Abstract

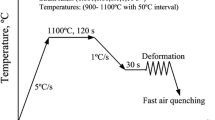

The isothermal compression tests of C71500 copper-nickel alloy at different temperatures (1 073–1 273 K) and strain rates (0.01–10 s−1) were carried out on Gleeble-3500 thermo-mechanical simulator. The real stress-strain data were obtained. On the basis of dynamic material model, the power dissipation was established. The peak efficiency of the power dissipation is 57%. At the same time, Prasad’s, Murty’s and Babu’s instability criteria based on Ziegler’s expectant rheology theory, and Gegel’s and Malas’s instability criteria based on Lyaponov’s function theory, were used to predict the unstable regions in the processing map. The maximum entropy generation rate and large plastic deformation principle are more in line with the hot deformation process of C71500 alloy, so the accuracy of Prasad’s instability criterion is much better. According to the obtained macro-crack and micro-metallographic structure morphologies, the temperature range of 1 098–1 156 K and the strain rate range of 2.91–10 s−1, and the temperature range of 1 171–1 273 K and the strain rate range of 0.01–0.33 s−1 are more suitable for the processing area of C71500 alloy. The accuracy of the above conclusions were verified by the forging of materials and the analysis of hot piercing tubes. The significance of this paper is to provide theoretical basis and technological conditions for hot-press processing of C71500 alloy.

Similar content being viewed by others

References

Taher AM. Effect of Alloying Elements on the Hardness Property of 90% Copper-10% Nickel Alloy[J]. Materials Science Forum, 2016, 872: 13–17

Cincera S, Bresciani E. De-nickelification of 70/30 Cupronickel Tubing in a Cooling Heat Exchanger[J]. Journal of Failure Analysis & Prevention, 2012, 12(3): 300–304

Beccaria AM, Crousier J. Influence of Iron Addition on Corrosion Layer Built up on 70Cu-30Ni Alloy in Sea Water[J]. British Corrosion Journal, 2013, 26(3): 215–219

Zhu X, Lei T. Characteristics and Formation of Corrosion Product Films of 70Cu-30Ni Alloy in Seawater[J]. Corrosion Science, 2002, 44(1): 67–79

Song Y, Shi H, Wang J, et al. Corrosion Behavior of Cupronickel Alloy in Simulated Seawater in the Presence of Sulfate-Reducing Bacteria[J]. Acta Metallurgica Sinica, 2017, 30(12): 1–9

Frost HJ, Ashby MF. Creep Fracture: Creep Laws and Elementary Microscopic-Fracture Models[M]. London: Pergamon Press, 1982

RAJ R. Development of a Processing Map for Use in Warm-Forming and Hot-Forming Processes[J]. Metall Trans A, 1981, 12(6): 1 089–1 097

Gegel HL, Malas JC, Gunasekera JS, et al. Computer-aided Design of Extrusion Dies by Metal-flow Simulation[C]. In: AGARD Process Modeling Appl to Metal Forming and Thermomech Process, 1984: SEE N85-15086 15006–15031

Prasad Yvrk, Seshacharyulu T. Modelling of Hot Deformation for Microstructural Control[J]. Metallurgical Reviews, 1998, 43(6): 243–258

Gegel HL, Malas JC, Dorelvalu SM. Modeling Techniques Used in Forging Process Design[M]. OH: ASM, 1988

Malas JC, Seetharaman V. Using Material Behavior Models to Develop Process Control Strategies[J]. JOM, 1992, 44(6): 8–13

Alexander JM. Modelling of Hot Deformation of Steel[M]. Springer Berlin Heidelberg, 1989: 105–115

Prasad Yvrk, Rao KP. Processing Maps and Rate Controlling Mechanisms of Hot Deformation of Electrolytic Tough Pitch Copper in the Temperature Range 300–950 °C[J]. Materials Science and Engineering: A, 2005, 391(1): 141–150

Sun ZC, Wu HL, Cao J, et al. Modeling of Continuous Dynamic Recrystallization of Al-Zn-Cu-Mg Alloy during Hot Deformation Based on the Internal-state-variable (ISV) Method[J]. International Journal of Plasticity, 2018, 106: 1–35

Maizza G, Pero R, Richetta M, et al. Continuous Dynamic Recrystallization (CDRX) Model for Aluminum Alloys[J]. Journal of Materials Science, 2018, 53(12): 1–11

Liang Q, Hao Q, Zhao H, et al. Constitutive Equation and Processing Map of CuNi10Fe1Mn Alloy based on High-temperature Deformation Behavior[J]. Materials Research Express, 2018, 5(5): 1–10

Wen Z, Gao X, Cheng J, et al. Processing Map and Hot Deformation Behavior of Mo-Nb Single Crystals[J]. Rare Metal Materials & Engineering, 2018, 47(2): 485–490

Lianggang G, Shuang Y, He Y, et al. Processing Map of As-cast 7075 Aluminum Alloy for Hot Working[J]. Chinese Journal of Aeronautics, 2015, (6): 1 774–1 783

Qin S, Jie L, Zhang H, et al. The Microstructure Evolution and Processing Map of Ni-18.3Cr-6.4Co-5.9W-4Mo Superalloy during Hot Deformation[J]. Journal of Materials Engineering & Performance, 2016, 25(6): 2 489–2 499

Yu H, Li J, Liu L, et al. Head Curvature of Pure Titanium Sheet Influenced by Process Parameters and Controlling in Hot Rolling Process[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2017, 32(2): 444–450

Krishna VG, Prasad Yvrk, Birla NC, et al. Processing Map for the Hot Working of Near-α Titanium Alloy 685[J]. J. Mater Process Technol., 1997, 71(3): 377–383

Xiu ZHI, YANG, LI Chao, et al. Effect of Niobium Addition on Hot Deformation Behaviors of Medium Carbon Ultra-high Strength Steels [J]. Journal of Wuhan University of Technology-Materials Science Edition, 2017, 32(1): 162–172

Yi Z, Sun H, Volinsky AA, et al. Hot Deformation and Dynamic Recrystallization Behavior of the Cu-Cr-Zr-Y Alloy[J]. Journal of Materials Engineering & Performance, 2016, 25(3): 1 150–1 156

Samantaray D, Mandal S, Jayalakshmi M, et al. New Insights into the Relationship between Dynamic Softening Phenomena and Efficiency of Hot Working Domains of a Nitrogen Enhanced 316L(N) Stainless Steel[J]. Materials Science & Engineering A, 2014, 598(2): 368–375

Ning L, Zhibao C, Chen L. Dynamic Recrystallization and Microstructure Evolution of BFe10-1-1 Copper Alloy[J]. Hot Working Technology, 2017, 46(04): 72–74

Prasad Yvrk. Processing Maps: A Status Report [J]. Journal of Materials Engineering & Performance, 2003, 12(6): 638–645

Sun H, Sun Y, Zhang R, et al. Study on Hot Workability and Optimization of Process Parameters of a Modified 310 Austenitic Stainless Steel Using Processing Maps[J]. Materials & Design, 2015, 67: 165–172

Lai L, Zhang K, MA Minglong, et al. Hot Deformation Behavior of AZ40 Magnesium Alloy at Elevated Temperatures[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2017, 32(6): 1 470–1 475

Murty Svsn, Rao BN, Kashyap BP. On the Hot Working Characteristics of 6061Al-SiC and 6061-AlO Particulate Reinforced Metal Matrix Composites[J]. Composites Science & Technology, 2003, 63(1): 119–135

Babu NS, Tiwari SB, Nageswara Rao B. Modified Instability Condition for Identification of Unstable Metal Flow Regions in Processing Maps of Magnesium Alloys[J]. Metal Science Journal, 2005, 21(8): 976–984

Ge Z, Hua D, Cao FR, et al. Flow Instability Criteria in Processing map of Superalloy GH79[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1 575–1 581

Guozhen L. Principle of Modern Steel Tube Rolling and Tool Design[M]. Beijing: Metallurgical Industry Press, 2006

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by the National Natural Science Foundation of China (No. 51801149) and the Ministry of Industry and Information Technology of the People’s Republic of China (TC170A2KN-8)

Rights and permissions

About this article

Cite this article

Gao, X., Wu, H., Liu, M. et al. Processing Map of C71500 Copper-nickel Alloy and Application in Production Practice. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 1104–1115 (2020). https://doi.org/10.1007/s11595-020-2361-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2361-y