Abstract

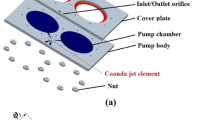

To eliminate check valve fatigue and valve clogging, diffuser/nozzle elements are used for flow rectification in a valveless diffuser/nozzle micropump instead of valves. However, the application of this type of micropump is restricted because of its pulsating or periodic flow and low pump flux. In this paper, a diffuser/nozzle Si/Glass micropump with two pump chambers by IC and MEMS technology is designed. The fabrication process requires only one mask and one etch step, so that the fabrication has the advantages of low cost, short processing period, and facilitation of miniaturization. The pump is equipped with a glass cover board so as to conveniently observe the flow status. Pump-chambers and diffuser elements are fabricated by the anisotropic KOH-etch technique on the silicone substrate, and the convex corner is designed to compensate for an anisotropic etch. The driving force of the micropump is produced by the PZT piezoelectric actuator. The pump performance with both actuators actuated in anti-or same-phase mode is also researched. The result indicates that the micropump achieves great performance with the actuators working at anti-phase. This may be because the liquid flows steadily, pulse phenomenon is very weak, and the optimal working frequency, pump back pressure, and flow rate are both double that of the pump driven in same-phase.

Similar content being viewed by others

References

Stemme E, Stemme G. A valeless diffuser/nuzzle-based fluid pump. Sensors and Actuators A, 1993, 39(2): 159–167

Gedlach T. Microdiffusers as dynamic passive valves for micropump applications. Sensors and Actuators A, 1998, 69(2): 181–191

Vishal S, Suresh V G, Raman A. Microscale pumping technologies for microchannel cooling systems. Applied Mechanics Reviews, 2004, 57(3): 191–221

Vishal S, Suresh V G. A novel valveless micropump with electrohydrodynamic enhancement for high heat flux cooling. IEEE Transaction on Advanced Packaging, 2005, 28(2): 216–230

Abdelgawad M, Hassanl I, Esmail N, et al. Numerical investigation of multistage viscous micropump configurations. Transactions of the ASME. 2005, 127(4): 734–742

Wagner B, Quenzer H J, Hoerschel S, et al. Bistable microvalve with pneumatically coupled membranes. In: Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), 1996, 384–388

Olsson A, Stemme G, Stemme E. A valve-less planar fluid pump with two pump chambers. Sensors and Actuators A, 1995, 47(1): 549–556

Zhang G W, Liu X W, Chen W P, et al. Valveless micropumps with planar channel based on silicon anistropic etching. In: Proceedings of the Chinese Micro/Nano-technology Annual Meeting, 2005, 16: 119–120

Bao Z Y, Wang W, Liu X W, et al. Effect factors on valve micropump capability. STC, 2005: 272–274

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Zhang, Y., Tian, L. et al. Piezoelectric diffuser/nozzle micropump with double pump chambers. Front. Mech. Eng. China 3, 449–453 (2008). https://doi.org/10.1007/s11465-008-0076-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-008-0076-4