Abstract

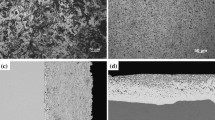

Arc sprayed Zn and Zn15Al coatings were chosen to protect the metal ends of prestressed high-strength concrete (PHC) pipe piles against corrosion of salina soil in northern china and neutral meadow soil in northeast China. The corrosion behavior of the coated Q235 steel samples in two simulated soil solutions were investigated by potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) methods. The experimental results show that the corrosion of the matrix Q235 steel in both simulated solutions is remarkably inhibited by Zn and Zn15Al coatings. The corrosion products on Zn and Zn15Al are thick, compact, firm and protective. The corrosion current density i corr of both Zn and Zn15Al-coated samples is decreased evidently with corrosion time, and the charge transfer resistance R ct is increased greatly. The corrosion resistance indexes of Zn and Zn15Al in simulated neutral meadow soil solution are more outstanding than those in salina soil. The corrosion resistance of Zn15Al in salina soil is slightly superior to that of Zn. When the sprayed coatings are sealed with epoxy resin, the corrosion resistance of the coatings is further enhanced markedly.

Similar content being viewed by others

References

Fisher A K, Bullen F, Beal D. The Durability of Cellulose Fibre Reinforced Concrete Pipes in Sewage Applications [J]. Cem. Concr. Res., 2001, 31(4): 543–553

Miyata Y, Nakano H, Abe M, et al. Effectiveness of Polyethylene Coating for Steel Pipe Piles [J]. Mater. Perform., 2006, 45(12): 24–27

Han Q W, Wei Y L. Low Durability of PHC Pipe Piles [N]. Guangdong Jianshe Newspaper, 2006-12-29-B03

Berger D M. Electrochemical and Galvanic Corrosion of Coated Steel Surfaces [J]. Chem. Eng. (New York), 1982, 89: 109–112

Du C W, Li X G, Liang P, et al. Effects of Microstructure on Corrosion of X70 Pipe Steel in an Alkaline Soil [J]. J. Mater. Eng. Perform., 2009, 18(2): 216–220

Lin B L, Lu X Y, Li L. Corrosion Behaviors of Metal End of PHC Pipe Pile in Simulated Soil Solutions [J]. J. Central South Univ. (Sci. Technol.), 2011, 42(2): 434–440

Vourlias G, Pistofidis N, Stergioudis G. Ability of Metallic Coatings to Protect Low Carbon Steels from Aqueous Corrosion [J]. Corros. Eng. Sci. Technol., 2008, 43(2): 163–172

Papavinasam S, Attard M, Arseneult B, et al. State-of-theart of Thermal Spray Coatings for Corrosion Protection [J]. Corros. Rev., 2008, 26(2–3): 105–146

Hou B R, Zhang J, Duan J Z, et al. Corrosion of Thermally Sprayed Zinc and Aluminium Coatings in Simulated Splash and Tidal Zone Conditions [J]. Corros. Eng. Sci. Technol., 2003, 38(2): 157–160

Tobe S. A Review on Protection from Corrosion, Oxidation and Hot Corrosion by Thermal Spray Coatings.// ASM Thermal Spray Society, German Welding Society, and High Temperature Society of Japan. Nice: ASM International, 1998: 3–11

Lee S H, Lee H S, Kyung J W, et al. Anti-Corrosion Performance of Zn-Al Thermal Metal Spraying Method Using Steel Structures [J]. Key Eng. Mater. Adv. Fract. Damage Mech. VI, 2007, 348–349: 453–456

Liu Y, Zhu Z X, Chen Y X, et al. Electrochemical Corrosion Behavior of Arc Sprayed Zn-Al Coatings [J]. Trans. Nonferrous Met. Soc. China, 2004, 14(SI): 443–445

Chaliampalias D, Vourlias G, Pistofidis N, et al. A Morphological and Microstructural Study of Flame-Sprayed Zinc Coatings on Low-Alloyed Steels as a Contribution to Explaining their Corrosion Resistance [J]. Phys. Status Solidi. (A) Appl. Mater., 2008, 205(7): 1566–1571

Tsuyoshi M, Kazuo F, Yasuyuki T, et al. Corrosion Rate and Corrosion Behavior of Al-2%Zn Alloy Spray Coating in Sodium Chloride Solution at Low Temperature [J]. Corros. Eng., 2005, 54(11): 520–525

Kuroda S, Kawakita J, Takemoto M. An 18-year Exposure Test of Thermal-Sprayed Zn, Al, and Zn-Al Coatings in Marine Environment [J]. Corrosion, 2006, 62(7): 635–647

Lin B L, Lu X Y, Li L. Corrosion Behaviors of Arc Spraying Single and Double Layer Coatings in Simulated Dagang Soil Solution [J]. Trans. Nonferrous Met. Soc. China, 2009, 19(6): 1 556–1 561

Yang X Z, Yang W. Electrochemical Thermodynamics of Metallic Corrosion: Potential-pH Diagrams and their Applications [M]. Beijing: Chemical Industry Press, 1991: 21–86

Cachet C, Ganne F, Joiret S, et al. EIS Investigation of Zinc Dissolution in Aerated Sulphate Medium. Part II: Zinc Coatings [J]. Electrochim. Acta, 2002, 47(21): 3409–3422

Cao C N, Zhang J Q. Introduction to Electrochemical Impedance Spectroscopy [M]. Beijing: Science Press, 2002: 143–189

Weng D, Jokiel P, Uebleis A, et al. Corrosion and Characteristics of Zinc and Manganese Phosphate Coatings [J]. Surf. Coat. Technol., 1997, 88(1–3): 147–156

Tang N, Ooij W J, Gorecki G. Comparative EIS Study of Pretreatment Performance in Coated Metals [J]. Prog. Org. Coat., 1997, 30(4): 255–263

Benedetti A V, Sumodjo P T A, Nobe K, et al. Electrochemical Studies of Copper, Copper-Aluminium and Copper-Aluminium-Silver Alloys: Impedance Results in 0.5 M NaCl [J]. Electrochim. Acta, 1995, 40(16): 2657–2668

Yao J M. College Physics (II) [M]. Beijing: Beijing Institute of Technology Press, 2008: 317–322

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the General Project of China Postdoctoral Science Foundation (20080440043), the Special Funded Project of China Postdoctoral Science Foundation (200902107), the Action Plan Project of Enterprise Scientific and Technological Envoys by Guangdong Province, Education Ministry, and the Science & Technology Ministry (2009B090600106)

Rights and permissions

About this article

Cite this article

Lin, B., Lu, X. & Li, L. Electrochemical corrosion behavior of arc sprayed Zn and Zn15Al coatings in simulated salina soil and neutral meadow soil solutions. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 1152–1156 (2011). https://doi.org/10.1007/s11595-011-0380-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0380-4