Abstract

Previous research regarding the performance of self-compacting concrete (SCC) incorporating nano-fly ash (NFA), especially after exposure to elevated temperatures, is scarce. Therefore, this experimental research was conducted to investigate the influence of NFA particles on the performance of SCC at normal and elevated temperatures. The effects of NFA particles were also compared with the influence of fly ash (FA) particles at the same replacement percentages. The experimental program was managed at two stages. At the first stage, the microparticles of FA were transformed into nanoparticles using electric milling process. The size, shape, and consistency of the FA and NFA particles were characterized using scanning electron microscopy. In the second stage, experimental tests were performed to examine the influences of FA and NFA particles on the performance and characteristics of SCC. The investigated parameters included fresh density, dry density, T50 slump flow time, slump flow diameter, elastic modulus, ultrasonic pulse velocity (UPV), and compressive as well as flexural strength. Furthermore, the residual compressive strength, weight loss, and UPV after exposing the concrete samples to 700 °C were also investigated. The results showed that addition of FA and NFA can cause a reduction in the workability as well as flowability of SCC mixtures. On the other hand, the transformation of FA to NFA significantly enhanced the microstructure of the SCC, which led to the enhancement of its mechanical properties and boosted the resistance of the SCC to high temperatures. The outcomes of this study also illustrated that through transforming the particles of FA from microscale to nanoscale, a sustainable and high-performance SCC can be produced.

Graphic abstract

Similar content being viewed by others

References

Beigi MH, Berenjian J, Omran OL, Nik AS, Nikbin IM (2013) An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater Des 50:1019–1029. https://doi.org/10.1016/j.matdes.2013.03.046

Barbhuiya S (2011) Effects of fly ash and dolomite powder on the properties of self-compacting concrete. Constr Build Mater 25(8):3301–3305. https://doi.org/10.1016/j.conbuildmat.2011.03.018

Oltulu M, Şahin R (2011) Single and combined effects of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strength and capillary permeability of cement mortar containing silica fume. Mater Sci Eng A 528(22–23):7012–7019. https://doi.org/10.1016/j.msea.2011.05.054

Aslani F, Khan M (2019) Properties of high-performance self-compacting rubberized concrete exposed to high temperatures. J Mater Civ Eng 31(5):04019040. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002672

Safiuddin M, West JS, Soudki KA (2011) Flowing ability of the mortars formulated from self-compacting concretes incorporating rice husk ash. Constr Build Mater 25(2):973–978. https://doi.org/10.1016/j.conbuildmat.2010.06.084

Jalal M, Mansouri E, Sharifipour M, Pouladkhan AR (2012) Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater Des 34:389–400. https://doi.org/10.1016/j.matdes.2011.08.037

Nazari A, Riahi S (2011) Al2O3 nanoparticles in concrete and different curing media. Energy Build 43(6):1480–1488. https://doi.org/10.1016/j.enbuild.2011.02.018

Noorvand H, Ali AAA, Demirboga R, Farzadnia N, Noorvand H (2013) Incorporation of nano TiO2 in black rice husk ash mortars. Constr Build Mater 47:1350–1361. https://doi.org/10.1016/j.conbuildmat.2013.06.066

Oltulu M, Şahin R (2013) Effect of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strengths and capillary water absorption of cement mortar containing fly ash: a comparative study. Energy Build 58:292–301. https://doi.org/10.1016/j.enbuild.2012.12.014

Raghavendra G, Ojha S, Acharya SK, Pal SK (2014) Fabrication and characterization of nano fly ash by planetary ball milling. Int J Mater Sci Innov 2:59–68

Tudjono S, Purwanto XXX, Apsari KT (2014) Study the effect of adding nano fly ash and nano lime to compressive strength of mortar. Procedia Eng 95:426–432. https://doi.org/10.1016/j.proeng.2014.12.202

Silvestre J, Silvestre N, De Brito J (2015) An overview on the improvement of mechanical properties of ceramics nanocomposites. J Nanomater 2015:3. https://doi.org/10.1155/2015/106494

Mohseni E, Miyandehi BM, Yang J, Yazdi MA (2015) Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on the mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr Build Mater 84:331–340. https://doi.org/10.1016/j.conbuildmat.2015.03.006

Madandoust R, Mohseni E, Mousavi SY, Namnevis M (2015) An experimental investigation on the durability of self-compacting mortar containing nano-SiO2, nano-Fe2O3 and nano-CuO. Constr Build Mater 86:44–50. https://doi.org/10.1016/j.conbuildmat.2015.03.100

Mohseni E, Naseri F, Amjadi R, Khotbehsara MM, Ranjbar MM (2016) Microstructure and durability properties of cement mortars containing nano-TiO2 and rice husk ash. Constr Build Mater 114:656–664. https://doi.org/10.1016/j.conbuildmat.2016.03.136

Nasr MS, Salih SA, Hassan MS (2016) Some durability characteristics of micro silica and nano silica contained concrete. J Univ Babylon 24(4):980–990

Nazari A, Riahi S (2011) Splitting tensile strength of concrete using ground granulated blast furnace slag and SiO2 nanoparticles as binder. https://doi.org/10.1016/j.enbuild.2010.12.006

Nazari A, Riahi S (2011) TiO2 nanoparticles effects on physical, thermal and mechanical properties of self compacting concrete with ground granulated blast furnace slag as binder. https://doi.org/10.1016/j.enbuild.2010.12.025

Joshaghani A, Balapour M, Mashhadian M, Ozbakkaloglu T (2020) Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): an experimental study. Constr Build Mater 245:118444. https://doi.org/10.1016/j.conbuildmat.2020.118444

Jalal M, Ramezanianpour AA, Pool MK (2012) Effects of titanium dioxide nanopowder on rheological properties of self compacting concrete. J Am Sci 8(4):285–288

Miyandehi BM, Behforouz B, Khotbehsara EM, Balgouri HA, Fathi S, Khotbehsara MM (2014) An experimental investigation on nano-Al2O3 based self-compacting mortar. J Am Sci 10(11):229–233

Faez A, Sayari A, Manie S (2020) Mechanical and rheological properties of self-compacting concrete containing Al2O3 nanoparticles and silica fume. Iran J Sci Technol Trans Civ Eng. https://doi.org/10.1007/s40996-019-00339-y

Khoshakhlagh A, Nazari A, Khalaj G (2012) Effects of Fe2O3 nanoparticles on water permeability and strength assessments of high strength self-compacting concrete. J Mater Sci Technol 28(1):73–82. https://doi.org/10.1016/S1005-0302(12)60026-7

Gülşan ME, Alzeebaree R, Rasheed AA, Niş A, Kurtoğlu AE (2019) Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr Build Mater 211:271–283. https://doi.org/10.1016/j.conbuildmat.2019.03.228

Aslani F (2015) Nanoparticles in self-compacting concrete—a review. Mag Concr Res 67(20):1084–1100. https://doi.org/10.1680/macr.14.00381

Faraj RH, Ali HFH, Sherwani AFH, Hassan BR, Karim H (2020) Use of recycled plastic in self-compacting concrete: a comprehensive review on fresh and mechanical properties. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101283

Faraj RH, Sherwani AFH, Daraei A (2019) Mechanical, fracture and durability properties of self-compacting high strength concrete containing recycled polypropylene plastic particles. J Build Eng 25:100808. https://doi.org/10.1016/j.jobe.2019.100808

Ali TKM, Hilal N, Faraj RH, Al-Hadithi AI (2020) Properties of eco-friendly pervious concrete containing polystyrene aggregates reinforced with waste PET fibers. Innov Infrastruct Solut 5(3):1–16. https://doi.org/10.1007/s41062-020-00323-w

Abbasi S, Jannaty MH, Faraj RH, Shahbazpanahi S, Mosavi A (2020) The effect of incorporating silica stone waste on the mechanical properties of sustainable concretes. Materials 13(17):3832. https://doi.org/10.3390/ma13173832

Faraj RH, Sherwani AFH, Jafer LH, Ibrahim DF (2020) Rheological behavior and fresh properties of self-compacting high strength concrete containing recycled PP particles with fly ash and silica fume blended. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101667

Iraqi Specifications, I. Q. S. No. 5, 1984. Properties of Normal Portland Cement

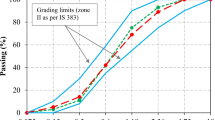

No, I. S. (1984). 45, Natural sources for gravel that is used in concrete and construction

ASTM, C. 33–03 2003) Standard specification for concrete aggregates. Annual book of ASTM standards. ASTM, West Conshohocken

Concrete SC (2005) The European guidelines for self-compacting concrete. BIBM et al, 22

Kheder GF, Al Jadiri RS (2010) New method for proportioning self-consolidating concrete based on compressive strength requirements. ACI Mater J 107(5):490–497

Standard B (1881) Part-116 (1983) method for determination of compressive strength of concrete cubes. British Standard Institution, London

ASTM C (2010) Standard test method for flexural strength of concrete (using simple beam with third-point loading). In: American society for testing and materials, vol 100, pp 19428–2959

ASTM, C (2009) 597, standard test method for pulse velocity through concrete. ASTM International, West Conshohocken

Morsy MS, Al-Salloum YA, Abbas H, Alsayed SH (2012) Behavior of blended cement mortars containing nano-metakaolin at elevated temperatures. Constr Build Mater 35:900–905. https://doi.org/10.1016/j.conbuildmat.2012.04.099

Diamantonis N, Marinos I, Katsiotis MS, Sakellariou A, Papathanasiou A, Kaloidas V, Katsioti M (2010) Investigations about the influence of fine additives on the viscosity of cement paste for self-compacting concrete. Constr Build Mater 24:1518–1522. https://doi.org/10.1016/j.conbuildmat.2010.02.005

Mohammed MK, Dawson AR, Thom NH (2014) Macro/micro-pore structure characteristics and the chloride penetration of self-compacting concrete incorporating different types of filler and mineral admixture. Constr Build Mater 72:83–93. https://doi.org/10.1016/j.conbuildmat.2014.08.070

Senff L, Hotza D, Lucas S, Ferreira VM, Labrincha JA (2012) Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater Sci Eng A 532:354–361. https://doi.org/10.1016/j.msea.2011.10.102

Voo YL, Nematollahi B, Mohamed Said AB, Gopal BA, Yee TS (2012) Application of ultra high performance fiber reinforced concrete—the Malaysia perspective. Int J Sustain Constr Eng Technol 3(1):26–44

Tadros MK, Voo Y (2016) Taking ultra-high-performance concrete to new heights. ASPIRE 10(3):36–38

Qadir HH, Faraj RH, Sherwani AFH, Mohammed BH, Younis KH (2020) Mechanical properties and fracture parameters of ultra high performance steel fiber reinforced concrete composites made with extremely low water per binder ratios. SN Appl Sci 2(9):1–12. https://doi.org/10.1007/s42452-020-03425-3

Wongkeo W, Thongsanitgarn P, Ngamjarurojana A, Chaipanich A (2014) Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater Des 64:261–269. https://doi.org/10.1016/j.matdes.2014.07.042

Shekari AH, Razzaghi MS (2011) Influence of nano particles on durability and mechanical properties of high performance concrete. Procedia Eng 14:3036–3041. https://doi.org/10.1016/j.proeng.2011.07.382

Jalal M, Pouladkhan A, Harandi OF, Jafari D (2015) Comparative study on effects of class F fly ash, nano silica and silica fume on properties of high performance self compacting concrete. Constr Build Mater 94:90–104. https://doi.org/10.1016/j.conbuildmat.2015.07.001

Shahbazpanahi S, Faraj RH (2020) Feasibility study on the use of shell sunflower ash and shell pumpkin ash as supplementary cementitious materials in concrete. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101271

Malhotra VM, Carino NJ (2003) Handbook on nondestructive testing of concrete. CRC Press, Boca Raton

Uysal M (2012) Self-compacting concrete incorporating filler additives: performance at high temperatures. Constr Build Mater 26(1):701–706. https://doi.org/10.1016/j.conbuildmat.2011.06.077

Yüksel İ, Siddique R, Özkan Ö (2011) Influence of high temperature on the properties of concretes made with industrial by-products as fine aggregate replacement. Constr Build Mater 25(2):967–972. https://doi.org/10.1016/j.conbuildmat.2010.06.085

Amin M, Tayeh BA (2020) Investigating the mechanical and microstructure properties of fibre-reinforced lightweight concrete under elevated temperatures. Case Stud Constr Mater. https://doi.org/10.1016/j.cscm.2020.e00459

Zhang B, Bicanic N (2002) Residual fracture toughness of normal-and high-strength gravel concrete after heating to 600°C. Mater J 99(3):217–226

Abed M, Nemes R, Lublóy É (2020) Performance of self-compacting high-performance concrete produced with waste materials after exposure to elevated temperature. J Mater Civ Eng 32(1):05019004. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002989

Lublóy É, Kopecskó K, Balázs GL, Restás Á, Szilágyi IM (2017) Improved fire resistance by using Portland-pozzolana or Portland-fly ash cements. J Therm Anal Calorim 129(2):925–936. https://doi.org/10.1007/s10973-017-6245-0

Yang H, Lin Y, Hsiao C, Liu JY (2009) Evaluating residual compressive strength of concrete at elevated temperatures using ultrasonic pulse velocity. Fire Saf J 44(1):121–130. https://doi.org/10.1016/j.firesaf.2008.05.003

Handoo SK, Agarwal S, Agarwal SK (2002) Physicochemical, mineralogical, and morphological characteristics of concrete exposed to elevated temperatures. Cem Concr Res 32(7):1009–1018. https://doi.org/10.1016/S0008-8846(01)00736-0

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alobaidi, Y.M., Hilal, N.N. & Faraj, R.H. An experimental investigation on the nano-fly ash preparation and its effects on the performance of self-compacting concrete at normal and elevated temperatures. Nanotechnol. Environ. Eng. 6, 2 (2021). https://doi.org/10.1007/s41204-020-00098-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41204-020-00098-6