Abstract

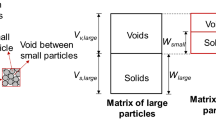

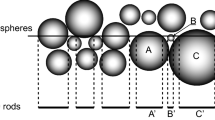

Permeability of binary mixtures of soils is important for several industrial and engineering applications. Previous models for predicting the permeability of a binary mixture of soils were primarily developed from Kozeny–Carman equation with an empirical approach. The permeability is predicted based on an equivalent particle size of the two species. This study is aimed to develop a model using a more fundamental approach. Instead of an equivalent particle size, the permeability is predicted based on the bimodal void sizes of the binary mixture. Because the bimodal void sizes are not available as commonly measured physical properties. We first develop an analytical method that has the capability of predicting the bimodal void sizes of a binary mixture. A permeability model is then developed based on the bimodal void sizes of the binary mixture. The developed permeability model is evaluated by comparing the predicted and experimentally measured results for binary mixtures of glass beads, crush sand, and gravel sand. The findings can contribute to a better understanding of the important influence of pore structure on the prediction of permeability.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Alyamani MS, Sen Z (1993) Determination of hydraulic conductivity from complete grain-size distribution curves. Ground Water 31(4):551–555

Arya LM, Paris JF (1981) A physico-empirical model to predict the soil moisture characteristic from particle size distribution and bulk density data. Soil Sci Soc Am J 45(6):1023–1030. https://doi.org/10.2136/sssaj1981.03615995004500060004x

Bear J (1988) Dynamics of fluids in porous media. Dover Publications, New York

Blunt MJ (2017) Multiphase Flow in Permeable. Media. https://doi.org/10.1017/9781316145098

Bodman GB, Constantin GK (1965) Influence of particle size distribution in soil compaction. Hilgardia 36(15):567–591. https://doi.org/10.3733/hilg.v36n15p567

Budhu M (2008) Soil mechanics and foundations. Wiley, New York

Burdine NT (1953) Relative permeability calculations from pore size distribution data. J Pet Technol 5:71–78. https://doi.org/10.2118/225-G

Carman PC (1937) Fluid flow through granular beds. Trans Inst Chem Eng 15:150–166

Carrier WD (2003) Goodbye, Hazen Hello, Kozeny-Carman. J Geotech Geoenviron Eng 129(11):1054–1056. https://doi.org/10.1061/(ASCE)1090-0241

Chang CS (2022) Jamming density and volume-potential of a bi-dispersed granular system. Geophys Res Lett. https://doi.org/10.1029/2022GL098678

Chang CS, Deng Y (2022) Compaction of bi-dispersed granular packing: analogy with chemical thermodynamics. Granul Matter. https://doi.org/10.1007/s10035-022-01219-5

Chapuis RP (2004) Predicting the saturated hydraulic conductivity of sand and gravel using effective diameter and void ratio. Can Geotech J 41(5):787–795. https://doi.org/10.1139/t04-022

Chapuis RP, Aubertin M (2003) On the use of the Kozeny–Carman equation to predict the hydraulic conductivity of soils. Can Geotech J 40(3):616–628

Choo H, Lee W, Lee C, Burns SE (2018) Estimating porosity and particle size for hydraulic conductivity of binary mixed soils containing two different-sized silica particles. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001802

Costa A (2006) Permeability-porosity relationship: a reexamination of the Kozeny–Carman equation based on a fractal pore-space geometry assumption. Geophys Res Lett 33(2):L02318

Das BM (2008) Advanced soil mechanics. CRC Press, New York

Freeze RA, Cherry JA (1979) Groundwater. Prentice Hall, Englewood Cliffs

Fujikura Y (2019) Estimation of permeability for sand and gravel based on pore-size distribution model. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002945

Gao QF, Zhao D, Zeng L, Dong H (2019) A pore size distribution-based microscopic model for evaluating the permeability of clay. KSCE J Civ Eng 23(12):5002–5011. https://doi.org/10.1007/s12205-019-2219-z

Hazen A (1911) Discussion of dams on sand foundations by A. C. Koenig, vol 73. Transaction ASCE, New York, pp 199–203

Hwang S, Powers SE (2003) Lognormal distribution model for estimating soil water retention curves for sandy soils. Soil Sci 168(3):156–166

Juang CH, Holtz RD (1986) A probabilistic permeability model and the pore size density function. Int J Numer Anal Methods Geomech 10(5):543–553

Koohmishi M, Azarhoosh A (2021) Assessment of permeability of granular drainage layer considering particle size and air void distribution. Constr Build Mater 270:121373. https://doi.org/10.1016/j.conbuildmat.2020.121373

Kozeny J (1927) Über Kapillare Leitung des Wassers im Boden. Sitzungsber Akad Wiss Wien 136:271–306

Lee H, Koo S (2014) Liquid permeability of packed bed with binary mixture of particles. J Ind Eng Chem 20:1937–1401. https://doi.org/10.1016/j.jiec.2013.07.024

Loudon AG (1952) The computation of permeability from simple soil tests. Geotechnique 3(4):165–183. https://doi.org/10.1680/geot.1952.3.4.165

Mitchell JK (1976) Fundamentals of soil behaviour. John Wiley, New York

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. John Wiley and Sons, Hoboken, NJ

Mokwa RL, Trimble NR (2008) Permeability of coarse-grain soil from void space and pore distribution. In: Proceedings of GeoCongress 2008: characterization, monitoring, and modeling of geosystems, pp 428–435. https://doi.org/10.1061/40972(311)54

Mortensen N, Okkels F, Bruus H (2005) Reexamination of Hagen–Poiseuille flow: shape dependence of the hydraulic resistance in microchannels. Phys Rev E. https://doi.org/10.1103/PhysRevE.71.057301

Mota M, Teixeira JA, Bowen WR, Yelshin A (2001) Binary spherical particle mixed beds: Porosity and permeability relationship measurement. Trans Filtr Soc 1(4):101–106

NAVFAC (Naval Facilities Engineering Command) (1974) Soil mechanics, foundations, and earth structures. Design Manual DM7. US Government Printing Office, Washington

O’Sullivan C, Bluthé J, Sejpar K, Shire T, Cheung LYG (2015) Contact based void partitioning to assess filtration properties in DEM simulations. Comput Geotech 64:120–131. https://doi.org/10.1016/j.compgeo.2014.11.003

Riva M, Sanchez-Vila X, Guadagnini A (2014) Estimation of spatial covariance of log conductivity from particle size data. Water Resour Res 50(6):5298–5308. https://doi.org/10.1002/2014WR015566

Roozbahani MM, Borela R, Frost D (2017) Pore size distribution in granular material microstructure. Materials 10:1237. https://doi.org/10.3390/ma10111237

Rosas J, Lopez O, Missimer TM, Coulibaly KM, Dehwah AHA, Sesler K, Lujan LR, Mantilla D (2014) Determination of hydraulic conductivity from grain-Size distribution for different depositional environments. Ground Water 52(3):399–413. https://doi.org/10.1111/gwat.12078

Sangani AS, Acrivos A (1982) Slow flow past periodic arrays of cylinders with application to heat transfer. Int J Multiph Flow 8(3):193–206

Silbey RJ, Alberty RA, Bawendi MG (2005) Physical chemistry, 4th edn. John Wiley & Sons Inc, Hoboken

Taylor HF, O’Sullivan C, Sim WW (2015) A new method to identify void constrictions in micro-CT images of sand. Comput Geotech 69:279–290. https://doi.org/10.1016/j.compgeo.2015.05.012

Terzaghi K, Peck RB (1948) Soil mechanics in engineering practice. Wiley, New York

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenviron Eng 124(6):479–491

Thies-Weesie DME, Philpse AP (1994) Liquid permeation of bidisperse colloidal hard-sphere packings and the Kozeny–Carman scaling relation. J Colloid Interface Sci 162:470–480. https://doi.org/10.1006/jcis.1994.1062

Wadell H (1935) Volume, shape, and roundness of quartz particles. J Geol 43(3):250–280

Wang J-P, François B, Lambert P (2017) Equations for hydraulic conductivity estimation from particle size distribution: a dimensional analysis. Water Resour Res 53(9):8127–8134. https://doi.org/10.1002/2017WR020888

Yilmaz Y (2009) A study on the limit void ratio characteristics of medium to fine mixed graded sands. Eng Geol 104:290–294. https://doi.org/10.1016/j.enggeo.2008.11.009

Zick AA, Homsy GM (1982) Stokes flow through periodic arrays of spheres. J Fluid Mech 115:13–26. https://doi.org/10.1017/S0022112082000627

Acknowledgements

The first author was supported by the National Science Foundation of the United States under a research grant (CMMI-1917238). The support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: A brief summary of a particle packing model by Chang and Deng [11]

Appendix 1: A brief summary of a particle packing model by Chang and Deng [11]

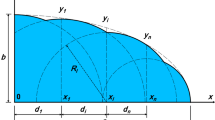

In the model derivation for particle packing of binary mixtures, specific volume \(\upsilon\) was used. By definition, specific volume \(\upsilon\) is related to void ratio \(e\) by \(\upsilon =1+e\). Thus, the equations in the derivation for the specific volume of a binary packing mixture can be replaced by the void ratio, which is a function of the solid fractions of species (\({y}_{1}\), \({y}_{2}\)) and the partial void ratios, given by

Based on the concept of excess particle volume-potential for each species in a mixture [11], the partial void ratios of the two species in a granular mixture were postulated to be:

where \({e}_{1}^{0}\) and \({e}_{2}^{0}\) are respectively the mono-sized void ratios of the two species. The values of two activity coefficients \({\alpha }_{1}\), \({\alpha }_{2}\) are between 0 and 1. With Eqs. (18), (19), and (20), the void ratio of the mixture can be expressed as:

The activity coefficients \({\alpha }_{i}\) is hypothesized to be a function of the two characteristic lengths in the form of power law, given by

where \({d}_{1}\) and \({d}_{2}\) are the particle size of the two species, x is the characteristic length of the packing and \(\eta\) is a material coefficient.

Based on the thermodynamics second law, the excess volume potential must be minimized at equilibrium of the system, thus it leads to

The unknown variables, \({\alpha }_{1}\), \({\alpha }_{2}\) and \(x\) can be solved by Eqs. (22) and (23). Then, the void ratio \(e\) of the binary mixture can be determined from Eq. (21). The partial void ratios can be determined from Eqs. (19) and (20).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chang, C.S., Ma, T.T. Void size distribution and hydraulic conductivity of a binary granular soil mixture. Acta Geotech. 19, 2175–2189 (2024). https://doi.org/10.1007/s11440-023-02025-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-02025-w