Abstract

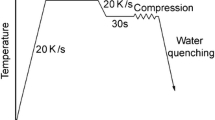

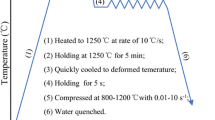

The hot deformation behavior of an ultralow-carbon microalloyed steel was investigated using an MMS-200 thermal simulation test machine in a temperature range of 1 073–1 373 K and strain rate range of 0.01–10 s−1. The results show that the flow stress decreases with increasing deformation temperature or decreasing strain rate. The strain-compensated constitutive model based on the Arrhenius equation for this steel was established using the true stress-strain data obtained from a hot compression test. Furthermore, a new constitutive model based on the Z-parameter was proposed for this steel. The predictive ability of two constitutive models was compared with statistical measures. The results indicate the new constitutive model based on the Z-parameter can more accurately predict the flow stress of an ultralow-carbon microalloyed steel during hot deformation. The dynamic recrystallization (DRX) nucleation mechanism at different deformation temperatures was observed and analyzed by transmission electron microscopy (TEM), and strain-induced grain boundary migration was observed at 1 373 K/0.01 s−1.

Similar content being viewed by others

References

Jiang B, Fang W, Chen R M, et al. Mechanical Properties and Microstructural Characterization of Medium Carbon Non-quenched and Tempered Steel: Microalloying Behavior[J]. Mater Sci. Eng. A, 2019, 748:180–188

Olasolo M, Uranga P, Rodriguez-Ibabe J M, et al. Effect of Austenite Microstructure and Cooling Rate on Transformation Characteristics in a Low Carbon Nb-V Microalloyed Steel[J]. Mater. Sci. Eng. A, 2011, 528(6): 2559–2569

Lambert-Perlade A, Gourgues A F, Pineau A. Austenite to Bainite Phase Transformation in the Heat-affected Zone of a High Strength Low Alloy Steel[J]. Acta Mater., 2004, 52(8): 2337–2348

Xiao F, Zhao M, Shan Y, et al. Processing of Ultralow Carbon Pipline Steels with Acicular Ferrite[J]. J. Mater. Sci. Technol., 2004, 20(6): 779–781

Gong P, Palmiere E J, Rainforth W M. Thermomechanical Processing Route to Achieve Ultrafine Grains in Low Carbon Microalloyed Steels[J]. Acta Mater., 2016, 119: 43–54

Lan L, Zhou W, Misra R D K. Effect of Hot Deformation Parameters on Flow Stress and Microstructure in a Low Carbon Microalloyed Steel[J]. Mater. Sci. Eng. A, 2019, 756: 18–26

Ouchi C. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Processes[J]. ISI J Int., 2001, 41(6): 542–553

Ge G W, Zhang L Q, Xin J J, et al. Constitutive Modeling of High Temperature Flow Behavior in a Ti-45Al-8Nb-2Cr-2Mn-0.2Y Alloy[J]. Sci. Rep., 2018, 8: 5 453

Wang X, Wang D, Jin J, et al. Effects of Strain Rates and Twins Evolution on Dynamic Recrystallization Mechanisms of Austenite Stainless Steel[J]. Mater. Sci. Eng. A, 2019, 761: 138 044

Huang K, Loge R E. A Review of Dynamic Recrystallization Phenomena in Metallic Materials[J]. Mater. Des., 2016, 111: 548–574

He G A, Liu F, Huang L, et al. Microstructure Evolutions and Nucleation Mechanisms of Dynamic Recrystallization of a Powder Metallurgy Ni-based Superalloy During Hot Compression[J]. Mater. Sci. Eng. A, 2016, 677: 496–504

Abedi H R, Hanzaki A Z, Liu Z, et al. Continuous Dynamic Recrystallization in Low Density Steel[J]. Mater. Des., 2017, 114: 55–64

Mirzadeh H, Cabrera J M, Prado J M, et al. Hot Deformation Behavior of a Medium Carbon Microalloyed Steel[J]. Mater. Sci. Eng. A, 2011, 528(10–11): 3876–3882

Zener C, Hollomon J H. Effect of Strain Rate Upon Plastic Flow of Steel[J]. J. Appl. Phys., 1944, 15(1): 22–32

Shen W F, Zhang C, Zhang L W, et al. A Modified Avrami Equation for Kinetics of Static Recrystallization of Nb-V Microalloyed Steel: Experiments and Numerical Simulation[J]. Vacuum, 2018, 150: 116–123

Wei H L, Liu G Q, Xiao X, et al. Characterization of Hot Deformation Behavior of a New Microalloyed C-Mn-Al High-strength Steel[J]. Mater. Sci. Eng. A, 2013, 564: 140–146

Akbari Z, Mirzadeh H, Cabrera J M, et al. A Simple Constitutive Model for Predicting Flow Stress of Medium Carbon Microalloyed Steel During Hot Deformation[J]. Mater. Des., 2015, 77: 126–131

Gong B, Duan X W, Liu J S, et al. A Physically Based Constitutive Model of As-forged 34CrNiMo6 Steel and Processing Maps for Hot Working[J]. Vacuum, 2018, 155: 345–357

Opiela M, Grajcar A. Hot Deformation Behavior and Softening Kinetics of Ti-V-B Microalloyed Steels[J]. Arch. Civ. Mech. Eng., 2012, 12(3): 327–333

Karmakar A, Misra R D K, Neogy S, et al. Development of Ultra-fine-Grained Dual-Phase Steels: Mechanism of Grain Refinement During Intercritical Deformation[J]. Metall. Trans. A, 2013, 44A(9): 4106–4118

Kumar S, Aashranth B, Samantaray D, et al. Influence of Nitrogen on Kinetics of Dynamic Recrystallization in Fe-Cr-Ni-Mo Steel[J]. Vacuum, 2018, 156: 20–29

Li B, Liu Q, Jia S, et al. Fabricating Ultrafine Grain by Advanced Thermomechanical Processing on Low-carbon Microalloyed Steel[J]. Scr. Mater., 2018, 152: 132–136

Chen X M, Lin Y C, Chen M S, et al. Microstructural Evolution of a Nickel-based Superalloy During Hot Deformation[J]. Mater. Des., 2015, 77: 41–49

Shalbafi M, Roumina R, Mahmudi R. Hot Deformation of the Extruded Mg-10Li-1Zn Alloy: Constitutive Analysis and Processing Maps[J]. J. Alloys Compd., 2017, 696: 1269–1277

Dai X, Yang B. Study on Hot Deformation Behavior and Processing Maps of SA508-IV Steel for Novel Nuclear Reactor Pressure Vessels[J]. Vacuum, 2018, 155: 637–644

Han Y, Wu H, Zhang W, et al. Constitutive Equation and Dynamic Recrystallization Behavior of As-cast 254SMO Super-austenitic Stainless Steel[J]. Mater. Des., 2015, 69: 230–240

Zeng S, Zhao A, Jiang H, et al. Hot Deformation Behavior of β Phase Containing γ-TiAl Alloy[J]. Mater. Sci. Eng. A, 2016, 661:160–167

Zhou M, Lin Y C, Deng J, et al. Hot Tensile Deformation Behaviors and Constitutive Model of an Al-Zn-Mg-Cu Alloy[J]. Mater. Des., 2014, 59: 141–150

Medina S F, Hernandez C A. General Expression of the Zener-Hollomon Parameter as a Function of the Chemical Composition of Low Alloy and Microalloyed Steels[J]. Acta Mater., 1996, 44(1): 137–148

Ueki M, Horie S, Nakamura T. Factors Affecting Dynamic Recrystallization of Metals and Alloys[J]. Mater. Sci. Technol., 1987, 3(5): 329–337

Mcqueen H J, Yue S, Ryan N D, et al. Hot Working Characteristics of Steels in Austenitic State[J]. J. Mater. Process. Technol., 1995, 53: 293–310

Aghaie-Khafri M, Adhami F. Hot Deformation of 15–5 PH Stainless Steel[J]. Mater. Sci. Eng. A, 2010, 527(4–5): 1052–1057

Li H Y, Wei D D, Hu J D, et al. Constitutive Modeling for Hot Deformation Behavior of T24 Ferritic Steel[J]. Comput. Mater. Sci., 2012, 53(1): 425–430

Pu E X, Feng H, Liu M, et al. Constitutive Modeling for Flow Behaviors of Superaustenitic Stainless Steel S32654 During Hot Deformation[J]. J. Iron Steel Res. Int., 2016, 23(2): 178–184

Xiao Y H, Guo C, Guo X Y. Constitutive Modeling of Hot Deformation Behavior of H62 Brass[J]. Mater. Sci. Eng. A, 2011, 528(21): 6510–6518

Lin Y C, Chen M S, Zhong J. Prediction of 42CrMo Steel Flow Stress at High Temperature and Strain Rate[J]. Mech. Res. Commun., 2008, 35(3): 142–150

Mandal S, Rakesh V, Sivaprasad P V, et al. Constitutive Equations to Predict High Temperature Flow Stress in a Ti-modified Austenitic Stainless Steel[J]. Mater. Sci. Eng. A, 2009, 500(1–2): 114–121

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Fundamental Research Funds for the Central Universities (Nos. HEUCFP201731 and HEUCFP201719), and the “One Three Five” Equipment Pre-research National Defense Science and Technology Key Laboratory Fund (No. KZ42180125)

Rights and permissions

About this article

Cite this article

Li, N., Huang, Y., Han, R. et al. Constitutive Modeling and Dynamic Recrystallization Mechanisms of an Ultralow-carbon Microalloyed Steel During Hot Compression Tests. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 946–957 (2020). https://doi.org/10.1007/s11595-020-2341-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2341-2