Abstract

Metal-dielectric-graphene hybrid heterostructures based on oxides Al2O3, HfO2, and ZrO2 as well as on complementary metal–oxide–semiconductor compatible dielectric Si3N4 covering plasmonic metals Cu and Ag have been fabricated and studied. We show that the characteristics of these heterostructures are important for surface plasmon resonance biosensing (such as minimum reflectivity, sharp phase changes, resonance full width at half minimum and resonance sensitivity to refractive index unit (RIU) changes) can be significantly improved by adding dielectric/graphene layers. We demonstrate maximum plasmon resonance spectral sensitivity of more than 30,000 nm/RIU for Cu/Al2O3 (ZrO2, Si3N4), Ag/Si3N4 bilayers and Cu/dielectric/graphene three-layers for near-infrared wavelengths. The sensitivities of the fabricated heterostructures were ~ 5–8 times higher than those of bare Cu or Ag thin films. We also found that the width of the plasmon resonance reflectivity curves can be reduced by adding dielectric/graphene layers. An unexpected blueshift of the plasmon resonance spectral position was observed after covering noble metals with high-index dielectric/graphene heterostructures. We suggest that the observed blueshift and a large enhancement of surface plasmon resonance sensitivity in metal-dielectric-graphene hybrid heterostructures are produced by stationary surface dipoles which generate a strong electric field concentrated at the very thin top dielectric/graphene layer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Surface plasmon resonance (SPR) has been extensively studied in the last three decades with focus placed on biosensing applications [1,2,3,4]. The main advantage of SPR biosensing is high raw sensitivity of SPR to variations of the refractive index (RI) of the medium covering the metal film that supports surface plasmon polaritons (SPP) [5,6,7]. In spite of extensive research efforts, SPR biosensing [4] of low concentration of analytes with small sizes (typically less than 500 Da) remains a challenging task [3]. Raw sensitivity of SPR sensors depends mainly on the design parameters and a method of measurements (amplitude/phase interrogation, spectral/angular dependences). Recently, researchers proposed several approaches to improve raw SPR sensitivity by changing the structure of a SPR sensor. Lahav et al. [8, 9] suggested guided-wave SPR configuration, where a 10–15-nm high-refractive-index dielectric layer (Si) between a metal layer and an analyte was added to the conventional SPR scheme. The proposed by Lahav et al. [8, 9] configuration has two prominent advantages. The first advantage is that sensitivity of the suggested configuration was enhanced several times as compared to a SPR sensor without a dielectric layer (nearly four times improvement in angular sensitivity has been achieved by adding a 10 nm Si film to a conventional SPR sensor). The second advantage is that the stability of the metal layer was improved because the silicon served as a protection layer for the silver which normally suffers from corrosion. The drawbacks of the suggested material combination are an additional absorption of the added Si layer in visible and near IR ranges and the difficulty to achieve bio-functionalization of the dielectric layer necessary for biosensor selectivity. Another prospective way to significantly improve SPR raw sensitivity is based on a layered material platform that was proposed and optimised in [6, 10, 11]. In this case, a 2D atomic layered material is added to a metal SPR chip with an idea to achieve extremely deep plasmon SPR with almost zero reflection in layered material-protected metal SPR chips. It was established that the points of zero reflection provide extremely sharp phase changes [12] which can be used for extremely sensitive phase SPR biosensing [13]. Recently, phase-sensitive graphene-protected copper SPR chips were applied to rapid and sensitive detection of malaria which is a major tropical disease affecting approximately 500 million people and causing 1.5 to 2.7 million deaths every year [14]. It is important to note that in hybrid graphene–plasmonic configuration, the graphene layer plays a dual role. First, graphene protects plasmonic metals (such as, e.g., reactive Cu or Ag films) from oxidation during biosensing which often requires liquid environment accelerating corrosion. Second, graphene is used as a bio-functionalized surface that provides selectivity of biosensing. Overall, graphene–plasmonic structures displayed enhanced sensitivity as well as pronounced chemical stability and bio-functionality [6, 11, 14].

Other hybrid SPR heterostructures containing 2D atomic materials have been studied for RI sensing; e.g., a graphene/MoS2-based heterostructure was investigated in Ref. [15]. Due to high values of optical constants of MoS2, a stronger SPR excitation can be achieved in the noble-metal/MoS2/graphene SPR chips. It was found that coating of a 45-nm Au thick film by 3-layer MoS2 and a monolayer graphene reduces the width of the SPR curve and provides phase sensitivity enhancement about two orders of magnitude as compared to Au/graphene SPR systems [15]. To achieve the maximum sensitivity in this structure, materials and the number of transition metal dichalcogenide (TMD) layers have been optimized [16, 17]. It was found that adding several layers of TMDs on the top of noble metal films improves electric field enhancement at the sensing interface (graphene in this case) and leads to improved sensitivity. This was confirmed in works [18, 19] where silver films covered by thin (< 10 nm) dielectric layer with high refractive index were considered. It is worth noting that most of the works devoted to SPR sensitivity of noble-metal/TMD/graphene hybrid heterostructures were theoretical ones. This is connected with experimental difficulties in producing heterostructures with given numbers of high-quality TMD monolayers and graphene for SPR-sensing applications. These difficulties can be elevated by replacing the top 2D layer with a reasonably thick metal layer; however, the sensitivity of the resonances would drop. To improve sensitivity in this case, one can use other geometries, e.g., metal–insulator-metal waveguides as proposed in [20].

The presence of an additional dielectric layer in a SPR structure can lead to complications connected with large electric fields induced in the layers. In our recent works [21,22,23], we have shown that electric double-layers (or ion traps) at the interfaces of metal-dielectric and dielectric-graphene can be easily formed. Due to this effect, it is possible to enhance the charge induced in graphene and hence to affect its properties. In a pioneering work, Agranovich et al. showed that the SPPs are strongly dependent on surface currents and charges present on the surfaces and interfaces [24]. These charges naturally occur in hybrid SPR heterostructures due to work-function considerations [18, 19] which lead to formation of a dipole layer at the interfaces [18, 25]. It could happen that frequencies of interface dipole oscillations would lie in the SPP frequency range. In this case, the presence of interface dipoles would strongly affect the SPR response [24, 26], and interface dipoles could produce a strong electric field enhancement in the sensing top layer that would lead to an ultrahigh sensitivity of the SPR-sensing system.

Here, we report a detailed study of hybrid heterostructures for SPR applications that include both thin layers of oxides and 2D layered materials. Namely, we consider noble-metal/dielectric/graphene heterostructures designed to achieve an improved raw SPR sensitivity to refractive index of environment and hence biosensing binding events. Both amplitude and phase interrogation SPR techniques [12, 27, 28] were evaluated. We study three-layer systems that combine plasmonic metal film Cu or Ag with a thin (~ 7 nm) dielectric film of a high refractive index such as Al2O3, HfO2, ZrO2 and Si3N4 and a graphene monolayer.

The improved SPR-sensing performances of these systems are provided by darkness (extremely low reflectivity at the minimum of a SPR curve), associated sharp phase changes and narrow full width at half minimum (FWHM) of the resonances. Our analysis reveals that the effective real and imaginary part of the dielectric permittivity plays an important role in determining the dispersion properties of SPP and spectral position and darkness of the SPR curve. We show that an optimization of the thicknesses of metal and dielectric films in such SPR chips can yield almost an order of magnitude gain of raw amplitude sensitivity as compared to the commercial gold SPR chips. In addition, copper and silver are inexpensive (compared to gold), have lower optical losses in the visible and NIR ranges, and are CMOS-compatible processes [6, 11]. Our work will be useful for researchers working with ultrasensitive label-free biosensing based on SPR platform.

Results and Discussion

Experimental Methods

Preparations of Noble Metal/Dielectric/Graphene SPR Chips and SPR Measurements

Copper and silver metal films were fabricated by electron-beam evaporation (see sect. “Materials and Methods”). Dielectric layers made of Al2O3 (HfO2, ZrO2) were deposited by electron-beam evaporation without breaking the vacuum between the Ag (Cu) and dielectric layer depositions. For deposition of Si3N4 dielectric layers, we used the method of chemical vapor deposition (CVD) which allows one to achieve better morphology and hence better plasmonic characteristic of the ultimate devices. The thicknesses of metal and dielectric layers were chosen according to Fresnel simulations to realize the deepest SPR curves. Note that optimized (theoretically and experimentally) thicknesses of layers in the proposed trilayer metal/dielectric/graphene heterostructure are a Cu layer (40 nm) or Ag (45 nm) and a dielectric layer (7–8 nm). Metal films of chosen thicknesses yielded strongly enhanced electromagnetic fields on the top of heterostructures, while a high-refractive dielectric layer of a small thickness reduced the losses. A graphene monolayer significantly improved sensor stability and promoted new type of bio-functionalization as compared to gold SPR. We noticed that blue shift of SPR and enhancements of bio-sensitivity in the system are only significant when thickness of the dielectric layer is less than 10 nm. The bare quartz/Al2O3 (HfO2, ZrO2, Si3N4) structures with thickness of dielectric 7–8 nm were also separately deposited and measured using ellipsometry. Their refractive indexes were extracted from angle and wavelength-dependent ellipsometric parameters with the help of the corresponding Cauchy functions and Fresnel fitting. To fabricate metal/dielectric/graphene samples, we transferred a monolayer of graphene on the top of the bilayer heterostructure. A Turbadar–Kretschmann–Raether scheme of SPP excitation on planar interfaces (see Fig. 1) has been employed (see sect. “Materials and Methods”) [29,30,31]. In this scheme, the prism is placed on top of the glass substrate carrying metal/dielectric/graphene heterostructure, and excitation of SPPs happens at the far side of the metal-dielectric layers. The ellipsometric spectra were collected using an unfocused beam Woollam ellipsometer M-2000 with spot diameter of ~ 3.5 mm and the angle range of 45–75°. The optical data were recorded as a pair of ellipsometric parameters Ψ and Δ in the spectral range of 240–1700 nm with a wavelength step of ~1 nm. The parameter Ψ represents the ratio of Fresnel reflection amplitudes and Δ phase shift between p-and s-components of polarized light [11, 27, 28]. The ellipsometric parameters are connected to the Fresnel amplitude reflection coefficients \({r}_{p}\) and \({r}_{s}\) for the p- and s-polarized light, respectively, as \(\mathrm{tan}\left(\Psi \right)\mathrm{exp}\left(i\Delta \right)=\frac{{r}_{p}}{{r}_{s}}\). The excitation of SPR at the surface of noble metal/dielectric/graphene was observed as a strong dip in Ψ accompanied by very sharp changes of Δ that happens for a specific combination of angle of incidence and light wavelength [6, 11, 28, 32].

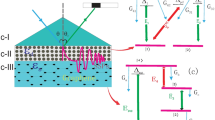

Copper(silver)-dielectric-graphene hybrid nanostructures with enhanced sensitivity. a Schematic of electron–hole (e–h) pairs production as dipole transitions at the interfaces of copper-dielectric and dielectric-graphene interfaces. b Schematic diagram of SPR sensor for copper-dielectric-graphene hybrid nanostructures with enhanced EM field due to SP propagation and interface dipoles emission

Experimental Results

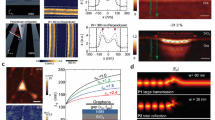

In Fig. 2, we plot the SPR spectral curves for the Cu(Ag)/Al2O3(HfO2, Si3N4, ZrO2) heterostructures with and without the top graphene monolayer. Monolayer nature of CVD graphene transferred on the top of the dielectric was checked by the Raman spectroscopy (see, Fig. 1 of Supplementary Information (SI)). For both metals Cu and Ag, the position of the sharp dip of the SPR curves shifts to smaller wavelengths (blueshifts) in the presence of dielectric layer except for the case of hafnia (HfO2). As expected, the spectral width of the SPR reflectance dip at half minimum, FWHM or ΔλR, is larger for bilayers based on Cu films (Fig. 2) and smaller for Ag heterostructures. Adding a thin layer of dielectrics to SPR structure does not only shifts the SPR position but also changes the FWHM. For optimized structures, the FWHM of SPR resonances obtained here in Cu(Ag)/Al2O3(HfO2, Si3N4, ZrO2)/graphene heterostructures is less than about ΔλR ~ 28 nm. This is smaller than typical values observed for the SPR on the Cu-air interface (Figs. 2, S.2, S.3, S.4). It is worth noting that the FWHM of SPR reflectance dip is twice as large as ~ 50 nm for Au films [26].

Strong and narrow SPR of copper(silver)-dielectric-graphene hybrid nanostructures (coupling prism, n = 1.5). a Ellipsometric parameters Ψ (amplitude) of the SPR curve of bilayer Cu (40 nm)/dielectric (7 nm). b Ellipsometric parameters Ψ of the SPR curve of bilayer Ag (45 nm)/dielectric (7 nm). c, d Ellipsometric parameters Ψ and p-polarised reflectivity RP of the SPR curve of three layers Cu(Ag)/dielectric/graphene

Figure 2c, d show the SPR reflectance spectra Ψ(λ) and Rp(λ) for metal/dielectric/graphene heterostructures. Graphene induces a small spectral shift of SPR at ~ 10 nm for hybrid heterostructures based on Cu and ~ 30 nm for heterostructures based on Ag. The measured p-polarised reflection spectra in Fig. 2d demonstrate very small values (approximately zero) of reflection at the dip of the SPR curve, Rp,min and the narrow FWHM ≈ 30–35 nm especially for Cu/ZrO2/graphene and Ag/Si3N4/graphene hybrid heterostructures. Remarkably, such small FWHM were not previously observed for Cu or Ag SPR chips. These measurements confirm that graphene monolayer on the top of noble-metal/dielectric heterostructures can improve SPR characteristics. The quality factor Q of the SPR (Q = λR/ΔλR, where λR is the resonance wavelength corresponding to the SPR reflection minimum and ΔλR is FWHM of the resonance curve) was maximal Q ~ 50 for the optimal Ag/Al2O3 heterostructure and minimal Q ~ 21 for optimized Cu/Si3N4 structures, as can be estimated from the ellipsometric Ψ(λ) SPR curves (Fig. 2). These characteristics are better than those observed for pure Au, Ag and Cu films with SPR in the green–red wavelength range [6, 11, 33, 34]. Such behaviour of the SPR spectral position and width indicates that the propagation characteristics of SPPs are very sensitive to the choice of metal and dielectric in hybrid heterostructures.

At the next stage, we have tested raw SPR sensitivity of the fabricated plasmonic metal/dielectric/graphene heterostructures to changes of RI of water-glycerol solutions placed at the top of SPR chip; see schematic, Fig. 1b. We used two types of interrogation: (i) the amplitude interrogation method based on the ellipsometric parameter Ψ(λ), where the shift of the reflectance minimum is determined at a fixed angle of incidence; (ii) the phase interrogation method, where changes of the ellispomteric phase Δ(λ) are measured (Figs. 3, 4, and 5). For the amplitude interrogation method, an intensity of reflected light at SPRs minimum for different Cu(Ag)/Al2O3(Si3N4, ZrO2) heterostructures is close to zero for water/glycerol mixture environment. The wavelengths of the SPR spectral position were extracted and plotted in Fig. 4e, f where we can see that the SPR wavelength shifts almost linearly with a change in RI of the surrounding medium. The slope in Fig. 4e, f gives the RI detection sensitivity. Therefore, we can introduce a sensitivity parameter S that describes the resonance wavelength shift per refractive index unit (nm/RIU) and can be expressed as S = dλ/dn [2, 35, 36]. Note that, for extracting sensitivity of SPR to RI, we have used ellipsometry methods which are immune to many sources of noise since they measure and fit the ratio of the reflection coefficients and phase difference which are extremely sensitive to small changes of RI. We showed that narrow and deep SPRs can be tuned from the near IR (~900 nm) to the mid-IR (~1600 nm) just by altering the environment’s RI (water/glycerol mixture). The linear fit yields a very high spectral sensitivity of S = dλ/dn ~ 38,000 nm/RIU for Cu/Al2O3 bilayers (without graphene); see Fig. 4e–f and Table 1. This sensitivity can be estimated from the resonance wavelength shift of dλ ~ 220 nm at the minimal detected changes of dn = 0.00577 as shown in Fig. S.2. It is worth mentioning that, for all investigated samples, we have repeated SPR-sensing experiments three times to precisely evaluate the amplitude and phase changes and confirm a high sensitivity.

SPR biosensing of copper-dielectric hybrid nanostructures (coupling prism, n = 1.8). a, b Change of spectral position Ψmin(λ) and corresponding change (jump) of phase (δΔ) as a function of the refractive index of water-glycerol solution for bilayer Cu (40 nm)/Al2O3(7 nm). c, d Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for bilayer Cu (40 nm)/Si3N4(8 nm). e, f Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for bilayer Cu (40 nm)/ZrO2(7 nm)

SPR biosensing of silver-dielectric hybrid nanostructures (coupling prism, n = 1.5). a, b Change of spectral position Ψmin(λ) and corresponding change of phase (δΔ) as a function of the refractive index of water-glycerol solution for bilayer Ag (45 nm)/Al2O3(7 nm). c, d Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for bilayer Ag (45 nm)/Si3N4 (8 nm). e, f High spectral sensitivity evaluated from shift of SPR wavelength (δλmin) for Ψ dependences versus of the refractive index of water-glycerol solution for bilayer Cu-dielectric (e) and for bilayer Ag-dielectric (f)

SPR biosensing of Cu(Ag)/Al2O3(HfO2,Si3N4,ZrO2)/graphene hybrid nanostructures (coupling prism, n = 1.8). a, b Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for three layers Cu (40 nm)/Al2O3(7 nm)/graphene. c, d Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for three layers Cu (40 nm)/Si3N4(8 nm)/graphene. e, f Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for three layers Ag (45 nm)/Si3N4(8 nm)/graphene. g, h Change of spectral position Ψmin(λ) and corresponding jump of phase (δΔ) as a function of the refractive index of water-glycerol solution for three layers Cu (40 nm)/ZrO2 (7 nm)/graphene

Near-infrared SPRs for the Ag/Al2O3(Si3N4) bilayers in the water-glycerol solutions exhibit broader FWHM than ones in air. The highest SPR sensitivity of S = 30,900 nm/RIU was recorded for Ag (45 nm)/Si3N4 (8 nm) hybrid structure (Fig. 4a–d and Table 1, Fig. S.2). The abrupt phase Δ(λ) changes are observed at the resonance due to low value of reflection at the resonance minimum. Note, that if investigated samples do not exhibit complete darkness at the SPR wavelengths, the ellipsometric phase Δ(λ) changes are not pronounced. Similar to the amplitude ellipsometric characteristic Ψ(λ), the phase parameter Δ(λ) exhibits linear dependence as a function of RI at a wavelength where phase jumps occur (Figs. 3 and 4). The spectral widths of the experimentally measured phase Δ(λ) are hard to define due to the drastic changes within the very narrow spectral range and the limited spectral resolution of the Woollam ellipsometer used in the experiments (~1 nm). Detailed analysis of the data shown in Figs. 3 and 4 suggests that the most sensitive heterostructure was Cu/Al2O3. It is worth noting that phase changes for Ag/Al2O3(Si3N4) SPR heterostructure are hysteretic as a function of RI (Fig. 4b, d). Generally, a phase response of the studied SPR heterostructures demonstrates noticeably strong changes for extremely close values of external parameters.

Finally, Fig. 5a–g show changes of the ellipsometric parameters Ψ(λ) and Δ(λ) for the metal/dielectric/graphene heterostructures measured in water-glycerol solutions. As one can see from Fig. 5, the SPR position shifts to longer wavelengths while the resonance widths ΔλR is slightly increased at an increase of the RI of the top liquid. It is interesting to note that the sharp changes of phase Δ(λ) are more significant than that of the amplitude Ψ(λ) at the resonance wavelengths. The changes in the phase δΔ(λ) are more than 250° for the refractive index change of 0.0012 RIU, which yields the phase sensitivity of ~1.7 × 105°/RIU for the case of Cu/Al2O3/graphene heterostructures (Fig. 5). Overall, among all the optimised sensing trilayer SPR chips, 40-nm Cu film with thin Al2O3 or Si3N4 dielectric layers (of the thickness 7–8 nm) covered by graphene monolayer provided the best sensing configuration with significant amplitude and phase sensitivities. At the same time, SPR sensitivity of bilayers Cu/Al2O3 was even better due to non-ideal properties of transferred graphene; see Raman spectra shown in Figure S.1.

The amplitude figure of merit (FOM) of SPR chips, defined as sensitivity S divided by the resonance linewidth FWHM, ΔλR [2, 34, 35], can be written as FOM = S/ΔλR. For the best of our bilayer metal/oxide heterostructures, FOM was at the level of FOM = 590 for Cu (40 nm)/Al2O3 (7 nm) and FOM = 690 for Ag (45 nm)/Si3N4 (8 nm) sandwiches; see Table 1 (these numbers were obtained using the sensitivity S of heterostructures and FWHM of plasmonic resonances ΔλR, which were S ~ 38,000 nm/RIU and ΔλR ≈ 65 nm in water for Cu/Al2O3 bilayer and S ~ 31,000 nm/RIU and ΔλR ≈ 45 nm for Ag/Si3N4 bilayer). It is at the same level as FOM = 590, the highest FOM that was previously obtained for complicated hyperbolic metamaterials, [37] and about 5 times higher than for standard Au-based sensors [33]. When covered by graphene, the sensing properties of metal/oxide bilayers change (see Fig. 5 and Table 1). The amplitude FOM was 450 for the most sensitive Cu (40 nm)/Al2O3 (7 nm)/graphene heterostructure (see Table 1). At the same time, due to the larger darkness of SPR, the phase sensitivity observed was ~ 105°/RIU for the studied heterostructures which is one order of magnitude higher than that of the conventional Au thin film with 50 nm thickness (which is usually ~ 104°/RIU, although it could be improved for some dedicated systems [38, 39]). Combining the amplitude and phase detection methods, the proposed biosensor hybrid system can maintain the unique advantages in terms of both high amplitude sensitivity of > 30,000 nm/RIU and the phase detection limit at the level of 10−8 RIU at the same time. The enhancement of the amplitude sensitivity for the studied plasmonic metal/dielectric/graphene heterostructures was about 5–8 times as compared with SPR amplitude sensitivity based on bare Cu or Ag thin films. Note also that the maximum of RI sensitivity of designed Cu(Ag)/dielectric/graphene nanostructures is more than one order of magnitude higher than that of a highly sensitive sensor-based localised surface plasmon resonances (~2000 nm/RIU) theoretically discussed in [40]. This shows that the proposed platform of heterostructure biosensors could outperform conventional SPR (as well as LSPR) chips by almost an order of magnitude by using the amplitude and phase interrogations.

Discussion

Dielectric Function of the Hybrid Plasmonic Nanostructures

From experimental results, we can see that thin dielectric or dielectric/graphene layers added to the SPR chip can strongly impacts the optical properties of SPR devices. Normally, the SPR chips with added heterostructures are modelled with the help of Fresnel theory [41]. However, when thickness of added layers becomes small, then, the surface effects can play an important role, and the optical constants of thin layers could be different from those of bulk materials. For example, graphene has optical constants different from those of bulk graphite [42] or optical properties of MoS2 monolayers can be different from those of bulk MoS2 [43]. Our modelling of the ellipsometric characteristic Ψ(λ) (p- and s-polarised reflections) based on the Fresnel approach [41] revealed that the lowest value of minima reflectivity Ψ(λ) are redshifted when we add the different dielectric layers of thickness 7–8 nm on top of plasmonic Cu film (Figure S.3). This result is in contradiction with the experimental dependences which demonstrate the unexpected blueshift of SPR for high-index dielectric covering; see Fig. 2. Moreover, we have found that the width of the experimental SPR reflectivity curves could be significantly reduced by combining noble metal and a thin dielectric layer (< 10 nm) in contrast to the Fresnel theory of SPR. The redshift of SPR of plasmonic Cu film in hybrid nanostructures with a HfO2 top layer as well as the blueshift of SPR for other bilayers (Cu/Al2O3, Si3N4, ZrO2) can be correlated with electronic states and morphology of dielectric surface. In recent work [21], we have checked stoichiometry of different oxides deposited by electron-beam evaporation on the top of a Cu thin film using X-ray photoelectron spectroscopy and found that density of oxygen vacancies in HfO2 layer is much larger than that in Al2O3. In addition, the surface roughness of deposited HfO2 films was found to be the largest (Fig. S.5). We suggest that non-stoichiometric nature of deposited hafnia together with higher surface roughness resulted in the observed redshifts for Cu/HfO2 hybrid nanostructures.

Knowing the complex dielectric function of the SPR chip covered with thin films and using an ingenious approach developed by Abeles [44], we can evaluate an important parameter of the problem: SPP propagation length (LSPP). According to [44], the LSPP is inversely proportional to the SPR minimum width and can be estimated as \({L}_{\mathrm{SPP}}\sim {\varepsilon }_{1,eff }^{2}/{\varepsilon }_{2,eff}\) (where ε1,eff and ε2,eff, in our case, are the effective real and imaginary part of the dielectric function of metal/dielectric-graphene nanostructure). Hence, to achieve larger LSPP, one needs a large real part of metal-dielectric constant, ε1,eff, and a small imaginary component, ε2,eff (larger LSPP indicates that the designed structures have higher transfer efficiency from the incident light to the SPR energy, leading to a stronger SPR excitation and a sharper phase change resulting in enhancement of RIU sensitivity). Using the measured ellipsometric functions Ψ(λ) and Δ(λ), we can reconstruct the effective real ε1,eff and imaginary part ε2,eff of the dielectric function of metal/dielectric-graphene nanostructure [41, 45]. To do so, we consider bilayer or three layers stack as single effective (homogenise) layer. This approach only works for films with total thickness satisfying the condition kd < < 1 (where k is wave vector of free space light and d is thickness of dielectric/graphene layers) [46]. This assumption is obviously valid for dielectric or dielectric/graphene layers which are thinner than the skin depth of noble metal (< 25 nm) on the probing wavelength (~600 nm) [47]. The resulting effective real and imaginary parts of the dielectric function (εeff = ε1,eff + iε2,eff) of different Cu(Ag)/dielectric/graphene nanostructures are shown in Fig. 6.

Dielectric function of Cu(Ag)/Al2O3(HfO2, Si3N4,ZrO2)/graphene hybrid nanostructures. a, b The effective real (ε1) and imaginary (ε2) parts of the dielectric function for Cu (45 nm) and bilayer Cu (40 nm)/dielectric (7 nm). c, d The effective real (ε1) and imaginary (ε2) parts of the dielectric function for Ag (45 nm) and bilayer Ag (45 nm)/dielectric (7 nm). e, f The effective real (ε1) and imaginary (ε2) parts of the dielectric function for three layers Cu/dielectric/graphene

Inspection of the ε1,eff demonstrates that, for Cu- and Ag-based hybrid nanostructures, ε1,eff are the smooth monotonic functions, which can be approximated by Drude permittivity in the red part of visible and the IR ranges. The behaviour of the ε2,eff is more complicated: it reaches the minimum at λmin (interband transitions), and then for λ > λmin, it grows and starts to follow Drude dependence [45, 47]. Note that Cu(Ag)/dielectric/graphene hybrid nanostructures show smaller values of the ε1,eff and ε2,eff functions in near IR region as compared to pure Cu(Ag) plasmonic films. Surface roughness and grain size can contribute to an increase of the imaginary part of the dielectric function ε2,eff over the intrinsic bulk value [47]. The surface roughness of the Cu(Ag)/dielectric bilayers on glass substrate was measured using an atomic force microscope (AFM) and is shown in Figure S.5. It is worth noting that Cu/dielectric heterostructures maintain smoother surface morphology (root mean square roughness (RMSR) changes from 1 to 2 nm) as compared to Ag/dielectric films (RMSR ~ 3–4 nm). The minimal RMSR of 1.2–1.3 nm was measured for Cu/Al2O3(ZrO2) bilayers which also yielded in the highest biosensitivity. Moreover, the significant increase of RMSR for Cu/HfO2 bilayer confirms the fact that the morphology of surface can significantly reduce SPR sensitivity. Comparison of the εeff = ε1,eff + iε2,eff function for different Cu(Ag)/dielectric/graphene nanostructures (Fig. 6) and amplitude sensitivity (Figs. 3, 4, and 5) reveals strong correlation between a small value of the imaginary part of effective permittivity ε2,eff and large spectral sensitivity of SPR, S = dλ/dn. Note that SPR exhibits much lower FWHM ΔλR and higher FOM in the case of the higher slope δε1,eff /δλ and smaller ε2,eff according to equation [48]: ΔλR = 4ε2,eff/ | δε1,eff /δλ |. By optimizing the parameters of the Cu(Ag)/dielectric/graphene hybrid heterostructures, we can balance the optical absorption efficiencies and the electron losses (ε2,eff) at the plasmonic resonance condition.

Interface Dipole Contribution in the Resulting Plasmonic Field

To explain the significant blueshift of the SPR spectral position for different Cu(Ag)/dielectric heterostructures in comparison to the pure Cu(Ag) films (except of HfO2 oxide) (Figs. 2 and S.3, S.4), we consider the existence of a transition layer on the reflecting surface of the interfaces [49]. Sivukhin [49] was first to introduce the surface polarizabilities of thin films, produced either by lattice defects, atoms in excess of stoichiometry or, even in the case of ideal lattice, by differences in the intermolecular interaction and symmetry of the internal field. In this scenario, an infinitely thin layer, placed on the surface of the thin film, provides the dipole-moment surface densities which contribute to the polarised reflection [49]. We can also assume the significant impact of the interface dipoles on the properties of propagating SPPs for Cu(Ag)-high-index dielectric heterostructures (Fig. 1a, b). In the modern theoretical description, the SPR frequency is modified by introducing the complex Feibelman frequency-dependent parameters dII,⊥ to the Fresnel approach according to [50,51,52,53,54]: \({\omega }_{SPR}={\omega }_{SPR}^{0}\sqrt{1-k{d}_{\perp }+k{d}_{\parallel }}\), where \({\omega }_{SPR}^{0}\) is the classical SPR frequency for pure noble metal film and k is the wavevector. Note that the Feibelman dII parameter is usually small and vanishes for locally uncharged surface while d⊥ can strongly impact the nonlocal correction to the SPP dispersion [53, 54]. Considering the d⊥ parameter, we can conclude that, if Re(d⊥) < 0, the SPR will be blueshifted while when Re(d⊥) > 0 the resonance redshifted [54]. Moreover, the value of Im(d⊥) can contribute to the narrowing/broadening of the SPR. Narrower resonances appear due to collective contribution in plasmonic resonance from assembles of interfaces dipoles—in rough analogy of the collective dipole-like resonances from arrays ordered nanoparticles [2, 55]. Note that the magnitude of Feibelman dII,⊥ parameters at the interface noble metal-dielectric are a few times higher than those at metal-air [53, 54]. Agranovich [24, 26] stressed that the appearance of microscopic surface excitons (interface dipoles in our case) causes the polarizability of the dielectric transition layer in the direction perpendicular to the separation boundary (interface) between the media. It could happen that the frequency of the microscopic surface exciton at ions falls into the surface-polariton band significantly affecting the SPP spectrum [24]. Note that the plasmon energies are found to increase with decreasing particle diameter for Si and SnOx nanoparticles [56]. These energy shifts are related to the change of the dielectric bandgap energy of the semiconductor due to quantum size effects [56].

In addition, electron transfer due to the work-function difference between different layers and noble metals Cu (Ag) can promote a large electric field enhancement at the sensing interface and thus leading to higher sensitivity of the biosensor. It is worth noting that the work function of Cu (~5.22 eV) [25, 57] is higher than that of dielectrics Al2O3(2.73 eV), HfO2(2.47 eV) and ZrO2 (2.3 eV) [18]. Due to this, the successful transfer of electrons from dielectric/graphene hybrid layers to Cu film could occur under optical excitation. The dimension scale of such electrons transfers extends beyond the Thomas–Fermi (TF) screening length (the characteristic length Lc = vF/ω, where vF is the Fermi velocity of electrons and ω is a light frequency). For standard values of about vF ~ 1.4 × 106 m/s, the resulting wavevector mismatch is on the scale of Δk ~ Lc−1 and it is about 2 nm−1 for noble metals at 600 nm (~2 eV photon energy), and it is much larger than wavevector of the electromagnetic wave [58]. This estimation confirms that only at the interfaces can form (e–h) pairs, creating dipoles. The in-plane SPP propagation can strongly couple with the out-of-plane interface dipoles emission, as illustrated in Fig. 1a, b. This process is insignificant at a metal-low-index interface [17, 18] due to the high barrier; however, it could be large at a metal-high-index interface and could lead to intensified energy of surface plasmon and narrowed absorption spectrum [18, 19]. This process could also promote larger electric field enhancement at the sensing interface thereby resulting in a higher SPR sensitivity to the target analytes.

Modelling of the SPR in the Plasmonic Heterostructures

To calculate the optical properties of the studied plasmonic metal/dielectric/graphene heterostructures, we introduced the Feibelman dII,⊥ parameters approach [18, 51,52,53,54] for the Fresnel equations of reflection/transmission of incident light from a planar Cu(Ag)/dielectric/graphene interface [41]. The core idea underlying Feibelman dII,⊥ parameters is an interface dipole expansion. In our modelling, we have only considered the changes of p-polarised reflectivity coefficients by introducing the Feibelman d⊥ parameter in the standard matrix calculation [41]. The real and imaginary parts of d⊥ were chosen from the best fit to our data. We set Re(d⊥) = − (0.15 − 0.17) for Al2O3, Si3N4, and ZrO2 dielectrics in our calculation. The imaginary part was chosen to be Im(d⊥)≈-0.1. In Figure S.6, we plot the ellipsometric parameter Ψ(λ) as a function of wavelength for all the dielectrics and reveal the blueshift SPRs which agrees with experimental dependences (Fig. 2). These results demonstrate that the suggested approach is suitable for the use in numerical modelling of complex heterostructures made of noble metals and high-index dielectrics/graphene layers and thus can predict an ultrahigh sensitivity of the SPR-sensing devices.

Conclusions

We have engineered a SPR-sensing hybrid heterostructures based on noble-metal/dielectric/graphene layers to achieve significant amplitude and phase sensitivity improvement of SPR sensing. The suggested planar noble metal/dielectric/graphene heterostructures possess high sensitivity owing to strong light-matter interaction region on the top of a graphene monolayer and could provide a simple and cost-effective solution for a label-free biosensing platform. We have shown the lower reflectivity values in SPR minimum for the noble-metal/dielectric/graphene heterostructures as well as high SPR raw biosensitivity and sharper phase changes at the resonance minimum. We have found that the highest spectral sensitivities for the studied system were observed for Cu/Al2O3 and Cu/ZrO2 heterostructures (with and without graphene) which were around 38,000 nm/RIU and possessed the FOM of 420–590. The phase sensitivity of this system is increased by more than one order of magnitude as compared to gold SPR platform. The sensitivity enhancement is due to concentration of electromagnetic energy of plasmonic waves on the top of dielectric/graphene layers. We suggested the mechanism of additional electric field enhancement at the sensing interface connected with creation of stationary surface dipoles at the interfaces between metals and dielectrics. This finding will be important for understanding and designing nanoplasmonic devices that utilize noble metals and high-index dielectrics/graphene layers with an idea to achieve ultrahigh sensitivity of SPR-sensing devices.

Materials and Methods

Sample Preparation

For the noble metal (Ag or Cu) deposition, we use electron-beam evaporation and strictly follow the same procedure all the time. Our deposition rate is controlled precisely at 1.0 ˚A s−1 and the base pressure is 1.0 × 10−6 torr. Growth of the metal film was monitored by a calibrated quartz microbalance (CQM). Adhesive layer was chosen thin Cr (1.5 nm) film deposited on clean glass substrates by electron-beam evaporation. Then, on top of metallic (Ag or Cu) layer was evaporated dielectric (Al2O3 or HfO2, ZrO2) using same technology process. Note that we did not break the vacuum between the Ag (Cu) and dielectric Al2O3 (HfO2, ZrO2) deposition. This guarantees no oxidized layer formation on the Ag (Cu) surface. When we have used CVD to grow the Si3N4 dielectric, the exposure time of the already evaporated Ag and Cu films is at most 1–2 h in the ambient cleanroom environment. There is no sign showing any of our experimental results to be related to oxidize Ag (Cu) surfaces.

To fabricate Cu(Ag)/dielectric/graphene samples, we transferred single-layer graphene (SLG) on top of the bilayer nanostructure. The process of CVD graphene transferring consists from the following steps: (i) a monolayer of graphene on Cu foil substrate and acquired from 2D semiconductors was spin-coated with a poly(methyl methacrylate) (PMMA) resist for support. (ii) The copper substrate was etched in a solution of ammonium persulfate, and the floating membrane was cleaned in a subsequent bath of deionized water. Next, the PMMA/graphene films on the scotch type were fished for transfer procedure. (iii) The resulting monolayer of graphene was transferred on top of Cu(Ag)/dielectric structure using the standard dry-transfer technique as described in [43]. (iv) Finally, after drying overnight, the PMMA layer was removed by soaking in acetone.

Raman Confirmation

We used CVD method for large-area SLG preparation and single layer of the graphene transferred on the bilayer was confirmed by Raman spectroscopy (see Figure S.1, Supporting Information). Raman spectra of CVD graphene transferred on top of dielectric thin film were recorded with a Witec confocal spectrometer at the excitation wavelength of 514.5 nm.

Morphology Testing

The surface morphology and the root mean square (RMS) surface roughness of deposited films were characterized by atomic force microscopy (AFM) (Nanoscope V with Dimension 3100). The samples were scanned by AFM using tapping mode, typically over a 5-μm2 area at a tip velocity of 1 μm/s and a corresponding scan rate of 1 Hz. Nasoscope software was utilized to analyse the images and extract the RMS.

Ellipsometric Measurements of the SPR Characteristics for Noble Metal-Dielectric Bilayers

Spectroscopic ellipsometry measurements are performed to check the sensitivity of SPR to refractive index, which further helps determine the corresponding wavelength for maximum sensitivity. Together with standard ellipsometric method, we have also employed recently developed method of total internal reflection ellipsometry (TIRE) which represents a very successful combination of the spectroscopic ellipsometry instrumentation with the Turbadar–Kretschmann–Raether type surface plasmon resonance geometry of the experiment [29,30,31, 44, 45]. The obvious advantages of the TIRE method are as follows: (i) a possibility of measurements of both the amplitude (Ψ) and phase (Δ) related parameters and (ii) the separation of the light beam pass from the investigated medium. For TIRE measurements, the most common Kretschmann configuration of SPR ellipsometry was realized and shown schematically in Fig. 1. The SPR ellipsometry set-up used in our experiment is based on the commercially available variable angle spectroscopic ellipsometry (VASE) from J.A. Woollam Company (USA) equipped with a 45° (or 60°) glass prism and home-built micro-fluidic flow cell. The glass slide is brought into optical contact to the glass prism through the index matching fluid. The investigated incident angles range φ = 45–75° were near the surface plasmon resonance angle for TIRE. The state of polarization can be described in terms of two ellipsometric parameters Psi (Ψ) and Delta (Δ), which are defined as \(r_{p} /r_{s} = \tan \psi \exp (i\Delta )\) (where rp =|Ep/Ei| and rs =|Es/Ei| are the Fresnel reflection coefficients for light polarization parallel (rp), and perpendicular (rs) to the plane of incidence, Ei denotes the electrical field of the incoming light) contain information for both p- and s- polarized light components reflected from the sample surface. In addition to ellipsometric parameters Ψ and Δ, the ellipsometer allowed us to separately measure Rp =|rp|2 and Rs =|rs|2, the intensity reflections for p- and s-polarised light, respectively, at various angles of incidence with respect to the total light intensity. Experimental results show that the changes for ellipsometric characteristics Ψ and Δ are the most strongest and they are very sensitive to environmental covering during monitoring in TIRE geometry.

Availability of Data and Material

All other data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Maier SA (2007) Plasmonics: fundamentals and applications: Springer Science & Business Media

Kravets VG, Kabashin AV, Barnes WL, Grigorenko AN (2018) Plasmonic surface lattice resonances: a review of properties and applications. Chem Rev 118:5912–5951. https://doi.org/10.1021/acs.chemrev.8b00243

Homola J, Piliarik M (2006) In Surface plasmon resonance based sensors Springer.

Liedberg B, Nylander C, Lundström I (1995) Biosensing with surface plasmon resonance—how it all started. Biosens Bioelectron 10:i–ix

Liedberg B, Nylander C, Lunström I (1983) Surface plasmon resonance for gas detection and biosensing. Sensors Actuators 4:299–304

Kravets VG, Jalil R, Kim Y-J, Ansell D, Aznakayeva DE, Thackray B, Britnell L, Belle BD, Withers F, Radko IP, Han Z, Bozhevolnyi SI, Novoselov KS, Geim AK, Grigorenko AN (2014) Graphene-protected copper and silver plasmonics. Sci Rep 4:5517. https://doi.org/10.1038/srep05517

Anker JN, Hall WP, Lyandres O, Shah NC, Zhao J, Van Duyne RP (2008) Biosensing with plasmonic nanosensors. Nat Mater 7(6):442–453

Lahav A, Auslender M, Abdulhalim I (2008) Sensitivity enhancement of guided wave surface plasmon resonance sensors. Opt Lett 33:2539–2541

Lahav A, Shalabney A, Abdulhalim I (2009) Surface plasmon resonance sensor with enhanced sensitivity using nano-top dielectric layer. J Nanophoton 3:031501

Zeng V, Sreekanth KV, Shang J, Yu T, Chen CK, Yin F, Baillargeat D, Coquet P, Ho HP, Kabashin AV, Yong KT (2015) Graphene–gold metasurface architectures for ultrasensitive plasmonic biosensing. Adv Mater 27:6163–6169

Wu F, Thomas PA, Kravets VG, Arola HO, Soikkeli M, Iljin K, Kim G, Kim M, Shin HS, Andreeva DV, Neumann C, Küllmer M, Turchanin A, De Fazio D, Balci O, Babenko V, Luo B, Goykhman I, Hofmann S, Ferrari AC, Novoselov KS, Grigorenko AN (2019) Layered material platform for surface plasmon resonance biosensing. Sci Rep 9:20286

Grigorenko AN, Nikitin PI, Kabashin AV (1999) Phase jumps and interferometric surface plasmon resonance imaging. Appl Phys Lett 75:3917–3919

Grigorenko AN, Beloglazov AA, Nikitin PI, Kuhne C, Steiner G, Salzer R (2000) Dark-field surface plasmon resonance microscopy. Opt Commun 174(1–4):151–155

Wu F, Singh J, Thomas PA, Ge Q, Kravets VG, Day PJ, Grigorenko AN (2020) Ultrasensitive and rapid detection of malaria using graphene-enhanced surface plasmon resonance. 2D Mater 7(4):045019

Zeng Sh, Hu S, Xia J, Anderson T, Dinh X-Q, Meng X-M, Coquet P, Yong K-T (2015) Graphene–MoS2 hybrid nanostructures enhanced surface plasmon resonance biosensors. Sensors Actuators B 207:801–810

Ouyang Q, Zeng Sh, Jiang L, Qu J, Dinh X-Q, Qian J, He S, Coquet P, Yong K-T (2017) Two-dimensional transition metal dichalcogenide enhanced phase-sensitive plasmonic biosensors: theoretical insight. J Phys Chem C 121:6282–6289

Jiang L, Zeng Sh, Ouyang Q, Dinh X-Q, Coquet P, Qu J, He S, Yong K-T (2017) Graphene-TMDC-graphene hybrid plasmonic metasurface for enhanced biosensing: a theoretical analysis. Phys Status Solidi A 214:1700563

Jin D, Hu Q, Neuhauser D, von Cube F, Yang Y, Sachan R, Luk TS, Bell DC, Fang NX (2015) Quantum-spillover-enhanced surface-plasmonic absorption at the interface of silver and high-index dielectrics. Phys Rev Lett 115:193901

Christensen T, Yan W, Jauho AP, Soljačić M, Mortensen NA (2017) Quantum corrections in nanoplasmonics: shape, scale, and material. Phys Rev Lett 118:157402

Chou-Chau C-T, Chou-Chau Y-F, Huang HJ, Kumara NTRN, Rahimi Kooh MR, Lim CM, Chiang H-P (2020) Highly sensitive and tunable plasmonic sensor based on a nanoring resonator with silver nanorods. Nanomaterials 10:1399

Yu T, Kravets VG, Imaizumi Sh, Grigorenko AN (2021) An effect of dielectric fabrication techniques on graphene gating. J Phys Chem C 125(1):865–872

Rodriguez FJ, Aznakayeva DE, Marshall OP, Kravets VG, Grigorenko AN (2017) Solid-state electrolyte-gated graphene in optical modulators. Adv Mater 29:1606372

Aznakayeva DE, Rodriguez FJ, Marshall OP, Grigorenko AN (2017) graphene light modulators working at near-infrared wavelengths. Opt Express 25:10255–10260

Agranovich VM (1975) Crystal optics of surface polaritons and the properties of surfaces. Sov Phys-Usp 18(2):99–117

Luth H (2001) Solid surfaces, interfaces and thin films. Springer-Verlag Berlin Heidelberg New York, 3 Ed

Mills DL, Agranovich VM (1982) Surface polaritons: electromagnetic waves at surfaces and interfaces. North-Holland publ

Kravets VG, Schedin F, Jalil R, Britnell L, Gorbachev RV, Ansell D, Thackray B, Novoselov KS, Geim AK, Kabashin AV (2013) Grigorenko AN (2013) Singular phase nano-optics in plasmonic metamaterials for label-free single-molecule detection. Nat Mater 12:304–309. https://doi.org/10.1038/nmat3537

Kabashin AV, Patskovsky S (2009) Grigorenko AN (2009) Phase and amplitude sensitivities in surface plasmon resonance bio and chemical sensing. Opt Express 17:21191–21204. https://doi.org/10.1364/OE.17.021191

Turbadar T (1959) Complete absorption of light by thin metal films. Proc Phys Soc London 73:40–44. https://doi.org/10.1088/0370-1328/73/1/307

Kretschmann E, Raether H (1968) radiative decay of non radiative surface plasmons excited by light. Z Naturforsch A 23:2135. https://doi.org/10.1515/zna-1968-1247

Raether H (1988) Surface plasmons on smooth and rough surfaces and on gratings. Springer-Verlag, Berlin

Kabashin AV, Kravets VG, Wu F, Shipunova V, Deyev SM, Grigorenko AN (2019) Phase-responsive Fourier nanotransducers for probing 2D materials and functional interfaces. Adv Func Mater. https://doi.org/10.1002/adfm.201902692

McPeak KM, Jayanti SV, Kress SJP, Meyer S, Iotti S, Rossinelli A, Norris DJ (2015) Plasmonic films can easily be better: rules and recipes. ACS Photonics 2:326–333

Zayats AV, Smolyaninov II, Maradudin AA (2005) Nano-optics of surface plasmon polaritons. Phys Rep 408:131–314

Mayer KM, Hafner JH (2011) Localized surface plasmon resonance sensors. Chem Rev 111:3828–3857

Offermans P, Schaafsma MC, Rodriguez SRK, Zhang Y, Crego-Calama M, Brongersma SH, Gómez Rivas J (2011) Universal scaling of the figure of merit of plasmonic sensors. ACS Nano 5(6):5151–5157

Sreekanth KV, Alapan Y, ElKabbash M, Ilker E, Hinczewski M, Gurkan UA, De Luca A, Strangi G (2016) Extreme sensitivity biosensing platform based on hyperbolic metamaterials. Nat Mater 15:621–627

Kabashin AV, Nikitin PI (1998) Surface plasmon resonance interferometer for bio-and chemical-sensors. Opt Commun 150:5–8

Huang Y, Ho HP, Kong SK, Kabashin AV (2012) Phase-sensitive surface plasmon resonance biosensors: methodology, instrumentation and applications. Ann Phys 524:637–662

Chou Chau Y-F, Chou Chao CT, Huang HJ, Rahimi Kooh MR, Kumara NTRN, Lim CM, Chiang H-P (2020) Perfect dual-band absorber based on plasmonic effect with the cross-hair/nanorod combination. Nanomaterials 10:493

Born M, Wolf E (1999) Principles of optics. Cambridge University Press, New York, p 704

Kravets VG, Grigorenko AN, Nair RR, Blake P, Anissimova S, Novoselov KS, Geim AK (2010) Spectroscopic ellipsometry of graphene and an exciton-shifted van Hove peak in absorption. Phys Rev B 81:155413

Kravets VG, Wu F, Auton GH, Yu T, Imaizumi S, Grigorenko AN (2019) Measurements of electrically tunable refractive index of MoS2 monolayer and its usage in optical modulators. NPJ 2D Mater Appl 3:36

Abeles F (1976) Surface electromagnetic waves ellipsometry. Surf Sci 56:237–251

Azzam RMA, Bashara NM (1987) Ellipsometry and polarized light. North-Holland

Kravets VG, Neubeck S, Grigorenko AN, Kravets AF (2010) Plasmonic blackbody: strong absorption of light by metal nanoparticles embedded in dielectric matrix. Phys Rev B 81:165401

Palik ED (1998) Handbook of optical constants of solids. Academic, San Diego

Svedendahl M, Chen S, Dmitriev A, Kall M (2009) Refractometric sensing using propagating versus localized surface plasmons: a direct comparison. Nano Lett 9:4428–4433

Sivukhin DV (1956) Theory of elliptic polarization of light reflected from isotropic media. Sov Phys JETP 3(2):269–273

Feibelman PJ (1982) Surface electromagnetic fields. Prog Surf Sci 12:287–407

Razaa S, Stengera N, Kadkhodazadeh Sh, Fischer SV, Kostesha N, Jauho AP, Burrows A, Wubs M, Mortensen NA (2013) Blueshift of the surface plasmon resonance in silver nanoparticles studied with EELS. Nanophotonics 2(2):131–138

Tiggesbäumker J, Köller L, Meiwes-Broer K-H, Liebsch A (1993) Blue shift of the Mie plasma frequency in Ag clusters and particles. Phys Rev A 48:R1749–R1752

Liebsch A (1997) Electronic excitations at metal surfaces. Springer

Yang Y, Zhu D, Yan W, Agarwal A, Zheng M, Joannopoulos JD, Lalanne P, Christensen Th, Berggren KK, Soljačić M (2019) A general theoretical and experimental framework for nanoscale electromagnetism. Nature 576:248–253

Kravets VG, Schedin F, Grigorenko AN (2008) Extremely narrow plasmon resonances based on diffraction coupling of localized plasmons in arrays of metallic nanoparticles. Phys Rev Lett 101:087403

Nienhaus H, Kravets V, Koutouzov S, Meier C, Lorke A, Wiggers H, Kennedy MK, Kruis FE (2006) Quantum size effect of valence band plasmon energies in Si and SnOx nanoparticles. J Vac Sci Technol B 24:1156–1161

Giovannetti G, Khomyakov PA, Brocks G, Karpan VV, van den Brink J, Kelly PJ (2008) Doping graphene with metal contacts. Phys Rev Lett 101:026803

Khurgin JB (2015) Ultimate limit of field confinement by surface plasmon polaritons. Faraday Discuss 178:109–122

Acknowledgements

We would like to thank the support from EU Graphene Flagship Core 3 and Graphene NOWNANO CDT from the University of Manchester.

Funding

This work is supported by the Graphene Flagship programme, Core 3 (Grant No. 881603).

Author information

Authors and Affiliations

Contributions

Vasyl Kravets and Alexander Grigorenko conceived the idea and developed the theory. Vasyl Kravets, Alexander Grigorenko and Fan Wu designed and performed the experimental sensor fabrication, ellipsometric measurements, materials and sensing characterizations and data analysis. Tongcheng Yu performed AFM measurements and theoretical simulations. All of the authors participated in manuscript preparation and revision processes.

Corresponding author

Ethics declarations

Consent for Publication

All authors agree to publish this paper.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kravets, V.G., Wu, F., Yu, T. et al. Metal-Dielectric-Graphene Hybrid Heterostructures with Enhanced Surface Plasmon Resonance Sensitivity Based on Amplitude and Phase Measurements. Plasmonics 17, 973–987 (2022). https://doi.org/10.1007/s11468-022-01594-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11468-022-01594-y