Abstract

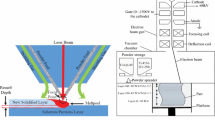

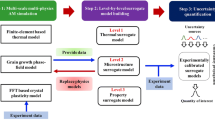

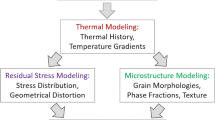

This paper presents our latest work on comprehensive modeling of process-structure-property relationships for additive manufacturing (AM) materials, including using data-mining techniques to close the cycle of design-predict-optimize. To illustrate the process-structure relationship, the multi-scale multi-physics process modeling starts from the micro-scale to establish a mechanistic heat source model, to the meso-scale models of individual powder particle evolution, and finally to the macro-scale model to simulate the fabrication process of a complex product. To link structure and properties, a high-efficiency mechanistic model, self-consistent clustering analyses, is developed to capture a variety of material response. The model incorporates factors such as voids, phase composition, inclusions, and grain structures, which are the differentiating features of AM metals. Furthermore, we propose data-mining as an effective solution for novel rapid design and optimization, which is motivated by the numerous influencing factors in the AM process. We believe this paper will provide a roadmap to advance AM fundamental understanding and guide the monitoring and advanced diagnostics of AM processing.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Standard terminology for additive manufacturing technologies. ASTM International, 2014

Smith J, Xiong W, Yan W, et al. Linking process, structure, property, and performance for metal-based additive manufacturing: Computational approaches with experimental support. Computational Mechanics, 2016, 57(4): 583–610

Yan W, Ge W, Smith J, et al. Multi-scale modeling of electron beam melting of functionally graded materials. Acta Materialia, 2016, 115: 403–412

Heinl P, Müller L, Körner C, et al. Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomaterialia, 2008, 4(5): 1536–1544

Huang R, Riddle M, Graziano D, et al. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. Journal of Cleaner Production, 2016, 135: 1559–1570

Yadroitsau I. tSelective laser melting: Direct manufacturing of 3Dobjects by selective laser melting of metal powders. Lambert Academic Publishing, 2009

Schoinochoritis B, Chantzis D, Salonitis K. Simulation of metallic powder bed additive manufacturing processes with the finite element method: A critical review. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2015, 231(1): 96–117

Körner C, Bauereiβ A, Attar E. Fundamental consolidation mechanisms during selective beam melting of powders. Modelling and Simulation in Materials Science and Engineering, 2013, 21(8): 085011

Khairallah S A, Anderson A T, Rubenchik A, et al. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Materialia, 2016, 108: 36–45

Qiu C, Panwisawas C, Ward M, et al. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Materialia, 2015, 96: 72–79

Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries. Journal of Computational Physics, 1981, 39(1): 201–225

Rai A, Markl M, Körner C. A coupled cellular automaton-lattice Boltzmann model for grain structure simulation during additive manufacturing. Computational Materials Science, 2016, 124: 37–48

Panwisawas C, Qiu C, Anderson M J, et al. Mesoscale modelling of selective laser melting: Thermal fluid dynamics and microstructural evolution. Computational Materials Science, 2017, 126: 479–490

Leuders S, Vollmer M, Brenne F, et al. Fatigue strength prediction for titanium alloy TiAl6V4 manufactured by selective laser melting. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, 2015, 46(9): 3816–3823

Hedayati R, Hosseini-Toudeshky H, Sadighi M, et al. Computational prediction of the fatigue behavior of additively manufactured porous metallic biomaterials. International Journal of Fatigue, 2016, 84: 67–79

Yan W, Smith J, Ge W, et al. Multiscale modeling of electron beam and substrate interaction: A new heat source model. Computational Mechanics, 2015, 56(2): 265–276

Yan W, Ge W, Qian Y, et al. Multi-physics modeling of single/ multiple track defect mechanisms in electron beam selective melting. Acta Materialia, 2017, 134: 324–333

Yan W, Qian Y, Lin S, et al. Meso-scale modeling of multiple-layer fabrication process in selective electron beam melting: Inter-layer/ track voids formation. Materials & Design, 2018, 141: 210–219

Yan W, Ge W, Smith J, et al. Towards high-quality selective beam melting technologies: Modeling and experiments of single track formations. In: Proceedings of 26th Annual International Symposium on Solid Freeform Fabrication. Austin, 2015

Yan W, Liu W K, Lin F. An effective finite element heat transfer model for electron beam melting process. In: Proceedings of Advances in Materials and Processing Technologies Conference. Madrid, 2015

Wolff S J, Lin S, Faierson E J, et al. A framework to link localized cooling and properties of directed energy deposition (DED)-processed Ti-6Al-4V. Acta Materialia, 2017, 132: 106–117

Smith J, Xiong W, Cao J, et al. Thermodynamically consistent microstructure prediction of additively manufactured materials. Computational Mechanics, 2016, 57(3): 359–370

Liu Z, Moore J A, Aldousari SM, et al. A statistical descriptor based volume-integral micromechanics model of heterogeneous material with arbitrary inclusion shape. Computational Mechanics, 2015, 55 (5): 963–981

Liu Z, Bessa M, Liu W K. Self-consistent clustering analysis: An efficient multi-scale scheme for inelastic heterogeneous materials. Computer Methods in Applied Mechanics and Engineering, 2016, 306: 319–341

Liu Z, Moore J A, Liu W K. An extended micromechanics method for probing interphase properties in polymer nanocomposites. Journal of the Mechanics and Physics of Solids, 2016, 95: 663–680

Groeber M A, Jackson M A. DREAM. 3d: A digital representation environment for the analysis of microstructure in 3D. Integrating Materials and Manufacturing Innovation, 2014, 3(1): 5

Moore J A, Frankel D, Prasannavenkatesan R, et al. A crystal plasticity-based study of the relationship between microstructure and ultra-high-cycle fatigue life in nickel titanium alloys. International Journal of Fatigue, 2016, 91(Part 1): 183–194

Bessa M, Bostanabad R, Liu Z, et al. A framework for data-driven analysis of materials under un-certainty: Countering the curse of dimensionality. Computer Methods in Applied Mechanics and Engineering, 2017, 320: 633–667

Witten I H, Frank E. Data Mining: Practical Machine Learning Tools and Techniques. New York: ACM, 2005

Acknowledgements

W. Liu and W. Yan acknowledge the support by the National Institute of Standards and Technology (NIST) and Center for Hierarchical Materials Design (CHiMaD) (Grant Nos. 70NANB13Hl94 and 70NANB14H012). S. Lin and O. L. Kafka acknowledge the support of the National Science Foundation Graduate Research Fellowship (Grant No. DGE-1324585).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided the appropriate credit is given to the original author(s) and the source, and a link is provided to the Creative Commons license, indicating if changes were made.

About this article

Cite this article

Yan, W., Lin, S., Kafka, O.L. et al. Modeling process-structure-property relationships for additive manufacturing. Front. Mech. Eng. 13, 482–492 (2018). https://doi.org/10.1007/s11465-018-0505-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-018-0505-y