Abstract

Ionics is a key technology for storing, converting and using energy efficiently as well as protecting the environment. Major progress has been achieved in recent years in the understanding and development of individual materials components needed for ionic devices. It should be emphasized that only combinations of materials are eventually important and at least four interfaces exist with electronic and ionic junctions. The electrical fields exist over distances in the atomic range. Examples are given of recent successful developments of practically useful solids for lithium and oxide ion conduction in combination with appropriate electrodes. In addition, recent approaches to the design of ionic devices are described, notably the SEA concept for generating voltages in fuel cells and the coloration of single phase electrochromic materials. In order to overcome the tremendous problems in developing wide spread commercial applications, it is necessary to intensify our efforts in fundamental materials research drastically.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ionics is the science and technology of the motion of ions alone or together with electrons within the bulk of materials and across interfaces. Some of the emerging economically and ecologically most important developments in the field of energy supply are based on this phenomenon [1]. The most prominent applications are:

-

Fuel and water electrolysis cells based on solid electrolytes,

-

Batteries with high energy and power densities with fast ionically conducting electrolytes and mixed ionically and electronically conducting electrodes for mobile and stationary energy storage,

-

Supercaps with high capacities obtained from ionic charge relocations at interfaces between an electrolyte and electronically conducting materials for fast storage and delivery of electrical energy, e.g., during braking and accelerating of automobiles,

-

Thermoelectric converters with solid electrolytes separating hot and cold regions with different chemical potentials of the mobile component for the currently most effective direct conversion of thermal into electrical energy,

-

Photogalvanic solar cells with interfaces between ionic conductors and semi-conductors with the generation of electrical fields for the separation of the electron-hole pairs generated by light,

-

Chemical sensors for environmental protection and process control for oxygen, CO x , NO x etc. based on electrolytes for the direct conversion of partial pressures or concentrations of chemical species into electrical signals and

-

Electrochromic systems with variable coloration of thin films by the electrochemical variation of the concentration of electronic charge carriers.

The various applications require quite different thermodynamic stabilities and kinetic properties as shown in Fig. 1.

There are some similarities between Ionics and Electronics since both technologies are based on the local displacement of electrical charges across interfaces which results in electrical fields. While only electrons move in the case of Electronics, both electrons and ions move in the case of Ionics. In addition, one material in the electrical circuit has to be blocked for the electrons in order to force the electronic charge carriers to move through the external circuit and to perform work [2].

In spite of the similarities with Electronics, the mobility of the ions and, as a consequence, the potential reactivity of the materials makes a big difference. The challenges are an order of magnitude larger than in the case of Electronics with immobile ions and SiO2 protected Si. The simplicity of Nernst’s law is fallacious since mainly the interfaces between different materials are important. These materials have to have quite different functional properties such as partial electronic conductivities and stoichiometric widths but should be compatible in other respects such as expansion coefficients and chemical stabilities. The more the large number of ionic charge carriers in solid electrolytes and electrons in electrodes screen the electrical field generated at the interfaces from penetrating into the bulk of the electrolyte, the more rapidly the electrical field drops over a distance in the range of atomic dimensions, i.e., 100–1,000 pm, in contrast to 1 μm in the case of semiconductors and liquid electrolytes. For long-term stability it is required that the materials in contact with each other are chemically stable within the regime of the electrical field. The development of practical ionic devices will not succeed without the identification of suitable materials and materials combinations. This aspect has to be considered more strongly in the future.

Commercially successful applications based on solid electrolytes are so far only dependent on electronic junctions than on the generation of electrical fields by the motion of ions. This holds true especially for the lambda probe in which the electrostatic potential drop between the platinum electrode and zirconia solid oxide electrolyte depends on the equilibration of electrons alone across the interface, since oxygen does not permeate through the bulk of the platinum. However, the surface of the electrolyte is equilibrated with the surrounding gas in some uncovered areas and changes the concentration of electrons in the electrolyte by the variation of the oxygen activity [3].

Research in the field of Ionics has to be interdisciplinary. It is necessary that we cross the traditional borders of education and knowledge. Progress is being made rapidly in this regard. A number of examples illustrating the rapid development in the field of Ionics will be presented in the following, and they are mostly based on recent results obtained in the authors’ laboratories.

Materials requirements

All applications are based on two electrodes and the combination of at least three materials which form a galvanic cell. Such an electrode is illustrated in Fig. 2 for the case of a lithium battery. The chemical energy levels μ of the ions, neutral component and electrons are shown together with the electrostatic energy \(q\varphi \) for the two materials before and after placing them together. Neglecting the lithium ions and atoms, this picture agrees with that before and after an electronic junction is made. When the materials are put in contact with each other, concentration gradients of all the charged species will occur. Diffusion will be the result and will continue until electrical fields are built up to compensate the charge flux according to Fick’s and Ohm’s laws:

where j D,i , j E,i , D i , c i , μ i , σ i , z i, q and \( \varphi \) are the flux by diffusion, flux by electrical field, diffusivity, concentration, chemical potential, electrical conductivity, charge number, elementary charge and electrostatic potential, respectively. The index i corresponds to any of the mobile species, i.e., electrons and ions. The chemical potential of the neutral component is constant across the interface but changes within the electrolyte since electrons are too few in number to be able to provide a compensation of the motion of the ions and accordingly the transport of the neutral species across the electrolyte.

Energy levels of the neutral and charged species involved in the equilibration across electrode–electrolyte interfaces. The chemical potentials and electrostatic energy are shown before (top) and after (below) the contact is made. For the electronic species the situation is the same as in the case of electronic junctions. However, the junctions are much narrower, i.e., of the order of magnitude of atomic dimensions. In the case of Ionics, additional equilibrations of the mobile ions will occur

The electrical field existing at the interface has to compensate simultaneously both the motion of ionic and electronic charge carriers, which have to have opposite concentration gradients in view of the different sign of the charge number in the case of excess electrons and lithium ions. If the equilibria are established according to Eq. 1, the electrical field may be calculated within the narrow regime of the junction by taking into account that the conductivity is related to the product of the concentration and diffusivity:

Accordingly, Eq. 1 may be rewritten for the local electrical field in the chemical potential gradient of species i

This equation holds both for the electronic and ionic charge carriers. The measurable open circuit cell voltage is given by the integral of Eq. 3 over the entire galvanic cell including the electronic leads to the electrometer. This may be done both for species i being the ions and the electrons. It should be considered, however, that only electrons may build up an electrical field at the electrode/electronic lead interfaces. Furthermore, it has to be taken into consideration that the chemical potential of the ions is constant within the bulk of the individual phases, whereas the electrons show a gradient within the electrolyte because of their very low mobility which prevents equilibration. The electrostatic and chemical potentials of the electrons and lithium ions in a complete galvanic cell are shown in Fig. 3. Accordingly, taking into account the chemical potential drops of the electrons between the electronic leads and the electrodes and the chemical potential drops of the lithium ions at the electrolyte/electrodes interfaces, this results in

where l and r stand for the left and right hand side electrode, respectively. In view of the ionisation equilibrium \( \mu _{A} = \mu _{{A^{{z + }} }} + z\mu _{{e^{ - } }} \), the terms of the ions and electrons may be combined to give the chemical potential of the neutral mobile component. That is Nernst’s law which appears to be very simple but hides the origin of the formation of the voltage. The development of ionic devices depends, accordingly, on the availability of a fast, predominantly ionically conducting electrolyte, mixed ionically electronically conducting electrodes with substantially different chemical potentials of the electroactive component and commonly wide variations of the composition, and the formation of at least four electronic and ionic junctions. The materials have to be chemically stable in contact with each other over an extended period of time without the formation of even an extremely thin reaction product, in spite of the presence of mobile ions. It is obvious that overcoming this problem is a major challenge. Systematic materials research is the most promising approach for coming up with useful ionic devices, rather than the presently often favoured promotion of “demonstration objects”.

Materials aspects

Major progress has been achieved in recent years in the discovery and development of solids with high ionic conductivities, especially for lithium- and oxide-ions and protons. These ionic conductors are most important for practical applications in lithium batteries and fuel cells, but also play a major role in sensors, electrochromic devices, thermoelectric converters and supercaps. The conductivities of the best ionic conductors are quite typical for the same kind of mobile ions. This is illustrated in Fig. 4. Solid silver ion conductors have generally higher conductivities than sodium ion conductors and these are faster than lithium ion conductors by an order of magnitude.

It has been found that high ionic conductivity is in conflict with thermodynamic stability [4]. This holds at least for simple crystallographic structures in which strong chemical bonds between the anions and cations exist to prevent the motion of the ions. However, the attractive forces may be reduced by a third kind of ions which are capable of partially screening the attractive forces. As an example, adding AlCl3 to LiCl results in LiAlCl4 in which the aluminium ions screen the chlorine from the lithium. In addition, large clusters of \( {\text{AlCl}}^{ - }_{4} \) ions are formed which are large building blocks providing the space for fast motion of the lithium ions between them [5].

The same considerations are applicable for all other fast lithium ion conductors which have been discovered so far. In the case of the solid solution of Li4SiO4 and Li3PO4, tetrahedra of \( {\text{SiO}}^{{4 - }}_{4} \) and \( {\text{PO}}^{{3 - }}_{4} \) exist. Furthermore, lithium ion vacancies are formed in accordance to the different valencies of the tetrahedra. An optimum conductivity is observed with approximately equal amounts of Li4SiO4 and Li3PO4 due to the optimum balance of vacancies and lithium ions [6].

A third example is the perovskite type lithium ion conductor Li0.32La0.56TiO3 (LLTO) which shows large structural blocks of \( {\text{TiO}}^{{8 - }}_{6} \) octrahedra corner-shared with lithium and lanthanum in the voids in between. Due to the different valence of lanthanum and lithium, about 10–14% of unoccupied A-sites are formed which allows the lithium ions to move by a vacancy mechanism. However, the lithium ion conductivity becomes exceeded by electronic conduction as soon as the lithium activity reaches sufficiently high levels, i.e., the oxygen activity is sufficiently low to generate a valence change from Ti4+ to Ti3+. This happens at around 1.7 V vs. elemental Li at room temperature which corresponds to the oxygen activity when titania becomes reduced. The large increase in the number of electrons is visible when a large shoulder in the coulometric titration curve occurs which indicates a very large broadening of the non-stoichiometry [7]. This is typical for good electronic conductors, as observed, e.g., in the case of alloys, in contrast to ionic conductors with very narrow ranges of stoichiometry [8]. Accordingly, LLTO is only practically applicable as a solid electrolyte at low lithium activities and may be used as an electrode at higher lithium activities. As a result, suitable solid lithium electrolytes should consist of other cations that may not be readily reduced as is the case both for LiAlCl4 and LLTO.

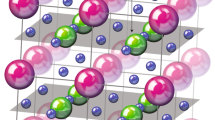

Very recently, systematic research has led to the discovery that some garnets have extraordinarily high lithium ion conductivities and are stable against reaction with elemental lithium. Furthermore, these compounds have decomposition voltages of >6 V. The nominal chemical composition of the garnet-like structured compounds is Li5La3M2O12 (M=Nb, Ta) [9]. Partial substitution of the lanthanum by alkaline earth elements with a lower valency results in the composition Li6ALa2M2O12 (A=Ca, Sr, Ba; M=Nb, Ta) [10]. The member Li6BaLa2Ta2O12 provides the highest conductivity among all lithium ion conductors known so far with a conductivity of 4×10−5 S/cm and an activation energy of 0.40 eV [11]. In addition, the tantalum compounds were found to be stable against chemical reaction with molten elemental lithium [12]. The material is also stable with LiCoO2 as cathode material [12]. The high ionic conductivity is due to the structural formation of \( {\text{LiO}}^{{11 - }}_{6} \)- and \( {\text{TaO}}^{{7 - }}_{6} \) (or \( {\text{NbO}}^{{7 - }}_{6} \))- octrahedra. The \( {\text{MO}}^{{7 - }}_{6} \)- octahedron is surrounded by six \( {\text{LiO}}^{{11 - }}_{6} \)- octahedra and two lithium-site vacancies cubically. Structurally equivalent sites are randomly occupied by the lithium. Fast lithium ion conduction paths have been made visible by bond valence analysis [13].

A lot of attention has also been paid to solid ionic conductors for other mobile ions, though progress has been less spectacular. Many doping and substitution experiments have been performed on La0.8Sr0.2Ga0.8Mg0.1O3−x (LSGM) both with regard to the A- and B-lattice sites of the perovskite. However, none of the compounds prepared so far exceeds the ionic conductivity of the original composition [14]. As in the case of other oxide ion conductors, a maximum conductivity is observed at about 7% oxygen vacancies.

Accidentally, the search for better solid oxide ion conductors has resulted in the observation of likely proton conduction in oxides without the simultaneous presence of structural water as that is the case for barium cerates. It has been discovered that the layered perovskite (Dion–Jacobson) phase ACa2Nb3O10 (A=K, Rb, Cs) shows an increasing conductivity in hydrogen atmospheres at low temperatures [15]. The proton conductivity has been concluded from the observation of the expected Nernst voltage when the material was employed in hydrogen-air concentration cells.

Another finding has been the increase in oxide ion conduction in an intermediate oxygen partial pressure range of a semi-conducting oxide which undergoes a p-n-transition as a function of the oxygen content. This has been the case for SrSnO3 in which up to 30 mol% of SrFeO3 are dissolved [16]. The ionic conductivity has been improved by employing pellets of the material in fuel cells. Voltages in the range of 800 mV have been observed at 750 °C. These Sr(Sn,Fe)O3 compounds, commonly being considered as semi-conductors, are an example that ionic conductivity is often not observed because of the strong dependence of the electronic conductivity on the stoichiometry.

The last example is a good opportunity for pointing out that ionic conductors may also be considered as poor electronic conductors [17]. This has to be the case over a wide range of activities of the electro-active component by which the concentration of electronic charge carriers changes over many orders of magnitude depending on the type of disorder [18]. In order to keep the electronic conductivity smaller than the ionic conductivity, it is, accordingly, necessary that the mobility of the electronic charge carriers is very small, i.e., a trapping mechanism holds. Otherwise, in the case of fast electrons, the electronic conductivity would readily become dominant when the material is employed in galvanic cells with electrodes of different activities of the electroactive component. For the same reason, impurities would have to be at a very low level in the case of fast electrons. This is fortunately not the case for solid ionic conductors which generally tolerate very large concentrations of impurities. Independence of the presence of impurities is certainly an advantage over semiconductor electronics.

Device considerations

All applications require a series of phases in contact with each other. A major challenge is to achieve chemical stability at the interfaces in view of the quite different materials properties. In addition, interfaces provide major barriers for the transport of the ions, especially when two solids are joined. Only a few contact points may exist and the situation is even worse in the case of materials with different expansion coefficients. Ductility of at least one of the materials is favorable; however, that is commonly only the case for metals, such as platinum, on top of ceramic electrolytes, e.g., zirconia employed in the lambda-probe.

Extensive materials research and new strategies are required to overcome the problems. One approach to simplifying the galvanic cell is the Kiel SEA concept for fuel and water electrolysis cells [19]. This approach takes advantage of the fact that the electronic conductivity varies with the oxygen partial pressure as described above for Sr(Sn,Fe)O3. If the material is appropriately doped by an acceptor it may become predominantly p-conducting in ambient air and appropriately doped by a donor it may become predominantly n-conducting at low oxygen partial pressures of the H2/H2O equilibrium. Separate electrodes made of different chemically reacting materials may be avoided. The oxide ions or protons may enter the surface everywhere instead of being restricted to the one dimensional triple phase line of metal electrodes. A single material plays the role of electrolyte and electrodes under the given conditions of the oxygen partial pressures at both sides. Only a single element arrangement (SEA) is required which simplifies production and provides chemical stability and there is no need for the ions to pass solid–solid interfaces.

Similarly, in reverse mode, a single element arrangement may be employed not for the generation of a cell voltage but for applying a voltage to a single material in order to generate a local variation of the composition, e.g., in order to generate colorations in single-element electrochromic cells [20]. This not only holds for predominantly ionically conducting but also for electronically conducting materials as long as chemical equilibria are established between the electrons and at least one kind of ionic species. Any voltage applied to any material generates a difference in the Fermi level or electrochemical potential \(\eta _{{e^{ - } }}\) at the two electrodes [21]:

l and r stand for the left and right hand electrode. The equilibrium between the neutral mobile component A, ions A z+ and electrons e −,

allows us to rewrite Eq. 5 and to express the cell voltage by the chemical and electrochemical potentials of the component A and ions Az+

When inert electrodes which do not allow the transport of ions A z+ are used, the difference in the electrochemical potentials of the ions A z+ has to disappear, since the gradient of the electrochemical potential of the ions is the driving force and no ions are passed anymore. This results in

which is Nernst’s law. This relation is generally applied to ionic conductors but holds also for mixed conductors with inert electrodes.

Accordingly, the local composition may be changed simply by a voltage and only a single layer has to be used instead of three layers of conventional electochromic cells, which simplifies the production especially in the case of application of thin film electrochromic cells for windows. Successfully developed materials of this kind are Li x La y(2−x)/3Fe z Ti1−y O3 and Li0.3Sr0.6Ta0.5Ti0.5O3 [22, 23]. The coloration of these materials has been demonstrated.

The SEA electrochromic cell is simple and avoids any chemical reaction at the interfaces as well as avoiding mechanical disruptions because of different expansion coefficients.

Conclusions

A few examples have been given which illustrate the major progress presently being achieved in the development of ionic devices. New materials and new approaches in the construction of solid state galvanic cells have resulted in major progress in recent years. Many more efforts are necessary in fundamental research, however. It is unlikely that the present materials and devices will be eventually employed in commercially successful applications. We need a lot of staying power to achieve the important ionic applications. Once appropriate materials have been discovered, engineering of the devices will be rather straightforward. Many new materials and technologies will arise in the future since there is no alternative to electrochemical devices in view of their efficiency, convenience and environmental neutrality.

References

Weppner W (1995) Ionics 1:1–4

Weppner W (2003) Ionics 9:444–464

Tsagarakis ED, Weppner W (2001) In: Wachsman D, Weppner W, Traversa E, Liu M, Vanysek P, Yamazoe N (eds) Solid State Ionic Devices: Ceramic Sensors. Proc Vol 200-32. The Electrochem Soc, Pennington, New Jersey, pp 297

Weppner W (2005) In: Linderoth S, Smith A, Bonanos N, Hagen A, Mikkelsen L, Kammer K, Lybye D, Hendriksen P v, Poulsen FW, Mogensen M, Wang WG (eds) Solid State Electrochemistry. Proc 26th Risoe Intl Sympos on Mater Sci. Risoe Natl Lab Roskilde, DK, pp 87

Weppner W, Huggins RA (1979) J Electrochem Soc 124:35–38

Hu Y-W, Raistrick ID, Huggins RA (1977) J Electrochem Soc 124:1240

Klingler M, Chu WF, Weppner W (1977) Ionics 3:289–291

Weppner W (2000) In: Chowdari BVR, Wang WJ (eds) Solid State Ionics: Materials and Devices. World Scientific, Singapore, p 3–12

Thangadurai V, Kaack H, Weppner W (2003) J Am Ceram Soc 86:437–440

Thangadurai V, Weppner W (2005) J Am Ceram Soc 88:411–418

Thangadurai V, Weppner W (2003) Ionics 9:308–314

Thangadurai V, Weppner W (2005) J Power Sources 142:339–344

Thangadurai V, Adams S, Weppner W (2004) Chem Mater 16:2998–3006

Ishihara T, Matsuda H, Takida Y (1994) J Am Chem Soc 116:3801, Ishihara T, Furutani H, Yamada T, Takita Y (1997) Ionics 3:209–213

Thangadurai V, Weppner W (2001) J Mater Chem 11:636–639

Thangadurai V, Schmid-Beurmann P, Weppner W (2002) Mater Res Bull 37:599–604

Weppner W (2000) In: Julien C, Stoynov Z (eds) Materials for Lithium-Ion Batteries. Kluwer, Dordrecht, NL, p 431–450

Rickert H (1982) Electrochemistry of Solids. Springer, Berlin Heidelberg New York

Weppner W (1998) Ionics 4:422–434

Thangadurai V, Weppner W (2003) In: Rougier A, Rank D, Nazri GA (eds) Proc Sympos Electrochromic Materials and Applications, PV 2003-17. The Electrochem Soc, Pennington, New Jersey, p 231–242

Weppner W (1993) In: Scrosati B, Magistris A, Mari CM, Mariotto G (eds) Fast Ion Transport in Solids. Kluwer, Dordrecht, p 9–39

Klingler M, Chu WF, Weppner W (1995) Ionics 1:251–256

Klingler M (1998) PhD thesis. University of Kiel, Faculty of Engineering

Acknowledgement

The authors wish to thank all co-workers of the Chair for Sensors and Solid State Ionics at the University of Kiel for their contributions to the research mentioned above.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Chu, WF., Thangadurai, V. & Weppner, W. Ionics—a key technology for our energy and environmental needs on the rise. Ionics 12, 1–6 (2006). https://doi.org/10.1007/s11581-006-0015-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-006-0015-5