Abstract

Geotextiles find wide applications in the field for filtration and drainage. When applied on the soil surface they influence soil evaporation. The objective of this work is twofold: (a) to assess the effectiveness of four different geotextiles as cover materials on soil evaporation, (b) to study the combined effect of geotextile and perforated mechanical barriers on soil evaporation. The first set of experimental programs consisted of three soil samples i.e. kaolin, dredged mud from the port of Brisbane and a locally obtained red mud sample from Queensland, Australia tested with four types of non-woven geotextiles under four controlled climatic conditions. All the 4 geotextiles had suppression effects on soil evaporation to degrees that varied with the type of soil, ratio of pore size to thickness of geotextiles (M*), product of pore size to thickness of the geotextiles (N*) and climatic conditions. Geotextiles with a higher pore size (O95) and M* allowed water vapor to move through relatively easily leading to higher evaporation rates. Geotextile with a higher thickness and N* value provided a higher suppression effect on soil evaporation. In a recently introduced dewatering method involving perforated ventilated well method, evaporation from soil take place through geotextiles and the perforated well. Mimicking this, impacts on soil evaporation with geotextiles sandwiched between soil sample and perforated sections were also studied. Maintaining similar number and arrangement of the perforations, soil evaporation was noted to be higher with rectangular shaped perforation compared to circular shaped perforations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Soil evaporation is a multi-physical process whereby water from soil moves into air in the form of water vapour due to vapour concentration gradient [23]. A three-stage soil evaporation theory is found in majority of the literature [2, 5, 11, 14]. When the water content in the soil is sufficient to meet the atmospheric evaporation demand, evaporation from soil occurs at its highest rate resulting in a linear reduction in moisture content over temporal scale. This is referred to as the first stage of soil evaporation or ‘rate limited stage’ and is solely governed by the climatic conditions. This leads to the top layer of soil becoming unsaturated and developing a crust of low permeability [13]. Therefore, soil evaporation rate starts to decrease significantly. The second and third stages of soil evaporation are characterised with relatively lower rate of moisture loss [11]. The efficiency of soil evaporation is dependent to several factors, such as climatic conditions (temperature, relative humidity, solar radiation and wind speed) and soil properties (salinity and hydraulic conductivity) [21]. Moreover, artificial barriers on soil surface (such as geotextiles or mechanical barriers) also have bearings on soil evaporation.

Zribi et al. [25] found that all cover materials suppress the evaporation rate in relation to the bare soil, especially for plastic materials, vine residues and pine bark materials compared with other cover materials tested. The suppression effects of different covers materials were different as well. Xie et al. [22] indicated that fine barrier materials (2–5 mm diameter sand and gravel) result in significantly less evaporation rate than coarse barrier materials (5–20- and 20–60-mm diameter sand and gravel). Yuan et al. [23] found that barrier materials dramatically reduce soil evaporation rate especially when moisture content is high, and the soil evaporation reduction is negatively correlated with gravel size. Overall, cover materials have suppression effect on soil evaporation in relation to bare soil. The degree of reduction in evaporation differs among different types of cover material, geomaterial type and climatic condition.

A newly proposed soft soil dewatering method, called the Ventilated Well Method (VWM), uses geotextiles wrapped around a perforated well as cover materials for dewatering and densification of soft soils [15, 20]. In VWM, several vertical perforated wells are installed by a driving mandrel into the ground. Air delivery hoses are placed inside the installed perforated well through which dry air (air at relatively low humidity) is pumped continuously into the well. Under this controlled evaporative load induced by the inlet air, the soil in close contact with the perforated well and geotextile is subjected to evaporation. This results in gradual reduction in moisture content of the soil along with increase in suction and suction stress in the soil. Under the induced suction stress, effective stress of the soil increases leading to densification. Schematic of the VWM has been presented in Fig. 1. VWM offers advantages over some of the other dewatering methods including conventional evaporation (limited depth of evaporation due to development of stiff surficial crust), prefabricated vertical drains (cost and energy intensive to maintain vacuum system, possible low efficiency of vacuum system) and surcharging (relatively long time required to achieve the desired degree of densification).

The role of the cover system (i.e. the geotextile and the mechanical barrier) is essentially to allow water evaporation but prevent soil particles to get inside the well. The combination of the chosen geotextile, perforation pattern on the mechanical barrier and climatic conditions (temperature and RH) of the input air plays a role in the achieved efficiency of the VWM. Quantitative information on the suppression effects of the geotextile and the perforated mechanical barrier is also a key parameter to for modelling of the VWM problem for possible upscaling. Moreover, geosynthetics play major roles in several geotechnical and geoenvironmental engineering applications. These usages can be categorised as mechanical (retainment and separation) or hydraulic (filtration and drainage). Furthermore, geotextiles are also used as filtration materials for tube dewatering [4, 16, 17, 19]. Non-woven geotextiles, manufactured by needle punching, are mainly used for soil drainage and filtration [3].

However, geotextiles in combination with perforated mechanical barriers of different perforations as covers has a specific application to the ventilated well method (VWM) and has not been considered so far. Thus, the objective of this study is to systematically evaluate and quantify through a series of experiments the following: (a) the effect of different types of non-woven geotextile on soil evaporation rate (b) the effect of climatic conditions on soil evaporation with non-woven geotextile as cover material (c) the effect of different opening areas and opening shapes of perforated mechanical barriers on soil evaporation rate. Outcomes of this experimental investigation feed directly to better understanding of the VWM problem by integrating the suppression effects on soil evaporation due to various geotextiles and perforated barriers. The outcomes are also applicable to studies where such covers are used to reduce soil evaporation.

2 Materials and methods

Two batches of experiments were conducted in this study. The first one is to study the effect of non-woven geotextile with varying climatic condition on soil evaporation. The second one is to study the effect of different opening areas and shapes of perforated mechanical barrier on soil evaporation rate.

2.1 Characteristics of geomaterials

For the first batch of experiments, three types of geomaterials were tested. The first one is a fine-grained reference geomaterial kaolin, the second one is a dredged mud sample from the Port of Brisbane, Australia (PoB) and the last one is a locally sourced red mud from Queensland, Australia. Some of the geotechnical characteristics of these materials have been listed in Table 1. The particle size distribution curve for investigated materials are presented in Fig. 2. A detailed characterisation of the materials can be found elsewhere [7,8,9, 18].

2.2 Characteristics of geotextiles

Four different commercially available non-woven geotextiles as barrier materials were studied. Pictures of the four geotextiles and their corresponding scanning electron microscope images have been presented in Fig. 3. Two parameters (M* and N*) are defined here to describe the degree of conductance of water vapour travelling through the geotextile from soil surface to atmosphere.

where, O95 is the pore size of the geotextile in μm, and d is the thickness of the geotextile in μm. From the definition of M*, a geotextile with a high M* value has a relatively larger pore size and smaller thickness. Pore size (O95) of the geotextiles determined in accordance with AS 3706.7 [1] was obtained from their respective product data sheets. Thickness of the geotextile samples was measured using a vernier caliper and the average value of 5 such measurements have been reported in Table 2. The geotextiles chosen are such that they vary in terms of their pore size and thickness. These geotextiles are commercially available and routinely used to engineer the mechanical and hydraulic behaviour of soils to fit the scope of the project at hand.

2.3 Experimental program

The three materials (kaolin, PoB and red mud) were oven-dried and then mixed with distilled water to targeted initial gravimetric water content (Table 1). After thoroughly mixing with distilled water, these samples were left in a desiccator for 24 h to ensure uniform distribution of moisture. Cylindrical moulds without lids were used in this experiment, in which the samples were placed with gentle tapping to avoid any potential entrapment of air bubbles. The diameter of the moulds was 5.5 cm and the height was 2 cm. Geotextile samples were cut in circular shape and then gently attached to the top surface of the prepared soil samples in the moulds. The climatic condition for the first batch of tests were varied at several levels. To study the soil evaporation efficiency with non-woven geotextiles in different climatic conditions, all the tests were conducted in a climatic chamber that maintained the temperature and relative humidity for the duration of the test. Four climatic conditions were used for the first batch of experiment which are: climatic condition 1 (A1) with temperature of 20 °C and relative humidity of 50%, climatic condition 2 (A2) with temperature of 30 °C and relative humidity of 60%, climatic condition 3 (A3) with temperature of 40 °C and relative humidity of 50%, and climatic condition 4 (A4) with temperature of 30 °C and relative humidity of 40%. For each condition, 14 tests were performed. The experimental program for the first batch of experiments has been listed in Table 3.

Each test in the first batch is named with the first letter representing the soil type (K represents kaolin, P represents dredged mud from the Port of Brisbane and R represents red mud). The second letter and number represent the type of cover material (B for bare soil, G1 for Geotextile 1, G2 for Geotextile 2, G3 for Geotextile 3 and G4 for Geotextile 4). The third letter and number represent the climatic conditions where the soil sample was tested in. (A1 represents climatic condition 1, A2 represents climatic condition 2, A3 represents climatic condition 3 and A4 for climatic condition 4).

For the second batch of experiments, only kaolin sample and geotextile no. 4 was used in climatic condition 1. The preparation method of kaolin sample and the size of moulds were the same as for the first batch of experiments. Kaolin was oven-dried firstly and then thoroughly mixed with distilled water to a targeted initial gravimetric water content. After reaching a uniform distribution of moisture by being left in a desiccator for 24 h, soil specimens were then filled into cylindrical moulds with gentle tapping to avoid entrapment of air bubbles. Geotextiles were firstly attached into the soil surfaces and then perforated discs were attached on the top of the geotextiles. A detailed sample preparation method has been discussed elsewhere [10, 12]. Six perforated discs with different total perforation areas and perforation shapes (rectangle and circle) were used in this batch of experiments. The perforated discs emulated the perforated well/mechanical barrier in the VWM.

Samples preparation methodology was similar to the first batch of experiments. The perforated discs were attached to the geotextiles, and then placed on top of the soil samples. The arrangement was such that the geotextile layer was sandwiched between the sample and the disc (Fig. 4). Figure 4 also demonstrates the perforation pattern in the perforated discs. Details on the perforation areas and perforation shapes on the discs have been summarised in Table 4.

For both batches of experiments, the samples were placed on digital scales connected to a data logger to record change in their mass at regular intervals. With the knowledge of mass loss over time, cumulative evaporation amount was calculated and analysed to compare the effect of geotextiles and climatic conditions on soil evaporation.

The Schematic representation of the experimental methodology is summarised in Fig. 5.

3 Results and discussion

3.1 Experimental batch 1

In total 56 samples were tested in the first batch where each of the sample evaporated from a fully saturated state to a completely dry state. Figure 6 presents the cumulative amount of water evaporated from the samples with different geotextiles under different climatic conditions. The cumulative amount of water evaporated increased linearly at the beginning of the evaporation process, when the samples were still saturated. This is called energy limited stage. Slopes of the curves in energy limited stages yield evaporation rate (in g/hr) of the samples. With continued drying of the samples, water supply from the samples failed to meet the climatic evaporation demand. Therefore, the evaporation rate was observed to decline and eventually reducing to zero asymptotically. This stage is called falling-rate stage.

In this study, evaporation rate derived in the energy-limited stage was used to study the geotextile effect on soil evaporation efficiency since the evaporation rate derived from falling-rate stage has been proven to be insensitive and similar for different barrier materials [25]. Within the energy-limited stage, the average evaporation rate for each soil sample can be derived from cumulative amount of water evaporated [24].

Evaporation rate (g/hr) was obtained as the slope of the cumulative amount of water evaporated vs. time curve during the rate limited stage of evaporation i.e. when the sample was still saturated. Mathematically,

where Mws is mass (in g) of evaporated water from soil sample, t is time in hours, ρw is the density of water (0.001 g/mm3), A is the evaporative cross-sectional area (top surface) of the soil in mm2.

The evaporative cross-sectional area (top surface) of the sample is considered as constant throughout the evaporation process.

The geotextile effect on soil evaporation efficiency is expressed with the following equation.

A representative calculation for estimation of geotextile effect for one test i.e. kaolin with geotextile no. 1 under climatic condition 1 (K-G1-A1) has been presented below.

Referring to Fig. 7, slopes from the energy limited stage of K-G1-A1 and the corresponding evaporation from bare soils (K-B-A1) were 0.24 and 0.46, respectively. Following Eq. 4, geotextile effect for the test K-G1-A1 was

i.e.

Physically, the introduction of the geotextile layer suppresses evaporation due to reduction in evaporative cross-sectional area to some “effective value”. The observed effect due to the “effective cross-sectional area” is interpreted comparing the rate of water loss with and without geotextile in terms of \(\frac{\mathrm{d}{M}_{ws}}{\mathrm{d}t}\). In the later section of the manuscript, an analysis has been made to correlate the thickness and pore size effect of the geotextile with the “geotextile effect”. This exercise is an attempt to indirectly infer the effect of reduced evaporative cross-sectional area (the reduced cross-sectional area is a function of pore size and thickness of the geotextile) with the suppressed evaporation due to introduction of the geotextile.

Referring to Eq. 4, a higher geotextile effect means higher suppression on soil evaporation efficiency, and vice versa. The geotextile effect for all the tests in the first batch of experiments have been listed in Table 5. It is observed that all 4 of the geotextiles have a suppression effect on soil evaporation efficiency and the degree of suppression varies in a large range due to different soil types, geotextile types and climatic conditions.

As shown in Table 5, geotextile no. 1 under the climatic condition no. 1 showed the highest geotextile effect (47%) for kaolin, and geotextile no. 4 under the climatic condition no. 3 showed the lowest geotextile effect (2%) for kaolin. Geotextile no. 1 under climatic condition no. 1 showed the highest geotextile effect (51%) for PoB and geotextile no. 4 under the climatic condition no. 1 showed the lowest geotextile effect (1%) for PoB. Geotextile no. 1 under the climatic condition no. 4 showed the highest geotextile effect (71%) for red mud and geotextile no. 4 under the climatic condition no. 3 showed the lowest geotextile effect (50%) for red mud. Furthermore, the geotextile effect for kaolin ranges from 2 to 47%. For PoB, it varies from 1 to 51%. However, for the red mud sample, the geotextile effect ranges from 50 to 71%; this range is prominently smaller than the other two other geomaterial materials (kaolin and PoB). This means that the placement of a geotextile on the red mud sample causes a more significant suppression than the other two geomaterials, regardless of the geotextile type and climatic condition.

For the same geotextile and climatic condition, geotextile effect is observed to be varying greatly for different geomaterial samples. Nevertheless, a clear trend was recognised in terms of the relative effect of the geotextile on evaporation. For any given geomaterial and climatic condition, the lowest geotextile effect occurred always with geotextile no. 4 and the highest geotextile effect with geotextile no. 1.

Corresponding O95, thickness, M* and N* values for the four geotextiles used in this study are listed in Table 2. Figure 8 shows the trend of geotextile effect plotted against O95, thickness, M*, and N* of the geotextiles. In each of the plots in Fig. 8, filled symbols in the same colour represent geotextile effects for geomaterial samples covered by geotextile 1, 2, 3 and 4, respectively, under the same climatic condition. For example, in Fig. 8(a), black circles represent geotextile effects for kaolin covered by geotextile no. 1 to 4 under climatic condition 1 (K-G1-A1, K-G2-A1, K-G3-A1 and K-G4-A1), red stars represent geotextile effects for kaolin covered by geotextile no. 1 to 4 under ambient condition 2 (K-G1-A2, K-G2-A2, K-G3-A2 and K-G4-A2), green squares represent geotextile effects for kaolin covered by geotextile no. 1 to 4 under ambient condition 3 (K-G1-A3, K-G2-A3, K-G3-A3 and K-G4-A3), and blue triangles represent geotextile effects for kaolin covered by geotextile no. 1 to 4 under ambient condition 4 (K-G1-A4, K-G2-A4, K-G3-A4 and K-G4-A4).

Variation of geotextile effect with O95 of the geotextiles for a kaolin, b PoB, c red mud; variation of geotextile effect with thickness of the geotextiles for a kaolin, b PoB, c red mud; variation of geotextile effect with M* for a kaolin, b PoB, c red mud; variation of geotextile effect with N* for a kaolin, b PoB, c red mud

Figure 8a–c indicates that for any given geomaterial, an increase in O95 of the geotextile correspond to a decrease in geotextile effect. Physically, this means that with increase in the pore size of the geotextile, lower suppression effect on soil evaporation is observed. An opposite trend is observed from Fig. 8d–f where for any given geomaterial, an increase in thickness of the geotextile corresponds to a decrease in geotextile effect.

From Fig. 8g–i, with an increase in the M* value of these four geotextiles, geotextile effects were observed to decrease. M* represents pore size per unit thickness of the geotextile, and follows the same trend as that of the geotextile effect vs. pore size of the geotextile.

From Fig. 8j–l, with an increase in N* value for the geotextiles, geotextile effects were observed to increase. A possible theoretical explanation may be N* is representative of amount of air trapped in the geotextile, increase in which leads to higher suppression effects on soil water evaporation.

Thus, to summarise the first batch of experiments, the derivation of the suppression effect for the four geotextiles have been made based on the linear part of cumulative amount of water evaporated from the samples under with 4 different geotextiles under 4 different climatic conditions. The geotextile effect (in %) is used here to represent the effect of geotextile on soil evaporation efficiency. The suppression effect of geotextile varies greatly for different geomaterials. For the same type of geomaterial and climatic condition, the geotextile effect decreases with increase in O95 and M* of the geotextile. However, for the same type of geomaterial and climatic condition, the geotextile effect increases with increase in thickness and N* of the geotextile.

3.2 Experimental batch 2

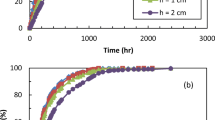

Six tests were conducted in the second experimental batch to investigate the effect of different perforation areas and shapes of perforations on discs (Table 4) on the soil evaporation rate. Figure 9a shows the cumulative amount of evaporated water for six tests in second batch of experiments with different types of perforated discs. Only energy-limited stage (saturated stage) was recorded and analysed to extract the evaporation rates. Linear fitting curves were used to obtain the evaporation rate for these geomaterial samples as explained earlier. In Fig. 9b, the circles represent evaporation rates of soil specimens covered by geotextile no. 4 and perforated discs with circular openings. The evaporation rates of the discs with rectangular perforations have been presented as squares.

For both perforation shapes, the evaporation rate was observed to increase with the increase in percentage of total perforation area. Li [6] indicated that soil evaporation rate increases with the increased open hole ratio of perforated plastic mulches. The presented study, where discs have been used in combination with geotextiles, confirmed this observation. It was also observed that for the same percentage of perforation area, rectangular perforations generate a higher evaporation rate than circular perforations.

3.3 Limitations and scopes for future work

A climatic chamber was used in this study to provide stable climatic conditions for soil evaporation. Only temperature and relative humidity were controlled to create these stable climatic conditions to study the effect on geotextile and mechanical barrier on soil evaporation. Wind and radiation effects need further investigation in the future.

4 Summary and conclusion

The outcomes of this study can be summarised as follows:

-

All the four geotextiles considered in this study had a suppression effect on soil water evaporation. However, the degree of suppression varies among different soil types and different geotextiles. The range of geotextile effect for the red mud sample have been observed to be lower than the kaolin and Port of Brisbane dredged soil when covered by the same geotextile and tested under the same climatic condition.

-

Besides, for the same type of geomaterial and climatic condition, geotextile effect i.e. degree of suppression on soil water evaporation increases with decrease in the pore size (O95) and M* of the geotextile. However, the suppression effect increases with increase in thickness and N* of the geotextile.

-

Considering the geomaterials and climatic conditions presented in this study, among the 4 geotextiles geotextile no. 1 was observed to maximally reduce the evaporation.

-

Perforated discs on the surface of soils covered with a geotextile suppressed evaporation. The larger the perforation area on the disc, the larger is the evaporation rate. Within the parameters considered in this study, for the same percentage of perforation area, rectangular perforations generated a higher evaporation rate than circular perforations.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- d :

-

Thickness of the geotextile in μm

- t :

-

Time in hours

- A :

-

Evaporative cross-sectional area (top surface) of the geomaterial sample

- \({E}_{i}\) :

-

Evaporation rate

- M* :

-

Ratio of O95 to d

- M ws :

-

Mass (in g) of evaporated water from the geomaterial sample

- N* :

-

Product of O95 to d in mm2

- O 95 :

-

Pore size of the geotextile in μm

- PoB:

-

Dredged soil from Port of Brisbane

- VWM:

-

Ventilated well method

- ρ w :

-

Density of water (0.001 g/mm3)

References

AS 3706.7-2014 Geotextiles - Methods of test Determination of pore-size distribution—Dry-sieving method

Bore T, Mishra PN, Wagner N, et al (2021) Coupled hydraulic, mechanical and dielectric investigations on kaolin. Eng Geol 294, p 106352. https://doi.org/10.1016/j.enggeo.2021.106352

Bouazza A, Freund M, Nahlawi H (2006) Water retention of nonwoven polyester geotextiles. Polym Test 25(8):1038–1043. https://doi.org/10.1016/j.polymertesting.2006.07.002

Christopher BR, Fischer GR (1992) Geotextile filtration principles, practices and problems. In: Koerner RM (ed) Geosynthetics in filtration, drainage and erosion control. Elsevier Oxford pp 1–17. https://doi.org/10.1016/B978-1-85166-796-3.50006-2

Idso SB, Reginato RJ, Jackson RD et al (1974) The three stages of drying of a field soil. Soil Sci Soc Am J 38(5):831–837. https://doi.org/10.2136/sssaj1974.03615995003800050037x

Li XY (2003) Gravel–sand mulch for soil and water conservation in the semiarid loess region of northwest China. CATENA 52(2):105–127. https://doi.org/10.1016/S0341-8162(02)00181-9

Mishra PN, Bore T, Jiang Y et al (2018) Dielectric spectroscopy measurements on kaolin suspension for sedimentation monitoring application. Measurement 121:160–169. https://doi.org/10.1016/j.measurement.2018.02.034

Mishra PN, Scheuermann A, Li L (2018) Significance of corrections and impact of saline pore fluid on kaolin. J Mater Civ Eng 30(11):06018016. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002458

Mishra PN, Patel P, Bore T, et al (2018c) An integrated approach for capturing dielectric response of the dredged material from the port of Brisbane. In: Proceedings of 7th international conference on unsaturated soils (UNSAT-2018). Hong Kong

Mishra PN, Scheuermann A, Bore T, Li L (2019) Salinity effects on soil shrinkage characteristic curves of fine-grained geomaterials. J Rock Mech Geotech Eng 11(1):181–191. https://doi.org/10.1016/j.jrmge.2018.06.008

Mishra PN, Bore T, Scheuermann A, Li L (2020) Characterisation of pore fluid salinity dependent evaporative dewatering of kaolin using dielectric spectroscopy. J Rock Mech Geotech Eng 12(1):112–125. https://doi.org/10.1016/j.jrmge.2019.08.002

Mishra PN, Zhang Y, Bhuyan MH, Scheuermann A (2020) Anisotropy in volume change behaviour of soils during shrinkage. Acta Geotech 15(12):3399–3414. https://doi.org/10.1007/s11440-020-01015-6

Mishra PN, Scheuermann A, Li L (2020) Evaluation of hydraulic conductivity functions of saturated soft soils. Int J Geomech 20(11):04020214

Mishra PN, Scheuermann A, Bhuyan MH (2021) A unified approach for establishing soil water retention and volume change behavior of soft soils. Geotech Test J 44(5):1197–1216. https://doi.org/10.1520/gtj20200009

Mishra PN, Scheuermann A (2021) Ventilated well method for efficient dewatering of soft soils: experimental investigations. J Geotech Geoenviron Eng 147(11):04021112. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002643

Moo-Young HK, Gaffney DA, Mo X (2002) Testing procedures to assess the viability of dewatering with geotextile tubes. Geotext Geomembr 20(5):289–303. https://doi.org/10.1016/S0266-1144(02)00028-6

Muthukumaran AE, Ilamparuthi K (2006) Laboratory studies on geotextile filters as used in geotextile tube dewatering. Geotext Geomembr 24(4):210–219. https://doi.org/10.1016/j.geotexmem.2006.03.002

Olaya SQ, Zhang C, Williams DJ, Lei X, Zhao Z, Llano-Serna M (2020) Use of high-performance fibres to enhance tailings. Tailings and Mine Waste 2020, Fort Collins, CO USA, 15–18 November 2020. Vancouver, BC Canada: UBC Studios

Palmeira EM, Fannin RJ, Vaid YP (1996) A study on the behaviour of soil–geotextile systems in filtration tests. Can Geotech J 33(6):899–912. https://doi.org/10.1139/t96-120

Scheuermann A, Mishra PN, Zhang Y, et al (2022) The ventilated well method as an alternative solution for dewatering of soft soils. In: Proceedings of the 20th international conference on soil mechanics and geotechnical engineering, Sydney, Australia

Smits KM, Ngo VV, Cihan A, et al (2012) An evaluation of models of bare soil evaporation formulated with different land surface boundary conditions and assumptions. Water Resour Res 48(12): n/a-n/a. https://doi.org/10.1029/2012WR012113

Xie Z, Wang Y, Jiang W, Wei X (2006) Evaporation and evapotranspiration in a watermelon field mulched with gravel of different sizes in northwest China. Agric Water Manag 81(1–2):173–184. https://doi.org/10.1016/j.agwat.2005.04.004

Yuan C, Lei T, Mao L et al (2009) Soil surface evaporation processes under mulches of different sized gravel. CATENA 78(2):117–121. https://doi.org/10.1016/j.catena.2009.03.002

Zhang Y, Mishra PN, Scheuermann A (2021) An improved evaporation quantification method: accounting for soil deformability and side evaporation effect. J Hydrol 598:126486. https://doi.org/10.1016/j.jhydrol.2021.126486

Zribi W, Aragüés R, Medina E, Faci J (2015) Efficiency of inorganic and organic mulching materials for soil evaporation control. Soil Tillage Res 148:40–45. https://doi.org/10.1016/j.still.2014.12.003

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

Alexander Scheuermann serves as an editor for the journal. Hence, the manuscript was handled by an editor other than him.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, Y., Mishra, P.N., Tiwari, S. et al. Suppressive effects of geotextiles on soil water evaporation. Acta Geotech. 19, 2163–2174 (2024). https://doi.org/10.1007/s11440-023-02042-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-02042-9