Abstract

This study presents the experimental and statistical examination of different process applications in the production process of the glycoalkaloid level in potato chips to which consumers are exposed. In the first stage, slice washing temperature (swt), frying temperature (ftemp) and frying time (ft) were determined as factors that could affect the glycoalkaloid level. Considering industrial applications, three different slice washing temperatures (25, 55 and 85 °C), frying temperatures (180, 185 and 190 °C) and frying times (165, 185 and 205 s) were evaluated for the study. The L9 orthogonal array of the Taguchi method, which has been successfully applied in the analysis of multiple parameters, was used as the experimental design. Examining the S/N (signal/noise) ratios, the optimum process parameters for minimum content of α-solanine (As) were obtained as 25 °C swt, 190 °C ftemp and 165 s ft. The optimum process parameters were determined for minimum content of α-chaconine (Ac) as 55 °C swt, 190 °C ftemp and 165 s ft. In the analysis results, as swt decreased, ftemp increased, and ft was shortened; the glycoalkaloid ratio in the chips decreased. Analysis of variance results showed the most effective process parameter was the frying time for α-solanine and α-chaconine with 68.2% and 76.5%, respectively. Then comes ftemp with an effectiveness rate of 17.35% and 16.77%. In addition, the regression model developed to estimate the output parameters (As and Ac) yielded successful results with high determination coefficients (R2) of 90.6% and 92.5%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Approximately 350 million tons of potatoes per year are produced in the world. Potato is an important food source, a cheap energy source and a quality protein. Therefore, potatoes and potato products are highly demanded worldwide (Babazadeh et al. 2016). Potato chips are an industrially produced snack product that is highly consumed by many people worldwide. As a result of high consumption, potato chips have become an everyday food in our lives.

However, a food safety concern has been associated with glycoalkaloids in raw potato processing. The formation of toxic glycoalkaloids in potatoes occurs both during farm operations and post-harvest processing (Irungu et al. 2022). Glycoalkaloid levels in potatoes are affected by regional and geographical conditions and vary genetically depending on the potato variety (Friedman 2006). Other factors include growing conditions, storage, transportation, temperature, cutting, sprouting and phytopathogens (Friedman 2006; Nema et al. 2008).

Potato has a high concentration of glycoalkaloids in wounded areas, shoots and the skin of tubers (Lachman et al. 2001). Potato contains several different toxic glycoalkaloids (Korpan et al. 2004). The most well-known of these are α-solanine and α-chaconine. Solanine and chaconine are widely recognized as toxic steroidal glycoalkaloids derived from Solanum tuberosum L. (potato), and their effects are still subject of scientific studies (Sawai et al. 2014). The side chain of α-chaconine is one glucose and two rhamnoses, while the side chain of α-solanine is one glucose, one galactose and one rhamnose sugar (Jiang et al. 2016). The ratio of α-chaconine to α-solanine ranges from 1:2 to 2:6. Since α-chaconine is more toxic than α-solanine, it is convenient to keep these ratios as low as possible (Friedman and Levin 2009). Some researchers have reported that α-solanine and α-chaconine represent total glycoalkaloids (TGA) since α-solanine and α-chaconine comprise 95% of glycoalkaloids (Laus et al. 2017; Liu et al. 2020).

Glycoalkaloids are exceptionally high in potato peel. They appear simultaneously with the greening of the potato peel. The TGA content of potatoes may fluctuate depending on the potato variety or the rate of potato ripening. In some potato varieties, the TGA content increases during storage. Sprouting potatoes also contain high concentrations of α-solanine and α-chaconine. TGA content decreases towards the center of the tuber (Aziz et al. 2012). A normal potato tuber contains an average of 12–20 mg/kg of glycoalkaloids, while a green tuber can contain an average of 250–280 mg/kg of glycoalkaloids. Most commercial potato cultivars contain less than 12 mg/100 g of solanine, which ranges from 2 to 13 mg/100 g (Omayio et al. 2016). Also, solanine levels in potato above 14 mg/100 g exert a bitter taste (Milner et al. 2011).

The World Health Organization has set the upper limit of glycoalkaloids in potato tubers at 20 mg/100 g. In animal studies, solanine is thought to be responsible for food poisoning. In humans, α-solanine toxicity begins with gastrointestinal disturbances, vomiting, diarrhea and abdominal pain (Schrenk et al. 2020). Ahamad et al. (2022) reported that glycoalkaloids cause intestinal discomfort, diarrhea, vomiting, fever, neurological problems and acute toxicity even death in humans and animals. In higher doses, it causes neurological disorders, low blood pressure, fever and rapid or weak pulse (Langkilde et al. 2009). Some indications are that α-solanine and other glycoalkaloids in potatoes may accumulate in body tissues. In particular, it has been found that glycoalkaloids bioaccumulate in the body during daily consumption of foods containing glycoalkaloids, and studies have shown that glycoalkaloids can remain in the body without being excreted even after 24 h from the time they enter the body (Mensinga et al. 2004). Some researchers have applied a number of methods to reduce the glycoalkaloids values in eggplant (Nobuyuki et al. 2006; Wang et al. 2017), potato (Bejarano et al. 2000; Romanucci et al. 2018) and tomato (Itkin et al. 2011; Kazachkova et al. 2021).

The potato is peeled and then sliced at a certain thickness in the production of potato chips. Washing pre-treatment at a certain temperature is applied to the potato slices and after this process, the remaining water on the slices is removed with air. Finally, the potato slices are subjected to frying at a specific temperature and time. Considering these process steps, it has been reported that washing pretreatment (Rytel et al. 2018) and frying temperature-duration parameters (Friedman and Dao 1992) are the most critical process parameters that will affect the quality characteristics of potato slices. The present study aimed to determine the effect of these three different process parameters on the glycoalkaloid (α-solanine, α-chaconine) levels in potato chips. For this purpose, the widely used Taguchi method was used for the optimization of multiple parameters. In addition to determining the optimum parameters, the most influential parameters for reducing the α-solanine and α-chaconine content were investigated.

Material and Methods

Materials

Opal variety potatoes (Solanum tuberosum L.) with a size of 37–85 mm were used in the production of chips, and these potatoes were provided by Derpat Seeds Industry and Trade Inc (Hatay, Turkey). Opal potatoes are promoted for processing into potato chips and for dehydration. Palm olein oil was used for frying the chips, and the oil was obtained from Cargill Foods (Turkey).

Preparation of Potato Samples

Potatoes were first peeled with a peeling machine (Florigo, England) and subsequently sliced into 2.60-mm-thick slices on a slicing machine (Bigtem, Turkey). Sliced potatoes were subjected to a washing process (Bigtem, Turkey) for 90 s at three different temperatures (25 °C, 55 °C and 85 °C). After washing, the water on the potato slices was dried, and the potatoes were then fried at three different temperatures (180 °C, 185 °C and 190 °C) and three different durations (165 s, 190 s and 205 s) using a frying system (Rosenqvists CF10, Sweden). Fresh oil was used for each batch in the frying process. After frying, the cooled potato slices were filled into polypropylene-based packages in a modified atmosphere (98% nitrogen + 2% oxygen gas) packaging device (Ishida Astro S 103 L, Japan).

Nine different product (chips) groups were formed using the variables in the process stage described above. The process parameters and their levels are shown in Table 1. The samples were taken from each product group and analyzed for the content of α-solanine and α-chaconine.

Methods

Temperature Measurements

The washing water and frying oil temperature of potato slices were recorded with a digital thermometer (Testo 110, Germany).

Slice Thickness Measurement

The slice thickness of potato slices was measured using a digital caliper (Mitutoyo ABS ID-C547, Japan) according to the AOAC (2000) method.

Moisture Content Determination

The moisture content of fried potato slices (chips) was determined using the AOAC (2000) method. The slices were kept in an oven at 105 °C (Binder ED 53, Germany) until reaching constant weight, and the weights were measured.

Oil Content Determination

Oil content of fried potato slices (chips) was determined using a Soxhlet extraction device (Behr Labor ES 2 + 2, Germany) according to AOAC (2000).

Solanine and Chaconine Analysis

Α-solanine and α-chaconine were analyzed using a liquid chromatography/mass spectrometry (LC–MS/MS) system (Agilent 6495, USA). The compounds were separated on an Agilent Hilic Plus RRHD column (100 × 3.0 mm, particle size 1.8 µm) using a mixture of 0.1% formic acid in water and 2 mmol/L ammonium formate (Solvent A) and acetonitrile (Solvent B). The following stepwise program was performed: 0.5 min at 20% A and then increased from 0.5 to 6 min from 20 to 35% A. The potatoes were held in this state for 4 min. Finally, A was reduced to 20% in 0.1 min and held in this state for 3 min for equilibrium. The flow rate was 0.4 ml/min, and the injection volume was 2.0 µL. Mass spectrometry (MS) multiple reaction monitoring (MRM) modes were used to measure α-solanine and α-chaconine. MS parameters were gas flow rate 12 L/min, gas temperature 350 °C, capillary voltage 4 kV, MS1 heater temperature 100 °C and MS2 heater temperature 100 °C (Wan et al. 2022).

Statistical Analysis

The data obtained from the experimental studies were analyzed to determine the optimum slice washing temperature, frying temperature and frying time to achieve the minimum α-solanine and α-chaconine values. The Taguchi method was employed to determine these optimum process parameters (Minitab® 19.1). Taguchi, a statistical method, is created against factors that cannot be controlled and cause variability in experimental studies. Thanks to this method, trial-and-error losses are minimized (Cibik and Duran 2023). The Taguchi method utilizes experimental design theory, orthogonal (vertical) arrays and regression models to examine many variables with a small number of experiments.

Experimental Design

The present study determined the process parameters to be studied utilizing the L9 standard orthogonal array of the Taguchi method (Table 2). With this experimental design, the number of experiments required with different combinations to see the effect of three variables on the results was reduced to 9 experiments (Alvarez and Saldaña 2013). To reach the optimum process parameter, slice washing temperature (A), frying temperature (B) and frying time (C) were taken as input parameters, and α-solanine and α-chaconine contents were taken as output parameters. In addition, the relationship between dependent variables and independent variables was defined and modeled with S/N ratio analysis, analysis of variance (ANOVA) and regression analysis. The formula in Eq. 1 was used to calculate the S/N ratios, and the result was based on the “the smallest the best” approach (Rubilar et al. 2012).

- n:

-

number of experiment repetitions

- yi:

-

experiment data

Results

In the study, three technological repetitions were performed for α-solanine, α-chaconine, moisture and oil analyses. Three samples were taken from each technological process and analyzed. The average of triplicate was taken for statistical analyses, and the results are shown in Tables 3 and 4.

As seen in Table 3, the highest α-solanine value was 79.8 mg/kg, and the highest α-chaconine value was 125.2 mg/kg. By applying the different process parameters, these values reduced to 22.4 mg/kg for α-solanine and 25.5 mg/kg for α-chaconine.

Analysis of S/N Ratios

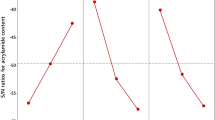

To analyze and interpret the values obtained in the study, a statistical calculation known as the S/N ratio was used. In this method, S indicates the actual value given by the system, and N indicates the factors affecting the experimental result. All values known as N are characterized as all variables that cause deviations from the targeted result (Hu et al. 2005). The standard L9 orthogonal table of S/N ratios and S/N responses of α-solanine and α-chaconine output parameters is given in Table 3. Likewise, S/N responses for moisture and oil are given in Table 4. The values in this tables with the highest S/N value are considered to determine the optimum slice washing temperature, frying temperature and frying time parameters. Also, the level values of the process parameters of slice washing temperature, frying temperature and frying time are shown in the visual form in Figs. 1 and 2.

The S/N response table for α-solanine and α-chaconine is shown in Table 3. Here, the highest S/N ratio for each process parameter indicates the optimum level. Accordingly, the optimum process parameters for the lowest α-solanine were determined as 25 °C slice washing temperature, 190 °C frying temperature and 165 s frying time (A1B3C1). Since the A1B3C1 level and parameter were not given in the study design, they were also studied, and the result was found to be 14.6 mg/kg. For the lowest α-chaconine value, the optimum process parameters were measured as 55 °C slice washing temperature, 190 °C frying temperature and 165 s frying time (A2B3C1). According to the results in Fig. 1, α-solanine and α-chaconine values decreased with increasing frying temperature. Additionally, it was observed that decreasing the frying time caused a significant decrease in α-solanine and α-chaconine values.

Analysis of Variance (ANOVA)

Analysis of variance was performed to determine the effect of process parameters (slice washing temperature, frying temperature and frying time) on α-solanine, α-chaconine, moisture and oil values. The results are given in Table 5. The P value in the tables indicates the significance, and the F value indicates the effect level (Özbek et al. 2021).

According to the analysis of variance results, frying time had the highest effect on α-solanine and α-chaconine values. Slice washing temperature had the lowest effect. It is seen that frying time, the most effective parameter, had a high effective rate of 68.2% on the α-solanine content and 76.5% on the α-chaconine content.

Discussion

Evaluation of the Experiment Results

The results showing the effects of frying temperature and time on the α-solanine and α-chaconine content in potato chips samples are shown in Fig. 3. Both figures show that the α-solanine and α-chaconine content decreased with increasing temperature and especially with decreasing frying time. The lowest glycoalkaloid level was measured at 190 °C and 165 s frying time.

Table 5 shows that the slice washing temperature had the lowest effect on the α-solanine and α-chaconine content. These effects were realized as 6.83% for α-solanine and 3.71% for α-chaconine. These effects did not significantly increase or decrease the glycoalkaloid levels, as shown in Fig. 1. The slice washing temperature at which the α-solanine content decreased the most was 25 °C. The highest decrease in α-chaconine content was observed at 55 °C slice washing temperature. According to the results of similar studies, it was reported that the washing process applied to potato slices did not cause significant changes in the glycoalkaloids level (Peksa et al. 2006). It was confirmed that the boiling process had a low effect on glycoalkaloid level. This effect was in the direction of decreasing the glycoalkaloids level (Rytel et al. 2018).

Potato slices were subjected to frying after the slice-washing process. As seen in Fig. 3, the highest glycoalkaloid values were found at 180 °C frying temperature, and this value decreased slightly when the temperature increased to 185 °C. The frying temperature at 190 °C caused the highest decrease in the glycoalkaloid value. The frying temperature was one of the process steps that affected the α-solanine and α-chaconine values (Table 5). D’Amelia et al. (2022) made a comparison of the glycoalkaloid value after some processes such as frying, baking, microwaving and boiling and observed that only frying caused a decrease in the glycoalkaloid value. Friedman (2006) stated that the temperature required to significantly reduce the glycoalkaloid value should be 170–180 °C. Tajner-Czopek et al. (2008) examined glycoalkaloids (α-solanine and α-chaconine) values in potato, peeled potato, washed potato and finally fried potato in the potato chips production process. They reported that frying caused a significant decrease in glycoalkaloid levels. Tajner-Czopek et al. (2012) found a higher loss in the α-chaconine value compared to that of α-solanine in the cooking process of potatoes. In the present study, it was seen that there was a higher decrease in the α-chaconine value compared to that of α-solanine as a result of the frying process (Table 3).

Frying time was the most effective factor in decreasing the α-solanine and α-chaconine values (Table 5). Reducing the frying time caused a decrease in the α-solanine and α-chaconine content. Rytel et al. (2018) reported that frying time greatly reduced the glycoalkaloid values in the production process of fried and dried potato products.

As a result of all the experiments, it was found that the optimum process values to reach the minimum content of α-solanine were 25 °C slice washing temperature, 190 °C frying temperature and 165 s frying time. To obtain the minimum content of α-chaconine, the optimum process values were 55 °C slice washing temperature, 190 °C frying temperature and 165 s frying time (Table 6). According to the results of the analysis in the study, it was understood that the frying temperature (Friedman and Dao 1992; Rytel et al. 2005; Peksa et al. 2006; Tajner-Czopek et al. 2008) and especially frying time (Rytel et al. 2018) applied to potatoes caused a significant decrease in the content of glycoalkaloids.

Although there was no significant change in the moisture value of the chips as the slice washing temperature decreased, the amount of oil decreased. It is seen that as the frying temperature increases, the moisture values of the chips decrease, and the amount of oil increases. In addition, it is observed that increasing the frying time causes the moisture value to decrease and the oil amount of the chips to increase (Fig. 2). As seen in Figs. 1 and 2, increasing the frying temperature causes the moisture and glycoalkaloid levels in the chips to decrease (Rytel et al. 2018). As can be seen in the same tables, shortening the frying time causes both the amount of oil retained by the chips and the glycoalkaloid level to decrease.

According to the results of variance analysis, frying temperature and frying time had a significant effect on the moisture value of the chips. A significant effect of frying time was observed on the fat content of the chips. However, it appears that frying time has a high impact on both quality parameters (Table 5). When the production was carried out according to the optimum process values determined, the oil content in potato chips was 33.0–34.0%, and the moisture value was 1.14–1.28%. It has been observed that these oil and moisture values are in the appropriate range according to the local potato chip standard (TS 3628/T1 2017).

Regression Analysis

Regression analysis was performed to mathematically express the relationship between the inputs of the study, washing temperature, frying temperature and time, and the outputs of the study, α-solanine and α-chaconine.

Regression analysis is a statistical calculation method used to predict the relationship between dependent variables and independent variables. The R2 value in this method is an important indicator of the estimation performance in the relationship between the variables. An R2 value between 0 and 100% (or 1) and close to 100% (or 1) indicates that the relationship between the dependent (α-solanine and α-chaconine content) and independent (washing temperature, frying temperature and time) variables is strongly compatible (Sun et al. 2022). Equation 2 shows the regression equations for α-solanine content, and Eq. 3 shows the regression equations for α-chaconine content based on experimental data.

- As (mg/kg):

-

α-solanine value

- Ac (mg/kg):

-

α-chaconine value

- swt (°C):

-

slice washing temperature

- ftemp (°C):

-

frying temperature

- ft (s):

-

frying duration

According to the linear regression equation formed with the data of our study, the R2 value for α-solanine was 90.6% and for α-chaconine 92.5%. As a result, estimation equations with a very high coefficient of determination (R2) produce values close to the actual values and support the accuracy of the interpretations made on the results. Figure 4 demonstrates the true value of glycoalkaloids (α-solanine and α-chaconine) and the corresponding predicted amount of that, represented by ANOVA. As it is depicted that the points are close to the line Y = X, the amounts of R-squared and R-adjusted are close to unity, which is another proof on the integrity of the model (Ghasemian et al. 2014).

Validation Tests

In the last stage of the study, validation experiments were carried out with optimum and random levels to check the accuracy of the optimization. To determine the success of the optimization, the confidence interval (CI) for the output parameters (As, Ac) was calculated using Eqs. 4 and 5.

N in Eq. 4 represents the total number of experiments, and \({{\varvec{T}}}_{{\varvec{d}}{\varvec{o}}{\varvec{f}}}\) represents the total degrees of freedom. \({{\varvec{F}}}_{{\varvec{a}},1,{\varvec{f}}{\varvec{e}}}\) in Eq. 5 represents the 95% confidence level, the \({\varvec{a}}\) significance level and the error degree of freedom, respectively. Ve represents error variance, \({{\varvec{n}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\) the effective iteration count and \({\varvec{R}}\) the number of repetitions for validation experiments. The values of these parameters for confidence interval calculations are given in Table 7. As a result, it was calculated as \({{\varvec{C}}{\varvec{I}}}_{{\varvec{A}}{\varvec{s}}}=43.815\) and \({{\varvec{C}}{\varvec{I}}}_{{\varvec{A}}{\varvec{c}}}=48.068\) for the α-solanine and α-chaconine content obtained experimentally.

On the other hand, as seen in Table 6, the ideal parameter group for the lowest As is the A1B3C1 level and for Ac is A2B3C1 level. Equations 6 and 7 were used to calculate the estimated optimum As and Ac values. The \({{\varvec{T}}}_{{\varvec{A}}{\varvec{s}}}\) value (41.2 mg/kg) and \({{\varvec{T}}}_{{\varvec{A}}{\varvec{c}}}\) value (67.6 mg/kg) are the mean of the sum of the glycoalkaloid contents obtained for each parameter combination. As a result, the \({{\varvec{A}}{\varvec{s}}}_{{\varvec{o}}{\varvec{p}}{\varvec{t}}}\) and \({{\varvec{A}}{\varvec{c}}}_{{\varvec{o}}{\varvec{p}}{\varvec{t}}}\) values were calculated as 13.27 A by replacing the relevant data in Eqs. 6 and 7.

when the values were applied

when the values were applied

According to Eqs. (8) and (9), it was shown that outputs (α-solanine and α-chaconine amounts) are within the confidence interval limit, respectively. Consequently, the optimization process is successfully performed with the Taguchi method at 95% significance level. The validation results for outputs are given in Table 8. The random combination of process parameters for outputs has been chosen to be: A2B3C2. This means, slice washing temperature is 55 °C, frying temperature is 190 °C and frying time is 185 s. According to Table 8, the results produced by the mathematical equations developed to estimate the outputs are within the error limits compared with the actual results. Moreover, Akgün (2023) reported that error values should be less than 20% for reliable statistical analysis. As a result, it is noticeable that the estimation equations give successful results with the high coefficients of determination (R2) values and within the confidence interval in the confirmation test results.

Conclusion

The glycoalkaloid contents found in raw and processed potato products are vital due to their adverse effects on human health. The formation of these glycoalkaloids in potatoes and their presence in potato products are unwanted. In the study, it was ensured that the glycoalkaloids level was reduced by process interventions. The glycoalkaloid contents in the fried potato slices taken as samples were found below the recommended limits in all results. For the minimum α-solanine and α-chaconine values, different process parameters were statistically analyzed by applying the Taguchi, ANOVA and regression methods. As a result of the analysis, optimum process parameters were obtained for the minimum content of glycoalkaloids. According to the S/N ratios results, 25 °C slice washing temperature, 190 °C frying temperature and 165 s frying time (A1B3C1) were optimal combinations for α-solanine. In the α-solanine analysis performed on these parameters, the As value was measured as 14.6 mg/kg. In a similar vein, 55 °C slice washing temperature, 190 °C frying temperature and 165 s frying time (A2B3C1) were determined as the optimum process parameters for α-chaconine. The Ac value is measured as 25.5 mg/kg in the α-chaconine analysis performed in these parameters. According to the analysis of variance, frying time was found to be the most effective process parameter on the α-solanine and α-chaconine content. It was seen that the regression equation developed to predict the amounts of α-solanine (As) and α-chaconine (Ac) in the product gave results very close to the experimentally obtained values. Mathematical models gave reliable results with coefficients of determination (R2) of 90.6% and 92.5%, respectively. The high reliability (R2) of the study demonstrated that the Taguchi method can be successfully applied in optimizing multiple parameters in the food industry, as seen in the production of potato chips. In the study, it was observed that the amount of glycoalkaloids decreased as the slice washing temperature was lowered, the frying temperature was increased and the frying time was reduced. According to the statistical analysis results of the study, short-term frying at high temperatures is recommended to reduce the amount of glycoalkaloid in chips production technology.

References

Ahamad J, Uthirapathy S, Anwer ET, Naim MJ, Mir SR (2022) Glycoalkaloids as food toxins, in Analysis of Naturally Occurring Food Toxins of Plant Origin (1st ed.), pp. 81–94. Boca Raton: CRC Press. https://doi.org/10.1201/9781003222194

Akgün M (2023) Measurement and optimization of cutting forces, surface roughness and temperature in turning of AZ91 Mg alloy. Sādhanā 48(2):60. https://doi.org/10.1007/s12046-023-02113-3

Alvarez VH, Saldaña MDA (2013). Hot pressurized fluid extraction optimization of potato peel using response surface and the Taguchi method. III Iberoamerican Conference on Supercritical Fluids, Cartagena de Indias (Colombia)

AOAC (2000) Official Methods of Analysis of AOAC International, 17th edn., ed. O. Cunniff. AOAC Int., Virginia, USA

Aziz A, Randhawa MA, Butt MS, Asghar A, Yasin M, Shibamoto T (2012) Glycoalkaloids (α-Chaconine and α-Solanine) contents of selected Pakistani potato cultivars and their dietary intake assessment. J Food Sci 77(3):58–61. https://doi.org/10.1111/j.1750-3841.2011.02582.x

Babazadeh S, Moghaddam PA, Sabatyan A, Sharifian F (2016) Classification of potato tubers based on solanine toxicant using laser induced light backscattering imaging. Comput Electron Agric 129:1–8. https://doi.org/10.1016/j.compag.2016.09.009

Bejarano L, Mignolet E, Devaux A, Espinola N, Carrasco E, Larondelle Y (2000) Glycoalkaloids in potato tubers: the effect of variety and drought stress on thea-solanine and a-chaconine contents of potatoes. J Sci Food Agric 80:2096–2100. https://doi.org/10.1002/1097-0010(200011)80:14%3c2096::AID-JSFA757%3e3.0.CO;2-6

Cibik S, Duran A (2023) Analysis and optimization of the effect of process parameters of silver anode technique on Pseudomonas aeruginosa in raw milk. Braz Arch Biol Technol 66:e23230099. https://doi.org/10.1590/1678-4324-2023230099

D’Amelia V, Sarais G, Fais G, Dessì D, Giannini V, Garramone R, Melito S (2022) Biochemical characterization and effects of cooking methods on main phytochemicals of red and purple potato tubers, a natural functional food. Foods, 11(3):384. https://doi.org/10.3390/foods11030384

Friedman M (2006) Potato glycoalkaloids and metabolites: roles in the plant and in the diet. J Agric Food Chem 54:8655–8681. https://doi.org/10.1021/jf061471t

Friedman M, Dao L (1992) Distribution of glycoalkaloids in potato plants and commercial potato products. J Agric Food Chem 40:419–423. https://doi.org/10.1021/jf00015a011

Friedman M, Levin CE (2009) Analysis and biological activities of potato glycoalkaloids, calystegine alkaloids, phenolic compounds, and anthocyanins. Adv Potato Chem Technol 127–161. https://doi.org/10.1016/B978-0-12-374349-7.00006-4

Ghasemian S, Rezaei K, Abedini R, Poorazarang H, Ghaziani F (2014) Investigation of different parameters on acrylamide production in the fried beef burger using Taguchi experimental design. J Food Sci Technol 51(3):440–448. https://doi.org/10.1007/s13197-011-0514-x

Hu CY, Changa YJ, Yin LT, Tsao CY, Changa CH (2005) Optimal design of nickel-coated protein chips using Taguchi approach. Sensors Actuators B 108:665–670. https://doi.org/10.1016/j.snb.2004.12.098

Irungu FG, Tanga CM, Ndiritu FG, Mwaura L, Moyo M, Mahungu SM (2022) Use of magnetic fields reduces α-chaconine, α-solanine, and total glycoalkaloids in stored potatoes (Solanum tuberosum L). J Food Process Preserv. 46(11):e16941. https://doi.org/10.1111/jfpp.16941

Itkin M, Rogachev I, Alkan N, Rosenberg T, Malitsky S, Masini L, Aharoni A (2011) Glycoalkaloid metabolism1 is required for steroidal alkaloid glycosylation and prevention of phytotoxicity in tomato. Plant Cell, 23(12):4507–4525. https://doi.org/10.1105/tpc.111.088732

Jiang QW, Chen MW, Cheng KJ, Yu PZ, Wei X, Shi Z (2016) Therapeutic potential of steroidal alkaloids in cancer and other diseases. Med Res Rev 36(1):119–143. https://doi.org/10.1002/med.21346

Kazachkova Y, Zemach I, Panda S, Bocobza S, Vainer A, Rogachev I, Aharoni A (2021) The gorky glycoalkaloid transporter is indispensable for preventing tomato bitterness. Nat Plants 7(4):468–480. https://doi.org/10.1038/s41477-021-00865-6

Korpan YI, Nazarenko EA, Skryshevskaya IV, Martelet C, Jaffrezic-Renault N, Anna V (2004) Potato glycoalkaloids: true safety or false sense of security? Trends Biotechnol 22(3):147–151. https://doi.org/10.1016/j.tibtech.2004.01.009

Lachman J, Hamouz K, Orsak M, Pivec V (2001) Potato glycoalkaloids and their significance in plant protection and human nutrition- review. Rostlinna Vyroba 47(4):181–191

Langkilde S, Mandimika T, Schroder M, Meyer O, Peijnenburg A, Poulsen M, Slob W (2009) A 28-day repeat dose toxicity study of steroidal glycoalkaloids, α-solanine and α-chaconine in the Syrian golden hamster. Food Chem Toxicol 47:1099–1108. https://doi.org/10.1016/j.fct.2009.01.045

Laus MC, Klip G, Giuseppin ML (2017) Improved extraction and sample cleanup of tri-glycoalkaloids α-solanine and α-chaconine in non-denatured potato protein isolates. Food Anal Methods 10(4):845–853. https://doi.org/10.1007/s12161-016-0631-2

Liu JM, Wang SS, Zheng X, Jin N, Lu J, Huang YT, Fan B, Wang FZ (2020) Antimicrobial activity against phytopathogens and inhibitory activity on solanine in potatoes of the endophytic bacteria isolated from potato tubers. Front Microbiol 11:570926. https://doi.org/10.3389/fmicb.2020.570926

Mensinga TT, Sips AJAM, Rompelberg CJM, Twillert K, Meulenbelt J, Top HJ, Egmond HP (2004) Potato glycoalkaloids and adverse effects in humans; an ascending dose study. Regul Toxicol Pharmacol 41:66–72. https://doi.org/10.1016/j.yrtph.2004.09.004

Milner SE, Brunton NP, Jones PW, O’Brien NM, Collins SG, Maguire AR (2011) Bioactivities of glycoalkaloids and their aglycones from Solanum species. J Agric Food Chem 59(8):3454–3484. https://doi.org/10.1021/jf200439q

Nema PK, Ramayya N, Duncan E, Niranjan K (2008) Potato glycoalkaloids: formation and strategies for mitigation. J Sci Food Agric 88:1869–1881. https://doi.org/10.1002/jsfa.3302

Nobuyuki K, Han JS, Choi SK, Byun GI, Suh BS, Choi SH, Park ML (2006) The changes on ascorbic acid and glycoalkaloid contents of eggplant by parts and cooking methods. Culinary Sci Hosp Res 12(4):247–258

Omayio DG, Abong GO, Okoth MW (2016) A review of occurrence of glycoalkaloids in potato and potato products. Curr Res Nutr Food Sci Jour. 4(3):195–202. https://doi.org/10.12944/CRNFSJ.4.3.05

Özbek N, Özbek O, Kara F (2021) Statistical analysis of the effect of the cutting tool coating type on sustainable machining parameters. J Mater Eng Perform 30:7783–7795. https://doi.org/10.1007/s11665-021-06066-8

Peksa A, Golubowska G, Aniolowski K, Lisinska G, Rytel E (2006) Changes of glycoalkaloids and nitrate contents in potatoes during chips processing. Food Chem 97(1):151–156. https://doi.org/10.1016/j.foodchem.2005.03.035

Romanucci V, Di Fabio G, Di Marino C, Davinelli S, Scapagnini G, Zarrelli A (2018) Evaluation of new strategies to reduce the total content of α-solanine and α-chaconine in potatoes. Phytochem Lett 23:116–119. https://doi.org/10.1016/j.phytol.2017.11.024

Rubilar M, Villarroel M, Paillacar M, Moenne-Locóz D, Shene C, Biolley E, Acevedo F (2012) Native black Michuñe potato variety: characterization, frying conditions and sensory evaluation. Arch Latinoam Nutr 62(1):87–93

Rytel E, Golubowska G, Lisinska G, Peksa A, Aniolowski K (2005) Changes in glycoalkaloid and nitrate contents in potatoes during French fries processing. J Sci Food Agric 85:879–882. https://doi.org/10.1002/jsfa.2048

Rytel E, Tajner-Czopek A, Kita A, Kucharska AZ, Sokół-Łętowska A, Hamouz K (2018) Content of anthocyanins and glycoalkaloids in blue-fleshed potatoes and changes in the content of α-solanine and α-chaconine during manufacture of fried and dried products. Int J Food Sci Technol 53:719–727. https://doi.org/10.1111/ijfs.13647

Sawai S, Ohyama K, Yasumoto S, Seki H, Sakuma T, Yamamoto T, Umemoto N (2014) Sterol side chain reductase 2 is a key enzyme in the biosynthesis of cholesterol, the common precursor of toxic steroidal glycoalkaloids in potato. Plant Cell 26(9):3763–3774. https://doi.org/10.1105/tpc.114.130096

Schrenk D, Bignami M, Bodin L, Chipman JK, del Mazo J, Grasl‐Kraupp B (2020) Risk assessment of glycoalkaloids in feed and food, in particular in potatoes and potato‐derived products. EFSA J 18(8):e06222. https://doi.org/10.2903/j.efsa.2020.6222

Sun X, Li J, Cameron D, Zhou A (2022) Field monitoring and assessment of the impact of a large eucalypt on soil desiccation. Acta Geotechnic 17:1971–1984. https://doi.org/10.1007/s11440-021-01308-4

Tajner-Czopek A, Jarych Szyszka M, Lisinska G (2008) Changes in glycoalkaloids content of potatoes destined for consumption. Food Chem 106:706–711. https://doi.org/10.1016/j.foodchem.2007.06.034

Tajner-Czopek A, Rytel E, Kita A, Peksa A, Hamouz K (2012) The influence of thermal process of coloured potatoes on the content of glycoalkaloids in the potato products. Food Chem 133:1117–1122. https://doi.org/10.1016/j.foodchem.2011.10.015

TS, 3628/T1 (2017). Turkish Standards Institution, Potato Chips, Necatibey Caddesi No.112 Bakanlıklar/Ankara

Wan L, Gao H, Gao H, Du R, Wang F, Wang Y, Chen M (2022) Selective extraction and determination of steroidal glycoalkaloids in potato tissues by electromembrane extraction combined with LC-MS/MS. Food Chem 367:130724. https://doi.org/10.1016/j.foodchem.2021.130724

Wang CC, Sulli M, Fu DQ (2017) The role of phytochromes in regulating biosynthesis of sterol glycoalkaloid in eggplant leaves. PLoS ONE 12(12):e0189481. https://doi.org/10.1371/journal.pone.0189481

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koyuncu, D., Duran, A. Optimization of Process Parameters Affecting Glycoalkaloids in Potato Chips Using the Taguchi Method. Potato Res. (2024). https://doi.org/10.1007/s11540-023-09689-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11540-023-09689-7