Abstract

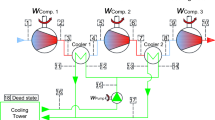

Large-scale cryogenic air separation units (ASUs), which are widely used in global petrochemical and semiconductor industries, are being developed with high operating elasticity under variable working conditions. Different from discrete processes in traditional machinery manufacturing, the ASU process is continuous and involves the compression, adsorption, cooling, condensation, liquefaction, evaporation, and distillation of multiple streams. This feature indicates that thousands of technical parameters in adsorption, heat transfer, and distillation processes are correlated and merged into a large-scale complex system. A lumped parameter model (LPM) of ASU is proposed by lumping the main factors together and simplifying the secondary ones to achieve accurate and fast performance design. On the basis of material and energy conservation laws, the piecewise-lumped parameters are extracted under variable working conditions by using LPM. Takagi-Sugeno (T-S) fuzzy interval detection is recursively utilized to determine whether the critical point is detected or not by using different thresholds. Compared with the traditional method, LPM is particularly suitable for “rough first then precise” modeling by expanding the feasible domain using fuzzy intervals. With LPM, the performance of the air compressor, molecular sieve adsorber, turbo expander, main plate-fin heat exchangers, and packing column of a 100000 Nm3 O2/h large-scale ASU is enhanced to adapt to variable working conditions. The designed value of net power consumption per unit of oxygen production (kW/(Nm3 O2)) is reduced by 6.45%.

Similar content being viewed by others

Abbreviations

- ai, bi, Ci :

-

Parameter set of the shape-changing degree of the membership function

- A f :

-

Total area of the hole (m2)

- Cp:

-

Specific heat capacity at constant pressure (J · kg−1 · K−1)

- C1, C2, C3 :

-

Constants

- d :

-

Bore diameter (m)

- d p :

-

Particle diameter (m)

- D :

-

Diameter of PC (m)

- D e :

-

Equivalent diameter of the flowing passage (m)

- f :

-

Friction factor

- f 0 :

-

Friction factor for flow past a single particle

- F f :

-

Packing factor of the flooding point (m · s−1 · (kg·m−3)0.5)

- Fr 1 :

-

Froude number for liquid

- g :

-

Gravitational acceleration (m/s2)

- h :

-

Specific enthalpy (J/kg)

- Δh :

-

Enthalpy drop (kJ/kg)

- h 0 :

-

Liquid holdup below the loading point

- h d :

-

Dynamic liquid holdup of the packing column

- h l :

-

Liquid holdup of the packing column

- h s :

-

Static liquid holdup of the packing column

- H :

-

Height of MSA (m)

- k1, k2 :

-

Constants

- L :

-

Heat exchanger length (m)

- ṁ :

-

Fluid mass flow rate (kg/s)

- N :

-

Iteration number

- ΔP :

-

Pressure drop (MPa)

- P c :

-

Critical pressure (MPa)

- P s :

-

Shaft power of AC (kW)

- \(\dot Q\) :

-

Heat transfer rate (kW)

- \(\rm{\dot{Q}}_{\rm{act}}\) :

-

Actual cooling capacity of TE (kW)

- Re g :

-

Reynolds number for the gas

- S :

-

State parameter set

- T :

-

Temperature of fluid (K)

- T c :

-

Critical temperature (K)

- ΔTm :

-

Mean temperature difference between streams (K)

- u :

-

Fluid flow speed (m/s)

- u f :

-

Flooding velocity (m/s)

- u g :

-

Actual gas flow velocity (m/s)

- U :

-

Overall heat transfer coefficient (W · m−2·K−1)

- V :

-

Kinematic viscosity (m2/s)

- V s :

-

Volume flow rate of fluid under working conditions (m3/s)

- x :

-

Input or variables in premise

- y :

-

Output of the model

- Z :

-

Total height of packing (m)

- α p :

-

Specific surface area of packing (m2/g)

- β :

-

Truncation error

- γ :

-

Compression ratio of the air compressor

- ε :

-

Porosity

- η :

-

Isentropic efficiency

- λ i :

-

Fuzzy approximation error of ith judgement

- µ :

-

Dynamic viscosity (Pa·s)

- ρ 1 :

-

Fluid density (kg/m3)

- ρ c :

-

Critical density (kg/m3)

- ψ :

-

Heat transfer efficiency

- ω :

-

Degree of variable working condition of PC in ASU

- AC:

-

Air compressor

- c:

-

Cold streams

- d:

-

Unirrigated (dry) bed

- EC:

-

Evaporator condenser

- g:

-

Gas fluid

- h:

-

Hot streams

- i:

-

Inlet

- irr:

-

Irrigated bed

- k:

-

Known

- l:

-

Liquid fluid

- LC:

-

Lower column

- MSA:

-

molecular sieve adsorber

- o:

-

Outlet

- PC:

-

Packing column

- PFHEs:

-

Plate-fin heat exchangers

- TE:

-

Turbo expander

- UC:

-

Upper column

References

Fu Q, Kansha Y, Song C, et al. A cryogenic air separation process based on self-heat recuperation for oxy-combustion plants. Applied Energy, 2016, 162: 1114–1121

Hashim S S, Mohamed A R, Bhatia S. Oxygen separation from air using ceramic-based membrane technology for sustainable fuel production and power generation. Renewable & Sustainable Energy Reviews, 2011, 15(2): 1284–1293

Smith A R, Klosek J. A review of air separation technologies and their integration with energy conversion processes. Fuel Processing Technology, 2001, 70(2): 115–134

Zhang W, Lu S, Ding X. Recent development on innovation design of reconfigurable mechanisms in China. Frontiers of Mechanical Engineering, 2019, 14(1): 15–20

Huang R, Zavala V M, Biegler L T. Advanced step nonlinear model predictive control for air separation units. Journal of Process Control, 2009, 19(4): 678–685

Kansha Y, Kishimoto A, Nakagawa T, et al. A novel cryogenic air separation process based on self-heat recuperation. Separation and Purification Technology, 2011, 77(3): 389–396

Fu Q, Zhu L, Chen X. Complete equation-oriented approach for process analysis and optimization of a cryogenic air separation unit. Industrial & Engineering Chemistry Research, 2015, 54(48): 12096–12107

Aneke M, Wang M. Potential for improving the energy efficiency of cryogenic air separation unit (ASU) using binary heat recovery cycles. Applied Thermal Engineering, 2015, 81: 223–231

Cao Y, Swartz C L E, Flores Cerrillo J, et al. Dynamic modeling and collocation-based model reduction of cryogenic air separation units. AIChE Journal. American Institute of Chemical Engineers, 2016, 62(5): 1602–1615

Ebrahimi A, Ziabasharhagh M. Optimal design and integration of a cryogenic air separation unit (ASU) with liquefied natural gas (LNG) as heat sink, thermodynamic and economic analyses. Energy, 2017, 126: 868–885

Rizk J, Nemer M, Clodic D. A real column design exergy optimization of a cryogenic air separation unit. Energy, 2012, 37(1): 417–429

Tong L, Zhang A, Li Y, et al. Exergy and energy analysis of a load regulation method of CVO of air separation unit. Applied Thermal Engineering, 2015, 80: 413–423

Jin B, Zhao H, Zheng C, et al. Control optimization to achieve energy-efficient operation of the air separation unit in oxy-fuel combustion power plants. Energy, 2018, 152: 313–321

Xu J H, Zhang S Y, Tan J R, et al. Multi-actuated mechanism design considering structure flexibility using correlated performance reinforcing. Journal of Zhejiang University. Science A: Applied Physics & Engineering, 2015, 16(11): 864–873

Xu J H, Chen X J, Zhang S Y, et al. Thermal design of large plate-fin heat exchanger for cryogenic air separation unit based on multiple dynamic equilibriums. Applied Thermal Engineering, 2017, 113: 774–790

Zhang S Y, Xu J H, Guo H W, et al. A research review on the key technologies of Intelligent design for customized products. Engineering, 2017, 3(5): 631–640

Xu J H, Wang T T, Zhang S Y, et al. Energy-efficient enhancement for viscoelastic injection rheomolding using hierarchy orthogonal optimization. Mathematical Problems in Engineering, 2018, 2018: 7054385

Abdo R F, Pedro H T C, Koury R N N, et al. Performance evaluation of various cryogenic energy storage systems. Energy, 2015, 90: 1024–1032

Karellas S, Schuster A, Leontaritis A D. Influence of supercritical ORC parameters on plate heat exchanger design. Applied Thermal Engineering, 2012, 33–34(1): 70–76

Son C H, Park S J. An experimental study on heat transfer and pressure drop characteristics of carbon dioxide during gas cooling process in a horizontal tube. International Journal of Refrigeration, 2006, 29(4): 539–546

Lisboa P F, Fernandes J, Simões P C, et al. Computational-fluid-dynamics study of a Kenics static mixer as a heat exchanger for supercritical carbon dioxide. Journal of Supercritical Fluids, 2010, 55(1): 107–115

Negoescu C C, Li Y, Al-Duri B, et al. Heat transfer behaviour of supercritical nitrogen in the large specific heat region flowing in a vertical tube. Energy, 2017, 134: 1096–1106

Avili M G, Sabet J K, Ghoreishi S M. Experimental characterization of a random packing with high specific surface area in a small diameter cryogenic distillation column. Progress in Nuclear Energy, 2018, 106: 417–424

Raman A S, Li H, Chiew Y C. Widom line, dynamical crossover, and percolation transition of supercritical oxygen via molecular dynamics simulations. Journal of Chemical Physics, 2018, 148(1): 014502

Lemmon E W, Tillner-Roth R. A Helmholtz energy equation of state for calculating the thermodynamic properties of fluid mixtures. Fluid Phase Equilibria, 1999, 165(1): 1–21

Zhu L, Garst M, Rosch A, et al. Universally diverging Gruneisen parameter and the magnetocaloric effect close to quantum critical points. Physical Review Letters, 2003, 91(6): 066404

Saha P, Sandilya P. A dynamic lumped parameter model of injection cooling system for liquid subcooling. International Journal of Thermal Sciences, 2018, 132: 552–557

Liu Q, Xu X. PID neural network control of a membrane structure inflation system. Frontiers of Mechanical Engineering, 2010, 5(4): 418–422

Takagi T, Sugeno M. Fuzzy identification of systems and its applications to modeling and control. Readings in Fuzzy Sets for Intelligent Systems, 1993, 15(1): 387–403

Škrjanc I, Blažič S, Agamennoni O. Identification of dynamical systems with a robust interval fuzzy model. Automatica, 2005, 41(2): 327–332

Willems F, Heemels W P M H, de Jager B D, et al. Positive feedback stabilization of centrifugal compressor surge. Automatica, 2002, 38(2): 311–318

Semlitsch B, Mihăescu M. Flow phenomena leading to surge in a centrifugal compressor. Energy, 2016, 103(C): 572–587

Torrisi G, Grammatico S, Cortinovis A, et al. Model predictive approaches for active surge control in centrifugal compressors. IEEE Transactions on Control Systems Technology, 2016, 25(6): 1947–1960

Gravdahl J T, Egeland O, Vatland S O. Drive torque actuation in active surge control of centrifugal compressors. Automatica, 2002, 38(11): 1881–1893

Boinov K O, Lomonova E A, Vandenput A J A, et al. Surge control of the electrically driven centrifugal compressor. IEEE Transactions on Industry Applications, 2006, 42(6): 1523–1531

Rege S U, Yang R T, Buzanowski M A. Sorbents for air prepurification in air separation. Chemical Engineering Science, 2000, 55(21): 4827–4838

Niu L, Hou Y, Sun W, et al. The measurement of thermodynamic performance in cryogenic two-phase turbo-expander. Cryogenics, 2015, 70: 76–84

Wang K, Sun J, Song P. Experimental study of cryogenic liquid turbine expander with closed-loop liquefied nitrogen system. Cryogenics, 2015, 67: 4–14

Yan J, Han Y, Tian J, et al. Performance investigation of a novel expander coupling organic Rankine cycle: Variable expansion ratio rotary vane expander for variable working conditions. Applied Thermal Engineering, 2019, 152: 573–581

Van der Ham L V, Kjelstrup S. Improving the heat integration of distillation columns in a cryogenic air separation unit. Industrial & Engineering Chemistry Research, 2011, 50(15): 9324–9338

Bruinsma O S L, Krikken T, Cot J, et al. The structured heat integrated distillation column. Chemical Engineering Research & Design, 2012, 90(4): 458–470

Hwang Y L. On the nonlinear wave theory for dynamics of binary distillation columns. AIChE Journal. American Institute of Chemical Engineers, 1991, 37(5): 705–723

Stichlmair J, Bravo J L, Fair J R. General model for prediction of pressure drop and capacity of countercurrent gas/liquid packed columns. Gas Separation & Purification, 1989, 3(1): 19–28

Bradtmöller C, Janzen A, Crine M, et al. Influence of viscosity on liquid flow Inside structured packings. Industrial & Engineering Chemistry Research, 2015, 54(10): 2803–2815

Kiss A A, Olujić Ž. A review on process intensification in internally heat-integrated distillation columns. Chemical Engineering and Processing, 2014, 86: 125–144

Chang L, Liu X, Dai L, et al. Modeling, characteristic analysis, and optimization of ideal internal thermally coupled air separation columns. Industrial & Engineering Chemistry Research, 2012, 51(44): 14517–14524

Acknowledgements

This work was funded by the National Natural Science Foundation of China (Grant Nos. 51775494, 51821093, and 51935009), the National Key Research and Development Project (Grant No. 2018YFB1700701), and Zhejiang Key Research and Development Project (Grant No. 2019C01141).

Author information

Authors and Affiliations

Corresponding author

Additional information

Jinghua XU, born in 1979, is currently an associate professor at Zhejiang University in China. He received his Ph.D. from Zhejiang University, China, in 2009. His research interests include mechanical design.

Tiantian WANG, born in 1995, is currently a Master’s Degree candidate in Mechanical Engineering College, Zhejiang University, China. His research interests include CAD.

Qianyong CHEN, born in 1993, is currently a Ph.D. candidate in Mechanical Engineering College, Zhejiang University, China. His research interests include CAD.

Shuyou ZHANG, born in 1963, is currently a professor at Zhejiang University, China. He received his Ph.D. from Zhejiang University, China, in 1999. His research interests include CAD/CG.

Jianrong TAN, born in 1954, is currently an academician in the Chinese Academy of Engineering and a professor in the Mechanical Engineering College of Zhejiang University, China. He received his Ph.D. from Zhejiang University, China, in 1992. His research interests include product design methodology.

Rights and permissions

About this article

Cite this article

Xu, J., Wang, T., Chen, Q. et al. Performance design of a cryogenic air separation unit for variable working conditions using the lumped parameter model. Front. Mech. Eng. 15, 24–42 (2020). https://doi.org/10.1007/s11465-019-0558-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-019-0558-6