Abstract

Solid-state batteries are considered the next step in battery technology. Materials investigated for application as solid-state electrolytes are mainly oxide ceramics, sulfidic (glass-) ceramics, and polymers. Besides these, another class of solid electrolytes with promising properties is based on plastic crystals. Especially due to their waxy behavior, they promise good interfaces within a solid-state battery. In this work, a new plastic crystal, 2-adamantanone, is investigated as basis for a solid electrolyte for the first time. Its large temperature window from − 95 to 255 °C for its plastic (conductive) state and the high dipole moment of 3.4 D make it a promising material for battery application. The mixture with a lithium salt was investigated thermally with TGA and DSC revealing stability in a large temperature range from − 30 to + 80 °C. IR investigations show the dissociation of the conductive salt, which is necessary for the lithium ion conduction. The ionic conductivity of the electrolytes reaches values up to 1.4·10−4 S/cm at room temperature with a very low activation energy of only 0.32 eV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lithium-ion batteries (LIBs) are one of the most attractive energy storage systems for future applications due to their high energy densities. However, safety and toxicity concerns still remain in commercial LIBs equipped with organic liquid electrolyte [1]. By replacing the liquid electrolyte with a lithium-ion conducting solid, these issues may be resolved and will result in inherent cell safety and increased energy density by the usage of lithium metal anodes [2]. These so-called solid-state lithium-ion batteries (SSBs) have been extensively studied with regard to the ionic conductivity of the electrolytes and the interfacial issues between the electrode active materials and electrolyte [3,4,5].

An interesting basis for solid-state electrolytes are plastic crystals (PCs). Due to their globular molecule structure, they exhibit a solid–solid transition from solid to a plastic phase where one degree of freedom (rotation) is given in the lattice [6]. In this phase, the material exhibits a waxy behavior allowing for a good processing due to a good compaction of components on the one hand and, on the other hand, may be able to compensate volume changes occurring in a solid-state battery during cycling. For creating a working electrolyte, it is important that the molecules should act as solid solvents allowing for ionic movement when mixed with a lithium salt. To achieve this, PCs need to provide a certain degree of polarity to allow for the dissociation of the lithium salt similar to a liquid solvent. In case of ionic plastic crystals (IOPCs), the molecule consists of an ionic lattice itself allowing for a good dissociation of added lithium salt [7, 8]. Hydroborates, as a special inorganic compound in this group, even incorporate lithium removing the need of an additional conducting salt [9]. Uncharged PCs on the other hand need to exhibit a strong dipole moment to dissociate lithium salts. The most prominent compound in this class is succinonitrile (SN) which was extensively investigated by Abouimrane and co-workers [10,11,12]. It exhibits a room temperature conductivity of 1.47·10−3 S/cm and is now often used as additive in liquid electrolytes to enhance the thermal stability [13]. With a dipole moment of 3.8 D, the polarity of SN is slightly lower than common components of liquid electrolytes like propylene carbonate (µ = 5.36 D) or ethylene carbonate (µ = 4.81 D) [14] but strong enough to dissociate salts.

In an ideal solid-state battery, the temperature control is expected to be obsolete to increase the energy density of the battery system. This should be possible as the solid-state battery is expected to withstand higher temperatures that may occur during operation. The temperature values for this scenario range from − 20 to 80 °C to cover engine cold start and high-power situations equally. However, the temperature range of the plastic phase of pure SN is between − 40 and 50 °C. Therefore, it faces the problem of melting during battery operation. Due to the melting point reduction by the addition of a lithium salt, the transition to the liquid state is even lower [10].

In this study 2-adamantanone (ADA) is investigated as a competitor to the SN system for the first time. The plastic phase of ADA is very large ranging from − 95.15 to 255.85 °C making it an excellent candidate for battery applications such as electromobility. In addition, with a dipole moment of 3.4 D, the molecule should be able to dissociate lithium salt similar to SN [15]. This work explores its ability to dissociate lithium salts and, consequently, its suitability to act as a matrix for a solid electrolyte.

Experimental

For the preparation of the solid electrolyte (SE), 2-adamantanone (ADA; ≥ 99%, Carl Roth) and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI; 99%, IoLiTec, dried in vacuum at 80 °C for 12 h) were dissolved in THF (anhydrous, ≥ 99.9%, Sigma-Aldrich) in weight ratios of 80:20 (SE-82) and 50:50 (SE-55), corresponding to 1 M and 5 M solutions, respectively, compared to liquid electrolytes. After stirring for 30 min, the mixture was poured into a flat bowl and allowed to dry under ambient conditions. Thermogravimetric analysis (TGA) and FTIR spectroscopy confirmed the complete removal of THF in the dried samples. All preparation steps were performed in an argon-filled glove box (H2O, O2 < 0.1 ppm, MBraun).

For determination of thermal properties, TGA and temperature-modulated differential scanning calorimetry (DSC) measurements were performed under dry nitrogen flow. The TGA was measured between 30 and 500 °C (STA 449 F3 Jupiter, Netzsch) with a heating rate of 5 K·min−1 and the DSC scan was performed between − 30 and 80 °C (Discovery DSC, TA Instruments) with a heating rate of 10 K·min−1.

To confirm the solvation of LiTFSI within the ADA matrix, FTIR spectra of SE-82 were recorded in ATR mode (Vertex 70 FTIR, Bruker) and compared to spectra of pure ADA. Here, the samples were prepared and measured under inert (Ar atmosphere) conditions.

For conductivity measurements, cylindrical samples with a diameter of 15 mm and a thickness of 2 mm were placed between two stainless steel blocking electrodes in an airtight custom-made sample holder. A photograph of the SE-82 pellet is shown in Fig. 1. For the determination of the temperature-dependent ionic conductivity, electrochemical impedance spectroscopy (EIS) was performed with a Gamry 600 potentiostat between − 20 and 60 °C with an amplitude of 20 mV in a frequency range of 1 MHz to 1 Hz.

Linear sweep voltammetry (LSV) was conducted to determine the electrochemical window of the material exchanging one steel blocking electrode with a lithium metal foil as counter/reference electrode. The scan was performed up to 6 V vs. Li with a scan rate of 1 mV/s.

The Li + transference number (tLi+) was examined using the electrochemical combination method of direct current (DC) polarization/alternating current impedance between two lithium electrodes proposed by Bruce and Vincent for polymer electrolytes with mobile cations and anions [16]. A voltage of 20 mV was applied during the polarization step and steady state condition was reached after DC polarization for 16 h at room temperature. Voltage and frequency parameters for initial and steady state EIS measurements were taken from conductivity measurements.

For application in full battery cells, solid state composite cathodes were prepared by one-step doctor blading process. NCM622, PVDF (Solef 5130, Solvay), C (Super C65, Timcal), and SE-55 (62:30:4:4) were mixed in N-methylpyrrolidone (NMP, > 99%, Sigma Aldrich) and doctor bladed onto Al foil. The resulting active mass loading was around 2 mAh/cm2. Cells comprising SSCC, separator (SE-55) with a diameter of 18 mm, and a smaller Li anode (diameter 15 mm) to avoid short circuits were assembled inside the glovebox in airtight sample holders. The cycling performances of the cells were evaluated using Maccor series 4000. At 60 °C, the cells were cycled at C/10 and C/30 in a potential range between 3–4.1 and 3–4.3 V, respectively.

Results and discussion

The results from the thermoanalytic measurements are depicted in Fig. 2. In the TGA curve (Fig. 2a) a steep mass loss of the pure ADA and the SEs are shown. The curve of pure ADA shows an onset of mass loss at 104 °C. The onset is shifted to slightly higher temperatures visible in the onset temperatures of 109 °C for SE-82. In both cases, the mass loss results in a complete depletion of ADA at 150 °C for the pure material and 200 °C for SE-82. In the latter, only the LiTFSI remains with 20 wt% which decomposes slowly at an onset temperature of 380 °C. This mass loss of ADA is a result of the high vapor pressure of ADA in the plastic phase. At determined temperatures and under constant gas flow, the material sublimes from the crucible. Increasing the salt content within the electrolyte composition drastically changes the thermal stability, as can be seen from the TGA curve of SE-55. The onset temperature is shifted to 132 °C. Furthermore, the mass loss is more gradual. The distinct discrimination between ADA sublimation and LiTFSI decomposition is no longer possible. The steep mass loss is observed above 425 °C that can be attributed to the decomposition of LITFSI; however, a higher degree of residue (13%) remains at 500 °C.

In addition, no mass loss around the boiling point of THF (66 °C) is visible showing the complete evaporation of the solvent during the drying step when preparing the sample.

In Fig. 2b, the DSC scan between − 30 and 80 °C of the pure ADA and the SEs are depicted. All three samples do not exhibit any phase transition like melting or solid–solid transition between the plastic and solid phase. The plastic phase of ADA itself ranges from − 95 to 255 °C [17] extending well beyond the investigated temperature range. Adding LiTFSI, which is expected to lower the melting point of the ADA, does not lead to changes regarding the phase stability within the investigated temperature region. Also, the sublimation visible in the TGA experiment is absent proving that the vapor pressure is still very low in this temperature region.

The thermal properties illustrate an important aspect of the work with neutral PCs. Due to the rotational degree of freedom, in the crystal lattice these compounds exhibit an increased vapor pressure leading to sublimation at elevated temperatures. This property enables the purification of these materials, but limits the useable temperature window in an electrochemical system. However, in the TGA experiment, the gas flow and the open crucible accelerate the sublimation. Consequently, the onset temperature of 109 °C seen in the TGA can be seen as the lower limit for sublimation. This is also obvious from the DSC scans stopping at 80 °C and showing no signs of material loss or phase change. In addition, this behavior will change when using an ADA electrolyte in a closed and stiff setup, such as a battery, comparable to the vapor pressure of liquid electrolytes.

FTIR measurement results are shown in Fig. 3. Comparing pure ADA with the SE-82, the overview spectrum of the electrolyte shows all peaks from the original ADA spectrum as well as from the LiTFSI, more precisely the TFSI− anion [18]. If the ADA is able to dissociate the LiTFSI, the influence should be visible at the carbonyl group located around 1700 cm−1 because of the coordination of the lithium ion toward the partial negative charge of the oxygen. To investigate this influence a magnification of the carbonyl region between 1640 and 1760 cm−1 is given in Fig. 3b. The carbonyl signal of the ADA (black) already exhibits a complex structure. In the cage-like structure of ADA, Fermi resonance coupling with the C–C symmetric deformation, rocking, and waging leads to a splitting of the C = O stretching mode into three major peaks at 1715 cm−1, 1698 cm−1, and 1673 cm−1 [19, 20]. Adding the lithium salt, the C = O stretching modes change resulting in only two major peaks at 1700 cm−1 and 1679 cm−1. Also, the intensity distribution changes, making the peak at 1700 cm−1 most prominent. This effect can be explained by the coordination of the lithium ion at the carbonyl oxygen, which lead to a slight change of the Fermi energies. A similar effect on the carbonyl stretching was observed in liquid electrolytes [21, 22]. The complete solvation of the lithium cations leads to strong interactions with the carbonyl stretching band shifting these toward lower wavenumbers. Therefore, the observed changes in the carbonyl region give a good indication for the salt dissociation inside of the ADA forming a solid electrolyte.

Both spectra show no absorbance above 3000 cm−1 and therefore no water contamination. Residual THF from the electrolyte preparation would be visible especially with strong absorption at 1067 cm−1 (mixed valence-deformation vibrations) and 908 cm−1 (ring breathing) [23]. While the first one is superimposed by the asymmetric valence vibration of the S–N–S bond [18], the latter is completely missing showing the absence of any liquid solvent in the electrolyte.

To validate this finding, impedance measurements to determine ionic conductivity were conducted. The results are depicted in Fig. 4. In Fig. 4a, the Nyquist plots for temperatures between − 20 and 60 °C are shown. They reveal the typical appearance of a solid electrolyte, exhibiting one semi-circle, which is commonly attributed to the bulk conductivity and can be fitted using a single R||CPE-element. Hence, no separate grain boundary resistance can be observed. In addition, no frequency-independent resistance can be observed which would be associated with the bulk resistance of a liquid electrolyte. In the low-frequency region, the spectra exhibit a straight line showing the blocking behavior of the electrodes.

In Fig. 4b, the extracted specific conductivities are plotted as a function of temperature. The electrolytes SE-82 and SE-55 exhibit a room temperature conductivity of (1.5 ± 0.5) · 10−5 S/cm and (1.2 ± 0.2) · 10−4 S/cm, respectively, making it a promising material for electrolyte application. Although the values of SE-82 are below those of most oxide (~ 10−4–10−3 S/cm), sulfidic (~ 10−3–10−2 S/cm) [24], they are above the value of organic polymer-based dry PEO-based electrolytes (~ 10−6 S/cm) [25]. Nevertheless, the conductivity is two orders of magnitude lower than the values of plastic crystal electrolytes based on SN (~ 10−3 S/cm) [10]. This deviation may occur because of the different molecule sizes sterically hindering the movement of both the Li+ cation and the TFSI− anion. Another reason could be the electrostatic situation. Besides the similar dipole moment, the polarizability of ADA and SN is different because of their dielectric constants. The SN exhibits with 55 at 25 °C [10] a very high dielectric constant due to the possible conformational changes of the molecule. This value even exceeds those of liquid electrolytes. On the other hand, the ADA exhibits a cage-like structure in which no conformational changes are possible. This results in a lower dielectric constant of about 14 at 25 °C [14] and, therefore, reduce the ion conductivity. Furthermore, increasing the ion concentration (SE-55) leads to significant increase in conductivity, proving that optimizing electrochemical properties is possible by adjusting the electrolyte composition. In addition, the materials reveal a very stable conductivity changing only one order of magnitude between − 20 and 60 °C. They exhibit Arrhenius behavior resulting in a low activation energy of 0.24 eV and 0.32 eV which is in the range of sulfidic electrolytes [26]. These values are considerably lower than the value for SN (0.6 eV [27]) showing fast lithium-ion diffusion inside the ADA matrix in its plastic state. The different values for the two electrolytes are the result of different amounts of disordered fraction of salt and 2-adamantanone in the matrix previously described by Alarco et al. for succinonitrile [10]. These fractions exist in the matrix due to the low residual energy needed for the transition to a liquid phase and are dispersed in the plastic crystalline phase. The higher the amount of conductive salt, the stronger is the influence of these fractions on the overall conductivity and therefore the conduction mechanism.

The electrochemical stability of the two materials is shown in Fig. 5a. The onset potential of the electrolyte decomposition is around 4.25 V for the SE-82 and 5.10 V for the SE-55, revealing a stable cycling window even for high-voltage cathode materials like NMC622 especially for the SE-55. It should be noted that the current densities for the SE-55 are three orders of magnitude higher due to the increased ionic conductivity of the material.

The results of the polarization experiment of SE-55 for the calculation of the transference number tLi+ are shown in Fig. 5b. Here, the chronoamperometry profile and the impedance spectra (inset) are depicted. The tLi+ value can be estimated by the following equation:

where ΔV is the applied voltage (20 mV) and I0 and Is are the initial current and steady state current, respectively, during DC polarization process. R0I, RSI are the interface resistances of the Li symmetric cell before and after DC polarization, respectively. The calculated value for tLi+ is 0.35 ± 0.05 which is in the same region as polymer electrolytes.

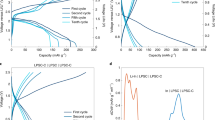

Due to the higher absolute values in conductivity and the larger electrochemical stability window, electrolyte SE-55 was used for preliminary cycling tests to evaluate the applicability in full solid state battery cells. Charge and discharge capacities of an exemplary cell are depicted in Fig. 6. The voltage profile is typical for a Li/NMC622 cell. Disregarding the first formation cycle, the cells can be cycled with a stable capacity of 75 mAh/g. The good match between charge and discharge capacities shows there are no side reactions like electrolyte decomposition taking place, underlining the stable cycling behavior. Attempting to increase the discharge capacity, the cut-off voltage during charging was increased to 4.3 V and the C-rate was decreased to C/30. The voltage profiles and the capacity values remain stable. The capacity values are lower than the nominal capacity of NCM; however, the composite cathode composition and manufacturing are not yet optimized. Usually, for utilizing the full capacity of the cathode active material, percolation pathways for both electronic and ionic conductors are mandatory and achieved using a two-step manufacturing process by infiltrating conventionally cast LIB cathodes with solid electrolyte [28]. In contrast, the cathodes used here were prepared by doctor blading a slurry already containing the electrolyte facilitating the SSCC manufacturing process to one step. The optimization of production steps mixing, casting, and drying necessary to achieve the electronic and ionic pathways mentioned above are the topic of currently ongoing investigation and will be published in the future. Nevertheless, the reproducible charge and discharge prove that SE-55 remains stable in the extended voltage window, making it a promising electrolyte class for further investigation.

Conclusion

In summary, 2-adamantanone as basis for a solid-state electrolyte was investigated for the first time. It exhibits good thermal stability in wide temperature window (− 20 and 80 °C) for battery applications. FTIR investigations showed the ability of the ADA to dissociate the LITFSI. Finally, the determination of the ionic conductivity by EIS measurements revealed a room temperature conductivity of 1.2·10−4 S/cm with 50 wt% LiTFSI which is higher than most polymeric electrolytes. An important feature is the activation energy of the material of 0.32 eV and a transference number tLi+ of 0.35, which shows a good mobility of the Lithium ions inside the 2-adamantanone matrix. In addition, the electrolyte is stable up to a potential of 5.10 V vs. Li, making it suitable for application with high-voltage cathode materials like NMC622. In total, ADA is a promising new candidate for building all-solid-state lithium-ion batteries.

References

Armand M, Tarascon J-M (2008) Building better batteries. Nature 451:652–657. https://doi.org/10.1038/451652a

Takada K (2013) Progress and prospective of solid-state lithium batteries. Acta Mater 61:759–770. https://doi.org/10.1016/j.actamat.2012.10.034

Thangadurai V, Narayanan S, Pinzaru D (2014) Garnet-type solid-state fast Li ion conductors for Li batteries: critical review. Chem Soc Rev 43:4714–4727. https://doi.org/10.1039/C4CS00020J

Goodenough JB, Singh P (2015) Review—solid electrolytes in rechargeable electrochemical cells. J Electrochem Soc 162:A2387–A2392. https://doi.org/10.1149/2.0021514jes

Kim JG, Son B, Mukherjee S et al (2015) A review of lithium and non-lithium based solid state batteries. J Power Sources 282:299–322. https://doi.org/10.1016/j.jpowsour.2015.02.054

Timmermans J (1961) Plastic crystals: a historical review. J Phys Chem Solids 18:1–8. https://doi.org/10.1016/0022-3697(61)90076-2

Pringle JM, Howlett PC, MacFarlane DR et al (2010) Organic ionic plastic crystals: recent advances. J Mater Chem 20:2056. https://doi.org/10.1039/B920406G

Zhu H, MacFarlane DR, Pringle JM et al (2019) Organic ionic plastic crystals as solid-state electrolytes. Trends Chem 1:126–140. https://doi.org/10.1016/j.trechm.2019.01.002

Duchêne L, Remhof A, Hagemann H et al (2020) Status and prospects of hydroborate electrolytes for all-solid-state batteries. Energy Storage Mater 25:782–794. https://doi.org/10.1016/j.ensm.2019.08.032

Alarco P-J, Abu-Lebdeh Y, Abouimrane A et al (2004) The plastic-crystalline phase of succinonitrile as a universal matrix for solid-state ionic conductors. Nat Mater 3:476–481. https://doi.org/10.1038/nmat1158

Abouimrane A, Abu-Lebdeh Y, Alarco P-J et al (2004) Plastic crystal-lithium batteries: an effective ambient temperature all-solid-state power source. J Electrochem Soc 151:A1028–A1031. https://doi.org/10.1149/1.1759971

Abouimrane A, Whitfield PS, Niketic S et al (2007) Investigation of Li salt doped succinonitrile as potential solid electrolytes for lithium batteries. J Power Sources 174:883–888. https://doi.org/10.1016/j.jpowsour.2007.06.103

Chen R, Liu F, Chen Y et al (2016) An investigation of functionalized electrolyte using succinonitrile additive for high voltage lithium-ion batteries. J Power Sources 306:70–77. https://doi.org/10.1016/j.jpowsour.2015.10.105

Chernyak Y (2006) Dielectric constant, dipole moment, and solubility parameters of some cyclic acid esters. J Chem Eng Data 51:416–418. https://doi.org/10.1021/je050341y

Amoureux JP, Sahour M, Fernandez C et al (1994) Dielectric properties of chloroadamantane and adamantanone. Phys Stat Sol (a) 143:441–448. https://doi.org/10.1002/pssa.2211430231

Bruce PG, Evans J, Vincent CA (1988) Conductivity and transference number measurements on polymer electrolytes. Solid State Ionics 28–30:918–922. https://doi.org/10.1016/0167-2738(88)90304-9

Butler IS, Cole HBR, Gilson DFR et al (1986) Differential scanning calorimetric studies of the phase transition in adamantanone. J Chem Soc Faraday Trans 2 82:535. https://doi.org/10.1039/F29868200535

Howlett PC, Brack N, Hollenkamp AF et al (2006) Characterization of the lithium surface in N-methyl-N-alkylpyrrolidinium Bis(trifluoromethanesulfonyl)amide room-temperature ionic liquid electrolytes. J Electrochem Soc 153:A595. https://doi.org/10.1149/1.2164726

Bistričić L, Pejov L, Baranović G (2002) A density functional theory analysis of Raman and IR spectra of 2-adamantanone. J Mol Struct (Thoechem) 594:79–88. https://doi.org/10.1016/S0166-1280(02)00367-6

Bistričić L, Baranović G, Mlinarić-Majerski K (1998) Vibrational analysis of 2-adamantanone and its deuterated isotopomers. Spectrochim Acta Part A Mol Biomol Spectrosc 54:1961–1986. https://doi.org/10.1016/S1386-1425(98)00158-9

Cazzanelli E, Croce F, Appetecchi GB et al (1997) Li+ solvation in ethylene carbonate–propylene carbonate concentrated solutions: a comprehensive model. J Chem Phys 107:5740–5747. https://doi.org/10.1063/1.474334

Deepa M, Sharma N, Agnihotry SA et al (2002) FTIR investigations on ion–ion interactions in liquid and gel polymeric electrolytes: LiCF3SO3-PC-PMMA. J Mater Sci 37:1759–1765. https://doi.org/10.1023/A:1014921101649

Evseeva LA, Sverdlov LM (1968) Analysis and interpretation of vibrational spectra of tetrahydrofuran and its deutreo derivatives. Sov Phys J 11:87–90. https://doi.org/10.1007/BF01890931

Zhang Z, Shao Y, Lotsch BV et al (2018) New horizons for inorganic solid state ion conductors. Energy Environ Sci 11:1945–1976. https://doi.org/10.1039/C8EE01053F

Mindemark J, Lacey MJ, Bowden T et al (2018) Beyond PEO—alternative host materials for Li + -conducting solid polymer electrolytes. Prog Polym Sci 81:114–143. https://doi.org/10.1016/j.progpolymsci.2017.12.004

Ceder G, Ong SP, Wang Y (2018) Predictive modeling and design rules for solid electrolytes. MRS Bull 43:746–751. https://doi.org/10.1557/mrs.2018.210

Das S, Prathapa SJ, Menezes PV et al (2009) Study of ion transport in lithium perchlorate-succinonitrile plastic crystalline electrolyte via ionic conductivity and in situ cryo-crystallography. J Phys Chem B 113:5025–5031. https://doi.org/10.1021/jp809465u

Coeler M, van Laack V, Langer F et al (2021) Infiltrated and isostatic laminated NCM and LTO electrodes with plastic crystal electrolyte based on succinonitrile for lithium-ion solid state batteries. Batteries 7:11. https://doi.org/10.3390/batteries7010011

Funding

Open Access funding enabled and organized by Projekt DEAL. The financial support of the BMW Group is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Ingo Bardenhagen, Frederieke Langer, and Marc Soto. The first draft of the manuscript was written by Ingo Bardenhagen and Frederieke Langer and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bardenhagen, I., Soto, M., Langer, F. et al. Solid electrolyte based on 2-adamantanone for all-solid-state lithium-ion batteries. Ionics 28, 3615–3621 (2022). https://doi.org/10.1007/s11581-022-04614-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04614-3