. Shear strength of joints in precast posttensioned segmental bridges during 1959–2019, review and analysis. Struct. 2019;20:527–42.

Shin J. Ultra-high performance concrete (UHCP) precast segmental bridges, Doctoral dissertation, Technische Universität Hamburg. Germany: Hamburg; 2016.

Gopal BA, Hejazi F, Hafezolghorani M, Voo YL. Shear strength of dry and epoxy joints for ultra-high-performance fiber-reinforced concrete. ACI Struct J. 2020;117(1):279–88.

Ye M, Li L, Li H, Zhou C. Shear behavior of joints in precast UHPC segemntal bridges under direct shear loading. Constr Build Mater. 2022;357:129212.

Aparicio AC, Ramos G. Flexural strength of externally prestressed concrete bridges. Struct J. 1996;93:512–23.

Aparicio AC, Ramos G. Ultimate analysis of monolithic and segmental externally prestressed concrete bridges. J Bridge Eng. 1996;1:10–7.

Aparicio AC, Ramos G, Casas JR. Testing of externally prestressed concrete beams. Eng Struct. 2002;24:73–84.

Ng CK. Tendon stress and flexural strength of externally prestressed beams. ACI Struct J. 2003;100:644–53.

Ng CK, Tan KH. Flexural behaviour of externally prestressed beams Part I: analytical model. Eng Struct. 2006;28:609–21.

Ng CK, Tan KH. Flexural behaviour of externally prestressed beams. Part II: experimental investigation. Eng Struct. 2006;28:622–33.

Li G, Zhang C, Niu C. Experimental study on shear behavior in negative moment regions of segmental externally prestressed concrete continuous beams. J Bridge Eng. 2013;18(4):328–38.

Li G, Yang D, Lei Y. Combined shear and bending behavior of joints in precast concrete segmental beams with external tendons. J Bridge Eng. 2013;18(10):1042–52.

Yuan A, Dai H, Sun D, Cai J. Behaviors of segmental concrete box beams with internal tendons and external tendons under bending. Eng Struct. 2013;48:623–34.

Yuan A, He Y, Dai H, Cheng L. Experimental study of precast segmental bridge box girders with external unbonded and internal bonded posttensioning under monotonic vertical loading. J Bridge Eng. 2015;20:04014075.

Jiang H, Cao Q, Liu A, Wang T, Qiu Y. Flexural behavior of precast concrete segmental beams with hybrid tendons and dry joints. Constr Build Mater. 2016;110:1–7.

Jiang H, Li Y, Liu A, Ma ZJ, Chen L, Chen Y. Shear behavior of precast concrete segmental beams with external tendons. J Bridge Eng. 2018;23:04018049.

Hu Z, Xu Z, Zhang S, Jiang H, Chen Y, Xiao J. Experimental study on shear behavior of precast high-strength concrete segmental beams with external tendons and dry joints. Buildings. 2022;12(2):134.

Jiang H, Hu Z, Cao Z, Gao X, Tian Y, Sun X. Experimental and numerical study on shear performance of externally prestressed precast UHPC segmental beams without stirrups. Structures. 2022;46:1134–53.

Feng J, Li P, Wu J, Jiang H, Tian Y, Sun X. Shear behavior of externally prestressed UHPC beams without stirrups. Case Stud Constr Mat. 2023;18:e01766.

AFNOR, Ultra-highperformance fibre-reinforced concrete—Specifications, performance, production, and conformity (NF P18-470), AFNOR, Paris, 2016.

AFNOR, National addition to the Eurocode 2—Design of concrete structures: Specific rules for ultra-high performance fibre-reinforced concrete (UHPFRC) (NF P 18-710), AFNOR, Paris, 2016.

Qi J, Ma ZJ, Wang J, Bao Y. Post-cracking shear behaviour of concrete beams strengthened with externally prestressed tendons. Structures. 2020;23:214–24.

AASHTO, Guide Specifications for Design and Construction of Segmental Concrete Bridges. interim revisions, 2nd ed., 2003.

Ministry of Transport of the People’s Republic of China. Specification for application of highway ultra high performance concrete bridges and culverts (Draft). Beijing: China Communications Press; 2022. (in Chinese).

SIA (Swiss Society of Engineers and Architects). Ultra-high performance fibre reinforced concrete (UHPFRC)-materials, design and execution. Zurich: Final Draft; 2016.

JSCE, Recommendations for design and construction of ultra–high strength fiber reinforced concrete structures, Japan Soc. Civil. Eng. 2004.

ACI Committee 318, Building code requirements for structural concrete (ACI 318-14), American Concrete Institute, 2014.

Fehling E, Schmidt M, Walraven J, Leutbecher T, Fröhlich S. Ultra-High Performance Concrete UHPC Fundamentals, Design, Examples. Berlin: Wiley Ernst & Sohn; 2014.

Lee JH, Hong SG, Joh C, Kwahk I, Lee JW. Biaxial tension–compression strength behaviour of UHPFRC in-plane elements. Mater Struct. 2017;50:1–7.

Acknowledgements

This research is sponsored by the National Natural Science Foundation of China (Grant No. 51978257 and No. 52278176), the Natural Science Foundation of Changsha (kq2202133), and the Support Plan for Scientific and Technological Innovation and Entrepreneurship Team of Enterprises in Hunan Province (2020). In addition, the financial support from the China Scholarship Council (Grant No. 202206130070) to the first author is gratefully acknowledged. The authors are grateful for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ye, M., Li, L., Yoo, DY. et al. Shear behavior of precast ultrahigh-performance concrete (UHPC) segmental beams with external tendons and dry joints. Archiv.Civ.Mech.Eng 23, 143 (2023). https://doi.org/10.1007/s43452-023-00687-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00687-7