Abstract

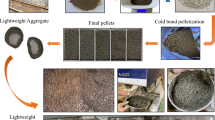

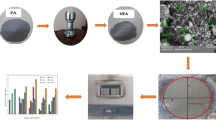

Waste solid propylene oxide sludge (POS) and fly ash were used as main raw material to prepare propylene oxide sludge aggregate (POSA) under the condition of autoclaved (180 °C, 1.0 MPa) curing. Three different test methods namely cylinder compressive strength (CCS), individual aggregate compressive strength (IACS) and strength contribution rate (SCR) proposed were used to characterize the mechanical properties of the autoclaved POSA. POS shell-aggregate with SCR of 94% were prepared under the hydrothermal synthesis and autoclaved curing. The experimental results indicate that CCS and IACS have good consistency in characterizing mechanical properties of POSA. It is suggested that SCR not only can characterize the strength of POSA core, but also can reflect the effect of shell on the performance of POSA. By means of least square method, relationships between CCS and IACS, CCS and SCR, IACS and SCR were deduced.

Similar content being viewed by others

References

Matar S, Hatch LF. Chemistry of Petrochemical Processes[M]. Houston: Gulf Publishing Company, 1994

Sun KH, Zhang ML, Meng XY. Production and Market Analysis of Propylene Oxide in China[J]. Mod. Chem. Industry, 2003, 23(2):50–53 (In Chinese)

Zhang ZF, Zhen HY, Wu GD, Zhang YJ. Techno-economic Comparisons and Market Analysis for Propylene Oxide[J]. Techno-Economics in Petrochemicals, 2009, 25(5):30–34 (In Chinese)

Swamy RN, Wu L. The Ingredients for High Performance in Structural Lightweight Aggregate Concrete[J]. Struct. Lightweight Aggregate Concr., 1995, 13:628–639

Chandra S, Berntsson L. Production of Lightweight Aggregates and Its Properties, Lightweight Aggregate Concrete Science, Technology, and Applications[M]. New York: William Andrew Inc, 2002:21–65

Chandra S, Berntsson L. Applications of Lightweight Aggregate Concrete, Lightweight Aggregate Concrete Science, Technology, and Applications[M]. New York: William Andrew Inc, 2002:369–400

Chandra S, Berntsson L. Historical Background of Lightweight Aggregate Concrete, Lightweight Aggregate Concrete, Technology, and Applications [M]. New York: William Andrew Inc, 2002:5–19

Ramamurthy K, Harikrishnan KI. Influence of Binders on Properties of Sintered Fly Ash Aaggregate [J]. Cement Concrete Composites, 2006, 28:33–38

Huang SC, Chang FC. Production of Lightweight Aggregates from Mining Residues, Heavy Metal Sludge, and Incinerator Fly Ash[J]. Journal of Hazardous Materials, 2007, 144:52–58

Wang XR, Jin YY, Wang ZY. Development of Lightweight Aggregate from Dry Sewage Sludge and Coal Ash[J]. Waste Management, 2009, 29:1 330–1 335

González-Corrochanoa B, Alonso-Azcáratea J, Rodasb M. Characterization of Lightweight Aggregates Manufactured from Washing Aggregate Sludge and Fly Ash [J]. Resour Conserv Recy, 2009, 53:571–581

Mun KJ. Development and Tests of Lightweight Aggregate Using Sewage Sludge for Nonstructural Concrete [J]. Construction and Building Materials, 2007, 21:1 583–1 588

Kourti I, Cheeseman CR. Properties and Microstructure of Lightweight Aggregate Produced from Lignite Coal Fly Ash and Rrecycled Glass [J]. Resour Conserv. Recy., 2010, 54:769–775

GB/T 17431.2-1998. Lightweight Aggregates and Its Test Methods-Part 2: Test Methods for Lightweight Aggregates[S]. (In Chinese)

Yashima S, Kanda Y, Sano S. Relationship Between Particle Size and Fracture Energy or Impact Velocity Pequired to Fracture as Estimated from Single Particle Crushing [J]. Power Technol., 1987, 51:277–282

Li Y. Measurement and Statistics of Single Pellet Mechanical Strength of Differently Shaped catalysts [J]. Power Technol., 2000, 113:176–184

UNEEN-13055-1. Áridos Ligeros. Parte 1: Áridos Ligeros Para Hormigón, Mortero Einyectado [S].

JCPDS (Joint Committee on Powder Diffraction Standards). International Center for Diffraction Data [M]. Swarthmore, Pennsyvania, 2002

Diamond S. The Microstructures of Cement Paste in Concrete[C]. In: Proc. of the 8th International Conference on the Chemistry of Cement, 1986, 1: 122–147

Lo TY, Cui HZ. Effect of Porous Lightweight Aggregate on Strength of Concrete [J]. Materials Letters, 2004, 58:916–919

Hu SG, Wang FZ. Lightweight Aggregate Concrete[M]. Beijing: Chemical Industry Press, 2005 (In Chinese)

GB/T 50081-2002. Standard for Test Methods of Mechanical Properties of Ordinary Concrete [S](In Chinese).

Johnson RA, Wichern DW. Applied Multivariate Statistical Analysis [M]. New Jersey: Prentice-Hall Inc, 1992

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Fundation of China(51061015), the scientific Research Program of Jiangsu Economic Information Committee, the Program for Postgraduates Research Innovation in University of Jiangsu Province (CX10B_122Z) and the Science and Technology Project of Jiangsu Province Construction System (JS2010JH22)

Rights and permissions

About this article

Cite this article

Ma, H., Cui, C., Li, X. et al. Mechanical properties of autoclaved shell-aggregate. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 723–729 (2011). https://doi.org/10.1007/s11595-011-0301-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0301-6