Abstract

Establishing relationships between physical and sensorial properties of semi-solid foods is essential to develop tailored products. Whey protein/polysaccharide mixed gels were used to model both natural and fabricated semi-solid foods. The presence of various polysaccharides modulated the microstructure and large deformation properties of the mixed gels. The gels exhibited a large spectrum of sensorial properties as evaluated by panellists in a quantitative descriptive analysis. Mouthfeel attributes that discriminated best between the gels were wateriness, crumbliness, and spreadability. Wateriness strongly correlated with the amount of exuded phase (serum) measured during uniaxial compression. Serum release may have a positive effect on, for instance, the juiciness of a product. Large deformation measurements showed that highly crumbly gels fracture readily via a free-running crack. Low serum release is a requirement for that. Low crumbly gels fracture slowly, often releasing a high amount of serum. Spreadability related to the occurrence of multiple microcracks during deformation as observed by confocal laser scanning microscopy, which resulted in a large number of pieces after oral processing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sensorial properties of foods are one of the main criterions for their quality as evaluated by consumers. Knowledge about the relationships between these properties and physical characteristics of foods is required to bring benefits for both consumers and food industry. These relationships can help in designing products with:

-

(1)

Novel sensorial properties

-

(2)

Improved composition with respect to health issues of consumers (i.e., obesity, salt content, vitamin, and mineral deficiencies) but unchanged sensorial properties

-

(3)

Physical and sensorial properties intended for target consumers (i.e., consumers with diabetes and dysphagia)

Current study focuses on semi-solid foods. These can be modeled best by mixed gels.1 Particularly, protein/polysaccharide mixed gels are frequently used, as they approximate best the composition and functional properties of these foods. Among many proteins, whey proteins are increasingly used in these gels because they are used in various foods including dairy products and desserts, beverages, confectionery, convenience foods, and meat products.2 Moreover, in the presence of polysaccharides, they form a large spectrum of gels with different physical properties.1

Most of the studies on whey protein/polysaccharide mixed gels focused only on small deformation properties and/or the microstructure of the gels. In general, synergistic effects of protein/polysaccharide mixtures were observed. The gels formed microphase-separated structures, and the extent of the microphase separation depended on the polysaccharide concentration and pH.3–11 Only few of these studies focused on relating the microstructural and rheological properties. Sittikijyothin et al.11 showed that microphase separation did not affect small deformation properties of β-lactoglobulin/tara gum gels,11 and similar results were shown by Tavares et al.9 for whey protein isolate (WPI)/galactomannan gels.

Consumption of foods involves relatively high speed and large deformations. Therefore, mechanical properties of semi-solid foods need to be measured under large deformations at relevant speeds to better understand the relation with sensorial perception.12 This has been demonstrated, for example, for emulsion-filled gels whose large deformation properties were strongly speed-dependent and related to sensory scores only when measured at speeds close to oral processing.13, 14

There are only a limited number of studies focusing on large deformation and microstructural properties of whey protein/polysaccharide mixed gels. Gustaw et al.6 showed that large deformation properties of whey protein/xanthan heat-set gels related to gel’s microstructure in contrast to small deformation properties. Hardness of the gels related to the protein concentration in the protein phase. Similar relations were observed for WPI/κ-carrageenan and WPI/pectin gels.15 This underlines the importance of large deformation properties in structure–functionality relationship of the gels. But none of these studies related the properties of the gels to sensorial data.

In our laboratory, we used WPI/polysaccharide cold-set gels because of high variability in their physical properties to identify the relationships between these properties and sensory perception. The process of cold gelation of these gels was thoroughly described before.16 The gels formed different microstructures, showed a broad variation in deformation properties, and released serum during deformation. The relationship between serum release and large deformation properties was described previously.17 Additionally, the effect of gel’s microstructure on sensorial properties has been reported,18 and particularly crumbly properties of the gels in relation to physical properties were studied.19 The objective of the current study was to discuss all relations between physical and sensorial properties of WPI/polysaccharide mixed gels that have been studied in our laboratory so far.

Materials and Methods

Gel Preparation

Mixed WPI/polysaccharide cold-set gels were prepared at sterile conditions according to van den Berg et al.18 Polysaccharides included gellan gum, locust bean gum (LBG), κ-carrageenan, GSK-carrageenan (κ/ι-hybrid carrageenan extracted from Gigartina skottsbergii), and high-methyl pectin (degree of esterification of 68%) as described in van den Berg et al.18 The gels were designated as WPI 9–3/polysaccharide gels and WPI 9–5/polysaccharide gels. The first numeral corresponds to the concentration of the WPI aggregates during the heating step (i.e., 9%, w/w), and the second numeral designates the concentration of the WPI aggregates used for the gelation (i.e., 3% and 5%, w/w, respectively). Table 2 summarizes the abbreviations of the gels. The large deformation measurements, serum release, and microstructure of the gels were measured according to van den Berg et al.17

Quantitative Descriptive Analysis

Sensory characteristics of the WPI/polysaccharide mixed gels were investigated by a sensory panel trained according to the principles of quantitative descriptive analysis (QDA).20 QDA analysis was carried out according to van den Berg et al.18

Particle Size Analysis

Size and shape of broken down gels were analyzed by a so-called scanning procedure. Spit-out samples were collected during the QDA analysis. The judges had to take a bit of a gel at three moments in time. A piece of gel of around 2 to 4 ml was pushed out of the syringe, and the gel part above the syringe was bitten away by the judge using their teeth. Then, the product was moved with the tongue all through the oral cavity and pressed against the palate, so-called palating movement. The product was spit out every time before a new bite was taken, and the residue was swallowed. After the last bite, the spit out sample was collected in a beaker. The residue was removed with water and added to the beaker. Within 30 min, the spit out samples were poured into Petri dishes containing water. Digital images of the broken-down gels in the Petri dishes were obtained using a Canon Canoscan 9900 F (Canon, Hoofddorp, The Netherlands). The Petri dish was always placed at the same position at the scanner. It was covered with a black paper, and the lid of the scanner was closed. The settings of the scanner within the analysis were unchanged. The digital images were acquired in a gray-scale color mode at the resolution of 600 dpi. The size of the imaged field was 10 × 10 cm (see example in Figure 1). The images were analyzed by the software program QWin (Image analysis package of Leica Microsystems), and the output parameters included the number, total area, and roundness of the particles. The lower threshold value for the total area of particles was set on 0.3 mm2. The resolution of the imaging procedure was 0.03 mm2.

Statistical Analysis

One-way analysis of variance and principal component analysis (PCA) were done using Statistica data analysis software system (version 7, StatSoft Inc., Tulsa, USA, 2004) and Unscrambler program (Camo, Process AS, Oslo, Norway, version 9.5). Level of significance (p) was set on 0.05. The same software systems were used to calculate a correlation coefficient (R 2).21

Results

Sensorial Properties

During training sessions of the QDA, panellists defined 23 mouthfeel attributes characterizing the gels (Table 1). Twelve of these attributes distinguished significantly between the samples (p < 0.05; upper block, Table 1). These attributes can be divided in firmness-related, serum-release-related, and spreadability-related mouthfeel attributes, and two single attributes that could not be grouped: crumbliness and resilience. Contribution of other attributes such as roughness or stickiness to the PC1 and PC2 were low. All firmness-related attributes (crumbling effort, firmness, and toughness) were positively correlated with each other (correlation coefficient, >0.8). The attribute firmness distinguished most between the gels and will, therefore, represent this group. Similarly, serum-release attributes (separating, watery, cooling, and spongy) showed a positive correlation (>0.8). The attributes separating, watery, and cooling as defined by the panel related to the amount of water perceived in the oral cavity. The attribute watery was selected to represent this group. Spongy, however, relates to both the serum release and materials properties. It will, therefore, be discussed separately next to separating. Finally, spreadability-related attributes (spreadable, slippery, and grainy) were positively correlated (correlation coefficient, >0.8). Mouthfeel spreadability distinguished most between the gels and will represent this group. Summarizing, we will primarily focus on the following attributes: firm, watery, spongy, spreadable, crumbly, and resilient.

Figure 2 shows a PC plot that is based on all attributes listed in Table 1 but shows only the significant attributes. Explained variance for the first two principal components accounted for a cumulative variation of 91% (Figure 2). As the explained variance in the third principal component was 5%, PC1 and PC2 will be discussed only. PCA are mathematical axes. The vectors of the PCA axes do not necessarily line up with a group of attributes. Logical groups of attributes and the relation between them can be specified by sensory axes that fall on one line crossing the origin of the PCA plot. There were two main sensory axes found in the PC plot, one going from firm to spreadable and second one going from watery to crumbly gels. The axes were approximately perpendicular. Firm to spreadable mouthfeel attributes showed a significant negative correlation of 0.93. Watery and crumbly attributes had a significant negative correlation of 0.95.

Physical Properties

The physical properties of the gels discussed in the current study are microstructure, mechanical properties measured under large deformations, and serum release. They are summarized in Table 2.

Microstructural Properties

Microstructure of the gels as obtained by confocal laser scanning microscopy (CLSM) was classified on a micrometer length scale into homogeneous and phase-separated. Phase-separated microstructures can be further divided in protein continuous, bicontinuous, and coarse stranded.18 Figure 3 (top row) shows CLSM images of some examples of these microstructures. The bright areas depict the protein phase, whereas dark areas correspond to the serum phase. Gel microstructure was studied not only under static conditions but also during deformation and breakdown of the gels. This was done by a microrheology setup that combines a CLSM with a compression unit.18, 22 Changes in gel microstructure, particularly the porosity, were strongly related to serum release from the gels during deformation. In addition, two breakdown mechanisms were identified in the gels: distinct fracture and multiple fracture (Figure 3, bottom row). Homogeneous, protein continuous, and bicontinuous gels showed a distinct fracture. The gels fractured through the protein beams and serum phase in one distinct plane. Whereas coarse-stranded gels showed multiple fracture, i.e., the fracture started at several places and was accompanied by coarsening of the network.18

Mechanical Properties

Mechanical properties tested on the various gels included parameters that characterize each part of the breakdown process, i.e., deformation and fracture point, macroscopic breakdown of the gels, and a broken-down product.

Deformation of the gels and the fracture point were characterized during uniaxial compression by a true fracture strain (ɛ H ), the true fracture stress (σ t ), and the energy to fracture. The fracture point corresponds to the maximum in the force versus applied deformation curve. Fracture strains of all gels varied from 0.9 to 1.4. The fracture stress of gels with 3% (w/w) WPI were between 3 to 10 kPa, whereas gels containing 5% (w/w) WPI fractured at higher stresses (e.g., 12 and 16 kPa).

Macroscopic breakdown is characterized by the curve following the fracture point. This part reflects the breakdown of the sample after fracture has started, which can be approximated by the energy balance in the gels during deformation. This concept has been reported before.19 It can be measured directly by compression–decompression test as a recoverable energy or indirectly by a wedge test as a critical speed for fracture (CSF). Recoverable energy is a measure of the energy fraction that has been stored in a gel during deformation and correlates negatively with the CSF. Highly elastic gels, which can store energy during deformation, have thus high recoverable energy values. These gels show fast breakdown that corresponds with a steep drop of force in the force versus deformation curve. Highly elastic gels tend to fracture via a free-running crack. This means that the breakdown of a sample proceeds faster than the applied deformation due to the access of energy stored in the gels during deformation.

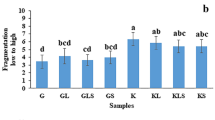

The last stage of the breakdown process, broken-down gels, was characterized by a so-called scanning procedure. The samples were collected after QDA analysis, imaged using a digital scanner, and analyzed. The outcome parameters included the number and total area of particles in the broken-down products (Table 2). It has to be noted that differences in the number and total area of particles between the gels were larger than differences between the panellists. Individual palating and chewing patters thus did not affect the results. Coarse-stranded gels broke down into the highest number of particles. These gels showed multiple fracture and coarsening of the protein network during deformation, which results in a larger number of particles in the broken-down gels. Breakdown mechanisms as described in “Microstructural Properties” thus affect size of the broken-down products.

Serum Release

During deformation, the gels released varying amounts of serum. Serum release has been measured during uniaxial compression between two parallel plates and related clearly to the porosity of gel’s microstructure. Bicontinuous and coarse-stranded gels released the highest amount of serum, whereas protein continuous and homogeneous gels showed low serum release. In addition, serum release affects large deformation and fracture properties of the gels, which have to be corrected for the effect of serum.17 Corrected fracture stresses were higher than the non-corrected ones (Table 2). Finally, it has been shown that serum phase and release of serum during deformation causes energy dissipation and therefore affects breakdown of the gels.19 Gels with low serum release were highly elastic and broke down readily via a free-running crack, i.e., they showed high recoverable energy values and fast breakdown (Table 2).

Physical–Sensorial Properties Relationships

Relation of physical properties of the gels to sensory perception was done using an overlay plot of physical and sensorial properties (Figure 4). The main focus is on the significant attributes determining the sensory axes (i.e., firm, watery, spongy, spreadable, crumbly, and resilient).

There was a significant correlation between the amount of serum released from the gels and a watery perception. True strain correlated significantly to spongy, and both true stress and energy to fracture to firmness. True stress corrected for the effect of serum release correlated better with firmness than the non-corrected stress (the correlation coefficient increased from 0.77 to 0.85).

Crumbly mouthfeel attribute correlated positively with the recoverable energy (correlation coefficient of 0.70). Gels with a high elastic component (high recoverable energy), which broke down fast via free-running crack, were perceived as crumbly. Besides, crumbly did not correlate with the large deformation properties of the gels (fracture strain, stress, and energy to fracture) nor did it correlate with the size of the broken-down products (Figure 5). This means that crumbly perception relates purely to the breakdown of the sample regardless its fracture strain, stress, or energy to fracture and size of particles upon breakdown. In this paper, macroscopic breakdown is defined as the falling apart of the sample after fracture has started. From another view, fracture stress and energy to fracture could describe only firmness of the sample in the current sample set but did not characterize its breakdown. Resilient mouthfeel attribute relates by the definition to the elasticity of the gels. However, it did not correlate significantly to any of the physical properties.

Finally, the results showed that the attribute spreadable correlated significantly to the properties of broken-down gels, i.e., the number and the total area of particles (Figure 6). For both parameters, the correlation coefficient with spreadable was 0.85. The variation in the number of particles was however larger than the variation in the total area. It is thus likely that the variation in the number of particles affected primarily the spreadable mouthfeel attribute rather than the variation in the total area. Spreadability is defined as the ability of the sample to spread between the tongue and palate. Gels that fracture into a high number of particles can cover a large area of the oral cavity and can therefore be perceived as spreadable. An additional property affecting spreadability is the firmness of the gels. As Figure 5 shows, firmer gels break down in fewer particles. If a gel is firm, it requires more effort to fracture and will therefore be broken down to a less extent during oral processing.

Overall, the results show that gel firmness is related to the large deformation properties, crumbliness to breakdown, and spreadability to the properties of a broken-down product. This shows that it is necessary to study the complete breakdown of the gels in relation to sensory than just fracture properties that were studied in literature so far.

Discussion

When establishing the relationships between the sensorial and physical properties of the WPI/polysaccharide mixed gels, it is important to realize that most of the physical properties are interrelated. Correlation matrices can be used to find relationships of physical properties with relatively simple attributes such as firmness of the gels. Or they can be used to find relationships between measured physical properties and a sensorial attribute as it was done in “Physical–Sensorial Properties Relationships.” However, to engineer certain mouthfeel attribute, a complex approach providing a model of the relationship between physical and sensorial properties is required to fully understand these relationships. Let us start this analysis from the attributes determining the two principal sensorial axes (Figures 2 and 4).

The crumbly–watery axis is clearly dominated by serum release that primarily affected energy dissipation (measured by recoverable energy) in the systems tested in this study. Energy dissipation can be also affected by the presence of other structural features (i.e., emulsion droplets, air bubbles) in the gel matrix.13, 14 This has, however, not been the case for the gels used in this study. Gels with high serum release are perceived as watery, whereas gels with low serum release have low energy dissipation and are perceived as crumbly. Serum release is dominated by a microstructure of the gels.18 As Table 2 shows, protein continuous and homogeneous gels release low amount of serum; i.e., there is low energy dissipation and they show high recoverable energy values. Bicontinuous and coarse-stranded gels release high amounts of serum and are therefore likely to be perceived as watery.

The firm–spreadable axis is determined by firmness and breakdown mechanisms rather than serum release. Even though serum release affects energy dissipation and therefore also breakdown; in this case, firmness relates to large deformation properties (the fracture point) and spreadability to the number of particles resulting from the breakdown. Gels with high WPI concentration (5%, w/w) were perceived as firm. It is intriguing that all coarse-stranded gels were perceived as spreadable. These gels showed multiple fracture events accompanied with coarsening of the network. Due to the multiple fracture events, the samples fell apart in more particles during oral processing, a phenomenon that was perceived as spreadable. Spreadability could be affected also by other properties of the particles than just their number and size. These could be firmness, and surface and adhesive properties of the particles. Assuming that firm particles derive primarily from firm gels, it was shown that firm gels break down to a lower extent during oral processing (see “Physical–Sensorial Properties Relationships”) and are therefore not perceived as spreadable. Surface and adhesive properties of the particles have not been studied. It is therefore not possible to judge their relevance for sensory perception.

From the above, it is clear that both sensorial axes are indirectly related to the microstructure. Concerning microstructure, it is important to realize that different length scales can affect the gel’s properties. In this work, we focused only on the microstructure at length scales above 1 μm. It was shown that negatively charged polysaccharides were not present in the serum phase that was released from the gels upon compression.18 At final pH of the gels (pH 4.8), the protein phase is positively charged. Therefore, we suggest that these polysaccharides interact electrostatically within the protein phase. Microstructural properties at length scales below 1 μm and their effect on the gel’s properties are currently studied by scanning electron microscopy. However, serum release, energy dissipation, and breakdown relate to the serum phase at a micrometer length scale. Therefore, we propose that sensorial properties of the gels are dominated by the phase separation at a micrometer scale rather than by the microstructure at length scale below 1 μm.

Summarizing, all physical properties of WPI/polysaccharide mixed gels (serum release, energy dissipation, large deformation properties, and breakdown) are inherent to and/or derive from the gel’s microstructure. So far, physical properties were rarely studied in relation to the microstructure of such gels.6, 15 Our results show that the mechanical and microstructural properties of the gels are interrelated, and both affect sensory perception. The integrated relations are depicted in Figure 7. Both properties are determined by ingredients (i.e., polysaccharide type and concentration). Ingredients are, thus, the main tools for engineering sensorial properties of the gels via affecting their physical properties.

Conclusion

Sensorial properties of WPI/polysaccharide mixed gels can be explained only if both mechanical and microstructural properties of the gels are taken into account. These properties are interrelated and can be varied by ingredients such as polysaccharide type and concentration. Two principal axes were determined in the sensory space of the gels: crumbly–watery and firm–spreadable axes. The first axis is determined by energy dissipation within the gel upon applied stress. Energy dissipation is mainly affected by serum release, which results from the gel’s microstructure. The second axis, firm–spreadable, is dominated by firmness and breakdown properties of the gels. Coarse-stranded gels, which break down into a large amount of particles via multiple fracture, are perceived as spreadable. The relationships identified in the current study provide an opportunity to control and engineer sensorial properties of semi-solid foods via their microstructure and mechanical properties.

References

V.B. Tolstoguzov, in Functional Properties of Food Macromolecules, ed. by J.R. Mitchell, D.A. Ledward (Elsevier Applied Science, London, UK, 1986), p. 385

J.N. de Wit, J. Dairy Sci. 81, 597–608 (1998)

E. Dumay, A. Laligant, D. Zasypkin, J.C. Cheftel, Food Hydrocoll. 13, 339–351 (1999)

C.M. Bryant, D.J. McClements, Food Hydrocoll. 14, 383–390 (2000)

M.M. Ould Eleya, S.L. Turgeon, Food Hydrocoll. 14, 29–40 (2000)

W. Gustaw, Z. Targoński, P. Glibowski, S. Mleko, S. Pikus, Electron. J. Pol. Agric. Univ. 6, 1505–1513 (2003)

C. Tavares, J.A. Lopes da Silva, Int. Dairy J. 13, 699–706 (2003)

M.P. Gonçalves, W. Sittikijyothin, M. Vázquez da Silva, J. Lefebvre, Rheol. Acta 43, 472–481 (2004)

C. Tavares, S.R. Monteiro, N. Moreno, J.A. Lopes da Silva, Colloids Surf. A 270, 213–219 (2005)

M.E. Bertrand, S.L. Turgeon, Food Hydrocoll. 21, 159–166 (2007)

W. Sittikijyothin, P. Sampaio, M.P. Gonçalves, Food Hydrocoll. 21, 1046–1055 (2007)

J.C. Montejano, D.D. Hamann, T.C. Lanier, J. Texture Stud. 16, 403–424 (1985)

G. Sala, R.A. De Wijk, F. van de Velde, G.A. van Aken, Food Hydrocoll. 22, 353–363 (2008)

G. Sala, T. van Vliet, M.A. Cohen Stuart, G.A. van Aken, F. van de Velde, Soft Matter, (2008, in press)

S.L. Turgeon, M. Beaulieu, Food Hydrocoll. 15, 583–591 (2001)

S. de Jong, F. van de Velde, Food Hydrocoll. 21, 1172–1187 (2007)

L. van den Berg, T. van Vliet, E. van der Linden, M.A.J.S. van Boekel, F. van de Velde, Food Hydrocoll. 21, 420–432 (2007)

L. van den Berg, T. van Vliet, E. van der Linden, M.A.J.S. van Boekel, F. van de Velde, Food Hydrocoll. 21, 961–976 (2007)

L. van den Berg, A.L. Carolas, T. van Vliet, E. van der Linden, M.A.J.S. van Boekel, F. van de Velde, Food Hydrocoll., (2008, in press). DOI 10.1016/j.foodhyd.2007.08.006

H. Stone, J.L. Sidel, Sensory Evaluation Practices (Academic, Orlando, FL, USA, 1985)

K. Pearson, Philos. Trans. R. Soc. Ser. A 187, 253–318 (1896)

L. van den Berg, H.J. Klok, T. van Vliet, E. van der Linden, M.A.J.S. van Boekel, F. van de Velde, Food Hydrocoll., (2008, in press). DOI 10.1016/j.foodhyd.2007.11.002

Acknowledgment

The authors thank CP Kelco Inc. (Lille Skensved, Denmark) and Purac Biochem (Gorinchem, The Netherlands) for their kind provision of ingredients.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

van den Berg, L., van Vliet, T., van der Linden, E. et al. Physical Properties Giving the Sensory Perception of Whey Proteins/Polysaccharide Gels. Food Biophysics 3, 198–206 (2008). https://doi.org/10.1007/s11483-008-9084-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-008-9084-5