Abstract

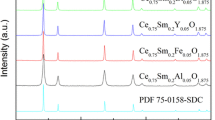

Ce1 − xYxO2 − x/2 (YDC) powders were successfully prepared using the polyol method. All of the prepared YDC powders were found to have a single-phase fluorite structure after calcination at 500 °C. It was also determined that nominal dopant concentrations of YDC samples were very close to the values obtained by EDS. The crystallite sizes varied in the range of 11.54–15.76 nm depending on the dopant concentration, and the lattice parameters of YDC samples were compatible with Vegard’s law. YDC pellets with high relative densities were obtained via sintering at 1400 °C at 6 h. The ionic conductivities of YDC pellets increased significantly until x = 0.15, and YDC15 exhibited an ionic conductivity of 2.23 × 10−2 S cm−1 at 800 °C. The ionic conductivity of YDC20 showed a small increase of 12% at the same measurement temperature, reaching 2.5 x 10−2 S cm−1.

Similar content being viewed by others

References

Kaur P, Singh K (2020) Review of perovskite-structure related cathode materials for solid oxide fuel cells. Ceram Int 46:5521–5535. https://doi.org/10.1016/j.ceramint.2019.11.066

Hussain S, Yangping L (2020) Review of solid oxide fuel cell materials: cathode, anode, and electrolyte. Energy Trans 4:113–126. https://doi.org/10.1007/s41825-020-00029-8

Molenda J, Świerczek K, Zajac W (2007) Functional materials for the IT-SOFC. J Power Sources 173:657–670. https://doi.org/10.1016/J.JPOWSOUR.2007.05.085

Viazzi C, Bonino JP, Ansart F, Barnabé A (2008) Structural study of metastable tetragonal YSZ powders produced via a sol–gel route. J Alloys Compd 452:377–383. https://doi.org/10.1016/J.JALLCOM.2006.10.155

Peng R, Xia C, Liu X et al (2002) Intermediate-temperature SOFCs with thin Ce0.8Y0.2O1.9 films prepared by screen-printing. Solid State Ionics 152–153:561–565. https://doi.org/10.1016/S0167-2738(02)00365-X

Wang LS, Li CX, Li CJ, Yang GJ (2018) Performance of La0.8Sr0.2Ga0.8Mg0.2O3-based SOFCs with atmospheric plasma sprayed La-doped CeO2 buffer layer. Electrochim Acta 275:208–217. https://doi.org/10.1016/j.electacta.2018.04.101

Lee JH, Kim KN, Kim JWSJ et al (2007) An investigation of the interfacial stability between the anode and electrolyte layer of LSGM-based SOFCs. J Mater Sci 42:1866–1871. https://doi.org/10.1007/s10853-006-1315-x

Wang Z, Cheng M, Bi Z et al (2005) Structure and impedance of ZrO2 doped with Sc2O3 and CeO2. Mater Lett 59:2579–2582. https://doi.org/10.1016/J.MATLET.2004.07.065

Kumar A, Jaiswal A, Sanbui M, Omar S (2016) Oxygen-ion conduction in scandia-stabilized zirconia-ceria solid electrolyte (xSc 2 O 3-1CeO 2-(99Àx)ZrO 2 , 5 ≤ x ≤ 11). J Am Ceram Soc. https://doi.org/10.1111/jace.14595

Vasylyev OD, Brodnikovskyi YM, V'yunov O et al (2018) Zirconium oxide stabilized by scandium (III) and cerium (IV) complex oxides as the basis for preparation of thick films and multilayers structures for low temperature (600 °C) fuel cell. French-Ukrainian J Chem 6:16–20. https://doi.org/10.17721/FUJCV6I1P16-20

Sarat S, Sammes N, Smirnova A (2006) Bismuth oxide doped scandia-stabilized zirconia electrolyte for the intermediate temperature solid oxide fuel cells. J Power Sources 160:892–896. https://doi.org/10.1016/J.JPOWSOUR.2006.02.007

Hirano M, Oda T, Ukai K, Mizutani Y (2003) Effect of Bi2O3 additives in Sc stabilized zirconia electrolyte on a stability of crystal phase and electrolyte properties. Solid State Ionics 158:215–223. https://doi.org/10.1016/S0167-2738(02)00912-8

Wang H, Lei Z, Jiang W et al (2022) High-conductivity electrolyte with a low sintering temperature for solid oxide fuel cells. Int J Hydrog Energy 47:11279–11287. https://doi.org/10.1016/j.ijhydene.2022.01.168

Spirin A, Ivanov V, Nikonov A et al (2012) Scandia-stabilized zirconia doped with yttria: synthesis, properties, and ageing behavior. Solid State Ionics 225:448–452. https://doi.org/10.1016/j.ssi.2012.02.022

Politova TI, Irvine JTS (2004) Investigation of scandia-yttria-zirconia system as an electrolyte material for intermediate temperature fuel cells — influence of yttria content in system (Y2O3)x(Sc2O3) (11-x)(ZrO2)89. Solid State Ionics 168:153–165. https://doi.org/10.1016/j.ssi.2004.02.007

Badwal SPS, Ciacchi FT, Rajendran S, Drennan J (1998) An investigation of conductivity, microstructure and stability of electrolyte compositions in the system 9 mol% (Sc2O3–Y2O3)–ZrO2(Al2O3). Solid State Ionics 109:167–186. https://doi.org/10.1016/S0167-2738(98)00079-4

Zhigachev AO, Zhigacheva DV, Lyskov NV (2019) Influence of yttria and ytterbia doping on phase stability and ionic conductivity of ScSZ solid electrolytes. Mater Res Express 6:105534. https://doi.org/10.1088/2053-1591/AB3ED0

Yamamoto O, Arati Y, Takeda Y et al (1995) Electrical conductivity of stabilized zirconia with ytterbia and scandia. Solid State Ionics 79:137–142. https://doi.org/10.1016/0167-2738(95)00044-7

Vijaya Lakshmi V, Bauri R (2011) Phase formation and ionic conductivity studies on ytterbia co-doped scandia stabilized zirconia (0.9ZrO2-0.09Sc2O3-0. 01Yb2O3) electrolyte for SOFCs. Solid State Sci 13:1520–1525. https://doi.org/10.1016/j.solidstatesciences.2011.05.014

Shukla V, Balani K, Subramaniam A, Omar S (2019) Effect of thermal aging on the phase stability of 1Yb2O3 − xSc2O3 − (99 − x)ZrO2 (x = 7, 8 mol %). https://doi.org/10.1021/acs.jpcc.9b05672

Sriubas M, Kainbayev N, Virbukas D et al (2019) Structure and conductivity studies of Scandia and alumina doped zirconia thin dilms. Coatings 9(5):317. https://doi.org/10.3390/COATINGS9050317

Guo CX, Wang JX, He CR, Wang WG (2013) Effect of alumina on the properties of ceria and scandia co-doped zirconia for electrolyte-supported SOFC. Ceram Int 39:9575–9582. https://doi.org/10.1016/j.ceramint.2013.05.076

Wang H, Lei Z, Zhang H et al (2022) Al2O3 toughening ScSZ electrolyte fabricated by water-based tape casting technique for solid oxide fuel cells. J Electrochem Energy Convers Storage 19. https://doi.org/10.1115/1.4052313/1119262

Grosso RL, Muccillo R, Muccillo ENS (2014) Stabilization of the cubic phase in zirconia-scandia by niobium oxide addition. Mater Lett 134:27–29. https://doi.org/10.1016/j.matlet.2014.07.039

Grosso RL, Reis SL, Muccillo ENS (2017) Improved ionic conductivity of zirconia-scandia with niobia addition. Ceram Int 43:10934–10938. https://doi.org/10.1016/J.CERAMINT.2017.05.131

Kumar A, Singh RP, Singh S et al (2017) Phase stability and ionic conductivity of cubic xNb2O5-(11-x)Sc2O3-ZrO2 (0 ≤ x ≤4). J Alloys Compd 703:643–651. https://doi.org/10.1016/J.JALLCOM.2017.01.301

Basu RN (2007) Materials for solid oxide fuel cells. Recent Trends Fuel Cell Sci Technol 286–331. https://doi.org/10.1007/978-0-387-68815-2_12

Irvine JTS, Dobson JWL, Politova T et al (2007) Co-doping of scandia-zirconia electrolytes for SOFCs. Faraday Discuss 134:41–49. https://doi.org/10.1039/b604441g

Li Y, Geysens P, Zhang X et al (2020) Cerium-containing complexes for low-cost, non-aqueous redox flow batteries (RFBs). J Power Sources 450:227634. https://doi.org/10.1016/j.jpowsour.2019.227634

Dönmez G, Sarıboğa V, Gürkaynak Altinçekiç T, Öksüzömer MAF (2014) Polyol synthesis and investigation of Ce1-xRExO2-x/2 (RE = Sm, Gd, Nd, La, 0 ≤ x ≤ 0.25) electrolytes for IT-SOFCs. J Am Ceram Soc 98:501–509. https://doi.org/10.1111/jace.13300

Shirbhate SC, Singh K, Acharya SA, Yadav AK (2017) Review on local structural properties of ceria-based electrolytes for IT-SOFC. Ionics (Kiel) 23:1049–1057. https://doi.org/10.1007/s11581-016-1893-9

Yamamura H, Katoh E, Ichikawa M et al (2000) Multiple doping effect on the electrical conductivity in the (Ce1-x-yLaxMy)O2-δ (M = Ca, Sr) system. Electrochemistry 68:455–459. https://doi.org/10.5796/ELECTROCHEMISTRY.68.455

Sha X, Lü Z, Huang X et al (2007) Study on La and Y co-doped ceria-based electrolyte materials. J Alloys Compd 428:59–64. https://doi.org/10.1016/J.JALLCOM.2006.03.077

Burbano M, Nadin S, Marrocchelli D et al (2014) Cite this. Phys. Chem Phys 16:8320. https://doi.org/10.1039/c4cp00856a

Kumar Singh N, Singh P, Kumar D, Parkash O Electrical conductivity of undoped, singly doped, and co-doped ceria. Iconics. https://doi.org/10.1007/s11581-011-0604-9

Arabacı A Conductivity properties of lanthanide-co-doped ceria-based solid oxide electrolytes. Iconics. https://doi.org/10.1007/s11581-019-03052-y

Chen H, Hui Z, Shen S et al Numerical study on charge transport and electrochemical performance of Gd and Pr co-doped ceria-based solid oxide fuel cells free from internal shorting. Iconics 28(7). https://doi.org/10.1007/s11581-022-04563-x

Puente-Martínez DE, Díaz-Guillén JA, Montemayor SM et al (2020) High ionic conductivity in CeO2 SOFC solid electrolytes; effect of Dy doping on their electrical properties. Int J Hydrog Energy 45:14062–14070. https://doi.org/10.1016/J.IJHYDENE.2019.11.032

Zhang L, Meng J, Yao F et al (2018) Insight into the mechanism of the ionic conductivity for Ln-doped. https://doi.org/10.1021/acs.inorgchem.8b01853

Artini C (2018) Rare-Earth-doped ceria systems and their performance as solid electrolytes: a puzzling tangle of structural issues at the average and local scale. Inorganic Chemistry. https://doi.org/10.1021/acs.inorgchem.8b02131

Yoo C-Y, Nam S-H, Lee Y et al (2022) Quantitative analysis of ceria co-doped with samarium and gadolinium using laser-induced breakdown spectroscopy. https://doi.org/10.1039/d1ay01678d

Solovyev AA, Rabotkin SV, Shipilova AV, Ionov IV (2019) Magnetron sputtering of gadolinium-doped ceria electrolyte for intermediate temperature solid oxide fuel cells. Int J Electrochem Sci 14:575–584. https://doi.org/10.20964/2019.01.03

Zhu B, Liu X, Zhou P et al (2001) Cost-effective yttrium doped ceria-based composite ceramic materials for intermediate temperature solid oxide fuel cell applications. J Mater Sci Lett 20:591–594. https://doi.org/10.1023/A:1010900829589

Montalvo-Lozano RA, Montemayor SM, Padmasree KP, Fuentes AF (2012) Effect of Ca2+ or Mg2+ additions on the electrical properties of yttria doped ceria electrolyte system. J Alloys Compd 525:184–190. https://doi.org/10.1016/j.jallcom.2012.02.045

An J, Bae J, Hong S et al (2015) Grain boundary blocking of ionic conductivity in nanocrystalline yttria-doped ceria thin films. Scr Mater 104:45–48. https://doi.org/10.1016/j.scriptamat.2015.03.020

Rey JFQ, Muccillo ENS (2004) Lattice parameters of yttria-doped ceria solid electrolytes. J Eur Ceram Soc 24:1287–1290. https://doi.org/10.1016/S0955-2219(03)00498-9

Ou DR, Mori T, Ye F et al (2006) Microstructures and electrolytic properties of yttrium-doped ceria electrolytes: dopant concentration and grain size dependences. Acta Mater 54:3737–3746. https://doi.org/10.1016/j.actamat.2006.04.003

Zhang TS, Ma J, Huang HT et al (2003) Effects of dopant concentration and aging on the electrical properties of Y-doped ceria electrolytes. Solid State Sci 5:1505–1511. https://doi.org/10.1016/j.solidstatesciences.2003.10.001

Van Herle J, Horita T, Kawada T et al (1997) Fabrication and sintering of fine yttria-doped ceria powder. J Am Ceram Soc 80:933–940. https://doi.org/10.1111/j.1151-2916.1997.tb02924.x

Ping XY, Meng B, Liang WK et al (2021) Electrical conductivity of Y2O3-doped CeO2 based composite ceramics by spark plasma sintering: the effects of a second phase of CeAlO3. Solid State Ionics 365. https://doi.org/10.1016/j.ssi.2021.115653

Öksüzömer MAF, Dönmez G, Sarıboǧa V, Altınçekiç TG (2013) Microstructure and ionic conductivity properties of gadolinia doped ceria (GdxCe1-xO2-x/2) electrolytes for intermediate temperature SOFCs prepared by the polyol method. Ceram Int 39:7305–7315. https://doi.org/10.1016/j.ceramint.2013.02.069

Gondolini A, Mercadelli E, Sanson A et al (2013) Effects of the microwave heating on the properties of gadolinium-doped cerium oxide prepared by polyol method. J Eur Ceram Soc 33:67–77. https://doi.org/10.1016/j.jeurceramsoc.2012.08.008

Fievet F, Ammar-Merah S, Brayner R et al (2018) The polyol process: a unique method for easy access to metal nanoparticles with tailored sizes, shapes and compositions. Chem Soc Rev 47:5187–5233. https://doi.org/10.1039/C7CS00777A

Subbarao EC, Sutter PH, Hrizo J (1965) Defect structure and electrical conductivity of ThO2-Y2O3 Solid Solutions. J Am Ceram Soc 48(9):443–446. https://doi.org/10.1111/j.1151-2916.1965.tb14794.x

Andrievskaya ER (2008) Phase equilibria in the refractory oxide systems of zirconia, hafnia and yttria with rare-earth oxides. J Eur Ceram Soc 28:2363–2388. https://doi.org/10.1016/J.JEURCERAMSOC.2008.01.009

Cosentino IC, Muccillo R (2001) Lattice parameters of thoria–yttria solid solutions. Mater Lett 48:253–257. https://doi.org/10.1016/S0167-577X(00)00311-6

Guan X, Zhou H, Liu Z et al (2008) High performance Gd3+ and Y3+ co-doped ceria-based electrolytes for intermediate temperature solid oxide fuel cells. Mater Res Bull 43:1046–1054. https://doi.org/10.1016/j.materresbull.2007.04.027

Stephens IEL, Kilner JA (2006) Ionic conductivity of Ce1-xNdxO2-x/2. Solid State Ionics 177:669–676. https://doi.org/10.1016/j.ssi.2006.01.010

Ando M, Oikawa I, Noda Y et al (2011) High field O-17 NMR study of defects in doped zirconia and ceria. Solid State Ionics 192:576–579. https://doi.org/10.1016/J.SSI.2010.04.024

Fabián M, Menzel D, Yermakov AY et al (2021) Nanostructure and magnetic anomaly of mechanosynthesized Ce1-xYxO2-δ (x ≤ 0.3) solid solutions. J Phys Chem Solids 148:109673. https://doi.org/10.1016/J.JPCS.2020.109673

Fabián M, Antić B, Girman V et al (2015) Mechanosynthesis and structural characterization of nanocrystalline Ce1–xYxO2–δ (x=0.1–0.35) solid solutions. J Solid State Chem 230:42–48. https://doi.org/10.1016/J.JSSC.2015.06.027

Simonenko TL, Simonenko NP, Mokrushin AS et al (2020) Microstructural, electrophysical and gas-sensing properties of CeO2–Y2O3 thin films obtained by the sol-gel process. Ceram Int 46:121–131. https://doi.org/10.1016/J.CERAMINT.2019.08.241

Li JG, Wang Y, Ikegami T, Ishigaki T (2008) Densification below 1000 °C and grain growth behaviors of yttria doped ceria ceramics. Solid State Ionics 179:951–954. https://doi.org/10.1016/j.ssi.2008.01.053

Mori T, Drennan J, Wang Y et al (2003) Influence of nano-structural feature on electrolytic properties in Y2O3 doped CeO2 system. Sci Technol Adv Mater 4:213–220. https://doi.org/10.1016/S1468-6996(03)00047-0

Van Herle J, Horita T, Kawada T et al (1996) Sintering behaviour and ionic conductivity of yttria-doped ceria. J Eur Ceram Soc 16:961–973. https://doi.org/10.1016/0955-2219(96)00012-X

Dirstine RT, Blumenthal RN, Kuech TF (1979) Ionic conductivity of calcia, yttria, and rare Earth-doped cerium dioxide. J Electrochem Soc 126:264–269. https://doi.org/10.1149/1.2129018

Eguchi K, Setoguchi T, Inoue T, Arai H (1992) Electrical properties of ceria-based oxides and their application to solid oxide fuel cells. Solid State Ionics 52:165–172. https://doi.org/10.1016/0167-2738(92)90102-U

Zha S, Fu Q, Lang Y et al (2001) Novel azeotropic distillation process for synthesizing nanoscale powders of yttria doped ceria electrolyte. Mater Lett 47:351–355. https://doi.org/10.1016/S0167-577X(00)00265-2

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dönmez, G., Gürkaynak Altınçekiç, T., Sarıboğa, V. et al. Fabrication of YDC electrolytes via polyol method and investigation of their properties for IT-SOFCs. Ionics 29, 2841–2851 (2023). https://doi.org/10.1007/s11581-023-05021-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-023-05021-y