Abstract

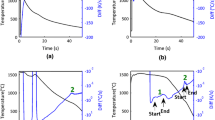

This article describes in detail the effect of cooling rate on the microstructure of a low-carbon Fe-12 pct Cr alloy. The alloy was prepared using a relatively simple technique, i.e., rapid cooling of the melt in a copper wedge mold. The dependence of microstructure on the cooling rate (∼40 to 105 K/s) has been determined by X-ray diffraction (XRD), microhardness measurement, optical microscopy (OM), and transmission electron microscopy (TEM). It has been found that the matrix structure over a large cooling rate range is composed of columnar ferrite grains, the size of which decreases with increasing cooling rate. Precipitation of second phases has been observed at either the ferrite grain boundaries or within the ferrite grains. The former takes place along the entire wedge sample, whereas the latter characterizes a region 12 mm away from the tip of the wedge sample. The essential structure of the grain boundary precipitates was identified as martensite, which is a transformation product of austenite precipitated at high temperatures. Retained austenite was identified at the tip region as isolated particles (<4 µm). The precipitates within the ferrite grains appeared as planar colonies consisting of two sets of needles. The density of these precipitates increases with increasing the cooling rate while their size decreases. Characteristic precipitate-free zones (PFZs) at the ferrite grain boundaries were observed and are discussed.

Similar content being viewed by others

References

E.A. Little, D.R. Harries, F.B. Pickering, and S.R. Keown: Met. Technol., 1977, vol. 4, p. 205.

D.J. Gooch: Met. Sci., 1982, vol. 16, p. 79.

R.R. Petri, E. Schnabel, and P. Schwaab: Arch. Eisenhüttenwes., 1980, vol. 51, p. 335.

R.R. Petri, E. Schnabel, and P. Schwaab: Arch. Eisenhüttenwes., 1981, vol. 52, p. 27.

C.A. Dubé, H.I. Aaronson, and R.F. Mehl: Rev. Métall., 1958, vol. 55, p. 201.

H.I. Aaronson: in The Decomposition of Austenite by Diffusional Processes, V.F. Zackay and H.I. Aaronson, eds., Interscience, New York, NY, 1962, p. 387.

M.V. Kral and G. Spanos: Acta Mater., 1999, vol. 47, p. 711.

R.K.W. Honeycombe: Steel: Microstructure and Properties, Edward Arnold, London, 1981.

J.V. Wood and R.W.K. Honeycombe: Phil. Mag. A, 1978, vol. 37, p. 501.

C.N. Elliot, H.A. Davies, and G.W. Greenwood: Mater. Sci. Eng., 1988, vol. 98, p. 285.

K. Ozbaysal and O.T. Inal: Mater. Sci. Eng. A, 1990, vol. 130, p. 205.

N.H. Pryds: Ph.D. Thesis, Risø National Laboratory, Roskilde, Denmark, Mar. 1997.

N.H. Pryds, E. Johnson, S. Linderoth, and A.S. Pedersen: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 367–76.

N.H. Pryds, T. Juhl, and A.S. Pedersen: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1817–26.

X. Huang and N.H. Pryds: Acta Mater, in press.

D.R. Barraclough and D.J. Gooch: Mater. Sci. Technol., 1985, vol. 1, p. 961.

K. Ameyama, T. Maki, and I. Tamura: J. Jpn Inst. Met., 1986, vol. 50, p. 10.

N.H. Pryds and X. Huang: Scripta Mater., 1997, vol. 36, p. 1219.

G. Thewlis: Mater. Sci. Technol., 1994, vol. 110.

H.I. Aaronson, G. Spanos, R.A. Masamura, R.G. Vardiman, D.W. Moon, E.S.K. Menon, and M.G. Hall: Mater. Sci. Eng., 1995, vol. B32, pp. 107–23.

G. Spanos and M.G. Hall: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1517–23.

K.E. Easterling and H.M. Miekk-Oja: Acta Metall., 1967, vol. 15, p. 1133.

K.E. Easterling and G.C. Weatherly: Acta Metall., 1969, vol. 17, p. 845.

M. Lin, G.B. Olson, and M. Cohen: Acta Metall. Mater., 1993, vol. 41, p. 253.

T. Tadaki, Y. Murai, A. Koreeda, Y. Nakata, and Y. Hirotsu: Mater. Sci. Eng. A, 1996, vol. 217–218, p. 235.

R.E. Cech and D. Turnbull: Trans. AIME, 1956, vol. 206, p. 124.

A.L. Schaeffler: Met. Progr., 1949, vol. 56, pp. 680 and 680B.

J. Zboril and Z. Posedel: Z. Metallkd., 1970, vol. 61, p. 214.

R. Maldonado and E. Nembach: Acta Mater., 1997, vol. 45, p. 213.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pryds, N.H., Huang, X. The effect of cooling rate on the microstructures formed during solidification of ferritic steel. Metall Mater Trans A 31, 3155–3166 (2000). https://doi.org/10.1007/s11661-000-0095-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0095-1