Abstract

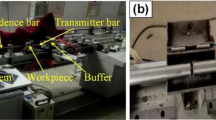

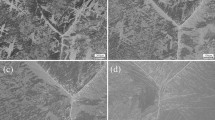

The dynamic tensile behaviors of a newly developed Ti-6Al-2Sn-2Zr-3Mo-1Cr-2Nb-Si alloy (referred as TC21 in China) over a wide range of strain rates from quasi-static to dynamic regimes (0.001–1 200 s−1) at different temperatures were experimentally investigated. A split Hopkinson tension bar apparatus and a static material testing system were utilized to study the stress-strain responses under uniaxial tension loading condition. The experimental results indicate that the tensile behavior of TC21 titanium alloy is dependent on the strain rate and temperature. The values of initial yield stress increase with increasing strain rate and decreasing temperature. The effects of strain rate and temperature on the initial yield behavior are estimated by introducing two sensitivity parameters. The phenomenological-based constitutive model, Johnson-Cook model, is suitably modified to describe the rate-temperature dependent constitutive behavior of TC21 titanium alloy. It is observed that the modified model is in good agreement with the experimental data subjected to the investigated range of strain rates and temperatures.

Similar content being viewed by others

References

Gysler A, Lütjering G. Influence of Test Temperature and Microstructure on the Tensile Properties of Titanium Alloys[J]. Metall. Trans. A, 1982, 13(8): 1 435–1 443

Reed-Hill R E, Iswaran C V, Kaufman M J. An Analysis of the Flow Stress of a Two- phase Alloy System Ti-6Al-4V[J]. Metall. Mater. Trans. A, 1996, 27(12): 3 957–3 962

Majorell A, Srivatsa S, Picu R C. Mechanical Behavior of Ti-6Al-4V at High and Moderate Temperatures-Part I: Experimental Results[J]. Mat. Sci. Eng. A, 2002, 326(2): 297–305

Zong Y Y, Shan D B, Xu M, et al. Flow Softening and Microstructural Evolution of TC11 Titanium Alloy during Hot Deformation[J]. J. Mater. Process. Tech., 2009, 209(4): 1 988–1 994

McEldowney D J, Tamirisakandala S, Miracle D B. Heat-treatment Effects on the Microstructure and Tensile Properties of Powder Metallurgy Ti-6Al-4V Alloys Modified with Boron[J]. Metall. Mater. Trans. A, 2010, 41(4): 1 003–1 015

Zhang X Y, Li M Q, Li H, et al. Deformation Behavior in Isothermal Compression of the TC11 Titanium Alloy[J]. Mater. Des., 2010, 31(6): 2 851–2 857

Sun Q J, Wang G C, Li M Q. The Super Plasticity and Microstructure Evolution of TC11 Titanium Alloy[J]. Mater. Des., 2011, 32(7): 3 893–3 899

Littlewood P D, Wilkinson A J. Local Deformation Patterns in Ti-6Al-4V under Tensile, Fatigue and Dwell Fatigue Loading[J]. Int. J. Fatigue, 2012, 43: 111–119

Gu Y, Zeng F H, Qi Y L, et al. Tensile Creep Behavior of Heat-treated TC11 Titanium Alloy at 450–550 °C[J]. Mater Sci. Eng. A, 2013, 575: 74–85

Park C H, Kim J H, Hyun Y T, et al. The Origins of Flow Softening during High-temperature Deformation of a Ti-6Al-4V Alloy with a Lamellar Microstructure[J]. J. Alloys Compd., 2014, 582: 126–129

Follansbee P S, Gray G T. An Analysis of the Low Temperature, Low and High Strain-rate Deformation of Ti-6Al-4V[J]. Metall. Trans. A, 1989, 20(5): 863–874

Silva M G, Ramesh K T. The Rate-dependent Deformation and Localization of Fully Dense and Porous Ti-6Al-4V[J]. Mater. Sci. Eng. A, 1997, 232(1–2): 11–22

Lee W S, Lin C F. Plastic Deformation and Fracture Behavior of Ti-6Al-4V Alloy Loaded with High Strain Rate under Various Temperatures[J]. Mater. Sci. Eng. A, 1998, 241(1–2): 48–59

Chichili D R, Ramesh K T, Hemker K J. The High-strain-rate Response of Alpha-titanium: Experiments, Deformation Mechanisms and Modeling[J]. Acta Mater, 1998, 46(3): 1 025–1 043

Nemat-Nasser S, Guo W G, Nesterenko V F, et al. Dynamic Response of Conventional and Hot Isostatically Pressed Ti-6Al-4V Alloys: Experiments and Modeling[J]. Mech. Mater, 2001, 33(8): 425–439

Lee D G, Lee S, Lee C S, et al. Effects of Micro Structural Factors on Quasi-static and Dynamic Deformation Behaviors of Ti-6Al-4V Alloys with Widmanstätten Structures[J]. Metall. Mater Trans. A, 2003, 34(11): 2 541–2 548

Khan A, Kazmi R, Farrokh B, et al. Effect of Oxygen Content and Micro-structure on the Thermo-mechanical Response of Three Ti-6Al-4V Alloys: Experiments and Modeling over a Wide Range of Strain-rates and Temperatures[J]. Int. J. Plasticity, 2007, 23(7): 1 105–1 125

Luntz R D, Griffin R M, Green S J, et al. High-strain-rate Tests on Titanium 6-6-2 Utilizing a Unique Rate-testing Machine[J]. Exp. Mech., 1975, 15(10): 396–402

Fundenberger J J, Philippe M J, Wagner F, et al. Modeling and Prediction of Mechanical Properties for Materials with Hexagonal Symmetry (Zinc, Titanium and Zirconium Alloys)[J]. Acta Mater, 1997, 45: 4 041–4 055

Gall K, Sehitoglu H, Chumlyakov Y I, et al. Tension-compression Asymmetry of the Stress-strain Response in Aged Single Crystal and Polycrystalline NiTi[J]. Acta. Mater, 1999, 47(4): 1 203–1 217

Williams J C, Baggerly R G, Paton N E. Deformation Behavior of HCP Ti-Al Single Crystals[J]. Metall. Mater Trans. A, 2002, 33(13): 837–850

Cheng S, Spencer J A, Milligan W W. Strength and Tension/compression Asymmetry in Nanostructured and Ultra Fine-grain Metals[J]. Acta Mater, 2003, 51(15): 4 505–4 518

Macdougall D A S, Harding J. A Constitutive Relation and Failure Criterion for Ti-6Al-4V Alloy at Impact Rates of Strain[J]. J. Mech. Phys. Solids, 1999, 47(5): 1 157–1 185

Roy S, Suwas S. The Influence of Temperature and Strain Rate on the Deformation Response and Microstructural Evolution during Hot Compression of a Titanium Alloy Ti-6Al-4V-0.1B[J]. J. Alloys Compd., 2013, 548(4): 110–125

Kotkunde N, Deole A D, Gupta A K, et al. Comparative Study of Constitutive Modeling for Ti-6Al-4V Alloy at Low Strain Rates and Elevated Temperatures[J]. Mater Des., 2014, 55: 999–1005

Huang W, Zan X, Nie X, et al. Experimental Study on the Dynamic Tensile Behavior of a Poly-crystal Pure Titanium at Elevated Temperatures[J]. Mat. Sci. Eng. A, 2007, 443(1–2): 33–41

Kapoor R, Nemat-Nasser S. Determination of Temperature Rise during High Strain Rate Deformation[J]. Mech. Mater, 1998, 27(1): 1–12

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China Academy of Engineering Physics and Jointly Set up “NSAF” Joint Fund (No. U1430119)

Rights and permissions

About this article

Cite this article

Li, Y., Zeng, X. Dynamic Tensile Behavior and Constitutive Modeling of TC21 Titanium Alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 707–716 (2019). https://doi.org/10.1007/s11595-019-2107-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2107-x