Abstract

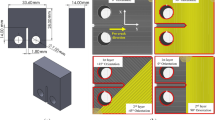

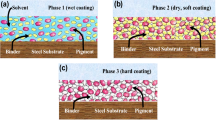

With Al foil, Cu foil and steel mesh as the metal interlayers, respectively, three types of alumina/epoxy/metal laminated composites were fabricated with epoxy resin adhesive as a binder via a simple process. The impact tests were performed and the fracture patterns and impact response of all the three laminates were analyzed. The experimental results indicate that the absorbed energy is mainly determined by metal interlayer. The peak load depends on not only alumina substrate but also metal interlayer. The Al2O3/epoxy/Cu laminates sustain the maximum peak load and Al2O3/epoxy/steel mesh laminates have the largest threshold energy for penetration. The fracture analysis shows that the main damage modes are Al2O3 matrix cracking and metal deformation for lower impact energies, and complete breakage and penetration for higher impact energies.

Similar content being viewed by others

References

Zuo KH, Jiang DL, Lin QL. Al2O3/Ni laminar Ceramics Shaped by Tape Casting and Electroless Plating[J]. Journal of the American Ceramic Society, 2005, 88(9): 2659–2661

Reynaud C, Thévenot F, Chartier T, et al. Mechanical Properties and Mechanical Behaviour of SiC Dense-porous Laminates[J]. Journal of the European Ceramic Society, 2005, 25(5): 589–597

Li C, Wang CA, Huang Y, et al. Effects of Sintering Aids on the Microstructure and Mechanical Properties of Laminated Si3N4/BN Ceramics[J]. Materials Letters, 2003, 57(22–23): 3473–3478

Chartier T, Merle D, Besson J. Laminar Ceramic Composites[J]. Journal of the European Ceramic Society, 1995, 15(2): 101–107

Kim BC, Park DC, Kim BJ, et al. Through-thickness Compressive Strength of a Carbon/Epoxy Composite Laminate[J]. Composite Structures, 2010, 92(2): 480–487

Blattner AJ, Lakshminarayanan R, Shetty DK. Toughening of Layered Ceramic Composites with Residual Surface Compression: Effects of Layer Thickness[J]. Engineering Fracture Mechanics, 2001, 68(1): 1–7

Yang G, Liu Y, Qiao G, et al. Preparation and R-curve Properties of Laminated Si/SiC Ceramics from Paper[J]. Materials Science and Engineering: A, 2008, 492(1–2): 327–332

Sun D, Yu X, Liu W, et al. Laminated Biomorphous SiC/Si Porous Ceramics Made from Wood Veneer[J]. Materials & Design, 2012, 34: 528–532

Zhou P, Hu P, Zhang X, et al. Laminated ZrB2-SiC Ceramic with Improved Strength and Toughness[J]. Scripta Materialia, 2011, 64(3): 276–279

Zhang X, Zhou P, Hu P, et al. Toughening of Laminated ZrB2-SiC Ceramics with Residual Surface Compression[J]. Journal of the European Ceramic Society, 2011, 31(13): 2415–2423

Zuo KH, Jiang DL, Lin QL. Fabrication and Interfacial Structure of Al2O3/Ni Laminar Ceramics[J]. Ceramics international, 2006, 32(6): 613–616

Zuo KH, Jiang DL, Lin QL. Mechanical Properties of Al2O3/Ni Laminated Composites[J]. Materials Letters, 2006, 60(9–10): 1265–1268

Zuo KH, Jiang DL, Lin QL. Improving the Mechanical Properties of Al2O3/Ni Laminated Composites by Adding Ni Particles in Al2O3 Layers[J]. Materials Science and Engineering: A, 2007, 443(1–2): 296–300

Chen B, Peng X, Wang J, et al. Laminated Microstructure of Bivalva Shell and Research of Biomimetic Ceramic/Polymer Composite[J]. Ceramics International, 2004, 30(7): 2011–2014

Zhao S, Zhang J, Zhao S, et al. Effect of Inorganic-organic Interface Adhesion on Mechanical Properties of Al2O3/polymer Laminate Composites[J]. Composites Science and Technology, 2003, 63(7): 1009–1014

Reis P, Ferreira J, Costa J, et al. Fatigue Life Evaluation for Carbon/ Epoxy Laminate Composites under Constant and Variable Block Loading[J]. Composites Science and Technology, 2009, 69(2): 154–160

Clegg WJ, Kendall K, Alford NM, et al. A Simple Way to Make Tough Ceramics[J]. Nature, 1990, 347(6292): 455–457

Li WX, Bai MM, Lu Y, et al. Preparation and Properties of Al2O3/Steelepoxy Laminated Composites[J]. Journal of Inorganic Materials, 2013, 28(4): 453–458

Li WX, Lu Y, Xie MG, et al. Lamianted Al2O3/Al Composites Bonded by Epoxy Resin Adhesive[J]. Journal of South China University of Technology:Natural Science Edition, 2013, 41(2): 117–122

Hosur M, Abdullah M, Jeelani S. Manufacturing and Low-velocity Impact Characterization of Hollow Integrated Core Sandwich Composites with Hybrid Face Sheets[J]. Composite Structures, 2004, 65(1): 103–115

Vaidya A, Vaidya U, Uddin N. Impact Response of Three-dimensional Multifunctional Sandwich Composite[J]. Materials Science and Engineering: A, 2008, 472(1–2): 52–58

Vaidya U, Hosur M, Earl D, et al. Impact Response of Integrated Hollow Core Sandwich Composite Panels[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(8): 761–772

Shyr TW, Pan YH. Low Velocity Impact Responses of Hollow Core Sandwich Laminate and Interply Hybrid Laminate[J]. Composite Structures, 2004, 64(2): 189–198

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Science and Technology Program of Guangdong Province of China (No. 2012B091000107) and the Subproject of China Education & Equipment Resource System (No. CERS-1-2)

Rights and permissions

About this article

Cite this article

Bai, M., Li, W., Li, Y. et al. Low-velocity impact property of alumina/epoxy/metal laminated composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 779–785 (2016). https://doi.org/10.1007/s11595-016-1445-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1445-1