Abstract

Fluid saturation plays an important role in rock weakening. However, few researches reveal the controlling factor(s) behind the rock weakening particularly from geochemical perspective. We performed rock failure/fracture reactivation tests on dry and wet samples (saturated with high/low salinity brine). We examined the effect of fluid saturation and salinity on rock mechanical properties through a unique triaxial compression system with combination of micro-seismicity monitoring. Besides, the induced time-dependent micro-seismicity events were located to characterize the fracture orientation together with medical CT imaging. Moreover, we performed geochemical modelling to link the surface energy to rock mechanics from geochemical perspective.

Our results show that the peak stress of saturated samples is 11.7% to 15.0% less than unsaturated samples, confirming that fluid saturation can weaken rock. Lowering salinity appears to play a negligible role in the reduction of elastic modulus and peak stress of intact sandstones. We also did not observe the expansion of micro-seismicity cloud along main fracture plane, suggesting that lowering salinity may not trigger micro-fracture generation under confining condition. However, sample saturated with low salinity brine shows a much slower increase rate of differential stress during the plastic deformation to reach yield point during fracture reactivation process compared to the sample saturated with high salinity brine. This work contributes to the existing knowledge of rock weakening by providing quantitative geochemical characterization with implications in water-assisted enhancing hydrocarbon recovery and CO2 geological storage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the increase in hydrocarbon exploration and production activities since the last century, megatons of water-based solutions have been injected into hydrocarbon reservoirs to improve hydrogen carbon recovery. For example, the waterflooding technique has been widely applied to improve oil recovery from conventional reservoirs (e.g., sandstone [1,2,3,4] and carbonate [5,6,7]). Similarly, a substantial amount of fluids have been used to generate fractures in unconventional reservoirs (e.g., shale [8,9,10]) to enhance formation permeability and thus the production efficiency. The injected fluids which usually contain certain types of ions such as Na+, K+, and Ca2+ can react with the mineral matrix and affect the rock mechanical properties, including compressive strength [11,12,13,14,15,16], Young’s modulus [17,18,19,20,21], brittleness index [19, 22], and the subcritical crack growth [23,24,25,26,27]. The fluid–rock interactions induced rock mechanical properties alteration would impact reservoir integrity and directly influence the efficiency of oil and gas production. Moreover, for some long-term underground storage projects such as CO2 [28,29,30] and H2 [31,32,33,34] storage, the caprock stability is crucially important as fluid–rock interactions would also take place. Therefore, understanding how fluid–rock interactions affect rock properties is of fundamental interest for subsurface entropic activities involving the water-based fluid injection.

Such fluid–rock interactions studies have been massively approached on sandstones through laboratory-scale geomechanical experiments. Triaxial compression tests were widely performed on various sandstones under dry and saturated conditions at room temperature to examine the water weakening effect in brittle faulting and cataclastic flow regime [35]. The results show that both compactive yield strength and brittle strength would decrease after water saturation. Furthermore, the effect of water content on tight sandstone mechanical behaviors was investigated through triaxial tests [36]. The results indicate that the peak strength and Young’s modulus would decrease with increasing water content due to the mineral particles dissolution. Similar results were also observed by Cai et al. [37] and Liu et al. [38], who reported that increasing pore water content can decrease sandstone’s uniaxial compressive strength, elastic modulus and critical strain. All of these works demonstrate that saturating sandstones with water can weaken the bulk strength.

Besides sandstones, the fluid–rock interactions induced rock softening has also been widely reported on carbonate and shale rocks. Under isotropic compression conditions, Lebedev et al. [40] performed precise indentation experiments on limestone rock under dry and distilled water-saturated conditions. Rock matrix softening and shear modulus reduction were observed after water saturation. The authors claimed that calcite dissolution and the alteration of cements into ooid cortices or void are the main reasons for the observed elastic modulus reduction. Besides, the strength of single calcite crystal at air and mixed glycol–water solutions was tested by measuring the forces acting between two calcite surfaces with an Atomic Force Microscope (AFM) [23]. The results indicate that fluid saturation would trigger mechanical weakening, and increasing the portion of water in this mixed fluid can further decrease rock strength. Megawati et al. [41] measured the strength dependency of chalk with deionized water, NaCl and Na2SO4 saturation, respectively. They report that increasing sulfate content of the fluid remarkably decreases the yield point and bulk modulus. SO42− adsorption on chalk surface and associated interaction of electrical double layer combined with disjoining pressure change was proposed to account for the rock weakening. Moreover, Gupta et al. [42] measured the Young’s modulus of Marcellus, Woodford, Eagle Ford and Wolfcamp shale rocks after KCl brine saturation through the spontaneous imbibition. The results show that the Young’s modulus of all tested shales decreases and strong water-wet samples (e.g., Marcellus) presents a higher Young’s modulus reduction than the oil-wet samples (e.g., Eagle Ford).

Although observations from laboratory experiments have shown the correlation between fluid–rock interactions and rock weakening, much of research up to now are only descriptive in nature. More quantitative work remains to be made to further reveal the correlation between fluid–rock interactions and rock mechanics in particular from geochemical perspective. For instance, fluid–rock interactions induced rock weakening is widely characterized as the comprehensive result of mechanical [35, 43, 44] and chemical [41, 45,46,47] reactions. Some researchers contribute this rock weakening mainly to the mineral dissolution [17, 40]. However, even for the sandstone rock which contains more than 92% quartz and should be fairly geochemical stable, the subcritical crack growth tests show that increasing relative humidity of the rock would facilitate micro-fracture propagation [48]. Recent studies point out that rock surface energy which is governed by the surrounding water chemistry may also affect rock mechanical properties [35, 41]. On the other hand, almost all studies on the effect of water saturation on rock weakening, either through the unconfined compression (UCS) test or triaxial test, used intact samples. However, for cracked samples, there may be much more micro-fractures present on main fracture planes, which would significantly increase the contact area between water and rock matrix and thus affect rock mechanical behaviors. Therefore, in this work, we aim to quantify the impact of fluid saturation and salinity on rock mechanics at core-scale (meso-scale) from geochemical perspective. To be more specific, triaxial tests were performed on Berea sandstones under dry, high salinity water (HSW) and low salinity water (LSW) saturation conditions in both intact rock failure and fracture reactivation. We monitored strain (axial and radial) and stress (axial loading stress, confining pressure and pore pressure) data with combination of micro-seismic monitoring during the whole experiments to characterize how the fluid–rock interactions can affect the mechanical properties and fracture propagation for both intact and fracture-existed samples.

2 Experimental methodology and procedures

2.1 Fluid samples

Assuming that the ion composition and salinity would affect rock physicochemical properties such as concentration of surface species or functional groups, surface potential, surface energy and disjoining pressure, which may further influence the rock mechanical properties [23, 49, 50], we used two types of contrasting saline brine in this study: high salinity water HSW (1 M NaCl + 0.05 M CaCl2 or 64,050 mg/L) and low salinity water LSW (0.01 M NaCl + 0.005 M CaCl2 or 1,140 mg/L). The HSW mimics a pre-existing formation brine which usually contains high concentration ions (sometimes can be up to 280,000 mg/L [51]), while the LSW mimics an injected water-based hydraulic fracturing fluid or the shallow groundwater where the typical salinity is less than 5,000 ppm [52].

2.2 Rock samples

Homogeneous Berea sandstones which are rich in quartz (75%) and exhibit little amounts of feldspar (10%), calcite (5%) and clay content (10%) are used in this experiment [53]. To minimize the effect of mineralogy and heterogeneity on rock weakening, four cylindrical samples with diameter of 38 mm and length around 80 mm were drilled perpendicular to the sedimentary bedding plane from the same block. CT-scanning was also performed to systematically check for the homogeneity between the selected samples before the experiment. After drying in an oven at 60 °C for 24 h, the porosity and permeability of all the samples were measured using AP-608 Automated Porosimeter and Permeameter Coretest System, INC. The results show that tested specimens exhibit porosity of 19.3 ± 1.2% and permeability of 121.3 ± 17.1 mD.

2.3 Triaxial stress test system

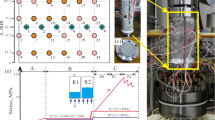

To assess the influence of a saturating fluid of contrasting salinity on the sandstone mechanical properties and subsequent micro-fracture propagation, an unique laboratory apparatus system (Autonomous Triaxial Cell ATC, Geomechanics and Geophysics Laboratory, CSIRO Perth) was used to control and monitor the system pressure (e.g., confining pressure and pore pressure), axial load and rock deformation. In addition, the system allows to measure horizontal and vertical P-wave velocity evolution and monitor the induced micro-seismic events (MSE) during the whole experiment (see Fig. 1). This system mainly consists of:

-

(1)

An axisymmetric triaxial stress cell where the axial loading is controlled by a load cell, and the radial pressure (confining) can be independently applied to the cylindrical rock sample. The rig is equipped to monitor/control axial deformation and radial strain [54];

-

(2)

A micro-seismic monitoring system from Applied Seismology Consulting, enabling active and passive ultrasonic measurement on 18 channels through P- wave ultrasonic Piezo-electric transducers located within the platens and at the sample circumference. In active mode, multi-directional P-wave velocity measurements is enabled, while in passive mode, the system can record any MSE radiating from the sample and within the frequency range of the transducers (0.1-1 MHz);

-

(3)

Affiliated setups, including an oil reservoir tank, pumps (a cell pump, a pore pump, a receiving pump and an actuator pump) and pore bottles which can be filled up with different brine solutions for fluid substitution experiments.

Triaxial stress rigs with micro-seismic monitoring system. a 18 channels Passive/active ultrasonic monitoring computer with 18 pulser-amplifiers. b Cylindrical sample within the Viton sleeve equipped with 18 P-wave transducers. Two LVDTs and a strain gauge instrumented radial cantilever are set to monitor the axial and radial strain, respectively. c Central computer controlling the ATC and ultrasonic systems. d Spatial location of 18 P-wave transducers on cylinder sample surface

The cylindrical rock sample is set into the Viton sleeve as shown in Fig. 1b. The main purpose of Viton sleeve is to isolate the sample from surrounding confining hydraulic oil. 18 P-wave transducers (with mean resonant frequency of 0.5 MHz) were used to perform active/passive ultrasonic monitoring, where 16 were located along the rock lateral surface through specially molded inserts and the other 2 embedded within the platens at the top and bottom surfaces (Fig. 1d). Two LVDTs are located on both sides of the sample to monitor the axial strain, while an instrumented cantilever gauge is set to hemi-encircle the specimen at mid-height and monitor the radial strain. The acquired data from monitoring computer can be then transmitted to the central computer (Fig. 1c), which can also control the status of triaxial stress system such as pressure (confining/pore/loading), fluid injection and circulation (HSW/LSW), strains, etc. via Labview software, and also pre-process the micro-seismicity (Insite Seismic Processor, Itasca-Image).

2.4 Experimental procedures

-

Triaxial test of intact samples

To explore the effect of fluid–rock interactions on rock mechanical properties, three case studies were conducted with intact samples at different saturation conditions: dry (Case #1), HSW (Case #2) and LSW (Case #3). The samples were initially placed into a heat shrink Teflon membrane to ease specimen handling after deformation test and further imaging.

The main procedures consist of: (1) Mount a dry rock specimen into a Viton sleeve sitting in the triaxial cell. (2) After fill up the cell with hydraulic oil, increase the confining pressure up to 20 MPa at 0.5 MPa/min. (3) For saturated samples, Case #2 and Case #3, vacuum the sample for 10 min prior to inject pore fluid at 2 MPa from the bottom end, maintaining 2 MPa pore pressure and the confining pressure is increased up to 22 MPa at 0.5 MPa/min. This allows to perform the tests for the three considered cases at similar 20 MPa effective cell pressure. (4) Axial loading of the sample at a constant strain rate of 10–6 s−1 until reaching brittle failure and maintain constant strain rate until sufficient residual stress is observed. (4) Unload axial stress at a rate equivalent to axial loading, then decrease both cell and pore pressure to zero at 0.5 MP/min and empty. (5) Unmount the specimen, dry it at 60 °C for 24 h prior to CT-scan imaging.

-

Fault reactivation of fractured samples

In addition to assess how fluid chemistry could affect the micro-seismic signature along the main fracture, we also performed another successive two sets of fracture reactivation tests using the failed dry sample in case 1. The protocol remains the same. For the first reactivation test, the sample is saturated with HSW before axial loading. After triaxial test and CT imaging, the same sample was set up again and saturated with LSW for the second reactivation test. To flush out high concentration Na+ and Ca2+ ions that may precipitate on fracture surfaces and within the pore network from the previous test, approximately 5 pore volumes of LSW were injected through the sample prior to the axial loading.

During all the tests mentioned above, active ultrasonic monitoring (velocity survey) was performed in every 5 min. Each velocity survey is composed of 18 consecutive shots, where each transducer served as the source to generate pulse and transmit mechanical vibration through the sample, while all the other transducers acted as receivers. In such configuration, 306 independent waveforms are recorded in each survey at a sampling rate of 10 MHz and amplitude resolution of 12 bits over 409.5 µs. Signal-to-noise ratio (SNR) is improved by stacking 20 recorded waveforms at each receiver induced by 20 shots at a given source transducer [54]. Each ray path from the source to receiver represents a specific direction of wave propagation referring to the sample axis and bedding planes. By conducting active ultrasonic survey, P-wave velocity along multi-independent ray path are calculated at different stress state from a semi-automatic picking of the first arrival of the recoded waveforms. This approach allows to define and update the velocity model during the tests to accurately locate the MSE sources recorded in passive ultrasonic mode described below.

Between two consecutive active velocity surveys, the monitoring system is automatically switched to the passive monitoring mode to record any induced MSE as result of stress change and fluid–rock interactions. In this mode, the voltages generated by the installed transducers sensing a given micro-seismic event were recorded according to a pre-defined trigger logic [20]. To be more specific, if five or more transducers exceed a voltage threshold of 15 mV within a time window of 100 µs, the waveforms from all 17 transducers would be recorded. These waveforms were also recorded with a sampling rate of 10 MHz and an amplitude resolution of 12 bits [54]. First P-wave arrival can then be determined for each recorded waveform of a single MSE via a semi-automatic picking process and the spatio-temporal location of the source of a given MSE can be determined.

3 Results

3.1 Mechanical properties

Figure 2 shows the axial strain (εa), radial strain (εr) and volumetric strain (εv, derived from εa and εr) change with differential stress at dry (Case #1), HSW saturation (Case #2) and LSW saturation (Case #3) conditions, respectively. All tested samples failed in the brittle regime domain, indicated by the sharp drop of differential stress and the establishment of a residual stress after failure. The dry sample has the highest peak stress (143.96 MPa) than fluid saturated rocks, and decreasing salinity would further decrease the yield point by 11.7% for HSW and 15.0% for LSW, indicating that fluid–rock interactions indeed weaken the rock [44, 55, 56]. However, the impact of brine saturation on the Berea sandstones’ static elastic moduli is not obvious (see Table 1).

Figure 3 shows the differential stress–strain data acquired during HSW and LSW reactivation test of the fractured Case#1 sample. The differential stress during LSW reactivation increases at a lower rate and then gradually reaches a plateau, while HSW reactivation shows an abrupt monotony change from a linear increase to the establishment of a residual stress. It is worth noting that despite a striking difference in the stress/strain reactivation response as a function of the saturating fluid, the residual stress is close to similar (56.92 MPa for HSW and 61.55 MPa for LSW). This difference might be caused by the different surface energy and disjoining pressure induced by the fluid salinity change, which will be discussed in Sect. 4.3.

3.2 P-wave velocity evolution

Figures 4 and 5 report the evolution with time of the horizontal and vertical P-wave velocities during the triaxial and reactivation tests, respectively. Based on the velocity evolution of P-wave with time and stress during triaxial and reactivation test, three phases are reported. Phase 1 (tan area in Fig. 4) represents the axial stress loading up to the shear faulting. After the confining pressure reaches and stabilizes at 20 MPa, axial load is constantly applied to the rock sample at a constant strain rate of 10–6 s−1. When the loading stress reaches its maximum (peak stress), it drops slightly about 5 to 10 MPa, prior to a sudden drop concomitant with the facture generation [39]. This process was observed in the test of dry sample in Case #1 and also saturated samples in Case #2 and Case #3. Phase 2 (blue area) responses to the fault generation, characterized by sudden stress decrease concomitantly with a rapid increment of displacement rate (elastic rebound of the cell assembly). Once constant displacement rate is recovered, the differential stress reaches a plateau associated with constant slip rate on the main fracture. Finally, the displacement is stopped, and stress allowed to relax (Pink area). Total imposed displacement ranges from 1.1 to 1.45 mm.

Vertical and horizontal P-wave velocity, differential stress, effective cell pressure, pore pressure and axial displacement vary with time for a,b dry sample in Case #1, c,d HSW saturation sample in Case #2, e,f LSW saturation sample in Case #3, respectively. The tan, blue and pink areas correspond to the axial stress loading up to failure, stress drop indicating the fracture propagation and establishment of a residual stress (e.g., slipping along the fracture plane), and relaxation phase, respectively

Figure 4 shows the time-dependent differential stress, effective pressure, pore pressure, horizontal and vertical P-wave velocity at different saturation conditions. The vertical P-wave velocity is calculated from the wave travel time between transducer embedded in the platens (17 and 18 as shown in Fig. 1d). Horizontal P-wave velocity is calculated from the mean value within each horizontal plane which is orthogonal to the vertical axis (ray path between transducer 1 and 2, 3 and 6, 4 and 7, 5 and 8, etc.). Vp-vertical/Vp-horizontal ratio and overall evolution of the velocity during the test are overall similar to those reported in [53].

As expected, brine saturated samples present higher initial P-wave velocity than the dry rock. For intact failure tests in Case #1 to Case #3, the horizontal P-wave velocity remains relatively constant with increasing axial loading stress, while the vertical P-wave velocity increases. The vertical velocity reaches a plateau when the sample enters the dilatant regime of deformation, i.e., onset of inelastic response, while the horizontal one shows a systematic decrease. Finally, the failure propagation induces a significant decrease in the vertical velocity while the horizontal remains constant and thereafter during the constant slip of the fracture at residual stress.

The observed discrepancy between horizontal and vertical P-wave velocity is possibly caused by the evolution of rock elastic anisotropy [53]. Considering the homogeneity of Berea sandstone used in this study, the aforementioned elastic anisotropy increase is primarily driven by the differential stress increment and the microstructure evolution [39, 53, 57]. At the initial stage of axial loading, pre-existing horizontal micro-fractures are prone to close, leading to an increase in vertical P-wave velocity, while horizontal Vp is not significantly influenced at this stage. As the axial load increases, pre-existing vertical micro-fractures start to open inducing a gradual horizontal Vp decrease, while the vertical Vp remains roughly constant. Finally, close to the peak stress, nucleation of a new micro-fractures network and its coalescence along the main fracture plane induces a diminution of both horizontal and vertical Vp.

For fracture reactivation test under HSW (Fig. 5a and b) and LSW (Fig. 5c and d) saturated conditions, although the horizontal and vertical Vp presents the same trend as other cases, the increasing and decreasing rate is much lower. Meanwhile, the vertical Vp is greater than the horizontal Vp during the whole test for all cases. The average ratio of Vp-vertical and Vp-horizontal is listed in Table 1.

3.3 Micro-seismicity evolution

Figure 6 shows the evolution of cumulative MSEs with time-dependent differential stress in the intact rock failure tests in Case #1 to Case #3 and subsequent fracture reactivation after HSW and LSW saturation in case 1, respectively. For the failure tests of intact dry sample in Case #1 and intact saturated samples in Case #2 and #3, the MSE evolution is quite similar that only a small quantity of MSEs occurs during the early axial stress loading stage, which may be due to the slip of pre-existing micro-fractures as results of compression [54]. MSE activity is null at the earlier stage of loading and a gradual increase in MSE activity can be observed when the samples sustain inelastic deformation. The MSE activity intensifies in the dilatancy regime, as micro-fractures start to develop past the yield point, and reaches a peak associated with the stress drop and the main shear fracture propagation. During the phase 2, no MSE are recorded until the differential stress reaches the residual and constant slip on the fracture plane is initiated. From this point, the MSE activity evolves linearly until the displacement stops, as observed in [54]. Note that the number of MSEs induced by the slip of the fault is limited in Case#3, compared to the saturated Case#2.

Figure 7 reports the cumulative MSEs recorded during the reactivation of dry shear fractured sample, successively saturated with HSW (Fig. 7a) and LSW (Fig. 7b). The cumulative MSEs follow similar trend as previously observed in the Phase 2 of the triaxial test reported above both qualitatively (same trend) and quantitatively (less events with LSW than HSW). Under HSW saturated condition, few MSEs are recorded prior to reaching the residual stress and the reactivation of fracture slip promoting a linear evolution of the MSEs. Under LSW saturated condition, MSE activity evolves linearly from the early stage of loading without significant changes when the residual stress is reached.

Besides, the number of MSE in brine saturated samples (less than 200 events for all cases) is much lower than the dry sample, indicating that the trapped water would strongly affect the transmission of pulse generated by the transducers [20]. Nevertheless, given the high quality of signals although they are limited, we are still able to pick the arrival time of the screened waveforms, which provides a relatively precise MSE locations.

3.4 Micro-seismicity Localization

The accuracy of MSE sources relocation relies primarily on the definition of an appropriate velocity model. Following the approach detailed in [53], the defined velocity model is verified and the uncertainty on the source relocation is quantified by comparison of relocated the source generated by our 16 lateral transducers and their known coordinates (Fig. 1) using active ultrasonic surveys. The velocity model is defined and updated from the dataset reported in subsection 3.2, which satisfied transversely isotropic (TI) conditions. The average anisotropy factor, which is defined as the ratio between Vp-horizontal and Vp-vertical, is assigned. In the case of an active survey recorded near the main failure propagation event, this ratio is set to 0.7 in Case #1, 0.87 in Case #2, 0.85 in Case #3, 0.83 for HSW reactivation and 0.85 for LSW reactivation. For these surveys, the uncertainty between the relocated sensor positions and their known positions (see Fig. 1d) provides the following uncertainty: 3.51 mm in the intact failure test of Case #1, 2.51 mm in Case #2, 3.62 mm in Case #3, 3.03 mm in the HSW reactivation and 3.58 mm in LSW reactivation, respectively.

Among all the triggered events, some sources cannot be accurately relocated and defined as MSE emanating from the sample, due to some inherent acquisition system noise or a poor SNR not allowing satisfactory Picking of the first arrivals. The system recorded 2838 events during intact failure test in case1 (dry), 271 in case 2 (HSW), 224 in case 3 (LSW), 337 in reactivation test with HSW and 83 with LSW. However, only 1479 events (52.1%) during intact failure test in Case#1 (dry), 197 (72.7%) in case 2 (HSW), 179 (53.1%) in case 3 (LSW), 189 (56.1%) in reactivation test with HSW and 73 (87.9%) with LSW were considered as successfully relocated. These events are cumulatively reported in Figs. 6 and 7.

The dynamic evolution of MSEs for samples in intact failure tests and reactivation tests is shown in Figs. 8. These MSEs are also superimposed with a volume rendering of the sample imaged at a resolution of 100 mm using a Medical CT-Scanner. The main fracture plane is segmented and reported in light gray for a directed comparison with the relocated sources of MSEs.

Location of MSEs and match with CT imaging at different views for a dry sample in Case #1, b HSW saturation sample in Case #2 and c LSW saturation sample in Case #3. Black triangles represent the pre-set 18 ultrasonic transducers. Spheres represent the time-dependent MSEs, where green dots occur in the early stage and red dots occur in the later stage

For the dry sample, intact failure test in Case #1 (Fig. 8a), a scattered events cloud was first formed at the bottom of specimen during the early axial stress loading in Phase 1, which is likely due to the initial diffuse damage [54]. When the stress reached the yield point, the MSEs gradually concentrated into a single plane, which aligns perfectly with the shear fracture. As previously mentioned, the number of observed MSEs during intact failure tests using saturated samples (Fig. 8b and c) is relatively limited. In general, most of recorded MSEs are still along the main fracture surfaces (indicated by the events cloud). Besides, the angle of fracture illustrated by the MSEs cluster with respect to the direction of axial load for Case #2 and Case #3 is estimated as 30° and 28°, which is slightly greater than the dry sample fracture angle (14°). Given the similar uncertainty between located sensor positions and the genuine positions for all cases, the results of MSEs localization with combination of fracture angles indicate that fluid–rock interactions indeed weaken the rock. However, no noticeable effects of brine salinity on MSEs distribution can be highlighted. To be more specific, decreasing salinity from 1 M NaCl + 0.05 M CaCl2 to 0.01 M NaCl + 0.005 M CaCl2 did not induce a more pronounced scattering of the MSEs cloud, which implies that lowering salinity may not generate more micro-fractures for intact samples under confining conditions.

Compared to the intact rock, the MSEs clusters during the reactivation after HSW saturation (Fig. 9a) and LSW saturation (Fig. 9b) occurred at the same position which is along the main fracture plane. These results combined with the evolution of cumulative MSEs with time (Fig. 4) indicate that the recorded MSEs during fracture reactivation are mainly caused by the slip and friction of the formed main fracture planes, rather than generating new fractures.

4 Discussions

4.1 Effect of saturation on rock mechanics during intact sample failure

Mechanical weakening has been evidenced through the triaxial tests performed on the intact samples saturated with both HSW and LSW, Case#2 and Case#3, respectively (see Fig. 2). Under similar and controlled testing conditions, brine saturation induced a decrease in the Berea Sandstone mechanical strength and to a lower extend in its elastic moduli. Such observation have been previously reported in various porous rock types, such as sandstones [20, 35, 58] and carbonates [16, 59] to cite few. Furthermore, it is worth recalling that our dataset does not show any significant effect on the residual stress taking place after the failure propagation and the slip of the fracture at a constant rate.

Brine saturation also induces an increase in the P-wave velocities measured under similar effect pressure prior to the loading. The effect of saturation on the P-wave velocities has also been extensively studied [60, 61] and our results indicate an ideal saturation of the samples, ensure by vacuuming prior to saturation and the application of a pore pressure of 2 MPa throughout the tests. Stiffness of the saturating fluid is known to increase the P-wave velocities at full saturation [62].

We also report a striking difference between the cumulative MSEs activity between the dry and brine saturated samples despite similar macroscopic shear fracture developments. In this study, passive ultrasonic monitoring was considered to relate the distribution micro-cracks induced by irreversible deformation with the nature of the saturating fluids. However, the limited number of MSEs recorded in saturated conditions, especially in Case#3, makes difficult a straight comparison of the sources location between the 3 considered cases. Such discrepancy can be primarily explained by dispersion and attenuation mechanisms induced by the presence and spatial distribution of fluid in the pore space and their interaction with the mineral matrix [63]. Within a specific and low frequency domain, the sample is considered into a relaxed state, i.e., a propagating wave will promote dispersion and attenuation mechanisms and motion of the saturating fluid in the porous space [64]. As we verified that the intact samples under triaxial load were tested in fully saturated conditions, macroscopic diffusion is one of the mechanisms potentially responsible for the attenuation of the MSEs and limit their detectability by our system. The macroscopic diffusion in water-saturated rock can be characterized by the cut-off frequency separating the drained and the undrained regimes (fd) [65]. This cut-off frequency is dependent on macroscopic properties of the samples and expressed as:

where \(k\) is the rock permeability (in m2), \(\eta\) is the fluid viscosity (Pa s−1), Ku is the rock bulk modulus at undrained or saturated regimes (in Pa), and L2 is the squared characteristic length. Accounting for the known properties of the sample and the fluids, it returns a value of cut-off frequency separating the drained and the undrained regimes for our saturated test fd ~ 126 Hz. The P-wave transducers used in this study have a frequency range of 0.1 to 1 MHz, with a mean resonant frequency of 0.5 MHz. Therefore, the attenuation associated with diffusion across the water-saturated samples is expected to occur at frequencies higher than those explored in the experiments, so that the attenuated signals are undetectable in this test. This attenuation mechanism can then explain the low amount of MSEs recorded in saturated conditions compared to the dry case.

An additional attenuation mechanism can be invoked to explain this discrepancy, when the samples experience micro-cracking beyond the yield point and after propagation of the main fracture. Indeed, newly generated high aspect ratio pores (cracks) can promote squirt-flow and local fluid motion [62, 64]. The cut-off frequency calculation for squirt-flow involved parameters not determined in this study, such as the aspect ratio of the micro-cracks. It is worth mentioning that this attenuation mechanism is also prone to occur in these tests.

4.2 Effect of brine salinity on mechanical and elastic properties of the intact Berea Sandstone

For intact rock samples, both HSW and LSW saturation process give a similar Young’s modulus and peak stress, suggesting that brine salinity has a limited effect on mechanical properties in particular for rocks without pre-existing micro-fractures. Results from MSEs localization also indicate that changing salinity would not increase the width of MSEs cloud along the main fracture plane, indicating that no marked fractures or micro-fractures would generate as the result of salinity change. Moreover, HSW and LSW saturation processes do not alter the differential stress profile over time, which implies that fluid–rock interaction may not trigger micro-fracture initiation along the main fracture. Similar results were observed by Hunfeld et al. [66], who reported that changing NaCl salinity had no effect on frictional strength of Upper Rotliegend Slochteren sandstone reservoir.

Overall, our triaxial tests point out that decreasing brine salinity has negligible influence on intact Berea sandstone mechanical behaviors. However, this is different to what we found in our previous works that decreasing salinity of NaCl and MgCl2 would decrease the average energy release rate (G0, J/m2) or the surface energy (γs, J/m2), which means that the salinity reduction would be in favor of fracture propagation and thus the rock weakening [50]. Surface energy is defined as the minimum energy required to generate a new unit surface at reversible conditions [67]. The surface energy is a thermodynamic characteristic and controlled by the in situ geochemical parameters such as pH and electrolyte concentrations [23, 26, 68, 69]. The change of rock surface energy from HSW to LSW condition can be calculated using the following equation:

where γHSW and γLSW, ФHSW and ФLSW, cHSW and cLSW are the surface energy, surface potential (mV), and capacitance (F/m2) at HSW and LSW condition, respectively [50].

We calculated the quartz surface potential at different salinity using PhreeqC (V3.5.0 plugged in Notepad + + V6.6.9 with the database of Lawrence Livermore National Laboratory thermo.com.V8.R6.230 [70], see Fig. 10). By shifting fluid from HSW to LSW and considering the capacitance as the constant, it would expect to see a greater negative of surface energy and thus the decrease in surface energy required to initiate the fracture (Eq 2).

However, neither the salinity effect on rock strength nor the further micro-fracture propagation were observed from triaxial compression tests on intact samples. In other words, although the energy threshold for fracture propagation is reduced, it would be still difficult for intact samples to generate more micro-fractures if the confining pressure is applied. It is worth mentioning that in the surface potential calculation, we only consider quartz particles. However, in actual fracturing process, the clay cementation-related processes (breakage, clay-rock slipping, etc.) may also come into play. Nevertheless, these findings are crucial to the implementation of hydraulic fracturing in tight sandstone reservoirs and siliceous or quartz-rich shale reservoirs. While the deeper formations brine usually contains high concentrations ions (sometimes can be up to 280,000 ppm [51]), the salinity of injected hydraulic fracturing fluid is quite low (< 5000 ppm [52]). Our works imply that the intact sandstone would not dismantle at reservoir conditions even with such huge geochemistry change, which is favor of the hydraulic fracture’s integrity. This result may also explain why industries did not report too much issues of reservoir integrity during the low salinity waterflooding in sandstone reservoirs.

4.3 Effect of brine salinity on rock mechanics during fracture reactivation process

The reactivation test (Case#1) shows that brine salinity seems to impact the kinetics of fault reactivation but return equivalent residual stress (Fig. 11a). In addition, as for the intact sample tests, we observed less MSE activity for LSW saturated pre-fractured sample compared to HSW. For HSW reactivation, the effective differential stress increases sharply and quickly to reach the residual and constant slip. However, the differential stress at LSW reactivation increase appears to be more progressive and residual stress established in a more gradual manner. The reproducibility of these tests is proven as similar trends can be observed in the intact samples after rock failure (Phase 2—blue in Figs. 4 and 6) where the axial loading reapplies on the sample and leads to slip of the generated fracture planes (Fig. 11b). To our best knowledge, no previous experimental study has shown the effect of brine salinity on the kinetics of reactivation of a pre-existing shear fracture. A more systematic study of such reactivation mechanisms is certainly required to better understand the fluid–rock interaction mechanisms responsible for this observation.

a Comparison of differential stress variation with time during fracture reactivation between HSW saturated sample and LSW saturated sample in Case #1, and b zoom-in area of the differential stress variation with time during reactivation after intact sample failure among dry sample in Case #1, HSW saturated sample in Case #2 and LSW saturated sample in Case #3, respectively

Nevertheless, a preliminary explanation invokes the chemistry of the brine. As reactivation processes occur on a shear fractured sample, we can assume that the generated micro-fractures along the fracture plane will promote a higher contact area between the saturating fluid and the mineral matrix. In addition, the slip of the fracture will generate more damage, extra tensile stress and create more micro-cracks [71], as shown by the MSE recorded during the Phase 2. Therefore, the aqueous ions can more effectively react with quartz and affect the in situ geochemistry. We believe that this will influence the disjoining pressure between adjacent mineral particles and thus the differential stress evolution.

Disjoining pressure describes the distance-dependent interaction between two surfaces. On the basis of classic Derjaguin–Landau–Verwey–Overbeek (DLVO) theory, the disjoining pressure consists of van der Waals force, electrostatic force and structural force [72]. When disjoining pressure is negative, the interactions between two surfaces exhibit an attraction force and lead to the high rock strength; when it is positive, the force would shift to repulsion, separate surfaces and decrease the rock strength [23, 56]. Figure 12 shows the disjoining pressure as a function of film thickness between adjacent quartz surfaces at HSW and LSW conditions (details of disjoining pressure calculation procedures can be found in our previous work [49]). The calculated result indicates that decreasing salinity can shift the disjoining pressure to more positive, leading to a more repulsion force between adjacent quartz particles [41]. Therefore, more in situ micro-fractures would be opened, and the differential stress of cracked sample saturated in LSW would take longer time to reach the residual and permanent slip regime.

Overall, our results suggest that for stimulated sandstone reservoirs after refracturing implementation, the formation matrix would be more sensitive to the surrounding water salinity. Compared to the HSW reactivation where the effective differential stress increases sharply and quickly to reach the residual and constant slip, the differential stress increment during LSW reactivation appears to be more progressive and the residual stress established in a more gradual manner, suggesting the effect of salinity on kinetics of fracturing (the delay of differential stress development). This process could be more remarkable in shale reservoirs typically those rich in natural fractures. Besides, the physicochemical reactions induced micro-fractures may trap certain amounts of water, and this may explain why some shale reservoirs have extremely low recovery of the flowback water after hydraulic fracturing in natural fractures developed formations [73,74,75,76].

4.4 Conclusions

Fluid–rock interactions play significant roles in rock mechanical behaviors and subsequent reservoir integrity and oil/gas production. In this study, we performed triaxial compression stress tests on intact and cracked Berea sandstone samples under dry, HSW and low LSW saturation conditions. Strain (axial and radial) and stress (axial loading stress, confining pressure and pore pressure) data were monitored during the whole experiments. Horizontal and vertical P-wave velocities were also recorded at selected stages to characterize the elastic anisotropy and were analyzed to exhibit the time-dependent location of micro-seismicity during fracture/micro-fracture propagation. Moreover, the potential reasons of fluid–rock interactions triggered rock weakening were discussed from physicochemical perspective. The main findings are summarized as follows:

-

1.

Compared to the dry intact sample, the brine saturation would further decrease rock strength by 11.7% for HSW and 15.0% for LSW, confirming that water indeed weakens the rock.

-

2.

Changing brine salinity has negligible effect on intact samples’ Young’s modulus, peak stress and residual stress. Although decreasing salinity can decrease the minimum surface energy required for fracture propagation, this effect would be minimal under our testing conditions, i.e., high confining pressure.

-

3.

The majority of MSEs during intact rock failure are located along the main fracture planes regardless of the wetting conditions, confirming that the change of water salinity can hardly facilitate micro-fracture propagation under confining condition for intact samples.

-

4.

Saturated samples generally present higher P-wave velocity than the dry rock. During the triaxial tests on intact samples, the horizontal P-wave velocity would gradually decrease with increasing axial loading stress, while the vertical P-wave velocity would slightly increase first then decrease at similar rate of horizontal P-wave velocity. This observed discrepancy between horizontal and vertical P-wave velocity is mainly caused by the evolution of rock elastic anisotropy.

-

5.

During reactivation process of re-saturated fractured sample, the rate of differential stress increase in LSW saturated rock is much less than the HSW saturated rock where the differential stress would increase sharply to reach the similar plateau. The same trends are also observed in the intact samples after rock failure where the axial loading reapplies on the sample and leads to slip of the generated fracture planes. We believe that the surrounding brine salinity would affect the kinetic of fracturing in sandstone and shale reservoirs typically those rich in natural fractures and influence the ultimate hydrocarbon recovery.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Akrad OM, Miskimins JL, Prasad M (2011) The effects of fracturing fluids on shale rock mechanical properties and proppant embedment. In: SPE annual technical conference and exhibition, Society of petroleum engineers

Al-adasani A, Bai B, Wu Y-S (2012) Investigating low-salinity waterflooding recovery mechanisms in sandstone reservoirs. In: SPE improved oil recovery symposium, Society of petroleum engineers

Al-Bazali T (2013) The impact of water content and ionic diffusion on the uniaxial compressive strength of shale. Egypt J Pet 22(2):249–260

Alemu BL et al (2011) Caprock interaction with CO2: a laboratory study of reactivity of shale with supercritical CO2 and brine. Appl Geochem 26(12):1975–1989

Al-Saedi HN, Flori RE, Brady PV (2019) Effect of divalent cations in formation water on wettability alteration during low salinity water flooding in sandstone reservoirs: oil recovery analyses, surface reactivity tests, contact angle, and spontaneous imbibition experiments. J Mol Liq 275:163–172

Al-Shalabi EW, Sepehrnoori K, Delshad M (2014) Mechanisms behind low salinity water injection in carbonate reservoirs. Fuel 121:11–19

Anders MH, Laubach SE, Scholz CH (2014) Microfractures: a review. J Struct Geol 69:377–394

Arsalan N, Buiting JJ, Nguyen QP (2015) Surface energy and wetting behavior of reservoir rocks. Colloids Surf, A 467:107–112

Barati R, Liang JT (2014) A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci 131(16)

Baud P, Zhu W, Wong TF (2000) Failure mode and weakening effect of water on sandstone. J Geophys Res Solid Earth 105(7):16371–16389

Bergsaker AS et al (2016) The effect of fluid composition, salinity, and acidity on subcritical crack growth in calcite crystals. J Geophys Res Solid Earth 121(3):1631–1651

Biot MA (1956) Theory of propagation of elastic waves in a fluid-saturated porous solid. II. Higher frequency range. J Acoust Soc America 28(2):179–191

Boschee P (2014) Produced and flowback water recycling and reuse: economics, limitations, and technology. Oil and Gas Facilities 3(01):16–21

Cai X et al (2019) Water-weakening effects on the mechanical behavior of different rock types: phenomena and mechanisms. Appl Sci 9(20):4450

Chen G et al (2019) Weakening effects of the presence of water on the brittleness of hard sandstone. Bull Eng Geol Env 78(3):1471–1483

Chen X, Eichhubl P, Olson JE (2017) Effect of water on critical and subcritical fracture properties of Woodford shale. J Geophys Res Solid Earth 122(4):2736–2750

Dahi Taleghani A, Ahmadi M, Olson J (2013) Secondary fractures and their potential impacts on hydraulic fractures efficiency. In: ISRM international conference for effective and sustainable hydraulic fracturing. International society for rock mechanics and rock engineering

Dautriat J et al (2016) Remote monitoring of the mechanical instability induced by fluid substitution and water weakening in the laboratory. Phys Earth Planet Inter 261:69–87

Delle Piane C et al (2014) Frequency-dependent seismic attenuation in shales: experimental results and theoretical analysis. Geophys J Int 198(1):504–515

Demarco MM et al (2007) The impact of partial water saturation on rock strength: an experimental study on sandstone [Der Einfluss einer partiellen Wassersättigung auf die mechanischen Gesteinseigenschaften: eine Fallstudie an Sandsteinen]. Zeitschrift der Deutschen Gesellschaft für Geowissenschaften 158(4):869–882

Zeng L, Akhondzadeh H, Iqbal MA, Keshavarz A, Rezaee R, Xie Q (2022) Effect of fluid-shale interactions on shales micromechanics: Nanoindentation experiments and interpretation from geochemical perspective. J Natural Gas Sci Eng 101:104545

Duda M, Renner J (2013) The weakening effect of water on the brittle failure strength of sandstone. Geophys J Int 192(3):1091–1108

Dunning J et al (1984) The effects of aqueous chemical environments on crack propagation in quartz. J Geophys Res Solid Earth 89(B6):4115–4123

Fakcharoenphol P, et al. (2014) The effect of osmotic pressure on improve oil recovery from fractured shale formations. In: SPE unconventional resources conference. Society of Petroleum Engineers: The Woodlands, Texas, USA

Feng R, et al (2019) Brittleness index: from conventional to hydraulic fracturing energy model. Rock Mech Rock Eng

Flesch S et al (2018) Hydrogen underground storage—petrographic and petrophysical variations in reservoir sandstones from laboratory experiments under simulated reservoir conditions. Int J Hydrog Energy 43(45):20822–20835

Gupta R, et al (2011) Enhanced waterflood for carbonate reservoirs-impact of injection water composition. In: SPE Middle East oil and gas show and conference. Society of petroleum engineers

Gupta I et al (2019) Water weakening: a laboratory study of marcellus, woodford, eagle ford, and wolfcamp shales. SPE Reserv Eval Eng 22(02):418–427

Hadizadeh J, Law, R (1991) Water-weakening of sandstone and quartzite deformed at various stress and strain rates. In: International journal of rock mechanics and mining sciences and geomechanics abstracts. Pergamon

Hemme C, Van Berk W (2018) Hydrogeochemical modeling to identify potential risks of underground hydrogen storage in depleted gas fields. Appl Sci 8(11):2282

Hunfeld LB, Niemeijer AR, Spiers CJ (2017) Frictional properties of simulated fault gouges from the Seismogenic Groningen gas field under in situ P-T -chemical conditions. J Geophys Res Solid Earth 122(11):8969–8989

Kang Y et al (2016) Strengthening shale wellbore with silica nanoparticles drilling fluid. Petroleum 2(2):189–195

Kargbo DM, Wilhelm RG, Campbell DJ (2010) Natural gas plays in the marcellus shale: challenges and potential opportunities. Environ Sci Technol 44(15):5679–5684

Bo Z, Zeng L, Chen Y, Xie Q (2021) Geochemical reactions-induced hydrogen loss during underground hydrogen storage in sandstone reservoirs. Int J Hydrog Energy 46(38):19998–20009

King GE (2010) Thirty years of gas shale fracturing: What have we learned? In: SPE annual technical conference and exhibition, Society of petroleum engineers: Florence, Italy. P 50

Lal M (1999) Shale stability: drilling fluid interaction and shale strength. In: SPE Asia Pacific oil and gas conference and exhibition, Society of petroleum engineers: Jakarta, Indonesia, p 10

Lebedev M, Wilson ME, Mikhaltsevitch V (2014) An experimental study of solid matrix weakening in water-saturated Savonnières limestone. Geophys Prospect 62(6):1253–1265

Leung DY, Caramanna G, Maroto-Valer MM (2014) An overview of current status of carbon dioxide capture and storage technologies. Renew Sustain Energy Rev 39:426–443

Le Ravalec M, Guéguen Y (1996) High-and low-frequency elastic moduli for a saturated porous/cracked rock-differential self-consistent and poroelastic theories. Geophysics 61(4):1080–1094

Liu D et al (2018) Experimental investigation on the mechanical and acoustic emission characteristics of shale softened by water absorption. J Nat Gas Sci Eng 50:301–308

Liu H et al (2020) Effect of water imbibition on uniaxial compression strength of sandstone. Int J Rock Mech Min Sci 127:104200

Lu Y et al (2012) A mechanical model of borehole stability for weak plane formation under porous flow. Pet Sci Technol 30(15):1629–1638

Lu Y et al (2013) Influence of porous flow on wellbore stability for an inclined well with weak plane formation. Pet Sci Technol 31(6):616–624

Lyu Q et al (2016) Experimental investigation of mechanical properties of black shales after CO2-water-rock interaction. Materials 9(8):663

Lyu Q et al (2018) Experimental investigation on the mechanical behaviours of a low-clay shale under water-based fluids. Eng Geol 233:124–138

Marcon V, Kaszuba JP (2015) Carbon dioxide–brine–rock interactions in a carbonate reservoir capped by shale: experimental insights regarding the evolution of trace metals. Geochim Cosmochim Acta 168:22–42

Martin RJ III, Durham WB (1975) Mechanisms of crack growth in quartz. J Geophys Res 80(35):4837–4844

Mavko G, Bandyopadhyay K (2009) Approximate fluid substitution for vertical velocities in weakly anisotropic VTI rocks. Geophysics 74(1):D1–D6

Megawati M, Hiorth A, Madland M (2013) The impact of surface charge on the mechanical behavior of high-porosity chalk. Rock Mech Rock Eng 46(5):1073–1090

Nara Y et al (2011) Effects of humidity and temperature on subcritical crack growth in sandstone. Int J Solids Struct 48(7–8):1130–1140

Nara Y et al (2014) Influences of electrolyte concentration on subcritical crack growth in sandstone in water. Eng Geol 179:41–49

Nasralla RA, Alotaibi MB, Nasr-El-Din HA (2011) Efficiency of oil recovery by low salinity water flooding in sandstone reservoirs. In: SPE western north American region meeting, Society of petroleum engineers

Nicot J-P et al (2014) Source and fate of hydraulic fracturing water in the Barnett Shale: a historical perspective. Environ Sci Technol 48(4):2464–2471

Nur A, Simmons G (1969) Stress-induced velocity anisotropy in rock: an experimental study. J Geophys Res 74(27):6667–6674

Parkhurst DL, Appelo C (2013) Description of input and examples for PHREEQC version 3: a computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations, US Geological Survey

Paterson MS, Wong TF (2005) Experimental rock deformation-the brittle field. Springer

Risnes R et al (2005) Water weakening of chalk—mechanical effects of water–glycol mixtures. J Petrol Sci Eng 48(1–2):21–36

Rostom F et al (2013) Effect of fluid salinity on subcritical crack propagation in calcite. Tectonophysics 583:68–75

Røyne A, Dalby KN, Hassenkam T (2015) Repulsive hydration forces between calcite surfaces and their effect on the brittle strength of calcite-bearing rocks. Geophys Res Lett 42(12):4786–4794

Sarout J (2012) Impact of pore space topology on permeability, cut-off frequencies and validity of wave propagation theories. Geophys J Int 189(1):481–492

Sarout J et al (2017) Laboratory micro-seismic signature of shear faulting and fault slip in shale. Phys Earth Planet Inter 264:47–62

Scanlon BR, Reedy RC, Nicot JP (2014) Will water scarcity in semiarid regions limit hydraulic fracturing of shale plays? Environ Res Lett 9(12):124011

Shchukin ED et al (2006) Effects of adsorption–active media on the mechanical propreties of catalysts and adsorbents. Colloids Surf, A 282–283:287–297

Skrettingland K et al (2011) Snorre low-salinity-water injection-coreflooding experiments and single-well field pilot. SPE Reserv Eval Eng 14(02):182–192

Swolfs HS (1972) Chemical effects of pore fluids on rock properties

Velcin H et al (2020) Experimental Reactivation of Shear-fractured Berea and Boise Sandstones by Brine or Liquid CO2 Injection at Depth. J Geophys Res Solid Earth 125(2):e2019JB018281

Vengosh A et al (2014) A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States. Environ Sci Technol 48(15):8334–8348

Vidic RD et al (2013) Impact of shale gas development on regional water quality. Science 340(6134):1235009

Wasantha PLP, Ranjith PG (2014) Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng Geol 178:91–101

Xie Q et al (2016) Extended DLVO-based estimates of surface force in low salinity water flooding. J Mol Liq 221:658–665

Yan W, et al. (2018) Effects of fluid conditions on subcritical crack growth in tight sandstone. In: 52nd U.S. rock mechanics/geomechanics symposium, American Rock Mechanics Association: Seattle, Washington, p 7

Yousef AA, Al-Saleh S, Al-Jawfi MS (2011) Smart waterFlooding for carbonate reservoirs: salinity and role of ions. In: SPE middle east oil and gas show and conference, Society of petroleum engineers

Zeng L et al (2020) Role of brine composition on rock surface energy and its implications for subcritical crack growth in calcite. J Mol Liq 303:112638

Zeng L et al (2020) Interpreting micromechanics of fluid-shale interactions with geochemical modelling and disjoining pressure: implications for calcite-rich and quartz-rich shales. J Mol Liq 319:114117

Zivar D, Kumar S, Foroozesh J (2020) Underground hydrogen storage: a comprehensive review. Int J Hydrog Energy 46:23436

Zoback MD (2010) Reservoir geomechanics, Cambridge University Press

Acknowledgements

This work was supported by the open fund (PLN201901) of State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation (Southwest Petroleum University). The authors gratefully acknowledge the laboratory supports and constructive discussions from Joel Sarout, David Nguyen and Shane Kager from CSIRO Energy, and Mustafa Sari from CSIRO Mineral Resources. The first author also acknowledges the financial support through Higher Degree Research (HDR) Research Training Program (RTP) Scholarship from the Australian government.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zeng, L., Dautriat, J., Monmusson, L. et al. Effect of fluid saturation and salinity on sandstone rock weakening: experimental investigations and interpretations from physicochemical perspective. Acta Geotech. 18, 171–186 (2023). https://doi.org/10.1007/s11440-022-01583-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01583-9