Abstract

Today, consumer demand for food safety, especially in fried foods, is increasing. In the first place, it is demanded to reduce the amount of food toxins, in particular toxins resulting from the thermal process such as acrylamide. This study aimed to examine the effect of different technological treatments on the optimisation of minimum acrylamide and maximum colour properties by applying the Taguchi approach in the production of chips. In this study, design of experiments, signal-to-noise (S/N) ratio, analysis of variance, and regression analysis methods were used to optimise the minimum acrylamide and redness (a*), maximum brightness (L*), and yellowness (b*) values. The optimal parameters for acrylamide were found to be 90 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time. The optimal parameters for colour analysis were determined as 30 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time. Analysis of variance showed that frying temperature and time had a significant (p < 0.05) effect on the results. It was determined that a decrease in frying temperature and time led to a decrease in the amount of acrylamide and redness and an increase in brightness and yellowness. According to the results of the analysis of variance, the most effective technological treatments were frying temperature with effect rates of 37.45% and 60.26% for acrylamide and L* values, respectively, and frying time with effect rates of 40.50% and 44.19% for a* and b* values, respectively. As a result of the study, through the Taguchi method, while quality features in chips were preserved, the amount of acrylamide was reduced.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potatoes, produced in large amounts across the world, are a source of affordable energy and quality proteins (Babazadeh et al. 2016). Potato chips are an industrially produced snack product that is enjoyed by a wide audience around the world. As a result of high consumption, potato chips have become a part of our daily eating habits. Depending on the processing methods of food, many changes occur in the product structure, and as a result of these changes, new compounds are formed in the structure of the food. During the potato processing, acrylamide, one of the undesirable compounds due to its negative effects on health, is formed. Acrylamide is a monomer that is used in polyacrylamide synthesis. The monomer structure can be dissolved in water, ethanol, methanol, dimethyl ether, and acetone, while it cannot dissolve in heptane and benzene. It is a white, odourless, and weakly acidic chemical compound with a crystal structure (Eriksson and Karlsson 2006). Water purification, cosmetics, plastic, petroleum, paper, paint, and textile industries are among the areas where acrylamide is frequently used. Acrylamide is also a component of tobacco smoke (Scherer et al. 2007). The chemical property of acrylamide as a compound was first discovered by Christian Moureau in Germany in 1893 (Boettcher et al. 2005). Previously known information about acrylamide was limited to people’s exposure to acrylamide in drinking water and dam-tunnel construction works (Vainio 2003). With the research conducted by Stockholm University and the Swedish National Food Agency (SNFA) and reports presented, it was noted that acrylamide could also be formed in foods (Tareke et al. 2000). On April 24, 2002, the Swedish National Food Agency brought to the agenda that acrylamide was formed in foods rich in starch that are produced at high temperatures (Vainio 2003). The accuracy of these data was confirmed by research conducted in several countries such as the Netherlands, Norway, Switzerland, the United Kingdom, and the USA (Konings et al. 2003). Acrylamide has been included in the 2A group (Probably Carcinogenic to Humans) by the International Agency for Research on Cancer (IARC) (McDonald 1995). Some animal experiments have been conducted to determine the effect of acrylamide. In laboratory experiments on rats, acrylamide was shown to cause tumours in the lung, skin, brain, mammary gland, thyroid gland, and uterus (Maronpot et al. 2015). When adult rats were exposed to acrylamide, there was a significant decrease in glutathione (GSH) and total antioxidant levels in the liver (Elhelaly et al. 2019). It has been proven that acrylamide harms the nervous system in animals and that it has a negative impact on muscles and hormone glands when exposed to high dosages (Sharp 2003). As the level of acrylamide taken through nutrition in humans is below 500–1,000 times the level at which it produces side effects, no definite information has been found yet regarding the health risks that may be caused by acrylamide at these levels in the long term. The World Health Organization (WHO) and Food and Agriculture Organization (FAO) have reported that foods that are cooked and processed at high temperatures may contain high levels of acrylamide and that this may constitute a risk to human health (Kaplan et al. 2009). The Joint (FAO/WHO) Expert Committee for Food Additives (JECFA) has recommended that food producers reduce the level of acrylamide that may form in foods (WHO 2002).

Studies have been initiated in scientific circles around the world to determine the negative effects of food-related acrylamide on human health (Perera et al. 2021). As the food production procedures of each country are different, most of these studies remained limited to the countries themselves. However, studies have shown that French fries and potato chips contain high levels of acrylamide (Pedreschi et al. 2005). It has been reported that acrylamide is formed in foods processed at high temperatures (≥ 120 °C) and that the increase in temperature and time parameters increases the formation of acrylamide (Konings et al. 2003). It has also been reported that it is usually formed as a result of the reaction of the specific amino acid with reduced sugar during the Maillard reaction (browning formation) at high temperatures (Mottram et al. 2002). It is commonly formed during frying in oil, baking in the oven, and grilling and roasting processes. Acrylamide is mostly seen in foods with high starch content, such as potato chips, French fries, bread, and processed grains (Pedreschi et al. 2005). While acrylamide formation was not observed in foods without heat treatment, very low or undetectable values were observed in foods processed at low temperatures (Rosén and Hellenäs 2002) or with sous vide cooking technique (Ates and Unal 2023).

Among various physical properties of foods and fried products, colour is recognised as a significant visual feature in the perceived quality of and preference of a product (Rubilar et al. 2012). It has been reported that the specific colour of a fried product depends on the absorption of oil and the browning of the reduced sugar and protein sources (Baixauli et al. 2002). Therefore, colour is a very important criterion for potato chips (Rubilar et al. 2012).

In potato chip production, potatoes are peeled and sliced at a certain thickness. Potato slices are first washed at a certain temperature, and the water on the slices is removed using air. Finally, the potato slices are exposed to the frying process at a certain temperature and time. When the steps of this process are examined, it has been reported that the prewash process (Rytel et al. 2018) and temperature–time parameters applied in the frying process (Friedman and Dao 1992) are the most significant technological parameters that might affect the quality properties of the potato slices. Optimisation of the technological parameters is important in terms of controlling quality, productivity, and costs. Consumers’ search for healthy products requires the optimisation of frying conditions to minimise the harmful compounds occurring during the frying process (Di-Scala and Crapiste 2008). In parallel with this, a strategic design of experiments that exposes all process conditions to various levels of design parameters is needed. The Taguchi experiment design that the Japanese adopted to improve the quality of the products they produce has recently been successfully used by some researchers (Naik et al. 2017; Cortbaoui and Ngadi 2018; Hussein et al. 2021; Sruthi and Shanmugasundaram 2022; Yusuff and Onibonoje 2023). The main purpose of this technique is to optimise complicated processes to produce high-quality products at a significantly lower cost (Davis and John 2018).

Although the effects of technological treatments on potato chips have been evaluated separately, no study has yet been conducted in the literature on the optimisation of technological treatments with the Taguchi approach. Hence, the present study aimed to investigate the effects of different technological treatments in the production process on colour and acrylamide formation in potato chips and to optimise these parameters by using the Taguchi method.

Materials and Methods

Materials

In chips production, Opal variety potatoes 37–85 mm in size (Solanum tuberosum L.) were used, and these potatoes were supplied from Derpat Seed Industry and Trade Inc. (Hatay, Turkey). Palm olein procured from Cargill Foods (Turkey) was used to fry the chips.

Preparation and Processing of the Samples

The potatoes were first peeled in a peeling machine (Florigo, England), and then, they were sliced in a slicing machine (Bigtem, Turkey) at a thickness of 2.60 mm. The slice thickness of potato slices was measured using a digital calliper (Mitutoyo ABS ID-C547, Japan). The potato slices were exposed to the washing process at three different temperatures (30 °C, 60 °C, and 90 °C) for 90 s. After peeling, the water on the potato slices was dried, and the potato slices were fried at three different temperatures (175 °C, 180 °C, and 185 °C) and for three different times (175 s, 185 s, and 195 s) by using a frying system (Rosenqvist CF10, Sweden). Fresh oil was used for every batch in the frying process. The washing water temperatures and frying oil temperatures of the potato slices were recorded with a digital thermometer (Testo 110, Germany). Once cooled after frying, the potato slices were put into polypropylene-based packages using a packaging device (Ishida Astro S 103 L, Japan) with a modified atmosphere.

The technological parameter values explained above were chosen based on production values used in the potato chip production industry. The technological parameters used and their levels are presented in Table 1. Samples were taken from each product group and acrylamide content and colour values were analysed.

Methods

Moisture content: Moisture content of potato chips was measured by drying the samples in a convection oven (Binder ED 53, Germany) until constant mass at 105 °C (AOAC 2000).

Absorbed oil determination: The percentage of absorbed oil by potato chips after frying was determined using the Soxhlet extraction method (AOAC 2000). After frying, the samples were dried, crushed, and placed in a thick thimble of filter paper. The oil amount of these samples was determined by the oil extraction method on Soxhlet equipment (Behr Labor ES 2 + 2, Germany).

Colour measurements: Colours of the potato chips were determined according to the CIE (International Commission on Illumination) coordinate system. For colour measurement, each sample was homogenised and put into the chamber, and colours were measured in an environment isolated from natural light to catch the image using a chromameter device (Konika-Minolta CM-5, Osaka, Japan). L*, a*, and b* values were determined according to the CIE colour coordinate system. Here, L* value provides information about brightness, a* value about redness, and b* value about yellowness (Pedreschi et al. 2006).

Acrylamide analysis: The acrylamide amount was determined using the Agilent 1290 model ultra-high-performance fluid chromatography system (Agilent Technologies, USA) connected to a triple quadrupole mass spectrometer system equipped with electrospray ionisation (ESI) (6460 Agilent Technologies, USA). Analytic separation was made in water using pure water containing 0.1% formic acid (Solvent A) and acetonitrile (Solvent B) mixture in Agilent ZORBAX RRHD C18 column (50 × 2.1 mm, particle size 1.8 µm).

For gradient conditions, the gradual programme below was performed: The column was balanced at 2 min 5% B before the injection; it was kept at 0 min 95% A 5% and 3 min 85% A 15% B. The column temperature was 30 °C, the flow rate was 0.3 ml/min, and the injection volume was 1 µl. To measure acrylamide, the mass spectrometer (MS) multiple reaction monitoring (MRM) mode was used. ESI was operated at a 2-kV capillary voltage in the positive ion mode. The source gas temperature was set at 300 °C, and the dissolution temperature was set at 350 °C. Nitrogen was used as nebuliser gas (flow rate 12 l/min) and collision gas (flow rate 12 L7Min) at 35 psi pressure (Henao et al. 2021).

Statistical analysis: Based on the data obtained from experimental studies, it was aimed to determine the optimum slice washing temperature (A), frying temperature (B), and frying time (C) to reach the minimum amount of acrylamide and desired colour properties. The Taguchi method was employed to determine these technological parameters. As a statistical method, the Taguchi method is a method developed against factors that cannot be controlled and lead to variation in experimental studies. This method minimises losses resulting from trial and error (Akgun 2022). In the Taguchi method, design of experiments theory and orthogonal arrays are used to examine numerous variables (Cortbaoui and Ngadi 2018). For Taguchi design and subsequent analysis, the software Minitab® 19.1 was used.

Taguchi Design of Experiments

Since all interaction effects between factors were tried to be observed in the study, the L27 (33) array was chosen by the programme. That is, the appropriate orthogonal array for the experiment was determined by the software. This means that 27 experiments (Table 2) had to be conducted with different combinations of factors to examine main effects and interactions (Koyuncu and Duran 2024). To obtain the optimum technological parameter, slice washing temperature (A), frying temperature (B), and frying time (C) were used as input parameters, while the amount of acrylamide and colour values were employed as output parameters. In addition, the relationship between the independent experimental variables (slice washing temperature, frying temperature, and frying time) and the dependent variables (acrylamide and colour values) was identified with S/N ratio analysis, analysis of variance (ANOVA), and regression analyses. In the calculation of S/N ratios, the formulas in Eqs. 1 and 2 were used (Hussein et al. 2021). For acrylamide and a* outcomes, the smallest the best approach (1) was adopted, and for L* and b* outcomes, the largest best (2) approach was used.

Here, n is the number of experiments, and yi is the response in each experiment.

Results

In the study, acrylamide and colour analyses were performed in three technological replicates. Three samples were taken from each technological process, and experimental analyses were performed. For statistical analyses, the average of triplicates was taken, and the results for acrylamide are presented in Table 3, and the results for L*, a*, and b* values are presented in Table 4.

As seen in Table 3, the highest amount of acrylamide is 1400 mg/kg. By using different technological treatments, this amount was reduced to 2 mg/kg (experiment 19).

In potato chips, redness (a*) is desired to be low, while brightness (L*) is desired to be high (Pedreschi 2012). As seen in Table 4, in the colour analyses of the potato chips, the highest L* value was obtained in experiment 1 with 70.35, the lowest a* value was obtained in experiment 10 with 5.26, and the highest b* value was obtained in experiment 1 with 48.86.

S/N Ratio Analysis

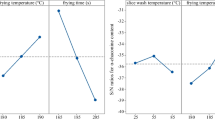

A statistical calculation method known as the S/N ratio was used to interpret the values obtained in the study. In this method, S indicates the real value generated by the system, and N shows the factors affecting the experiment result. All values described as N are qualified as all variables that lead to deviations from the targeted result. In the S/N ratios calculated by using the experimental data, the highest points are the targeted values (Yusuff and Onibonoje 2023). The level values of slice washing temperature (A), frying temperature (B), and frying time (C) technological parameters for acrylamide are presented in visual form in Fig. 1.

Acrylamide formation in foods is closely associated with the Maillard reaction, known as the non-enzymatic browning reaction (Lineback et al. 2012). There are numerous theories regarding acrylamide formation in heat-treated foods. The common opinion is that acrylamide is formed as a result of the reaction of asparagine, which is an amino acid, with simple (reducing) sugars (Stadler et al. 2002). The results in Fig. 1 show that an increase in slice washing temperature leads to a decrease at a very low level in the acrylamide value. On the other hand, it is seen that a significant decrease can be achieved in acrylamide values as a result of a reduction in frying temperature and a decrease in frying time.

Colour development in fried potatoes starts only when a sufficient amount of drying is achieved in potato slices and varies depending on the drying speed and heat transfer coefficient in the different phases of frying (Pedreschi 2012). In addition to the high frying temperature and time, the reduced sugar content on the potato surface leads to the Maillard (non-enzymatic) browning reaction (Lineback et al. 2012).

According to the results shown in Fig. 2a, the reduction in slice washing temperature led to a minimal increase in the L* value. In contrast, when frying temperature and frying time were decreased, a significant increase was seen in L* values. According to the results presented in Fig. 2b, while reducing slice washing temperature caused a minimal decrease in a* value, decreasing frying temperature and frying time led to a significant decrease in a* value. Finally, the results in Fig. 2c indicate that decreasing slice washing temperature did not lead to a significant increase in b* value, whereas reducing frying temperature and frying time caused a significant increase in b* values.

Analysis of Variance (ANOVA)

Practitioners with the Taguchi method mostly use analysis of variance (ANOVA) to confirm the factors affecting the average response. An analysis of variance was performed to determine the impact values of technological parameters (slice washing temperature, frying temperature, and frying time) on acrylamide, L*, a*, and b* values. The results of the analysis are presented in Table 5. The lowest p-values (p ≤ 0.05) indicate that the factors have a significant impact on the responses (Sruthi and Shanmugasundaram 2022).

According to the results of the variance analysis, frying temperature, frying time, and slice washing temperature had a significant effect on the acrylamide amount (p < 0.05). Among the technological applications, the parameter that had the highest effect (37.45%) was found to be the frying temperature. Slice washing temperature displayed the least effect.

According to Table 5, frying temperature, frying time, and slice washing temperature all exhibited a significant effect on the L* value (p < 0.05). While the lowest effect was shown by slice washing temperature, frying temperature had the highest effect rate on brightness (L*) with an effect rate of 60.26%. According to the results of the variance analysis, frying temperature, frying time, and slice washing temperature all affected the redness (a*) value. The least effect was observed for the slice wash temperature, while the most effective parameter, frying time, had an effect rate of 40.50% on the a* value. As seen in Table 5, both frying temperature and frying time significantly affected the b* value (p < 0.05). Frying time was found to be the parameter with the highest effect (44.19%). Slice washing temperature did not have a significant effect on the yellowness (b*) value.

Discussion of Experimental Results

According to ANOVA results (Table 5), the most effective two parameters in the process stage on acrylamide, L*, a*, and b* values were frying temperature and frying time. The surface area graphs showing the effect of frying temperature and time in potato chip samples on acrylamide, L*, a*, and b* values are presented in Fig. 3.

As seen in Fig. 3a, along with the decrease in frying temperature or time, acrylamide amount significantly decreased (p < 0.05). The lowest acrylamide amount was measured with a frying temperature of 175 °C and a frying time of 175 s. This is a result of enzymatic browning reactions that depend on the oil temperature. It was the frying temperature that affected the amount of acrylamide the most (Table 5). In a study conducted, it was observed that the amount of acrylamide increased in parallel with the increase in frying temperature in potatoes fried at 160 °C, 180 °C, and 210 °C (Lu et al. 2016). In the study they conducted, Gokmen and Şenyuva (2006) reported that frying temperature had a greater effect on acrylamide formation compared to frying time. They observed that when frying time was kept constant, there was an increase in the amount of acrylamide as a result of an increase in frying temperature. It was also observed that when the frying temperature was kept constant, the amount of acrylamide increased along with the increase in the frying time (Matthӓus et al. 2004). In the present study, three different frying times (175, 185, and 195 s) were applied. It was seen that frying time had an effect ratio of 28.82% on the formation of acrylamide (Table 5). In a study, it was reported that temperature and time had a great impact on acrylamide formation during the frying process of potatoes and that high temperature–short time displayed more effect compared to low temperature–long time (Zhang and Zhang 2007). In a study conducted, acrylamide amount showed a fast increase in potatoes baked at 200 °C. In addition, it was observed that as the time increased, the acrylamide amount increased, albeit at a low speed (Rydberg et al. 2003).

Figure 3b shows the increase in L* value with the decrease in temperature. The highest L* value was measured with the frying temperature at 175 °C. The decrease in L* value means a decrease in the brightness of potato chips and the darkening of their colour. It has been reported that the darkening of the colour of the potato chips was due to the non-enzymatic browning reaction as a result of the increase in the frying temperature applied to the potato slices (Oztop et al. 2007). In Fig. 3c, a decrease in the a* value was observed as the frying temperature and time decreased. The lowest a* value was obtained with a frying temperature of 175 °C and a frying time of 175 s. In the study they conducted on potato slices, Pedreschi et al. (2006) determined that the a* value significantly increased due to browning reactions occurring during frying and that the higher the frying temperature was, the faster the slices became red. As seen in Fig. 3d, with the decrease in temperature, the b* value increased as well. The highest b* value was again obtained with the frying temperature of 175 °C and the frying time of 175 s. In the study they conducted on potato slices, Pedreschi et al. (2006) found that the b* value increased with the increase in the frying time and that it displayed a faster tendency to increase with the increase in the frying temperature.

In conclusion, in technological treatments, as slice washing temperature increases, the amount of acrylamide decreases, the brightness rate of the product (L*) decreases, the rate of redness (a*) increases, and the rate of yellowness (b*) decreases. With the decrease in frying temperature and time, the amount of acrylamide in potato chips decreases, the rate of brightness increases, the rate of redness decreases, and the rate of yellowness increases.

S/N responses for acrylamide, L*, a*, and b* values are presented in Table 6. In determining the parameters of optimum slice washing temperature, frying temperature, and frying time, the values with the highest S/N ratio are considered. Accordingly, the optimum technological treatments for the lowest acrylamide amount were determined to be 90 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time (A3B1C1). The values of slice washing temperature, frying temperature, and frying time parameters for colour analysis values (L*, a*, b*) are displayed separately in Fig. 2. In Table 6, the highest point of the S/N ratio for L*, a*, and b* values shows the optimum level. Accordingly, the optimum technological treatments for colour were determined to be 30 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time (A1B1C1).

While the optimum process conditions for acrylamide were A3B1C1, they were A1B1C1 for L*, a*, and b* values (Table 7). It was determined that the two most effective parameters, frying temperature (B) and frying time (C), had the same optimum technological treatments for acrylamide and colour analysis values (175 °C and 175 s). It was also found that the lowest temperature was the most ideal temperature for the desired minimum acrylamide content and desired colour analysis values. Similarly, it was observed that the shortest frying time could be used to achieve the minimum acrylamide amount and desired colour analysis values. In conclusion, with low frying temperatures and times, both the desired minimum acrylamide levels and the desired colour quality features for potato chips are ensured.

Potato chip samples were taken from the optimum technological parameters and subjected to chemical analyses. According to the results of the analyses performed, the percentage components of the chips were found to be as summarized in Table 8. When production was made according to the determined process values, it was seen that the chemical analysis values in the potato chips were within the appropriate range according to the potato chips standard (TS 3628/T1, 2017).

Multiple Regression Analysis

The multiple regression analysis attempts to model the relationship between two or more independent variables and a dependent variable by fitting a linear equation to observed data. In food product development, the application of regression analysis generally leads to insights into possible mechanisms of change in the foods, which in turn leads to new process development. Therefore, as a predictive application, multiple regression analysis helps to explore the potential for improving existing processes without performing numerous, often expensive experiments.

The R2 value in this method is an important indicator of the prediction performance in the relationship between variables. The fact that the R2 value, which is between 0 and 100%, is close to 100% indicates that the relationship between the dependent (acrylamide amount and colour values) and independent (washing temperature, frying temperature, and time) variables is strongly compatible. Table 9 contains the multiple linear regression equations created with experimental data regarding the outcomes of the study. Cibik and Duran (2023) reported that error values should be less than 20% for reliable statistical analysis. As a result, the fact that multiple linear regression equations have a high coefficient of determination (R2) between the predicted data and the experimental data indicates that the regression shows successful results.

Conclusion

Acrylamide found in processed potato products is considered an important component due to its negative effects on human health. Therefore, it is desired that the amount of acrylamide in fried products such as French fries and potato chips be as low as possible. There are too many complex technological applications in potato chip production. In our study, the optimum process interventions achieved reduced the amount of acrylamide formed in potato chips and improved their colour properties. For this purpose, it was analysed statistically by applying Taguchi and ANOVA methods. As a result of the analyses, the optimum technological parameters were obtained to achieve the minimum acrylamide amount and the desired colour quality features. The analyses performed showed that the optimum technological parameters for acrylamide were 90 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time (A3B1C1), and these parameters for colour quality features (L*, a*, b* values) were 30 °C slice washing temperature, 175 °C frying temperature, and 175 s frying time (A1B1C1). According to the results of the variance analysis, the frying temperature was found to have the highest effect on acrylamide and brightness values (L*) with effect rates of 37.45% and 60.26%, respectively. The highest effect on redness (a*) and yellowness (b*) was shown by the frying time at 40.50% and 44.19%, respectively. As a result, the A2B1C1 parameter (experiment no. 10) showed that we should produce at optimum values while preserving both health and quality features in the production of potato chips. The Taguchi method enabled us to obtain the desired features in our products without applying an additional process or making an additional financial investment. The results of this study will provide invaluable information to small or large-scale food producers and will serve as an operational guide for potato chip production.

References

Akgun M (2022) Optimization of process parameters affecting cutting force, power consumption and surface roughness using Taguchi-based gray relational analysis in turning AISI 1040 steel. Surf Rev Lett 29(03):2250029. https://doi.org/10.1142/S0218625X22500299

AOAC (2000) Official methods of analysis of AOAC International. Gaithersburg, USA: AOAC International

Ates E, Unal K (2023) The effects of deep-frying, microwave, oven and sous vide cooking on the acrylamide formation of gluten-free chicken nuggets. International Journal of Gastronomy and Food Science 31:100666. https://doi.org/10.1016/j.ijgfs.2023.100666

Babazadeh S, Moghaddam PA, Sabatyan A, Sharifian F (2016) Classification of potato tubers based on solanine toxicant using laser-induced light backscattering imaging. Comput Electron Agric 129:1–8. https://doi.org/10.1016/j.compag.2016.09.009

Baixauli R, Salvador A, Fiszman SM, Calvo C (2002) Effect of oil degradation during frying on the color of fried, battered squid rings. J Am Oil Chem Soc 79(11):1127–1131. https://doi.org/10.1007/s11746-002-0615-2

Boettcher MI, Schettgen T, Kütting B, Pischetsrieder M, Angerer J (2005) Mercapturic acids of acrylamide and glycidamide as biomarkers of the internal exposure to acrylamide in the general population. Mutat Res 580:167–176. https://doi.org/10.1016/j.mrgentox.2004.11.010

Cibik S, Duran A (2023) Analysis and optimization of the effect of process parameters of silver anode technique on Pseudomonas aeruginosa in raw milk. Braz Arch Biol Technol 66:e23230099. https://doi.org/10.1590/1678-4324-2023230099

Cortbaoui PE, Ngadi MO (2018) Optimization of postharvest handling of eggplant using the taguchi technique. Food Science and Quality Management 75:15–23

Davis R, John P (2018) Application of Taguchi-based design of experiments for industrial chemical processes. InTech, 137–155. https://doi.org/10.5772/intechopen.69501

Di-Scala K, Crapiste G (2008) Drying kinetics and quality changes during drying of red pepper. LWT- Food Sci Technol 41(5):789–795. https://doi.org/10.1016/j.lwt.2007.06.007

Elhelaly AE, AlBasher G, Alfarraj S, Almeer R, Bahbah EI, Fouda MM, Abdel-Daim MM (2019) Protective effects of hesperidin and diosmin against acrylamide-induced liver, kidney, and brain oxidative damage in rats. Environ Sci Pollut Res 26:35151–35162. https://doi.org/10.1007/s11356-019-06660-3

Eriksson S, Karlsson P (2006) Alternative extraction techniques for analysis of acrylamide in food: influence of pH and digestive enzymes. LWT-Food Science and Technology 39(4):393–399. https://doi.org/10.1016/j.lwt.2005.03.002

Friedman M, Dao L (1992) Distribution of glycoalkaloids in potato plants and commercial potato products. J Agric Food Chem 40(3):419–423. https://doi.org/10.1021/jf00015a011

Gokmen V, Şenyuva HZ (2006) A simplified approach for the kinetic characterization of acrylamide formation in fructose-asparagine model system. Food Addit Contam 23(4):348–354. https://doi.org/10.1080/02652030500482355

Henao SJ, Petrarca MH, Braga PAC, Arisseto AP (2021) Acrylamide in non-centrifugal sugar from Latin American markets: in-house validation of an LC-MS/MS method, dietary exposure assessment and risk characterisation in Brazil and Colombia. Food Additives & Contaminants: Part A 38(9):1456–1469. https://doi.org/10.1080/19440049.2021.1933205

Hussein JB, Oke MO, Abiona OO, Adebayo Q (2021) Optimization of processing parameters for drying of tomatoes (Solanum lycopersicum L. var) slices using Taguchi technique. Journal of Food Processing and Preservation 45(2):e15149. https://doi.org/10.1111/jfpp.15149

Kaplan O, Kaya G, Ozcan C, Ince M, Yaman M (2009) Acrylamide concentrations in grilled foodstuffs of Turkish kitchen by high performance liquid chromatography-mass spectrometry. Microchem J 93(2):173–179. https://doi.org/10.1016/j.microc.2009.06.006

Konings EJ, Baars AJ, van Klaveren JD, Spanjer MC, Rensen PM, Hiemstra M, Peters PWJ (2003) Acrylamide exposure from foods of the Dutch population and an assessment of the consequent risks. Food Chem Toxicol 41(11):1569–1579. https://doi.org/10.1016/S0278-6915(03)00187-X

Koyuncu D, Duran A (2024) Optimization of process parameters affecting glycoalkaloids in potato chips using the Taguchi method. Potato Res. https://doi.org/10.1007/s11540-023-09689-7

Lineback DR, Coughlin JR, Stadler RH (2012) Acrylamide in foods: a review of the science and future considerations. Annu Rev Food Sci Technol 3:15–35. https://doi.org/10.1146/annurev-food-022811-101114

Lu R, Yang Z, Song H, Zhang Y, Zheng S, Chen Y, Zhou N (2016) The aroma-active compound, acrylamide and ascorbic acid contents of pan-fried potato slices cooked by different temperature and time. J Food Process Preserv 40(2):183–191. https://doi.org/10.1111/jfpp.12595

Maronpot RR, Thoolen RJMM, Hansen B (2015) Two-year carcinogenicity study of acrylamide in Wistar Han rats with in utero exposure. Exp Toxicol Pathol 67(2):189–195. https://doi.org/10.1016/j.etp.2014.11.009

Matthӓus B, Haase NU, Vosmann K (2004) Factors affecting the concentration of acrylamide during deep-fat frying of potatoes. Eur J Lipid Sci Technol 106(11):793–801. https://doi.org/10.1002/ejlt.200400992

McDonald A (1995) Some industrial chemicals: IARC monographs on the evaluation of carcinogenic risks to humans Vol 60. Occupational and Environmental Medicine 52(5):360

Mottram DS, Wedzicha BL, Dodson AT (2002) Acrylamide is formed in the Maillard reaction. Nature 419(6906):448–449. https://doi.org/10.1038/419448a

Naik KM, Bala KL, Srinivas D (2017) Study on optimisation of microwave frying of potato slices. International Journal of Pure and Applied Bioscience 5(4):1207–1218. https://doi.org/10.18782/2320-7051.5545

Oztop MH, Sahin S, Sumnu G (2007) Optimization of microwave frying of potato slices by using Taguchi technique. J Food Eng 79(1):83–91. https://doi.org/10.1016/j.jfoodeng.2006.01.031

Pedreschi F (2012) Frying of potatoes: physical, chemical, and microstructural changes. Drying Technol 30(7):707–725. https://doi.org/10.1080/07373937.2012.663845

Pedreschi F, Moyano P, Kaack K, Granby K (2005) Color changes and acrylamide formation in fried potato slices. Food Res Int 38(1):1–9. https://doi.org/10.1016/j.foodres.2004.07.002

Pedreschi F, León J, Mery D, Moyano P (2006) Development of a computer vision system to measure the color of potato chips. Food Res Int 39(10):1092–1098. https://doi.org/10.1016/j.foodres.2006.03.009

Perera DN, Hewavitharana GG, Navaratne SB (2021) Comprehensive study on the acrylamide content of high thermally processed foods. Biomed Res Int 2021:6258508. https://doi.org/10.1155/2021/6258508

Rosén J, Hellenäs KE (2002) Analysis of acrylamide in cooked foods by liquid chromatography tandem mass spectrometry. Analyst 127(7):880–882. https://doi.org/10.1039/B204938D

Rubilar M, Morales E, Contreras K, Ceballos C, Acevedo F, Villarroel M, Shene C (2012) Development of a soup powder enriched with microencapsulated linseed oil as a source of omega-3 fatty acids. Eur J Lipid Sci Technol 114(4):423–433. https://doi.org/10.1002/ejlt.201100378

Rydberg P, Eriksson S, Tareke E, Karlsson P, Ehrenberg L, Törnqvist M (2003) Investigations of factors that influence the acrylamide content of heated foodstuffs. J Agric Food Chem 51(24):7012–7018. https://doi.org/10.1021/jf034649

Rytel E, Tajner Czopek A, Kita A, Kucharska AZ, Sokół Łętowska A, Hamouz K (2018) Content of anthocyanins and glycoalkaloids in blue-fleshed potatoes and changes in the content of α-solanine and α-chaconine during manufacture of fried and dried products. Int J Food Sci Technol 53:719–727. https://doi.org/10.1111/ijfs.13647

Scherer G, Engl J, Urban M, Gilch G, Janket D, Riedel K (2007) Relationship between machine-derived smoke yields and biomarkers in cigarette smokers in Germany. Regul Toxicol Pharmacol 47(2):171–183. https://doi.org/10.1016/j.yrtph.2006.09.001

Sharp D (2003) Acrylamide in food. The Lancet 361(9355):361–362. https://doi.org/10.1016/S0140-6736(03)12442-7

Sruthi PS, Shanmugasundaram S (2022) Optimization of process parameters by Taguchi method for the development of biosensor for the detection of acrylamide in fried foods. The Pharma Innovation Journal 11(10S):4–10

Stadler RH, Blank I, Varga N, Robert F, Hau J, Guy PA, Riediker S (2002) Acrylamide from Maillard reaction products. Nature 419(6906):449–450. https://doi.org/10.1038/419449a

Tareke E, Rydberg P, Karlsson P, Eriksson S, Törnqvist M (2000) Acrylamide: a cooking carcinogen? Chem Res Toxicol 13(6):517–522. https://doi.org/10.1021/tx9901938

TS 3628/T1 (2017) Potato chips. Turkish Standards Institution. Necatibey Caddesi No.112, Bakanlıklar Ankara Turkey. https://intweb.tse.org.tr/Standard/Standard/Standard.aspx?081118051115108051104119110104055047105102120088111043113104073099084098054103073105043080084081. Accessed 21 Mar 2024

Vainio H (2003) Acrylamide in heat-processed foods–a carcinogen looking for human cancer? Eur J Epidemiol 18:1105–1106. https://doi.org/10.1023/B:EJEP.0000006642.47761.1f

WHO (2002) Health implications of acrylamide in food: report of a joint FAO/WHO consultation, WHO Headquarters, Geneva, Switzerland, 25–27 June 2002. World Health Organization. https://iris.who.int/handle/10665/42563. Accessed 21 Mar 2024

Yusuff AS, Onibonoje MO (2023) Biodiesel production from transesterified yellow grease by ZSM-5 zeolite-supported BaO catalyst: process optimization by Taguchi’s experimental design approach. Materials for Renewable and Sustainable Energy, 1–10. https://doi.org/10.1007/s40243-023-00240-9

Zhang Y, Zhang Y (2007) Formation and reduction of acrylamide in Maillard reaction: a review based on the current state of knowledge. Crit Rev Food Sci Nutr 47(5):521–542. https://doi.org/10.1080/10408390600920070

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koyuncu, D., Duran, A. Optimising Technological Treatments with the Taguchi Approach to Reduce Acrylamide and Improve Colour Properties in Potato Chips. Potato Res. (2024). https://doi.org/10.1007/s11540-024-09719-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11540-024-09719-y