Abstract

Hydration-heat-inhibiting materials(HIM) with polysaccharide as core material was prepared using microcapsule sustained-releasing technology, through a centrifugal spray granulation process after melting together. The preparation process parameters of HIM were selected by the semi-adiabatic temperature rise test of cement paste. TAM air microcalorimeter was used to investigate the regulation performance of HIM on the hydration of cement. The influence of HIM on the microstructure of cement was investigated by XRD, SEM, and TG-DSC.The results showed that the most suitable wall material for HIM was polyethylene wax, the optimum polyethylene wax/polysaccharide mass ratio was 1, and the most effective particle size was 0.16–0.30 mm. Polysaccharide coated by polyethylene wax released slowly, and the peak heat release rate of cement could be reduced by 55.2% after continuous regulaion. The regulation period continued to 120 h. HIM mainly decreased the C3S reaction rate, which resulted in a 39.2% peak value reduction of hydration heat release rate. However, HIM had little regulation on C3A. The hydration heat release process of cement-based materials can be designed by adjusting the dosage of HIM.

Similar content being viewed by others

References

Metha P K, Monteiro P J. Microstructure, Properties and Materials of Concrete [M]. Beijing: China Electric Power Press, 2008

Bentz D P, Waller V, de Larrard F. Prediction of Adiabatic Temperature Rise in Conventional and High-Performance Concretes Using a 3-D Microstructural Model[J]. Cement and Concrete Research, 1998, 28(2): 285–297

Myers T G, Fowkes N D, Ballim Y. Modeling the Cooling of Concrete by Piped Water[J]. Journal of Engineering Mechanics, 2009, 135(12): 1375–1383

Chen S H, Su P F, Shahrour I. Composite Element Algorithm for The Thermal Analysis of Mass Concrete:Simulation of Cooling Pipes[J]. International Journal of Numerical Methods for Heat & Fluid Flow. 2011, 21(4): 434–447

Chen S H, Su P F, Shahrour I. Composite Element Algorithm for The Thermal Analysis of Mass Concrete:Simulation of Lift Joint[J]. Finite Elements in Analysis and Design, 2011, 47(5): 536–542

Chen S, Qing S. Composite Element Model for Discontinuous Rock Masses[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(5): 865–870

Jin K K, Kook H K. Thermal Analysis of Hydration Heat in Concrete Structures with Pipe-Cooling System[J]. Computers and Structures. 2001(1): 163–171

Seo T S, Kim S S, Lim C K. Experimental Study on Hydration Heat Control of Mass Concrete by Vertical Pipe Cooling Method[J]. Journal of Asian Architecture and Building Engineering, 2015, 14(3): 657–662

Sun Z P, Jiang Z W, Wang P M, et al. Concrete Pavement Crack Causes and Preventive Measures[J]. Journal of Highway and Transportation Research and Development, 2005(4): 15–19

Chen C H. Analysis of Temperature Field and Temperature Stress During Construction of Hydraulic Structure Considering Reinforcement Action[J]. Hohai University. 2006: 11–23

Choi W C, Khil B S, Chae Y S. Feasibility of Using Phase Change Materials to Control the Heat of Hydration in Massive Concrete Structures[J]. The Scientific World Journal, 2014 (9): 1–6

Kim Y R, Khil B S, Jang S J. Effect of Barium-Based Phase Change Material (PCM) to Control the Heat of Hydration on the Mechanical Properties of Mass Concrete[J]. Thermochimica Acta, 2015, 613(10): 100–107

Qian C X, Gao G B, He Z H. Feasibility Research of Using Phase Change Materials to Reduce the Inner Temperature Rise of Mass Concrete[J]. Journal of Wuhan University of Technology -Materials Science Edition, 2015, 30(5): 989–994

Lane G A. Solar Heat Storage: Latent Heat Material[M]. Boca Raton: CRC Press Inc, 1986

Lee T, Hawes D W, Banu D. Control Aspects of Latent Heat Storage and Recovery in Concrete[J]. Solar Energy Materials and Solar Cells. 2000, 62(3): 217–237

Darkwa K, O’Callaghan P W. Simulation of Phase Change Drywalls in A Passive Solar Building[J]. Applied Thermal Engineering, 2006, 26(8/9): 853–858

Aaron R S, Benta D P. Increasing the Service Life of Bridge Decks by Incorporating Phase-Change Materials to Reduce Freeze-Thaw Cycles[J]. Journal of Materials in Civil Engineering, 2012, 24: 1034–1042

Entrop A G, Brouwers H J H, Reinders A H M E. Experimental Research on the Use of Micro-Encapsulated Phase Change Materials to Store Solar Energy in Concrete Floors and to Save in Dutch House[J]. Solar Energy, 2011, 85(5): 1007

Arnault A, Mathieu-Potvin F, Gosselin L. Internal Surfaces Including Phase Change Materials for Passive Optimal Shift of Solar Heat Gain[J]. Int J. Thermal Sci., 2010, 49(11): 2148

Alawadhi E M, Alqallaf H J. Building Roof with Conical Holes Containing PCM to Reduce the Cooling Load: Numerical Study[J]. Energy Convers. Manag., 2011, 52(8–9): 2958

Pasupathy A, Velraj R. Effect of Double Layer Phase Change Material in Building Roof for Year Round Thermal Management[J]. Energy Build, 2008, 40(3): 193

Cabeza L F, Castellon C, Nogues M. Use of Microencapsulated PCM in Concrete Walls for Energy Savings[J]. Energy Build., 2007, 39(2): 113

Zhao S Z, Liu L, Jia F J, et al. A Kind of Hydration Heat Suppression Concrete Expansion Material, Preparation Method and Application[P]. China Patent for Invention, ZL 201310289190.9, 2013

Jia F J, Zhang J Q, Nie F Y, et al. Application of HCSA-R Hydration-Heat-Inhibiting Expansive Agent in Engineering[J]. Expansieve Agents&Expansive Concrete, 2013, (1): 5–8

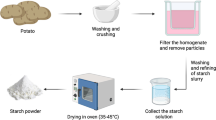

Zhang H, Wang W B, Li Q L, et al. A Starch-Based Admixture for Reduction of Hydration Heat in Cement Composites[J]. Consturction and Building Materials, 2018(173): 317–322

Y L, Liang G Z, Xie J Q, et al. Preparation and Characterization of Poly (Urea-Formaldehyde) Microcapsules Filled with Epoxy Resins[J]. Polymer, 2006, 47(15): 5338–5349

Y L, Liang G Z, Xie J Q, et al. Thermal Stability of Microencapsulated Epoxy Resins with Poly(Urea—Formaldehyde)[J]. Polym. Degrad. Stabil., 2006, 91(10): 2300–2306

Y L, Gu A J, Liang G Z. Preparation and Properties of Poly (Urea-Formaldehyde) Microcapsules Filled with Epoxy Resins[J]. Mater. Chem. Phys., 2008, 110(2/3): 417–425

Zhang L R, Xing F. Infulences of Silica Porous Shell Microcapsules on the Impermeability of Hardened Cement Mortar[J]. Acta Materiae Compositae Sinica, 2019(4): 982–992

Dong B Q, Wang Y S, Ding W J, et al. Chemical Selfhealing Microcapsule for Cementitious System[J]. Journal of Beijing University of Technology, 2014, 40(8): 1168–1173

Peschard A, Govin A, Pourchez J, et al. Effect of Polysaccharides on the Hydration of Cement Suspension[J]. J. Eur. Ceram. Soc., 2006, 26(8): 1435–1449

Funding

Funded by National Key R&D Program of China (No. 2017YFB0310102)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, F., Yao, Y. & Li, C. Preparation and Mechanism Research of Hydration-heat-inhibiting Materials with Microcapsule Sustained-releasing Technology. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 697–705 (2021). https://doi.org/10.1007/s11595-021-2462-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2462-2