Abstract

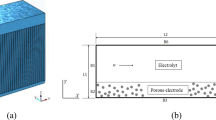

The formation of the electrolyte–electrode interface is essential for the performance of Li-ion batteries. This study aims to explore the wetting characteristics of an electrolyte within a porous electrode positioned between a current collector and a separator. By utilizing the Shan-Chen-based lattice Boltzmann method, an in-house code has been developed and thoroughly validated. This code integrates actual contact angles at the interfaces between the electrolyte and battery components. Furthermore, code acceleration through GPU-based parallel programming facilitates adequate meshing, underscoring the novelty and originality of our approach. The results of this study provide insights into the overall saturation curves and imbibition rates and clarify the primary mechanisms of electrolyte wetting within the porous matrix via local wetting rates. The electrode-current collector interface emerged as a critical factor influencing the imbibition rate and gas entrapment tendencies. Pore types at the interface have been categorized, focusing on how the material contact angle variations between the current collector and electrolyte influence wetting dynamics. Notably, it is observed that higher contact angles (90°) between the electrolyte and current collector increase the risk of trapping gas. Conversely, lower angles (15° and 35°) improve overall saturation; however, the enhancement of the wetting rate is particularly noticeable when interconnected pores are present at the interfaces of the electrode and battery components. This study underscores the combined influence of the separator and current collector in comprehending electrolyte wetting behavior, thus contributing to the advancement of battery technology.

Similar content being viewed by others

Abbreviations

- \({F}_{\upsigma } \) :

-

External force for component \(\sigma \)

- \({e}_{\text{i}}\) :

-

Particle lattice velocity in the \(ith\) direction

- \({FF}_{\upsigma } \) :

-

Fluid–fluid force for component \(\sigma \)

- \({f}_{\text{i}}^{\sigma }\) :

-

Particle distribution function for component \(\sigma \)

- \({G}_{\text{ff}}\) :

-

Fluid–fluid force parameter

- \({f}_{\text{i}}^{\upsigma ,\text{eq}}\) :

-

Equilibrium distribution function for component \(\sigma \)

- \({G}_{\text{sf}}\) :

-

Solid–fluid force parameter

- \(\tau \) :

-

Single-relaxation time

- \( \mathop u\limits^{ \vee } \) :

-

Common velocity of two components

- \({u}_{\upsigma } ^{\text{eq}}\) :

-

Macroscopic velocity

- \({\alpha }_{\text{i}}\) :

-

Weighting factor

- \( \upsilon \) :

-

Kinematic viscosity

- \({c}_{\text{s}}\) :

-

Speed of sound

- \(lu\) :

-

Lattice units

- R:

-

Final radius of the droplet

- \(\Delta P\) :

-

Laplace pressure

- CC- θ°:

-

Contact angle between electrolyte and current collector, θ = 15°, 35°, or 90°

- \(CMn\) :

-

Marker for specific imbibition rates (\(n = 1, 2\))

- PIRn:

-

Marker for poor imbibition rate

- \(\sigma \) :

-

Component indicator

- \(\gamma \) :

-

Surface tension

- \(i\) :

-

Discrete direction index

References

An SJ, Li J, Daniel C, Mohanty D, Nagpure S, Wood DL III. The state of understanding of the lithium-ion-battery graphite solid electrolyte interphase (SEI) and its relationship to formation cycling. Carbon N Y. 2016;105:52–76.

Wang A, Kadam S, Li H, Shi S, Qi Y. Review on modeling of the anode solid electrolyte interphase (SEI) for lithium-ion batteries. npj Comput Mater. 2018;4(1):1–26.

Sun YY, Hsieh TY, Duh YS, Kao CS. Thermal behaviors of electrolytes in lithium-ion batteries determined by differential scanning calorimeter. J Therm Anal Calorim. 2014;116(3):1175–9. https://doi.org/10.1007/s10973-014-3683-9.

Duh YS, Tsai MT, Kao CS. Characterization on the thermal runaway of commercial 18650 lithium-ion batteries used in electric vehicle. J Therm Anal Calorim. 2017;127(1):983–93. https://doi.org/10.1007/s10973-016-5767-1.

Reddy TB. Linden’s handbook of batteries. New York: McGraw-Hill Education; 2011.

Knoche T, Reinhart G. Electrolyte filling of large-scale lithium-ion batteries: challenges for production technology and possible approaches. Appl Mech Mater. 2015;794:11–8.

Armand M, Tarascon J-M. Building better batteries. Nature. 2008;451(7179):652–7.

Sakti A, Michalek JJ, Fuchs ERH, Whitacre JF. A techno-economic analysis and optimization of Li-ion batteries for light-duty passenger vehicle electrification. J Power Sources. 2015;273:966–80.

Wood DL III, Li J, Daniel C. Prospects for reducing the processing cost of lithium ion batteries. J Power Sources. 2015;275:234–42.

Wood DL III, Li J, An SJ. Formation challenges of lithium-ion battery manufacturing. Joule. 2019;3(12):2884–8.

Wang C, Lin Y, Chiu K, Leu H, Ko T. Advanced carbon cloth as current collector for enhanced electrochemical performance of lithium-rich layered oxide cathodes. ChemistrySelect. 2017;2(16):4419–27.

Lee H, Yanilmaz M, Toprakci O, Fu K, Zhang X. A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy Environ Sci. 2014;7(12):3857–86.

Arora P, Zhang Z. Battery separators. Chem Rev. 2004;104(10):4419–62.

Wanner J, Birke KP. Investigation of the influence of electrode surface structures on wettability after electrolyte filling based on experiments and a lattice Boltzmann simulation. Energies. 2023;16(15):5640.

Wanner J, Birke KP. Comparison of an experimental electrolyte wetting of a lithium-ion battery anode and separator by a lattice Boltzmann simulation. Batteries. 2022;8(12):277.

Jeon DH, Song J-H, Yun J, Lee J-W. Mechanistic insight into wettability enhancement of lithium-ion batteries using a ceramic-coated layer. ACS Nano. 2022;17(2):1305–14.

Kühnel R-S, Obeidi S, Lübke M, Lex-Balducci A, Balducci A. Evaluation of the wetting time of porous electrodes in electrolytic solutions containing ionic liquid. J Appl Electrochem. 2013;43(7):697–704.

Wu MS, Liao TL, Wang YY, Wan CC. Assessment of the wettability of porous electrodes for lithium-ion batteries. J Appl Electrochem. 2004;34(8):797–805. https://doi.org/10.1023/B:JACH.0000035599.56679.15.

Pfleging W, Pröll J. A new approach for rapid electrolyte wetting in tape cast electrodes for lithium-ion batteries. J Mater Chem A. 2014;2(36):14918–26.

Sheng Y, Fell CR, Son YK, Metz BM, Jiang J, Church BC. Effect of calendering on electrode wettability in lithium-ion batteries. Front Energy Res. 2014;2:56.

Schilling A, et al. Influence of separator material on infiltration rate and wetting behavior of lithium-ion batteries. Energy Technol. 2020;8(2):1900078.

Walji N, MacDonald BD. Influence of geometry and surrounding conditions on fluid flow in paper-based devices. Micromachines. 2016;7(5):73.

Chang S, Seo J, Hong S, Lee D-G, Kim W. Dynamics of liquid imbibition through paper with intra-fibre pores. J Fluid Mech. 2018;845:36–50.

Knoche T, Zinth V, Schulz M, Schnell J, Gilles R, Reinhart G. In situ visualization of the electrolyte solvent filling process by neutron radiography. J Power Sources. 2016;331:267–76.

Weydanz WJ, et al. Visualization of electrolyte filling process and influence of vacuum during filling for hard case prismatic lithium ion cells by neutron imaging to optimize the production process. J Power Sources. 2018;380:126–34.

Schilling A, Gümbel P, Möller M, Kalkan F, Dietrich F, Dröder K. X-ray based visualization of the electrolyte filling process of lithium ion batteries. J Electrochem Soc. 2018;166(3):A5163.

Lanz M, Lehmann E, Imhof R, Exnar I, Novák P. In situ neutron radiography of lithium-ion batteries during charge/discharge cycling. J Power Sources. 2001;101(2):177–81.

Chen H-S, et al. Quantificational 4D visualization and mechanism analysis of inhomogeneous electrolyte wetting. eTransportation. 2023;16:100232.

Davoodabadi A, Li J, Zhou H, Wood DL, Singler TJ, Jin C. Effect of calendering and temperature on electrolyte wetting in lithium-ion battery electrodes. J Energy Storage. 2019;26:1010354. https://doi.org/10.1016/j.est.2019.101034.

Kaden Nicolaj, Schlimbach Ricarda, García Álvaro Rohde, Dröder Klaus. A systematic literature analysis on electrolyte filling and wetting in lithium-ion battery production. Batteries. 2023;9(3):164. https://doi.org/10.3390/batteries9030164.

Quadrio M, et al. Review of computational fluid dynamics in the assessment of nasal air flow and analysis of its limitations. Eur Arch oto-rhino-laryngology. 2014;271(9):2349–54.

Chen L, Kang Q, Mu Y, He Y-L, Tao W-Q. A critical review of the pseudopotential multiphase lattice Boltzmann model: Methods and applications. Int J Heat Mass Transf. 2014;76:210–36.

Lee SG, Jeon DH. Effect of electrode compression on the wettability of lithium-ion batteries. J Power Sources. 2014;265:363–9. https://doi.org/10.1016/j.jpowsour.2014.04.127.

Shodiev A, Zanotto FM, Yu J, Chouchane M, Li J, Franco AA. Designing electrode architectures to facilitate electrolyte infiltration for lithium-ion batteries. Energy Storage Mater. 2022;49:268–77. https://doi.org/10.1016/j.ensm.2022.03.049.

Jeon DH. Wettability in electrodes and its impact on the performance of lithium-ion batteries. Energy Storage Mater. 2019;18:139–47. https://doi.org/10.1016/j.ensm.2019.01.002.

Doolen G. Lattice gas methods for partial differential equations. CRC Press; 2019.

Chen S, Wang Z, Shan X, Doolen GD. Lattice Boltzmann computational fluid dynamics in three dimensions. J Stat Phys. 1992;68:379–400.

Swift MR, Orlandini E, Osborn WR, Yeomans JM. Lattice Boltzmann simulations of liquid-gas and binary fluid systems. Phys Rev E. 1996;54(5):5041–52. https://doi.org/10.1103/PhysRevE.54.5041.

Shan X, Chen H. Lattice Boltzmann model for simulating flows with multiple phases and components. Phys Rev E. 1993. https://doi.org/10.1103/PhysRevE.47.1815.

Shan X, Doolen G. Multicomponent lattice-Boltzmann model with interparticle interaction. J Stat Phys. 1995. https://doi.org/10.1007/BF02179985.

Timm K, Kusumaatmaja H, Kuzmin A, Shardt O, Silva G, Viggen E. The lattice Boltzmann method: principles and practice. AG Cham: Switz. Springer Int. Publ; 2016.

Lee SG, Jeon DH, Kim BM, Kang JH, Kim C-J. Lattice boltzmann simulation for electrolyte transport in porous electrode of lithium ion batteries. J Electrochem Soc. 2013;160(4):H258–65. https://doi.org/10.1149/2.017306jes.

Jeon DH. Enhancing electrode wettability in lithium-ion battery via particle-size ratio control. Appl Mater Today. 2021;22:100976. https://doi.org/10.1016/j.apmt.2021.100976.

Shodiev A, et al. Insight on electrolyte infiltration of lithium ion battery electrodes by means of a new three-dimensional-resolved lattice Boltzmann model. Energy Storage Mater. 2021;38:80–92. https://doi.org/10.1016/j.ensm.2021.02.029.

Lautenschlaeger MP, et al. Understanding electrolyte filling of lithium-ion battery electrodes on the pore scale using the lattice boltzmann method. Batter Supercaps. 2022;5:202200090. https://doi.org/10.1002/batt.202200090.

Hagemeister J, Günter FJ, Rinner T, Zhu F, Papst A, Daub R. Numerical models of the electrolyte filling process of lithium-ion batteries to accelerate and improve the process and cell design. Batteries. 2022;8(10):159.

El Malki A, Asch M, Arcelus O, Shodiev A, Yu J, Franco AA. Machine learning for optimal electrode wettability in lithium ion batteries. J Power Sources Adv. 2023;20:100114.

Shodiev A, Duquesnoy M, Arcelus O, Chouchane M, Li J, Franco AA. Machine learning 3D-resolved prediction of electrolyte infiltration in battery porous electrodes. J Power Sources. 2021;511:230384.

Taner T. The novel and innovative design with using h2 fuel of pem fuel cell: Efficiency of thermodynamic analyze. Fuel. 2021;302:121109. https://doi.org/10.1016/j.fuel.2021.121109.

Taner T. The micro-scale modeling by experimental study in PEM fuel cell. J Therm Eng. 2017;3(6):1515–26. https://doi.org/10.18186/journal-of-thermal-engineering.331755.

Taner T, Naqvi SAH, Ozkaymak M. Techno-economic analysis of a more efficient hydrogen generation system prototype: a case study of PEM electrolyzer with Cr-C coated SS304 bipolar plates. Fuel Cells. 2019;19(1):19–26. https://doi.org/10.1002/fuce.201700225.

Taner T, Kürşat Demirci O. Energy and economic analysis of the wind turbine plant’s draft for the Aksaray city. Appl Ecol Environ Sci. 2014;2(3):82–5. https://doi.org/10.12691/aees-2-3-2.

Taner T. Energy and exergy analyze of PEM fuel cell: a case study of modeling and simulations. Energy. 2018;143:284–94. https://doi.org/10.1016/j.energy.2017.10.102.

Taner T. Economic analysis of a wind power plant: a case study for the cappadocia region. J Mech Sci Technol. 2018;32(3):1379–89. https://doi.org/10.1007/s12206-018-0241-6.

Kuzmin A, Januszewski M, Eskin D, Mostowfi F, Derksen JJ. Simulations of gravity-driven flow of binary liquids in microchannels. Chem Eng J. 2011;171(2):646–54.

Kuzmin A, Januszewski M, Eskin D, Mostowfi F, Derksen JJ. Three-dimensional binary-liquid lattice Boltzmann simulation of microchannels with rectangular cross sections. Chem Eng J. 2011;178:306–16.

Montellà EP, Chareyre B, Salager S, Gens A. Benchmark cases for a multi-component Lattice-Boltzmann method in hydrostatic conditions. MethodsX. 2020;7:101090.

Zakirov T, Galeev A. Absolute permeability calculations in micro-computed tomography models of sandstones by Navier-Stokes and lattice Boltzmann equations. Int J Heat Mass Transf. 2019;129:415–26.

Beuse T, Fingerle M, Wagner C, Winter M, Börner M. Comprehensive insights into the porosity of lithium-ion battery electrodes: A comparative study on positive electrodes based on lini0.6mn0.2co0.2o2 (nmc622). Batteries. 2021;7(4):622. https://doi.org/10.3390/batteries7040070.

Liu H, Valocchi AJ, Werth C, Kang Q, Oostrom M. Pore-scale simulation of liquid CO2 displacement of water using a two-phase lattice Boltzmann model. Adv Water Resour. 2014;73:144–58.

Xu A, Shi L, Zhao TS. Accelerated lattice Boltzmann simulation using GPU and OpenACC with data management. Int J Heat Mass Transf. 2017;109:577–88.

Adeeb E, Ha H. Computational analysis of naturally oscillating tandem square and circular bluff bodies: a GPU based immersed boundary–lattice Boltzmann approach. Eng Appl Comput Fluid Mech. 2022;16(1):995–1017. https://doi.org/10.1080/19942060.2022.2060309.

Davoodabadi A, Jin C, Wood DL, Singler TJ, Li J. On electrolyte wetting through lithium-ion battery separators. Extrem Mech Lett. 2020;40:100960. https://doi.org/10.1016/j.eml.2020.100960.

Davoodabadi A, Li J, Liang Y, Wood DL, Singler TJ, Jin C. Analysis of electrolyte imbibition through lithium-ion battery electrodes. J Power Sources. 2019;424(3):193–203. https://doi.org/10.1016/j.jpowsour.2019.03.115.

Sauter C, Zahn R, Wood V. Understanding electrolyte infilling of lithium ion batteries. J Electrochem Soc. 2020;167(10):100546. https://doi.org/10.1149/1945-7111/ab9bfd.

Abubaker M, Sohn CH, Ali HM. Wetting characteristics of Li-ion battery electrodes: Impact of calendaring and current collector contact angle-a lattice boltzmann method investigation. Energy Rep. 2024;11:2333–45.

Bhatnagar PL, Gross EP, Krook M. A model for collision processes in gases. I. Small amplitude processes in charged and neutral one-component systems. Phys Rev. 1954;94(3):511.

Landau LD, Lifshitz EM. Fluid mechanics: landau and lifshitz: course of theoretical physics. NJ: Elsevier; 2013. p. 6.

Montellà EP et al (2022) Benchmark cases for a multi-component Lattice–Boltzmann method in hydrostatic conditions to cite this version : HAL Id : hal-03493291 Benchmark cases for a multi-component Lattice-Boltzmann method in hydrostatic conditions. pp 0–20

Gennes P-G, Brochard-Wyart F, Quéré D. Capillarity and wetting phenomena: drops, bubbles, pearls, waves. New York: Springer; 2004. p. 21–65.

Rowlinson JS and Widom B (2013) Molecular theory of capillarity. Courier Corporation

Huang H, Thorne DT, Schaap MG, Sukop MC. Proposed approximation for contact angles in Shan-and-Chen-type multicomponent multiphase lattice Boltzmann models. Physical Review E. 2007. https://doi.org/10.1103/PhysRevE.76.066701.

Schmieschek S, Harting J. Contact angle determination in multicomponent lattice Boltzmann simulations. Commun Comput Phys. 2011;9(5):1165–78.

Yamada M, Watanabe T, Gunji T, Wu J, Matsumoto F. Review of the design of current collectors for improving the battery performance in lithium-ion and post-lithium-ion batteries. Electrochem. 2020;1(2):124–59.

Günter FJ, Rössler S, Schulz M, Braunwarth W, Gilles R, Reinhart G. Influence of the cell format on the electrolyte filling process of lithium-ion cells. Energy Technol. 2020;8(2):1801108.

Jiang M, et al. Full-cell cycling of a self-supporting aluminum foil anode with a phosphate conversion coating. ACS Appl Mater Interfaces. 2019;11(17):15656–61. https://doi.org/10.1021/acsami.9b02813.

“Particle size ratio control, DH Jeon, 2021.” .

Zakirov TR, Khramchenkov MG. Wettability effect on the invasion patterns during immiscible displacement in heterogeneous porous media under dynamic conditions: a numerical study. J Pet Sci Eng. 2021;206:109049. https://doi.org/10.1016/j.petrol.2021.109049.

Jung M, Brinkmann M, Seemann R, Hiller T, de La Lama MS, Herminghaus S. Wettability controls slow immiscible displacement through local interfacial instabilities. Phys Rev Fluids. 2016;1(7):74202.

Singh K, Jung M, Brinkmann M, Seemann R. Capillary-dominated fluid displacement in porous media. Annu Rev Fluid Mech. 2019;51:429–49.

Holtzman R, Segre E. Wettability stabilizes fluid invasion into porous media via nonlocal, cooperative pore filling. Phys Rev Lett. 2015;115(16):164501.

Sangrós Giménez C, Finke B, Schilde C, Froböse L, Kwade A. Numerical simulation of the behavior of lithium-ion battery electrodes during the calendaring process via the discrete element method. Powder Technol. 2019;349:1–11. https://doi.org/10.1016/j.powtec.2019.03.020.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2022R1F1A1061903).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abubaker, M., Sohn, CH. & Ali, H.M. Understanding wetting behavior in electrode–electrolyte interface formation and its sensitivity to electrode-current collector interaction: a lattice Boltzmann method approach. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13140-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13140-5