Abstract

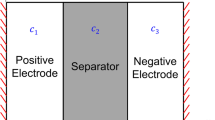

Ionic transport characteristics of separators significantly influence li-ion cell performance. In order to maximize the spatiotemporal ionic dynamics, the present study probed the multi-layered separator microstructure, which can lead to an increment in cell performance for discharging and charging mechanisms. The numerical simulations are performed considering the one-dimensional Newman model to study the effect of multi-layered porosity at different C-rates. Our study reports that the capacity strongly depends on the separator’s porosity distribution. Furthermore, the variation of average capacity among different separator porosity configurations becomes more evident with an increment in the C rate and charging behavior. Additionally, a strong interplay of separator porosity and its distribution on temporal cell characteristics, viz., electrolyte salt concentration and total power dissipation density, is revealed for the charging-discharging cycle. Further, the cell performance characteristics are found to be best when separator porosity is higher adjacent to the electrode-separator interphase for the charging-discharging cycle. The present study established the importance of multi-layered separator microstructure in improving ionic dynamics and cell performance.

Similar content being viewed by others

Data availability

No dataset was used in the present study.

Abbreviations

- r :

-

Particle radius, m

- D :

-

Salt diffusion coefficient, m2/s

- U :

-

Open circuit potential, V

- \({t}_{+}^{0}\) :

-

Transference number

- b :

-

Bruggeman coefficient for tortuosity

- Ɛ :

-

Electrode volume fraction

- c :

-

Salt concentration, mol/m3

- ø :

-

Electric potential, V

- J Li :

-

Current density, A/m2

- a :

-

Interfacial area per unit volume, m2/m3

- J Li0 :

-

Reference exchange current density, A/m2

- Q 0 :

-

Initial capacity, Ah/kg

- L a :

-

Length of anode, m

- T :

-

Cell temperature, K

- \(\sigma\) :

-

Active material conductivity, S/m

- k :

-

Ionic conductivity, S/m

- \(\alpha\) :

-

Transfer coefficient

- Rs :

-

Active material particle radius,

- t :

-

Time, s

- Lsep :

-

Length of separator, m

- Lc :

-

Length of cathode, m

- τ:

-

Tortuosity

- a :

-

Anode

- c :

-

Cathode

- sep :

-

Separator

- e :

-

Electrolyte phase

- s :

-

Solid-phase

- 0 :

-

Initial condition

- D :

-

Diffusion

- ch :

-

Charge

- disch :

-

Discharge

- max :

-

Maximum

- min :

-

Minimum

- eff :

-

Effective

References

Wang Y, Li QM, Xing Y (2020) Porosity variation of lithium-ion battery separators under uniaxial tension. Int J Mech Sci 174:105496. https://doi.org/10.1016/j.ijmecsci.2020.105496

Liao X, Ma C, Peng X et al (2019) Temperature distribution optimization of an air-cooling lithium-ion battery pack in electric vehicles based on the response surface method. J Electrochem Energy Convers Storage 16(4):041002. https://doi.org/10.1115/1.4042922

Lu X, Bertei A, Finegan DP et al (2020) 3D microstructure design of lithium-ion battery electrodes assisted by X-ray nano-computed tomography and modelling. Nat Commun 11:1–13. https://doi.org/10.1038/s41467-020-15811-x

Mistry AN, Smith K, Mukherjee PP (2018) Secondary-phase stochastics in lithium-ion battery electrodes. ACS Appl Mater Interfaces 10:6317–6326. https://doi.org/10.1021/acsami.7b17771

Reddy T, Linden D (2011) Linden’s Handbook of batteries, 4th edn. The McGraw-Hill Companies

Liu Y, Zhu Y, Cui Y (2019) Challenges and opportunities towards fast-charging battery materials. Nat Energy 4:540–550. https://doi.org/10.1038/s41560-019-0405-3

Walter M, Kovalenko MV, Kravchyk KV (2020) Challenges and benefits of post-lithium-ion batteries. New J Chem 44:1677–1683. https://doi.org/10.1039/c9nj05682c

Ue M, Sakaushi K, Uosaki K (2020) Basic knowledge in battery research bridging the gap between academia and industry. Mater Horiz 7:1937–1954. https://doi.org/10.1039/d0mh00067a

Huang X, He R, Li M et al (2020) Functionalized separator for next-generation batteries. Mater Today 41:143–155. https://doi.org/10.1016/j.mattod.2020.07.015

Zhang SS (2007) A review on the separators of liquid electrolyte Li-ion batteries. J Power Sources 164:351–364. https://doi.org/10.1016/j.jpowsour.2006.10.065

Lee H, Yanilmaz M, Toprakci O et al (2014) A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy Environ Sci 7:3857–3886. https://doi.org/10.1039/c4ee01432d

Li A, Chun A, Yuen Y et al (2021) A review on lithium-ion battery separators towards enhanced safety performances and modelling approaches. Molecules 26:26020478

Cannarella J, Arnold CB (2013) Ion transport restriction in mechanically strained separator membranes. J Power Sources 226:149–155. https://doi.org/10.1016/j.jpowsour.2012.10.093

Lagadec MF, Zahn R, Wood V (2018) Designing polyolefin separators to minimize the impact of local compressive stresses on lithium ion battery performance. J Electrochem Soc 165:A1829–A1836. https://doi.org/10.1149/2.0041809jes

Doyle M, Newman J, Gozdz AS et al (1996) Comparison of modeling predictions with experimental data from plastic lithium ion cells. J Electrochem Soc 143:1890–1903. https://doi.org/10.1149/1.1836921

Fuller TF, Doyle M, Newman J (1994) Simulation and optimization of the dual lithium ion insertion cell. J Electrochem Soc 141:1–10. https://doi.org/10.1149/1.2054684

Doyle M, Fuller TF, Newman J (1993) Modeling of galvanostatic charge and discharge. J Electrochem Soc 140:1526–1533

Darling R, Newman J (1997) Modeling a porous intercalation electrode with two characteristic particle sizes. J Electrochem Soc 144:4201–4208. https://doi.org/10.1149/1.1838166

Kalnaus S, Wang Y, Turner JA (2017) Mechanical behavior and failure mechanisms of Li-ion battery separators. J Power Sources 348:255–263

Spingler FB, Soc JE, Spingler FB et al (2021) The effects of non-uniform mechanical compression of lithium-ion cells on local current densities and lithium plating the effects of non-uniform mechanical compression of lithium- ion cells on local current densities and lithium plating. J Electrochem Soc 168:110515. https://doi.org/10.1149/1945-7111/ac33e1

Xiaoqing Y, Zhiyu H, Fengquan L et al (2021) The origin and elimination of separator wrinkles in lithium-ion batteries. Energy Storage Sci Technol 10:156–162. https://doi.org/10.19799/j.cnki.2095-4239.2020.0322

Xiao X, Huang X, Verbrugge MW, Halalay IC (2013) Lithium-ion batteries with coated separators. 2:1–10

Huang F, Xu Y, Peng B et al (2015) Coaxial electrospun cellulose-core fluoropolymer-shell fibrous membrane from recycled cigarette filter as separator for high performance lithium-ion battery. ACS Sustain Chem Eng 3(5):932–940. https://doi.org/10.1021/acssuschemeng.5b00032

Lv D, Chai J, Wang P et al (2021) Pure cellulose lithium-ion battery separator with tunable pore size and improved working stability by cellulose nanofibrils. Carbohyd Polym 251:116975. https://doi.org/10.1016/j.carbpol.2020.116975

Vaidya A (2020) Cellulose based separator for high-performance lithium-ion batteries. Masters Theses, Western Michigan University, p 5117. https://scholarworks.wmich.edu/masters_theses/5117

Chen K, Li Y, Zhan H (2022) Advanced separators for lithium-ion batteries advanced separators for lithium-ion batteries. In: IOP Conference Series: Earth and Environmental Science, vol 1011, no. 1. IOP Publishing, p 012009. https://doi.org/10.1088/1755-1315/1011/1/012009

Rajan D, Kannan R, Terala PK et al (2018) Analysis of the separator thickness and porosity on the performance of lithium-ion batteries. Int J Electrochem 2018:1925708. https://doi.org/10.1155/2018/1925708

Pan R (2019) Cladophora cellulose-based separators for lithium batteries. Digital Dissertations, Uppsala University

Zhang X, Sahraei E, Wang K (2016) Li-ion battery separators, mechanical integrity and failure mechanisms leading to soft and hard internal shorts. Sci Rep 6:1–9. https://doi.org/10.1038/srep32578

Song Y, Sheng L, Wang L et al (2021) Electrochemistry communications from separator to membrane: separators can function more in lithium ion batteries. Electrochem Commun 124:106948. https://doi.org/10.1016/j.elecom.2021.106948

Lv W, Zhang X (2022) Recent advances in lithium-ion battery separators with enhanced safety. In: 60 years of the Loeb-Sourirajan membrane principles, new materials, modelling, characterization, and applications. Elsevier, pp 269–304. https://doi.org/10.1016/B978-0-323-89977-2.00025-7

Liu Z, Jiang Y, Hu Q et al (2021) Safer lithium-ion batteries from the separator aspect development and future.pdf. Energy Environ Mater 4:336–362. https://doi.org/10.1002/eem2.12129

Jang J, Oh J, Jeong H et al (2020) A review of functional separators for lithium metal battery applications. Materials 13:1–37. https://doi.org/10.3390/ma13204625

Kim PJ (2021) Surface-functionalized separator for stable and reliable lithium metal batteries : a review. Nanomaterials 11:2275. https://doi.org/10.3390/nano11092275

Cannon A, Ryan EM (2021) Characterizing the microstructure of separators in lithium batteries and their effects on dendritic growth. ACS Appl Energy Mater 4:7848–7861. https://doi.org/10.1021/acsaem.1c00144

Song Y, Liu X, Ren D et al (2022) Simultaneously blocking chemical crosstalk and internal short circuit via gel-stretching derived nanoporous non-shrinkage separator for safe lithium-ion batteries. Adv Mater 34:2106335. https://doi.org/10.1002/ADMA.202106335

Song Y, Wang L, Cui H et al (2022) Boosting battery safety by mitigating thermal-induced crosstalk with a bi-continuous separator. Adv Energy Mater 12:2201964. https://doi.org/10.1002/AENM.202201964

Miranda D, Gonçalves R, Miranda F et al (2020) Theoretical simulation of different 3D separator geometries for lithium-ion batteries. AIP Conference Proceedings 2293(1). https://doi.org/10.1063/5.0026447/726306

Gonçalves R, Marques-Almeida T, Miranda D et al (2019) Enhanced performance of fluorinated separator membranes for lithium ion batteries through surface micropatterning. Energy Storage Mater 21:124–135. https://doi.org/10.1016/j.ensm.2019.05.044

Gonçalves R, Miranda D, Marques-Almeida T et al (2021) Patterned separator membranes with pillar surface microstructures for improved battery performance. J Colloid Interface Sci 596:158–172. https://doi.org/10.1016/j.jcis.2021.03.138

Dai H, Jiang B, Hu X et al (2021) Advanced battery management strategies for a sustainable energy future: multilayer design concepts and research trends. Renew Sustain Energy Rev 138:110480. https://doi.org/10.1016/J.RSER.2020.110480

Sulzer V, Mohtat P, Aitio A et al (2021) The challenge and opportunity of battery lifetime prediction from field data. Joule 5:1934–1955. https://doi.org/10.1016/j.joule.2021.06.005

DeMeuse MT (2021) Polymer-based separators for lithium-ion batteries: production, processing, and properties. Elsevier

Taleghani ST, Marcos B, Zaghib K, Lantagne G (2017) A study on the effect of porosity and particles size distribution on li-ion battery performance. J Electrochem Soc 164:E3179–E3189. https://doi.org/10.1149/2.0211711jes

Appiah WA, Ryou M-H, Lee YM (2019) A physics-based model capacity fade analysis of LiMn 2 O 4/graphite cell at different temperatures. J Electrochem Soc 166:A5109–A5116. https://doi.org/10.1149/2.0161903jes

Smith K, Wang CY (2006) Power and thermal characterization of a lithium-ion battery pack for hybrid-electric vehicles. J Power Sources 160:662–673. https://doi.org/10.1016/j.jpowsour.2006.01.038

Bläubaum L, Röder F, Nowak C et al (2020) Impact of particle size distribution on performance of lithium-ion batteries. ChemElectroChem 7:4755–4766. https://doi.org/10.1002/celc.202001249

Crompton TR (2000) Battery reference book, 3rd edn. Newnes, Oxford

Hariharan KS, Tagade P, Ramachandran S (2018) Mathematical modeling of lithium batteries, 1st edn. Springer, Bangalore

Newman J, Thomas-Alyea KE (2004) Electrochemical systems, 3rd edn. Wiley-Interscience, New Jersey

Kanchan BK, Randive PR, Pati S (2021) On the implication of porosity configuration on lithium-ion cell performance: a numerical study. J Electrochem Energy Convers Storage 18(1):011006. https://doi.org/10.1115/1.4046754

Ravikumar B, Mynam M, Rai B (2018) Effect of salt concentration on properties of lithium ion battery electrolytes: a molecular dynamics study. J Phys Chem C 122:8173–8181. https://doi.org/10.1021/acs.jpcc.8b02072

Author information

Authors and Affiliations

Contributions

•BKK: Idea, Simulation, Data Analysis, Writing draft, Editing, Methodology.

•PR: Review & Final editing, Supervision.

Corresponding author

Ethics declarations

Ethical approval

This research followed the American Psychological Association Code of Ethics.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanchan, B.K., Randive, P. Enhancement of ionic transport characteristics and cell performance through multi-layered separator microstructure in Li-ion cells. Ionics 30, 2093–2104 (2024). https://doi.org/10.1007/s11581-024-05419-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05419-2