Abstract

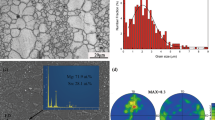

The effect of cooling rate on the microstructure of ZA48 alloy was investigated. The alloy was prepared using a relatively simple technique, i e, rapid cooling of the melt in a steel wedge mould. The dependence of microstructure on the cooling rate (about 40 to 103 K/s) was determined by the secondary dendrite arm space size measurement, optical microscopy(OM), and transmission electron microscopy (TEM). It is found that the matrix structure over a large cooling rate is composed of α-Al dendrite and eutectoid (α+η), the size of α-Al dendrite decreases with increasing cooling rate. The relationship between the cooling rate and the secondary dendrite arm space size has been established. TEM shows that a large number of small and dispersed precipitations can be seen in the primary α phase of tip region. Electron diffraction pattern shows that the precipitate phase is Zn3Mg2 phase.

Similar content being viewed by others

References

K Hildal, N Sekido, J H Perepezko. Critical Cooling Rate for Fe48Cr15Mo14Y2C15B6 Bulk Metallic Glass Formation[J]. Intermetallics, 2006, 14: 898–902

J Zhang, Z Fan, Y Q Wang, et al. Effect of Cooling Rate on the Microstructure of Hypereutectic Al-Mg2Si Alloys[J]. J Mater. Sci. Lett., 2000, 19: 1 825–1 828

N H Pryds, X Huang. The Effect of Cooling Rate on the Microstructures Formed during Solidification of Ferritic Steel[J]. Metall. Mater. Trans. A, 2000, 31(12): 3 155–3 166

M D Hanna, J T Carter, M S Rashid. Sliding Wear and Friction Characteristics of Six Zn-based Die-casting Alloys[J]. Wear, 1997, 203–204: 11–21

T J Chen, Y Hao, J Sun, et al. Phenomenological Observations on Thixoformability of a Zinc Alloy ZA27 and the Resulting Microstructures[J]. Mater. Sci. Eng. A, 2005, 396(1–2): 213–222

Gençağa Pürçek. Improvement of Mechanical Properties for Zn-Al Alloys Using Equal-channel Angular Pressing[J]. J. Mater. Process. Tech., 2005, 169(2): 242–248

Geng Haoran, Tian Xianfa, Cui Hongwei, et al. Antifriction and Wear Behaviour of ZAS35 Zinc Alloy: Influence of Heat Treatment and Melting Technique[J]. Mater. Sci. Eng. A, 2001, 316(1–2): 109–114

Temel Savaška, Zeki Azaklı. An Investigation of Lubricated Friction and Wear Properties of Zn-40Al-2Cu-2Si Alloy in Comparison with SAE 65 Bearing Bronze[J]. Wear, 2008, 264(11–12): 920–928

T Sava S kan, M S Turhal. Relationships Between Cooling Rate, Copper Content and Mechanical Properties of Monotectoid Based Zn-Al-Cu Alloys[J]. Mater. Charact., 2003, 51(4): 259–270

S Can Kurnaz. Production of Saffil Fibre Reinforced Zn-Al(ZA12) Based Metal Matrix Composites Using Infiltration Technique and Study of Their Properties[J]. Mater. Sci. Eng. A, 2003, 346(1–2): 108–115

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Yan, S., Xie, J. et al. Effect of cooling rate on the microstructure of ZA48 alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 25, 811–813 (2010). https://doi.org/10.1007/s11595-010-0098-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-010-0098-8