Abstract

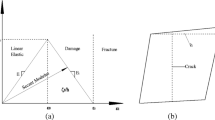

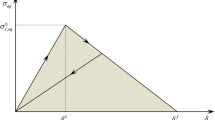

The longitude tensile properties of 3-Dimension-4-directional(3D-4d) braided C/SiC composites(CMCs) were investigated with the help of a double scale model. This model involves micro-scale and unit-cell scale. In micro-scale, the tensile properties of fiber tows which involves matrix cracking, interfacial debonding, and fiber failure are studied. The unit-cell scale model can reflect the braided structure and simulate the tensile properties of 3D-4d CMCs by introducing the tensile properties of fiber tows into it. Quasi-static tensile tests of 3D-4d braided CMCs were performed on a PWS-100 test system. The predicted tensile stress-strain curve by the double scale model is in good agreement with that of the experimental results.

Similar content being viewed by others

References

Dassios KG, Aggelis DG, Kordatos EZ, et al. Cyclic Loading of a SiC-fiber Reinforced Ceramic Matrix Composite Reveals Damage Mechanisms and Thermal Residual Stress State[J]. Composite: Part A, 2013, 44(1): 105–113

Chang Y, Jiao G, Wang B, et al. Elastic Behavior Analysis of 3D Angle-Interlock Woven Ceramic Composites[J]. Acta Mechanica Solida Sinica, 2006, 19(2): 152–159

Liu X, Cheng L, Zhang L, et al. Tensile Properties and Damage Evolution in a 3D C/SiC Composite at Cryogenic Temperatures[J]. Materials Science and Engineering: A, 2011, 528(25-26): 7 524–75 28

Kang TJ, Kim S, Jung K. Prediction of Mechanical Properties of 3-D Braided Composite Using CAD System[J]. Textile Research Journal, 2008, 78: 174–182

Sun H, Di S, Zhang N, et al. Micromechanics of Braided Composites via Multivariable FEM[J]. Computer and Structures, 2003, 81: 2 021–2 027

Chen L, Tao XM, Choy C L. On the Microstructure of Three- Dimensional Braided Preforms[J]. Composites Science and Technology, 1999, 59(3): 391–404

Fang G, Liang J, Wang B. Progressive Damage and Nonlinear Analysis of 3D Four-directional Braided Composites under Unidirectional Tension[J]. Composite Structures, 2009, 89: 126–133

Fang G, Liang J, Wang Y, et al. The Effect of Yarn Distortion on the Mechanical Properties of 3D Four-directional Braided Composites[J]. Composites Part a-Applied Science and Manufacturing, 2009, 40: 343–350

Yu XG, Cui JZ. The Prediction on Mechanical Properties of 4-step Braided Composites via Two-scale Method[J]. Composite Science and Technology, 2007, 67: 471–480

Niu X, Sun Z, Kong C, et al. The Elastic Modulus Prediction of 3 Dimension-4 directional Braided Cf/SiC Composite based on Doublescale model[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2015, 30(3): 500–508

Budiansky B, Evans AG, Hutchinson J W. Fiber-Matrix Debonding Effects on Cracking in Aligned Fiber Ceramic Composites[J]. International Journal of Solids and Structures, 1995, 32(3-4): 315–328

Henstenburg RB, Phoenix SL. Interface Shear Strength Studies Using the Singke-Filament-Composite Test. Part II: A Probability Model and Monte Carlo Simulation[J]. Polymer Composites, 1989, 10(6): 389–408

Netravali AN, Henstenburg RB, Phoenix SL, et al. Interface Shear Strength Studies Using the Singke-Filament-Composite Test. I:Experiments on Graphite Fibers in Epoxy[J]. Polymer Composites, 1989, 10(4): 226–241

Gundel DB, Wawner FE. Experimental and Theroetical Assessment of the Longitudinal Tensile Strength of Unidirectional SiC-fiber/ Titanium-matrix Composites[J]. Composites Science and Technology, 1997, 57(4): 471–481

Stawovy RH, Kampe SL, Curtin WA. Mechanical Behavior of Glass and Blackglas® Ceramic Matrix Composites[J]. Acta Materialia, 1997, 45(12): 5 317–5 325

Duva JM, Curtin WA, Wadley NG. An Ultimate Tensile Strength Dependence on Processing for Consolidated Metal Matrix Composites[J]. Acta Metallurgica et Materialia, 1995, 43(3): 1 119–1 126

Curtin WA. Ultimate Strengths of Fiber-reinforced Ceramics and Metals[J]. Composites, 1993, 24(2): 98–102

Curtin WA. Theory of Mechanical Properties of Ceramic-matrix Composites[J]. Journal of the Ameraican Ceramic Society, 1991, 74(11): 2 837–2 845

Curtin WA, Ahn BK, Takeda N. Modeling Brittle and Tough Stressstrain Behavior in Unidirectional Ceramic Matrix Composites[J]. Acta Materialia, 1998, 46(10): 3 409–3 420

Li Longbiao. Fatigue Damage Models and Life Prediction of Longfiber-reinforced Ceramic Matrix Composite[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010

Yan Miao. Research on the Failure Models of Matrix in Ceramic Matrix Composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007

Aveston JM, Cooper GA, Kelly A. Single and Multiple Fracture, the Properties of Fiber Composite[Z]. Guildford, UK: 1971

Li L. Fatigue Damage Models and Life Prediction of Long-fiberreinforced Ceramic Matrix Composite[D]. Nanjing: Nanjing: Nanjing University of Aeronautics and Astronautics, 2010

Gao Xi-guang. The Damage Coupled Macro- and Micro- Constitutive Models for Ceramic Matrix Composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2008

Curtin WA. Theory of Mechanical Properties of Ceramic Matrix Composite[J]. Journal of American Ceramic Society, 1991, 74(11): 2 837–2 845

Dalmaz A, Ducret D, Guerjouma RE, et al. Elastic Moduli of a 2.5D Cf/SiC Composite: Experimental and Theoretical Estimates[J]. Composites Science and Technology, 2000, 60: 913–925

Luo Guoqing. Tensile Performance of 3D-C/SiC Composites[D]. Xi'an: Northwestern Polytechnical University, 2003

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Basic Research Program of China, the National Natural Science Foundation of China (51675266), the Aeronautical Science Foundation of China (2014ZB52024), the Fundamental Research Funds for the Central Universities (NJ20160038), the Jiangsu Innovation Program for Graduate Education(CXLX13_165) and the Fundamental Research Funds for the Central Universities

Rights and permissions

About this article

Cite this article

Niu, X., Sun, Z., Song, Y. et al. Tensile properties of 3-Dimension-4-directional braided Cf/SiC composite based on double-scale model. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 1271–1279 (2017). https://doi.org/10.1007/s11595-017-1741-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1741-4