Abstract

Embedded retaining walls equipped with ground heat exchangers is one kind of energy geostructures, harvesting the shallow ground energy for heating and cooling buildings. However, past investigations mainly focus on the thermal assessment of energy walls, but pay limited attention to mechanical wall behavior and associated ground response. At present, there is no standard preliminary code for assessing the long-term mechanical performance of energy walls. In this study, a comprehensive literature review is conducted to summarize the existing studies on the long-term mechanical behavior of both conventional retaining walls and thermo-active ones, respectively. The review identifies three most critical mechanical factors for energy walls (i.e., horizontal wall movement, ground settlement, and basement heave), while their permissible values can be referred to standard preliminary design criteria of conventional retaining walls in the short-term and limited long-term field measurements. For elaborating the application of design criteria, a parametric study is implemented to evaluate the long-term mechanical performance of energy walls in stiff clay under various thermal conditions, including the influence of thermal solicitations, station temperature and asymmetrical operation mode. The vivid assessing results show that the thermal-induced mechanical movements due to geothermal operation may cause unfavorable serviceability issues (e.g., cracks), but are unlikely to bring critical damages to the structural performance. The identified critical mechanical factors and evaluation of thermal influences in this study provide some guidance for the mechanical assessment of long-term energy wall behavior, particularly in the light of limited field measurements and demonstration cases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ground source heat pump (GSHP) systems present proliferating implementations over the last few decades, harvesting shallow geothermal energy to meet heating and cooling demands of buildings and infrastructures. GSHP technology has a significant contribution to reducing greenhouse gas emissions and the development of low-cost energy buildings. As an essential component of GSHP systems, ground heat exchangers (GHEs) utilize relatively constant shallow ground temperature as the energy source instead of seasonal atmospheric temperature. Conventionally, GHEs were usually installed outside of the existing foundation in earth collectors, boreholes, and other subsurface areas, which requires additional cost and land nearby. More recently, energy geostructures—also referred as thermo-active foundations or geothermal structures—are emerging as an innovative type of GHEs, embedding heat exchangers within foundation elements (e.g., piles, tunnels, and embedded retaining walls). That is, the foundation not only carries loads but also provides energy supply in the long run. Considering the complex thermo-mechanical coupled foundation behavior, a systematic evaluation approach is indispensable to optimize the design of such geothermal structures.

Past studies of energy geostructures primarily focus on energy piles and spare only a few concerns to other thermo-active foundations. Since the installation of the first well-recognized energy pile case in Austria in 1984 [15], many practical full-scale energy pile cases have been constructed all over the world, e.g., the UK [7], Germany [48], Switzerland [48], China [41], Japan [43], and the USA [60]. Extensive experimental and numerical studies have comprehensively investigated the performance of energy piles with model-scale/prototype-scale simulations [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,21], regarding thermal (e.g., absorber pipe arrangement, heat exchange efficiency, temperature contour, thermal solicitation, and geothermal operation mode) and mechanical features (e.g., head load, head settlement, axial and radial strains, shaft resistance, bearing capacity, and ground pile effect). These existing research experiences significantly enhance the energy pile design, handling thermo-mechanical responses in a more accurate and reliable manner. For example, Faizal et al. [38] suggested that the geothermal operation of a single energy pile only induced reversible elastic deformations in dense sand, with a practical cyclic temperature load ranging from 8 to 30 °C; on the other hand, for complex ground conditions in tropical zones, Casagrande et al. [21] observed thermo-plastic deformations at the organic-clay-pile interface within field tests of an energy micropile. Hence, engineers would be suggested to adjust plans when constructing energy piles at various locations. For energy pile groups with contacting slabs, engineers can utilize the design charts provided in Ravera et al. [72] to predict the pile heat displacement under various pipe-soil-slab interactions preliminarily. Most recently, a performance-based design approach is constructed to assess the deformation and failure of energy piles at both serviceability limit states (SLS) and ultimate limit states (ULS), and systematically standardize the mechanical design of energy piles for engineering practice [73].

Nonetheless, the studies of other thermo-active foundations are not as comprehensive and specified as those for energy piles. One major obstacle to propose a complete design solution for non-pile energy geostructures is the lack of demonstration cases and feasibility studies. The well-recorded cases of non-pile energy geostructures are only a few but progressively growing: (1) energy decks (a concrete bridge located in the USA [30] and deicing system in China [46]); (2) energy tunnels (LT 22 of Lainzer tunnel in Vienna [5], Stuttgart Fasanenhof Tunnel in Germany [80], Linchang Tunnel in Inner Mongolia [93], and South Extension of Metro Torino Line 1 in Italy [10]); and (3) energy walls (Uniqa Tower in Vienna [5], Knightsbridge Palace Hotel in London [8], Shanghai Museum of Natural History in China [91], and U2 Line extension in Vienna [14]).

Due to the limitation of article space, this paper would then focus on the energy walls among the non-pile energy foundations. Unlike energy piles, energy walls are not only surrounded by soil but also in partial contact with the built environment (e.g., underground train station), providing more efficient energy exchange and temperature recovery capacity due to the interaction of rock-soil deposits, structural elements, groundwater, and airflows [15]. Besides, for energy wall design, the thermal and mechanical assessments require to consider ground-structure interactions, such as the thermally induced behaviors of the surrounding soil and the geothermal structures under the presence of airflow and groundwater flow. The design considerations of energy walls are hence more complicated than those of energy piles. For example, in addition to axial behavior, the geothermal wall study should also take the thermally induced bending moment and flexural deformation into account [49].

Past investigations analyze the performance of energy walls in two main categories: (1) thermal analyses including energy production, heat exchange efficiency, temperature field variation, effect of pipe arrangement, influence of operation mode, and etc. [5, 91, 35,36,37,38,39,40,41,42,43,44,58]; (2) mechanical analyses including thermally induced stress/strain variation, wall movement, ground settlement and etc. [14, 11, 46,47,48,49,50,51,52,53,79]. The thermal analyses simulate the heat exchange between the carrier fluid circulating inside the structural elements and the surrounding environment (e.g., outside/inner airflow, underground waterflow, and the adjacent soil) usually through a coupled thermo-hydro (TH) approach (e.g., in FEFLOW© and COMSOL Multiphysics). On the other hand, the mechanical analyses evaluate the long-term mechanical performance of energy walls under thermal solicitations through coupled thermo-mechanical (TM) and coupled thermo-hydro-mechanical (THM) approaches (e.g., in Abaqus and PLAXIS).

The aforementioned studies of energy geostructures mainly emphasize the thermal performance but pay limited attention to the mechanical response. So far, there have been some recommendations and guidelines for the design of energy geostructures available in some countries (e.g., Germany, Switzerland, the UK, and France). However, again, these guidelines hardly mention any standard design procedure or assessment code for energy walls, especially in relation to mechanical behavior [49]. Most recently, Loveridge et al. [55] conducted a comprehensive literature review on most of the energy geostructures investigations and listed the current research status, while Di Donna et al. [36] developed design charts for the preliminary evaluation of energy capacity of energy walls embedded in various ground conditions through a TM approach. In view of previous efforts, there is still a lack of comprehensive assessment of the mechanical performance of energy walls, which deserves more studies in greater depth and breadth.

This paper comprehensively reviews past studies on the mechanical performance of embedded retaining walls in the long term, considering both conventional cases and thermo-active ones. The review of previous studies identifies critical mechanical factors of long-term wall behavior, and the associated assessment can be based on well-established assessment methods for short-term wall performance. Compared to a conventional wall, the temperature change may play a role in the mechanical performance of an energy wall, and as such some thermal-related influences are evaluated in Sect. 4.

2 Previous studies of retaining walls in the long term

The mechanical study of energy walls is far from sufficient and significant. The lack of well-recorded field data of energy walls imposes difficulties in the validation of finite element models. This research carried out an extensive literature review of the long-term mechanical performance of embedded retaining walls and created a database of relevant past studies since 1977. The database comprises 20 long-term study cases of conventional embedded retaining walls and 13 long-term investigations of thermo-active retaining walls (i.e., energy walls), as summarized in Table 1, 2, 3 and Table 4, respectively. Ten well-recorded piled wall cases (consisting of eight conventional cases and two thermo-active studies) are also included in the tables, as their mechanism is similar to that of diaphragm walls. In addition, a field instrumentation case on the existing retaining wall refurbishment with thermo-active systems is included, which is an innovative installation of heat exchangers and different from the typical energy wall construction [9]. Compared with the 300-case database of retaining walls due to short-term deep excavations [53], the database of retaining walls in the long term is relatively small. However, these long-term cases may not be as diversified as those short-term cases subject to various construction techniques, and as such, the database of long-term cases should also be useful for the mechanical assessment of energy walls.

2.1 Conventional retaining wall cases

The long-term mechanical responses of embedded retaining walls are mainly determined by three approaches: direct measurements through field instrumentation, experimental investigations by centrifuge tests, and numerical simulations with finite element programs. In this section, the field monitoring studies are reviewed first followed by the discussion of relevant centrifuge tests and numerical analyses.

Table 1 lists eight long-term field studies of cut-and-cover underground structures constructed using piled wall and diaphragm wall techniques, and the maximum observation duration of them is up to 28 years [59,60,61,62,63,64,65,66,22]. The structural resisting system of retaining walls can be still reliable in the long term, on the basis of the anchors at Neasden that remained functional after 24 years [1]. However, the resisting effects may reduce during the long term, according to the propping force reduction of the roofing slab at Bell Common Tunnel [89], which may affect the bending moments and deflections of the retaining wall. Carswell et al. [20] found that the wall deflection and ground movement of an anchored diaphragm wall case continued to increase over the 18-year monitoring period. Apart from the structural behavior, the dissipation rate of excess pore water pressure close to the wall was much slower than that in the field far away from the construction site, due to the longer drainage path around the wall [20]. Besides, the total vertical stress beneath the base slab at Coventry reduced gradually but remained unchanged after 17 years [2], which might result in basal heave. The basal heave could continue for 21 years after the pit excavation for low-permeability ground conditions [22]. Nonetheless, the long-term heave is unlikely to cause failure of existing structures [81]. The continuous measurements of embedded retaining walls in the long run reveal enhancement of the long-term ground-wall interaction mechanisms and lay the basis for the understanding of energy wall performance in the long run.

Field monitoring is generally employed to ensure project safety at the construction stage; however, it is challenging to maintain field instruments in good service over decades after construction for long-term structural assessment. Instead, centrifuge modeling is a more practical method to predict the long-term behavior of geotechnical problems within an acceptable short period [12, 56]. In prototype scale, it can take years or even decades for the complete development of long-term foundation behavior, e.g., the dissipation of construction-induced excess pore water pressure around the retaining wall; however, such long-term development can be reduced to several hours by a factor of n−2 in a model scale created by the enhanced gravity field of a geotechnical centrifuge. Table 2 collects five centrifuge studies of long-term mechanical performance of embedded retaining walls, and the maximum testing period of them is up to 17 h in a 1/125-scale model, which is equivalent to 30 years in prototype scale [12, 70,71,23]. In a centrifuge test of a propped diaphragm wall, the pore water pressure on the unexcavated side can recover to hydrostatic condition with only one hour (i.e., 150 days in prototype scale after excavation), whereas the pore water pressure under the base slab is not back to the hydrostatic level even after a much longer time (250 days in prototype after excavation) [50]. The base slab acts as an impermeable boundary above the soil, increasing its drainage path distance and longer consolidation time. Similar to the short-term behavior of retaining walls, the long-term consolidation-induced deformation modes are mainly basement heave and wall bulging [50]. As a further study, the observed experimental results of basement heave [23] showed good agreement with the 21-year monitoring data at a site in London [22], which offers some guidance on the long-term heave estimation for future foundation pit projects.

Centrifuge tests suit well to develop a fundamental understanding of the soil-structure mechanism in a given problem. However, regarding various loading types and soil properties, conducting comprehensive research (e.g., parametric study) with centrifuge tests is impractical and expensive. Also, the investigation of correct failure mechanism for retaining walls by centrifuge tests remains uncertain, and some greater degree of progressive failure might occur in practice [12]. Alternatively, finite element modeling is widely adopted nowadays in analyzing time-dependent geotechnical problems at a lower cost than field instrumentation and centrifuge tests. The finite element models can be validated against some field measurements and centrifuge experimental data before being applied to predict the long-term wall performance, ensuring the accuracy and reliability of the simulations [12].

Table 3 summarizes seven long-term HM numerical modeling cases of conventional embedded retaining walls [20, 73,74,75,90]. According to the simulation results of three embedded retaining wall cases, Potts and Day [69] found that after the dissipation of excavation-induced excess pore water pressure, the wall flexibility contributed significantly to the reduction of bending moment along the wall. Such effect highly depends on the number of propping levels. In another study, the computed wall movements in Carswell et al. [20] agreed well with the monitoring data from the construction stage at Neasden. However, their model experienced difficulties simulating the stress decay of anchor loads at various levels, leading to an evident difference between the long-term predicted deflections and the monitoring data. As a further study, Ou and Lai [66] revealed that the dissipation of excess pore water was the main contribution to the long-term development of wall movement and ground settlement at the excavation side of the wall. They suggested that it was more appropriate to conduct drained analysis to simulate the pore water pressure dissipation under site conditions with drained material. More recently, Abela et al. [4] numerically evaluated the effect of blinding structs at the excavation line of a cantilever retaining wall during consolidation for two years after excavation, and noted that the profile of the basement heave was similar to a flat parabolic curve with a maximum curvature within 2 m away from the wall. Wiggan [90] indicated that the ground displacement toward soil side could be affected by the permeability of underground structures through back analyses on the field case of the contiguous pile wall. Similar to the trends derived from field measurements, he pointed out that pore water pressure near the retaining wall was less likely to reach long-term hydraulic equilibrium within a short computational period. For some specific ground conditions, e.g., London Clay, where extensive design experience and valuable investigation data are available, numerical modeling is generally reliable to predict the long-term mechanical performance of embedded retaining walls.

For brevity, key points summarized from the past conventional embedded retaining wall cases are listed as follows:

-

(1)

In clayey ground, the long-term ground settlement and wall deformation are mainly induced by excess pore water pressure dissipation, as noted by field measurements, experimental testing, and numerical modeling.

-

(2)

It is feasible to predict the long-term mechanical behavior of embedded retaining walls with numerical software, if some computed results (e.g., horizontal wall movement, ground settlement, and pore water pressure) can match with field monitoring and centrifuge testing data.

-

(3)

Practically, it may take decades for the complete development of structural movements and the excess pore water pressure dissipation in low-permeability clay. Thus, it is essential to model a sufficiently long period (e.g., 100 years) to reach a new steady-state equilibrium condition in the numerical simulation.

2.2 Thermo-active retaining wall cases

Compared to conventional cases, there are very few existing field studies and centrifuge tests of energy walls. Instead, numerical modeling dominates the energy wall studies in recent decades. Loveridge et al. [55] conducted a comprehensive literature review on energy geostructures; nonetheless, the only presented nine energy-wall cases focus on thermal performance but no mechanical behavior. To fill the blank, Table 4 lists 13 past energy wall studies containing thermo-mechanical analyses. These energy wall cases mainly concern three design aspects: (1) thermal-related response (thermal load and temperature variation contour), (2) geotechnical behavior (ground settlement, lateral soil stress and pore water pressure), and (3) structural behavior (vertical wall movement, horizontal wall movement, internal structural forces, and basement heave).

The collected thermo-mechanical projects are classified into two groups: (1) real-case group [32, 52,53,79, 76]—cases are based on practical projects—and (2) hypothetical-case group [14, 11, 86, 34, 31, 77]—the authors fully assume scenarios without referring to a practical project. Apart from numerical modeling, each group contains one physical study, i.e., field instrumentation [6] and laboratory test [34]. In the hypothetical-case group, it is noted that the coupled thermo-mechanical (TM) approach dominates the computational simulations. Some important findings include: (1) Bourne-Webb et al. [14] indicated variations of seasonal temperature and soil thermal expansion coefficient controlled the mechanical performance of the assumed diaphragm wall; (2) Rammal [31] found that the numerical simulations with hardening soil model provide more reliable thermo-mechanical responses of energy walls and surrounding ground than those with Mohr–Coulomb model, even though both predictions are not detrimental; and (3) Barla et al. [11] suggested employing preliminary numerical modeling to optimize the design of energy walls.

Although hypothetical cases are easy to emphasize thermo-mechanical performance by simplifying complex site situations, it can hardly be widely acceptable as a reliable engineering design reference. More studies to study energy walls under practical conditions, e.g., considering the excess pore water pressure dissipation. Sailer et al. [78] assumed the installation of GHEs into an existing underground car park case in London and simulated the soil–foundation interaction with the 2D Mohr–Coulomb failure mechanism. They indicated that the TM approach was more conservative in predicting the thermo-mechanical responses of energy walls than the coupled thermo-hydro-mechanical (THM) method. Sailer et al. [79] further suggested THM analysis was a reliable choice for designing structural performance of energy walls under various soil–structure interactions (e.g., ground permeability). Moreover, with the assistance of site monitoring data and laboratory results, the predictions from THM analyses are likely to anticipate more accurate long-term mechanical responses of energy walls under a complicated situation. For example, Rui [76] developed and validated a 2D THM model to investigate the thermo-mechanical performance of energy walls based on a well-documented true thermo-active diaphragm wall case in London—available with wall movement records at the construction stage. He systematically investigated how the variation of structural and geotechnical material properties—i.e., ground permeability, concrete thermal expansion coefficient, soil thermal conductivity coefficient, and soil nonlinearity—affected the mechanical performance of energy walls—e.g., pore water pressure and wall movement. However, the pore water condition under the base slab in his model was still far from hydrostatic condition even after 20 years. Dai and Li [32] hence conducted a THM analysis adopting the hardening soil model with small-strain stiffness and extended the dissipation of excess pore water pressure to 80 years, allowing the complete development of the thermo-mechanical responses. They indicated that the geothermal operation would not induce detrimental issues on the structural safety, and particular attention should be paid to enhance the serviceability—e.g., crack control and selection of proper soil stiffness modulus.

Incorporating thermal solicitations into an HM model is likely to give reasonable predictions for the long-term behavior of energy walls; however, the validation for these THM models is currently only available for the short-term mechanical behavior. There is still a lack of well-validated models of energy walls considering long-term thermal and mechanical behaviors. Dong et al. [34] validated a simple TM numerical model against the experimental data from a physical heating model in the laboratory and concluded that the asymmetric arrangement of heat exchange pipes led to heterogeneous thermal expansion inside the wall. They suggested that the prediction of TM performance of geothermal diaphragm walls could be made by a 2D FE analysis, where the heat exchanger pipes were modeled as a single line for each wall panel, ignoring its temperature difference between inlet and outlet ports.

The aforementioned studies simplify the heat exchanger pipes as single-line thermal boundaries in the 2D plane strain models; however, Sterpi et al. [86] suggested that predicting the thermo-mechanical behavior in 3D models could be more accurate than it in 2D models. They simulated absorber pipes in a 3D manner and predicted the thermally induced structural behavior of energy diaphragm walls under a thermostatic ground state, i.e., balancing the annually seasonal ground surface temperature with the pipe inlet temperature. They also pointed out that nonlinear heat transfer and various temperature distribution fields could be obtained from vertical sections in the longitudinal-plane direction of a wall panel, resulting in different structural behaviors along these vertical sections. Nonetheless, the computed out-of-plane length of the wall in Sterpi et al. [86] was too small, and the 3D model failed to consider the coupling effect of geothermal operation and excess pore water dissipation. There still remain some technical difficulties in the accurate 3D modeling of pipe thermal boundary (e.g., an inlet-and-outlet temperature difference), numerical convergence of 3D thermo-hydro-mechanical analysis, computational cost and etc. In this regard, assuming heat exchanger pipes as single-line thermal boundaries, a 2D model is more widely adopted and acceptable for a THM coupled analysis than a complicated 3D one.

Adinolfi et al. [6] conducted a field-scale experiment to validate the 3D TM model of sheet pile wall. They suggested that more attention should be paid to the selection of thermal boundaries and initial conditions for the design. One problem of the energy sheet pile walls modeled by Adinolfi et al. [6] is the difficulty in representing various pipe configurations in an actual energy wall. On the other hand, Ou et al. [25] and Zdravkovic et al. [92] simulated a quarter part of the whole excavation site with both 2D and 3D models, finding that 2D plane strain analysis predicted more conservative results for the center sections of the wall rather than the corner sections. Furthermore, Sailer et al. [77] provided two equivalent methods to replicate 3D modeling results of energy retaining walls with 2D models. Considering the aforementioned pros and cons of a 3D geothermal wall analysis, a 2D numerical analysis is still an appropriate and efficient choice for simplified thermal conditions.

The bullet points from the literature review in this section are listed as follows:

-

•

Due to limited existing mechanical-performance recorded cases of energy walls, hypothetical construction is a reasonable approach for studying long-term mechanical response. Considering the influence of excess pore water pressure, it is more reasonable to employ a THM model to simulate the thermo-active case than a TM model.

-

•

The 2D plane strain models adopt single-line thermal boundaries with constant temperature to simplify the heat exchanger pipe configurations, without considering the inlet and outlet temperatures in pipes. Such simplification of thermal boundary conditions is generally acceptable for the preliminary design of energy walls, as it evaluates more conservative wall mechanical behavior at a much lower computational cost than a 3D model.

-

•

In both the short and long terms, the mechanical behavior of energy walls is very sensitive to the material properties of structural elements and surrounding ground. The adjustment for the properties of relevant materials and the selection of proper constitutive models are essential for simulating long-term ground–wall interaction more realistically.

3 Critical mechanical factors and the assessment

3.1 Selection of mechanical factors

For an energy wall with simplified heat exchanger pipe arrangement, an efficient approach to predicting the long-term mechanical performance mostly relies on 2D THM numerical analyses and experience. However, there is still a lack of standard methods to carry out the energy wall assessment, and the selection of critical parameters is also challenging in energy wall design. This section aims to summarize some appropriate factors for the thermo-mechanical assessment of energy walls. Based on the literature review in Sect. 2, the mechanical performance of energy walls mainly includes two parts:

-

•

Structural responses: Horizontal and vertical wall movement (HWM and VWM, the strain obtained would also be defined as movement), propping force (PF), internal structural forces (M, N and Q), basement heave (BH), and heaving pressure (HP).

-

•

Geotechnical behaviors: Ground settlement (GS), lateral soil stress (LSS), pore water pressure (PWP), flow net (FN) and deformation mechanism (DM).

-

•

Apart from these mechanical factors, two critical thermal factors—thermal loads (TL) and temperature distribution curves (TDC)—are commonly adopted in the energy wall analysis, elaborating the mechanical variations along with the temperature development in the long term.

Figure 1 summarizes the number of occurrences of the aforementioned assessment factors in previous long-term mechanical studies of embedded retaining walls, based upon the data from Table 1 to Table 4. These study numbers can be categorized as convectional cases and thermo-active studies, as shown in Fig. 1a and b, respectively. Firstly, it is noted that the deformation is predominantly characterized by ground settlement (mentioned 15 times) and horizontal wall movement (mentioned 11 times) in the 20 conventional retaining wall cases. Meanwhile, wall movement is also considerable in energy wall cases, presenting nine times of vertical wall movement and eight times of horizontal wall movement out of the 13 thermo-active cases. Moreover, as an essential factor in crack control and structural durability, bending moment also receives significant attentions from both conventional and thermo-active groups, which has been discussed totally 19 times as frequently as horizontal wall movement. Due to paper space limitation, bending moment is only briefly discussed along with the horizontal wall movement in Sect. 4. It is reasonable to assess the critical bending moment along with horizontal wall movement, as the maximum long-term bending moment and maximum incremental horizontal wall movement may appear at the wall-base-slab connections at the same time [32]. Apart from the internal structure force, the pore water pressure in the surrounding ground is also a widely acknowledged critical factor, which is discussed in 60% of the conventional retaining wall cases and 31% of that in the thermo-active ones.

Hence, the systematic design method in this study focuses on these highly considered representative factors with a total number of occurrences greater than fifteen times (almost 50% of the past case histories). As an exception, basement heave is also discussed along with pore water pressure, even though it is only mentioned seven times in total. The long-term heave can creep for decades—more than double of the construction-stage movement [22]—and thus significantly challenge structural stability and serviceability.

For the sake of simplicity, the following subsections will briefly demonstrate the design criteria for horizontal wall movement, ground settlement and basement heave of embedded retaining walls in stiff clay, London Clay in particular. The selected long-term assessing essentials are evaluated based on standard codes presented in the following subsections. The permissible range of maximum horizontal movements of retaining walls in both short and long terms is between 0.15%He and 0.5%He, while the practical range for the short and long-term ground settlement is between 0.2%He and 1.0%He. To assess the influence on the basement heave, the excess pore water pressure ratio from existing projects is taken into account. All these standards are chosen to predict the long-term mechanical performance of energy walls in stiff clay.

3.2 Assessment on wall deflection

Many researchers have reported field measurements of excavation-induced wall movements and ground settlements of retaining walls. CIRIA C580 [40] considered the ground stiffness conditions as an essential factor on wall performance; thus, the design criteria should be selected based on ground conditions, e.g., stiff clay in this case. Clough and O'Rourke [27] presented envelopes to estimate maximum horizontal movements behind various wall types embedded in the sand, stiff to hard clay and soft to medium clay, respectively. They suggested that the maximum horizontal and vertical ground movement behind these walls were generally less than 0.5% of the excavation depth (He) in stiff clay.

Based on the observed maximum wall deflections due to excavations in London Clay, St John et al. [83] indicated maximum values of δh should be smaller than 0.2% of the excavation depth (He). Fernie and Sucking [39] investigated the horizontal deflections of bored pile walls, diaphragm walls and sheet pile walls in stiff soils. They found that the lateral deflection of walls surrounded by stiff soils was less than 0.3%He and that the typical value of δh for walls embedded in London Clay in top-down conditions was about 0.15%He.

Long [53] extended the database of Peck [68] to 296 case histories and provided typical trends and patterns of wall and ground deflections due to pit excavation. He pointed out that the chart given by Clough and O'Rourke [27] might overestimate wall deflections in stiff ground sites but underestimate ground movements of soil at dredge level in soft ground. Long [53] presented the average values of δh as a percentage of maximum excavation depth (He) for cases where the overserved values of δh were less than 0.16%He for walls embedded in stiff soils. He extensively verified the results of Clough and O'Rourke [27] for stiff soils with normalized values of \(\delta_{{\text{h}}}^{\max } /H_{{\text{e}}} = 0.05 - 0.25\%\) and \(\delta_{{\text{v}}}^{\max } /H_{{\text{e}}} = 0 - 0.20\%\).

Table 5 summarizes the permissible horizontal wall movement due to the excavation in stiff clay. These recommended values are summarized based on hundreds of case histories, and hence adopting these values as the standard references for the design assessment of wall movement of the London case is suitable. In summary, the designed wall movement smaller than 0.5%He should be acceptable in the stiff ground, and it becomes conservative if within 0.15%He.

3.3 Assessment on ground settlement

The ground settlement should be assessed from two aspects: (1) maximum ground settlement and the settlement distribution; (2) the influence on existing buildings.

3.3.1 Maximum settlement

Peck [68] summarized data on settlements behind walls in a graphical form (Fig. 2), identified by three zones with various ground conditions. Settlements are indicated not to exceed 1% of the maximum excavation depth. The ground conditions were considered the dominant factor in defining ground settlement assessment into three zones. The settlements varied between \(\delta_{{\text{v}}} /H_{{\text{e}}} < 1.0\%\) for zone I (sand and soft to hard clay) and \(\delta_{{\text{v}}} /H_{{\text{e}}} > 2.0\%\) for zone III (very soft to soft clay down to significant depth). For the London Clay case, zone I should be considered. Clough and O'Rourke [27] summarized the measured ground settlement during wall construction in four ground conditions, granular soil, soft-to-medium clay and stiff-to-very hard clay from various projects worldwide. The maximum ground settlements (δv) as a fraction of the excavation depth (He) were generally under a ratio of 0.5%. Although the ground settlement only took a small amount of the maximum excavation depth (He), the settlement distribution could reach a distance of 2He for the walls embedded in stiff clays. They found a maximum surface settlement of less than 0.3%He immediately adjacent to the wall decreasing to zero settlement at a lateral distance of some 2He.

Summary of settlement adjacent to excavation sites [68]

Long [53] pointed out that maximum cumulative ground settlements δv for walls entirely embedded in stiff soils should generally be less than 0.2%He. In practice, the total cumulative settlement is a result of the whole construction process including wall installation, soil excavation and etc., and the permissible value can still be useful for a preliminary assessment of thermo-active retaining wall performance in the long term. The summary on the prediction of ground settlement, including maximum settlement after construction and obtained maximum settlement for the long-term, is demonstrated in Table 6. The standard range adopted in this study for stiff clay is 0.2%He to 1%He.

3.3.2 Differential settlement

Practically, the foundations of existing buildings are susceptible to new additional ground displacement nearby. It is therefore essential to investigate the influence of ground movement induced by geothermal operation on the adjacent building foundations Table 3.

The most widely adopted assessment method for foundation movements with allowable differential settlements was proposed by Burland and Wroth [16], based on the assumption that the onset of visible cracking was associated with a critical value of tensile strain. For most constructions, the differential deflections occurred after construction put the foundations on a tilt. Burland and Wroth [16] provided a normalized damage criterion to eliminate the tilt of building foundations, the ratio of the differential settlement ∆ and the distance L between two points horizontally along the foundation plane. The recommended maximum value for this ratio is from 1/500 for steel and concrete frame infilled structures to 1/200 where there is no infill or no danger of damage to the cladding. As shown in Fig. 3, the maximum differential settlement is equal to the difference between the maximum ground settlement and the settlement at the soil-side edge of the wall.

Likewise, the same deflection ratio is adopted to assess the potential effect of the geothermal operation on the surrounding foundations. A deflection ratio (∆/L) can be calculated by relative deflection (∆) divided by the distance L. For simplicity, the L is taken as the distance between the edge of the wall and the peak point of the ground settlement profile, which is regarded as the most critical situation for adjacent foundations. The permissible values of this ratio also follow those suggested by Burland and Wroth [16].

3.4 Assessment on basement heave

The long-term basement heave is mainly due to the dissipation of excess pore water pressure under the base slab. Chan and Madabhushi [24] reported that the permanent removal of overburden due to basement excavation inevitably induces upward movement of the soil under the base slab with time, as the effective soil stress reduces. The ground heave continues over many years after basement construction in low-permeability clay (e.g., London Clay) with the recovery of pore water pressure underneath the slab. They suggested that a foundation should be designed to either withstand the uplifting force or accommodate heaving deflections in the long term.

Chan et al. [22] specifically investigated a diaphragm wall project in London with a total of 21 years of heave monitoring data, as shown in Fig. 4. In this project, the pit was excavated to about 12 m depth with 0.6 m width diaphragm panels and 0.9 m to 1.8 m thickness base slabs. The field monitoring data were used to validate the experimental results from a geotechnical centrifuge test [23], and investigated heave and pressure beneath slabs in the excavation of over-consolidated clays. The net unloading in this project was 184 kPa, comprising 234 kPa of initial total earth pressure inside the pit and 50 kPa of reloading by the new structure. Chan et al. [22] specified that the development of heave with time was generally consistent with one-dimensional consolidation theory and predicted that ultimate long-term heave at the center of the slab would increase up to 110 mm after consolidation. They suggested that the time-dependent long-term heave in London Clay can be determined as the net heave per net change in total stress as 0.6 mm/kPa (110 mm/184 kPa).

Basement structural details [22]

For clarity, shows the change of stresses under the bottom center of the base slab at different stages in the project of Chan et al. [22]. In the geostatic state, the total stress and effective stress are calculated based on an average depth of base slab (i.e., 12 m), 234 kPa and 189 kPa, respectively, while the pore water pressure before construction is 45 kPa, without the existing of excess pore water pressure. Immediately after the basement construction, the instant effective stress under the bottom of the base slab is 234 kPa, and the total stress is the same as the new structure weight (50 kPa). The pore water pressure is calculated to be − 184 kPa in theory. However, under the base slab, the negative pore water pressure is usually considered within − 100 kPa, assuming no cavitation in pore water. With the maximum net pore water pressure taking 100 kPa from 184 kPa of unloading stress, the remaining 84 kPa will add to the total stress to make a stress balance. When the model reaches a geostatic state in the long term, the total stress and effective stress underneath the bottom center of the basement will return to the basement weight. No pore water pressure and excess pore water pressure is expected to remain after consolidation finish. The excess pore water pressure change is the maximum stress variation during the long term. It is critical to adopt the net heave change via the net change in excess pore water pressure (110 mm/184 kPa = 0.6 mm/kPa) to predict the long-term basement heave.

This section mainly discusses critical mechanical factors and associated assessment of embedded retaining wall performance in stiff clay. The discussion would be useful for similar assessment in other ground conditions, especially in light of limited long-term monitoring data of retaining walls years after construction.

4 Thermal influences on energy wall mechanical performance

A parametric study is carried out based on the validated model presented by Dai and Li [32], to assess the long-term mechanical behavior of geothermal diaphragm walls under various thermal conditions, a typical type of energy walls. Dai and Li [32] conducted two finite element analyses of the geothermal wall using an HM model and a THM model—deactivating or activating the thermal boundaries, respectively. The comparison between their computed results assessed the role of geothermal operation on the long-term mechanical behavior of geothermal diaphragm walls. Dai and Li [32] preliminarily concluded that the thermally induced mechanical responses were unlikely to cause structural failure; nonetheless, the conclusion is not sufficiently practicable for engineering practice. The paper would thus adopt the design criteria in Sect. 3 to quantify the long-term mechanical performance of energy walls.

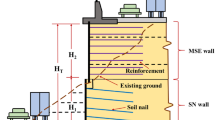

In their modeled project, a 28.9-m long and 32-m width thermo-active station is located at London Dean Street (Block B), extracting shallow ground energy to support the ticket hall of Tottenham Court Road Station, as shown in Fig. 5. The station box combines both geothermal piles and geothermal diaphragm walls, with the potential to generate 500 kW energy capacity. The foundation pit was constructed using the bottom-up method through five excavation stages. During the construction stage, 40-m-long heat exchanger pipes were installed and grouted together with the reinforcement cage of diaphragm wall panels. After completing the ticket hall, the in-built geothermal system was designed to work together with diaphragm walls, maintaining the energy demand and sustaining structural loads at the same time.

Dean Street Station design plan [62]

Figure 6 illustrates the ground layers along the depth at the site as follows: (a) 22.3 m of London Clay overlying and (b) 19.4 m of Lambeth Group, which overlies (3) a thick layer of Thanet Sand and Chalk. The initial pore water pressure was assumed hydrostatic with the water table at 3.0 m below the ground surface. The non-clayey soil is modeled using the Mohr–Coulomb model, while the clayey ground is simulated using Hardening Soil model with small-strain stiffness.

THM numerical model [32]

The vertical movement of the bottom boundary is fixed, while the movements of the two sides in this model are fixed laterally. The hydraulic boundaries around the station are impermeable, leading to significant excess pore water pressure generated under the base slab. However, the excavation-induced negative pore pressure is limited within − 100 kPa to avoid suction cavitation. Material properties can be referred to Appendix.

The parametric study assesses the effects of critical thermal factors on the long-term mechanical performance of geothermal diaphragm walls from the following three aspects:

-

(1)

Thermal solicitations: The seasonal thermal loads control the temperatures of the outside air and heat exchanger pipes. Two factors of the thermal loads are considered to evaluate the influence on the long-term mechanical performance, which are temperature amplitude (two variation temperature range) and variation rate (stepping-change thermal function and harmonic thermal function).

-

(2)

Station temperature: Practically, the station temperature is not always unchanged. For example, running trains inside the tube usually leads to a rise in the station temperature, whereas the station temperature may vary substantially if the air conditioning system is not in operation. To evaluate the influence of station temperature, despite the original 18 °C, two more models are considered, with two extreme station temperature scenarios at 1 and 26 °C, respectively.

-

(3)

Asymmetrical operation mode: To minimize the differential deformation, the geothermal extractors in both sides of a station box are preferably to operate simultaneously, which, however, may not always be the case in practice. The influence of asymmetrical temperature distribution due to single-one geothermal operation should be examined.

4.1 Parametric study scenarios

The model of Dai and Li [32] at the short-term construction stage has been validated with field monitoring data of horizontal wall movement. The evaluation of the mechanical performance of geothermal diaphragm walls in this study then only considers the long term. At the long-term geothermal operation stage, all the thermal conditions in Fig. 6 are activated. The soil temperature in the model is constant at 12 °C, according to a reference temperature at a depth 10–12 m in Europe. The temperature of the side boundaries (④ in the graph) persists at 12 °C, while three primary heat sources dominate the parametric study, outside air, station environment, and thermal system. The first thermal boundary (① in the graph) controls the air temperature, varying with seasons. The station temperature (② in the graph) consists of the contacting thermal boundaries with the diaphragm walls and the thermal boundaries of slabs, initially keeping constant at 18 °C all year round in the original model. Two thermal boundaries (③ in the graph) inside the diaphragm walls act as heat exchanger pipes, also controlled by seasonally changing thermal functions. The difference between the inlet and the outlet of geothermal operation temperature is usually less than 4 °C [70]; thus, the temperature distribution of heat exchanger pipes along the diaphragm wall in the plane-strain model is assumed to be uniformly controlled by seasonal thermal functions.

NOAA [64] indicated the local seasonal temperature in London naturally had a peak at 23 °C while a nadir at 4 °C. For simplicity, there are four assumed thermal functions, as shown in Fig. 7. TS1 and TS2 are step-fluctuating thermal functions representing seasonal variations, cycling from 4 °C for 6 months (winter cycle) to 23 °C for 6 months (summer cycle). The other type of thermal function (TH1 and TH2) is proposed to reproduce the real shape of annual temperature variation, harmonic variation. The thermal conditions of this function are generally controlled by the equation below [3]:

in which \(A\) is the amplitude (in the unit of temperature, °C), \(T\) is the wave period (in the unit of time, day) and \({\phi }_{0}\) is the initial phase angle. \({y}_{0}\) is the center of the harmonic variation, the average value of the maximum temperature and minimum temperature.

The step-fluctuating thermal function represents a simplified wall temperature scenario with only two values during a single year for winter and summer, respectively, while the harmonic thermal function considers a more realistically continuous sinusoidal temperature variation, e.g., in year and in day. Two temperature variation ranges are considered in the parametric study, 4 to 23 °C (Range 1) and 1 to 26 °C (Range 2), in terms of the unpredicted external air temperature fluctuations varying with time and location. Range 2 is also the selection basis for the station temperatures, while one model considers station temperature at 1 °C and the other at 26 °C.

The modeling scenarios are summarized in Table 8. For the assessment of the design serviceability period, the results at 30 years are discussed in this study. Dai and Li [32] concluded that the dissipation of excess pore water pressure (consolidation) was almost 80% complete 30 years after construction. Thus, the results at 30 years are adopted for assessing various thermal influences on the long-term mechanical performance of geothermal diaphragm walls (e.g., incremental horizontal wall movement, incremental ground settlement, and incremental basement heave).

4.2 Influence of thermal solicitations

In this section, two types of thermal functions (harmonic function and steeping change function) with two ranges (Range 1–4 to 23 °C and Range 2–1 to 26 °C) are applied to consider various thermal conditions. The temperature in a harmonic function rises from the average value to the peak smoothly and gradually decreases back to the average value, while the temperature varies suddenly in a steeping-change function. These four thermal solicitations are adopted to examine the influence of temperature amplitude and fluctuation on the long-term performance of geothermal diaphragm walls: Model M1 with thermal function TS1, Model MT2 with thermal function TS2, Model MT3 with thermal function TH1, and Model MT4 with thermal function TH2. The thermal function of the air temperature in these models is assumed to be consistent with that of the wall temperature.

Figure 8 presents the variations of incremental horizontal wall movements 30 years after construction under different thermal functions. The harmonic thermal function (MT3 and MT4) predicts an average 2 mm less horizontal wall movement than that by the stepping-change function (M1 and MT2), for the part of the wall above Slab 1 in particular. For this part of the wall, the more differential movement induced by the stepping-change function, the greater bending moment develops along the wall depth toward the excavation side. In terms of the maximum bending moment along the wall, the stepping-change function model predicts a magnitude of 3381 kNm, 18.4% greater than the 2855 kNm given by the harmonic function model. In Fig. 7, the average temperature of the harmonic function (TH1 and TH2) is less than that from a stepping-change function (TS1 and TS2), which is the main reason to cause the differential wall movements. Besides, the influence of temperature range is less significant in the results of the harmonic function than it in the stepping-change function.

The shapes of ground settlements predicted with various thermal functions are very similar, as shown in Fig. 9. The difference of the maximum ground settlement over 30-year geothermal operation between the harmonic function (MT3 and MT4) and the stepping-change function (M1 and MT2), is up to 10 mm. The function with greater temperature variation range (MT2 and MT4) predicts a greater differential ground settlement (∆). The temperature recovering rate and variation range can influence the ground settlement adjacent to the foundation pit. The harmonic function (MT3 and MT4) generally predicts less basement heave than the stepping-change function (M1 and MT2), with roughly 2 to 4 mm additional deflection at the center of the base slab as shown in Fig. 10. In comparison, the thermal function with larger variation amplitude predicts more heave than that with a small amplitude, for example, the model MT2 presents 3 to 4 mm additional deflection at the center compared with the original model M1. However, the excess pore water pressure change in Fig. 17 is very similar for all four models.

Table 9 collects the assessment ratios of δhi/He, ∆i/L, and δvbi/EPWP. The wall deflection ratios for all four models (i.e., M1, MT2, MT3, and MT4) are under the allowable range (0.15%He), varying from 0.023% to 0.026%. The thermal function does not predict impermissible long-term mechanical performance of geothermal diaphragm walls. Similarly, the computed differential ground settlement ratio, varying from 0.047% to 0.073%, is also much less than the allowable deflection ratio of 0.2%. In contrast, the application of a harmonic thermal function (MT3 and MT4) predicts a lower ground deflection ratio than the stepping-change function (M1 and MT2). The net heave change ratios via the net change of excess pore water pressure under various thermal functions are between 0.24 and 0.27 mm/kPa after a 30-year geothermal operation, also much lower than the monitoring ratio from the case of Chan et al. [22].

In summary, the design with a stepping-change function is more conservative than that with a harmonic function. Under the same temperature variation range, the stepping-change function provides more thermal loads on the temperature field than the harmonic function, and hence, greater thermo-mechanical responses (i.e., horizontal wall movement, ground settlement, and basement heave) can be observed. Although thermo-mechanical behaviors vary with thermal solicitations, the thermal-function selection is unlikely to predict significant damage to geothermal diaphragm walls and surrounding structures, far below the allowable threshold criteria.

4.3 Influence of station temperature

Apart from the original station temperature (18 °C for M1), two additional station temperatures are considered: 1 °C for MS2 and 26 °C for MS3. Unlike the thermal function, the constant station temperature affects the long-term incremental horizontal wall movements significantly, as shown in Fig. 11. The slabs shrink with a low station temperature (MS2), leading to larger wall movement toward the excavation side (2 mm on average greater than the original model M1). Likewise, these slabs expand with a high station temperature, pushing the wall toward the soil side (4 mm more deflection). Among the three cases, Model MS3 with a high station temperature shows the largest differential wall movement toward the soil side above the excavation line due to the greatest bending moment toward the excavation side (5714 kNm) near the base-slab-wall joints. On the other hand, Model MS2 with a low station temperature shows larger wall deflection toward the excavation side induced by the high bending moment (3748 kNm) between Slab 1 and Slab 2, which is the most likely case to cause damage to the wall-Slab 1-and-Slab 2 joints. Figure 12 presents the long-term changes of ground settlement under various station temperatures. The two additional models (MS2 and MS3) predict smaller incremental ground settlement (4.14 mm and 1.21 mm) than that for the original model M1 (10.17 mm). Figure 13 indicates the shrinkage/expansion of the concrete also dominates the basement heave. The lower-bound (MS2) and higher-bound (MS3) station temperatures show that the maximum and minimum basement heave, respectively (76.7 mm and 85.3 mm).

As shown in Fig. 17, the dissipation of excess pore water pressure during the 30 years is not affected much by station temperature variation. The observed difference between the higher-bound (MS3) and lower-bound (MS2) oscillation is less than 15 kPa. Although the influence of station temperature in this section leads to a greater wall deflection ratio than that by the original model M1, these ratios are all far below the allowable values given in Table 9. Besides, a sudden change of station temperature, regardless of increase or decrease, is not likely to damage the existing structures via differential ground settlement, which is less than 0.02% for both cases. The basement heave ratio and excess pore water pressure are barely influenced by the station temperature, and much smaller than 0.6 mm/kPa.

Overall, the station temperature variation induces the volume change in slabs—shrinkage or expansion—and remarkably affects the thermo-mechanical responses of energy walls. Although the influence is not detrimental under design assessment, particular attention should be paid to the wall-slab connections at the lower elevations where significant horizontal wall movements and bending moments are present.

4.4 Influence of asymmetrical operation mode

In practice, it is common to run an asymmetrical geothermal operation mode for some energy demand, possibly compromising the mechanical performance. Model MOP simulated the situation that only the right-side energy wall activated. The results were selected to compare with the original symmetrical model M1, which activates both sides of energy walls.

Figure 14 compares the horizontal wall movements between symmetrical and asymmetrical operations. Compared with the original model (M1), the wall above the base slab moves horizontally up to 6 mm toward the soil side when only a single side of the energy walls operates (MOP). The maximum horizontal wall movement in MOP (i.e., 7.8 mm) shifts from the base slab bottom (M1) to somewhere between Slab 1 and the base slab. In particular, the bending moment along the wall depth for the asymmetrical mode (MOP) generally reduces toward the excavation sides. For example, the bending moment builds up to 3535 kNm under the base slab, which is 22.8% less than that of 4578 kNm in the original symmetrical operation mode (M1). However, the differential ground settlement for model MOP is much less than it in M1 with an activated thermal system on the left side (Fig. 14. Operation mode influence on horizontal wall movement. Figure 15). The geothermal operation leads to a significant differential ground settlement in the long term, which is also noted by Dai and Li [32] by comparing a non-thermal model with a thermal-activated model. Figure 16 indicates that the vertical deflection of the base slab is slightly affected by the asymmetrical operation mode with a slightly smaller magnitude. Figure 17

Nevertheless, the asymmetrical geothermal operation is unlikely to induce detrimental damage to the structure, according to Table 9. The differential ground settlement of the asymmetrical geotcxhermal operation (MOP) drops significantly from 0.073% to 0.009%. There is also little change for the wall deflection ratio and the slab heave ratio between these two models. The dissipation of excess pore water pressure under the base slab can be affected by the operation mode, while the oscillation in the model MOP is much less than the model M1.

Therefore, it can be concluded that under asymmetrical geothermal operation mode, the thermo-mechanical responses of the activated-side walls would not challenge the mechanical performance of the deactivated-side walls. However, compared with other mechanical factors, the asymmetrical operation has a significant impact on the wall movement development of the deactivated-side walls, wall-base-slab connections in particular. Engineers are suggested to consider the change in the energy wall design.

5 Conclusions and recommendations

This paper conducted a comprehensive literature review on the mechanical performance of conventional and thermo-active embedded retaining walls in the long term. Based on the literature review, three critical mechanical factors (i.e., horizontal wall movement, ground settlement, and basement heave) were selected for long-term wall performance assessment. The prediction of those critical factors and the allowable values can be referred to extensive studies on short-term wall performance assessment. Their permissible values can be largely determined according to standard preliminary design criteria of conventional embedded retaining walls:

-

•

The limitation of horizontal wall movement in stiff clay due to excavation is 0.15%He, which is quite conservative for long-term movement evaluation.

-

•

The deflection ratio calculated by differential ground settlement dominates the ground settlement evaluation, with an allowable structural deflection of 0.2%.

-

•

In stiff clay, the net change in basement heave due to the net change in excess pore water pressure is measured to be 0.6 mm/kPa, as a reference for the long-term basement heave assessment.

The selected design criteria could provide a vivid and reliable assessment on the long-term mechanical performance of energy walls under various situations. Parameter studies are implemented to further elaborate these assessment criteria on energy walls in stiff clay, including thermal solicitations, station temperature, and the asymmetrical operation model. The main conclusions are listed as follows:

-

(1)

In the 2D model, a single-line thermal boundary is usually adopted to consider the 3D arrangement of heat exchange pipes inside the wall panels. Such simplification is generally acceptable for the mechanical performance research of energy walls.

-

(2)

The parametric study examines three thermal-related influences on the energy wall mechanical performance, and the computed critical structural deformation and ground response (i.e., horizontal wall movement, ground settlement, and basement heave) are found to be much smaller than the permissible design values.

-

(3)

In general, the geothermal operation inside the thermo-active retaining walls is unlikely to bring critical damages to the structure stability. Nonetheless, the wall-deflection-related bending moment around the connections between the slabs and walls deserves specific assessment, as it may affect the structural durability in the long term.

-

(4)

The selection of steeping-change thermal function generally leads to a more conservative design than that of a harmonic thermal function, while both the station temperature and the asymmetrical operation mode can significantly affect the horizontal wall movement.

-

(5)

For the design of energy walls, more attention should be paid to the selection of thermal functions and operation mode, as the thermal-induced mechanical movements/bending moment may lead to unfavorable serviceability issues (e.g., cracks) even though at little risk of damage on the structural stability.

Abbreviations

- Δ:

-

Differential ground settlement of adjacent buildings due to excavation

- ∆i :

-

Long-term differential ground settlement of adjacent buildings

- σ new structure :

-

Loading stress at the base slab bottom induced by new structure

- σ unloading :

-

Unloading stress at the construction stage

- σ net unloading :

-

Stress calculated by (σnew structure + σunloading)

- δ h :

-

Maximum horizontal wall deflection due to excavation

- δ hi :

-

Long-term maximum incremental horizontal wall deflection

- δ v :

-

Maximum ground settlement due to excavation

- δ vbi :

-

Long-term maximum incremental basement heave

- δ vi :

-

Long-term maximum incremental ground settlement

- δ ve :

-

Maximum ground settlement along the wall edge due to excavation

- δ vei :

-

Long-term maximum incremental ground settlement along the wall edge

- ϕ 0 :

-

Initial phase angle of the harmonic thermal function

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- A :

-

Amplitude of the harmonic thermal function

- BH:

-

Basement heave

- CRISP:

-

Critical state soil mechanics program by Cambridge University

- DM:

-

Deformation mechanism

- E:

-

Young’s modulus

- EPWP:

-

Excess pore water pressure

- FEM:

-

Finite element modeling

- FL:

-

Flow net

- GWT:

-

Groundwater table

- GHE:

-

Ground heat exchanger

- GS:

-

Ground settlement

- GSHP:

-

Ground source heat pump

- H :

-

Retaining wall height

- H e :

-

Maximum excavation depth

- HM:

-

Coupled hydro-mechanical analysis

- HP:

-

Heaving pressure of base slab

- HSS:

-

Hardening soil model with small-strain stiffness

- HWM:

-

Horizontal wall movement

- ICFEP:

-

Imperial college finite element program

- JFEST:

-

A computer program developed by Stanford University

- LSS:

-

Lateral soil stress

- M :

-

Bending moment inside retaining walls

- N :

-

Normal force inside retaining walls

- PF:

-

Propping force at wall-slab connections

- PWP:

-

Pore water pressure

- Q :

-

Shear force inside retaining walls

- SLS:

-

Serviceability limit states

- S u :

-

Undrained shear strength of the soil under base level

- T :

-

Wave period of the harmonic thermal function

- t w :

-

Retaining wall thickness

- TDC:

-

Temperature distribution contour

- TH:

-

Coupled thermo-hydro analysis

- THM:

-

Coupled thermo-hydro-mechanical analysis

- TL:

-

Thermal load

- TM:

-

Coupled thermo-mechanical analysis

- u excess :

-

Excess pore water pressure

- ULS:

-

Ultimate limit states

- VWM:

-

Vertical wall movement

- y 0 :

-

Centre of the harmonic thermal function

References

Abela JM, Potts DM, Vollum RL, Izzuddin BA (2013) Geotechnical analysis of blinding struts in cut-and-cover excavations. Comput Geotech 48:179–191. https://doi.org/10.1016/j.compgeo.2012.07.007

Adam D, Markiewicz R (2009) Energy from earth-coupled structures, foundations, tunnels and sewers. Geotechnique 59(3):229–236. https://doi.org/10.1680/geot.2009.59.3.229

Adinolfi M, Rotta AF, Loria LL, Aversa S (2021) Experimental and numerical investigation of the thermo-mechanical behaviour of an energy sheet pile wall. Geomech Energy Environent 25:100208. https://doi.org/10.1016/j.gete.2020.100208

Amis T, Bourne-Webb P, Davidson C, Amatya B, Soga K (2008) The effects of heating and cooling energy piles under working load at Lambeth College, UK. In: Presented at the 33rd Annual and 11th Intl. Conf. of the Deep Foundations Institute, New York

Amis T, Robinson C, Wong S (2010) Intergrating geothermal loops into the diaphragm walls of the Knightsbridge Palace Hotel project. In: presented at the In Proceedings pf 11th DFI/EFFC Int. Conf. Geotechnical Challenges in Urban Regeneration, London

Baralis M, Barla M (2021) Development and testing of a novel geothermal wall system. Int J Energy Environ Eng 12(4):689–704. https://doi.org/10.1007/s40095-021-00407-y

Barla M, Di Donna A, Perino A (2016) Application of energy tunnels to an urban environment. Geothermics 61:104–113. https://doi.org/10.1016/j.geothermics.2016.01.014

Barla M, Di Donna A, Santi A (2020) Energy and mechanical aspects on the thermal activation of diaphragm walls for heating and cooling. Renew Energy 147:2654–2663. https://doi.org/10.1016/j.renene.2018.10.074

Bolton MD, Powrie W (1987) The collapse of diaphragm walls retaining clay. Geotechnique 37(3):335–353. https://doi.org/10.1680/geot.1987.37.3.335

Bolton MD, Stewart DI (1994) The effect on propped diaphragm walls of rising groundwater in stiff clay. Geotechnique 44(1):111–127. https://doi.org/10.1680/geot.1994.44.1.111

Bourne-Webb P, Freitas TMB, Goncalves RAD (2016) Thermal and mechanical aspects of the response of embedded retaining walls used as shallow geothermal heat exchangers. Energ Buildings 125:130–141

Brandl H (2006) Energy foundations and other thermo-active ground structures. Geotechnique 56(2):81–122. https://doi.org/10.1680/geot.2006.56.2.81

Brinkgreve RBJ, Kumarswamy S, Swolfs WM, Foria F (2018) PLAXIS 2D Reference Manual Version 2018. Delft: PLAXIS

Burland JB, Wroth CP (1975) Settlement of buildings and associated damage. In: Presented at the Proceedings, British Geotechnical Society Conference on Settlement of Structures, Cambridge, Cambridge

Cao Z, Zhang G, Liu Y, Zhao X, Li C (2022) Influence of backfilling phase change material on thermal performance of precast high-strength concrete energy pile. Renew Energ 184:374–390. https://doi.org/10.1016/j.renene.2021.11.100

Carder DR, Symons IF (1989) Long-term performance of an embedded cantilever retaining wall in stiff clay. Geotechnique 39(1):55–75. https://doi.org/10.1680/geot.1989.39.1.55

Carder DR, Symons IF (1989) Long-term performance of an embedded cantilever retaining wall in stiff clay. Géotechnique 39(1):55–75. https://doi.org/10.1680/geot.1989.39.1.55

Carder DR, Darley P (1998) The long term performance of embedded retaining walls. Transport Research Laboratory, TRL REPORT 381.

Carswell IG, Carder DR, Symons IF (1991) Long term performance of an archored diaphragm wall embedded in stiff clay. Transport and Road Research Laboratory, Research Report 313

Casagrande B, Saboya F, McCartney JS, Tibana S (2022) Investigation of a field-scale energy micropile in stratified soil under cyclic temperature changes. Geomech Energy Envir 29:100263. https://doi.org/10.1016/j.gete.2021.100263

Chan D, Madabhushi G, Nicholson D, Chapman T, Solera S (2018) Twenty-one years of heave monitoring in London Clay at Horseferry Road Basement. Ground Eng. https://doi.org/10.17863/CAM.33027

Chan D, Madabhushi G, Hsu Y, O'Brien A, Williamson M, Solera S (2019) Experimental study of structural movements and swelling pressures on deep basements caused by long-term heave in over-consolidated clay. In: Presented at the Proceedings of the XVII ECSMGE-2019, At Reykjavik, Iceland

Chan D, Madabhushi G (2017) Designing urban deep basements in South East England for future ground movement-progress and opportunities for experimental simulation of long-term heave. In: Presented at the International Symposium for Next Generation Infrastructure, London

Chang-Yu O, Chiou DC, Tzong-Shiann W (1996) Three-dimensional finite element analysis of deep excavations. J Geotech Eng 122(5):337–345. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:5(337)

Clark J (2006) Performance of propped retaining wall at the channel tunnel rail link, ashford. School of Civil Engineering and the Environment. University of Southampton, Southampton

Clough GW, O’Rourke TD (1990) Construction induced movements of insitu walls. Geotech Sp 25:439–470

Coletto A, Sterpi D (2016) Structural and geotechnical effects of thermal loads in energy walls. Procedia Engineer 158:224–229. https://doi.org/10.1016/j.proeng.2016.08.433

Cornelio C, Di Donna A, Barla M (2016) Energy diaphragm walls for Turin Metro. In: Presented at the European Geothermal Congress 2016, Strasbourg, France

Cundy VA, Nydahl JE, Pell KM (1979) Geothermal Heating of Bridge Decks. In: Transportation Research Board Special Report

Daru R (2017) Thermal-mechanical behaviour of geothermal structures: numerical modelling and recommendations, Ph.D. thesis, Laboratory of Civil and Geo-Environmental Engineering LGCgE, University of Lille 1 Sciences et Technologies

Dai Q, Li Z (2019) Long-term mechanical performance of geothermal diaphragm walls in stiff clay. Tunn Undergr Space Technol 94:103113. https://doi.org/10.1016/j.tust.2019.103113

Di Donna A (2016) Energy walls for an underground car park. In: Presented at the Proceedings of 25th European Young Geotechnical Engineers Conference, Sibiu, Romania, 21st-24th of June 2016, pp 133–138

Dong S et al (2019) Thermo-mechanical behavior of energy diaphragm wall: physical and numerical modelling. Appl Therm Eng 146:243–251. https://doi.org/10.1016/j.applthermaleng.2018.09.054

Di Donna A, Laloui L (2015) Numerical analysis of the geotechnical behaviour of energy piles. Int J Numer Anal Met 39(8):861–888. https://doi.org/10.1002/nag.2341

Di Donna A, Loveridge F, Piemontese M, Barla M (2021) The role of ground conditions on the heat exchange potential of energy walls. Geomech Energy Environ 25:100199. https://doi.org/10.1016/j.gete.2020.100199

Faizal M, Bouazza A, McCartney John S (2021) Thermohydraulic responses of unsaturated sand around a model energy pile. J Geotech Geoenviron 147(10):04021105. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002640

Faizal M, Bouazza A, McCartney John S, Haberfield C (2019) Effects of cyclic temperature variations on thermal response of an energy pile under a residential building. J Geotech Geoenviron 145(10):04019066. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002147

Fernie R, Sucking T (1996) Simplified approach for estimating lateral wall movement of embedded walls in UK ground. In: Geotechnical Aspects of Underground Construction in Soft Ground, pp 131–136

Gaba A, Simpson B, Powrie W, Beadman D (2003) CIRIA C580 Embedded rataining walls—guidance for economic design. CIRIA, London

Gao J, Zhang X, Liu J, Li KS, Yang J (2008) Thermal performance and ground temperature of vertical pile-foundation heat exchangers: a case study. Appl Therm Eng 28(17):2295–2304. https://doi.org/10.1016/j.applthermaleng.2008.01.013

Gasparre A (2005) Advanced laboratory characterisation of London Clay, Ph.D. thesis, Imperial College London

Hamada Y, Saitoh H, Nakamura M, Kubota H, Ochifuji K (2007) Field performance of an energy pile system for space heating. Energ Build 39(5):517–524. https://doi.org/10.1016/j.enbuild.2006.09.006

Hight DW, Ellison RA, Page DP (2004) Engineering in the lambeth group. CIRIA, London

Knellwolf C, Peron H, Laloui L (2011) Geotechnical analysis of heat exchanger piles. J Geotech Geoenviron 137(10):890–902

Kong G, Wu D, Liu H, Laloui L, Cheng X, Zhu X (2018) Performance of a geothermal energy deicing system for bridge deck using a pile heat exchanger. Int J Energy Res 43(1):596–603. https://doi.org/10.1002/er.4266

Kurten S, Mottaghy D, Ziegler M (2015) A new model for the description of the heat transfer for plane thermo-active geotechnical systems based on thermal resistances. Acta Geotech 10(2):219–229. https://doi.org/10.1007/s11440-014-0311-6

Laloui L, Nuth M, Vulliet L (2006) Experimental and numerical investigations of the behaviour of a heat exchanger pile. Int J Numer Anal Met 30(8):763–781. https://doi.org/10.1002/nag.499

Laloui L, Rotta Loria AF (2019) Analysis and design of energy geostructures: theroretical essentials and practical application. Academic Press, London, p 1082

Lam SY (2010) Ground movements due to excavation in clay: physical and analytical models, Ph.D. thesis, University of Cambridge

Liu H-L, Wang C-L, Kong G-Q, Bouazza A (2019) Ultimate bearing capacity of energy piles in dry and saturated sand. Acta Geotech 14(3):869–879. https://doi.org/10.1007/s11440-018-0661-6

Liu H-L, Wang C-L, Kong G-Q, Ding X-M, Bouazza A (2019) A simplified design method for energy piles. Acta Geotech 14(5):1605–1613. https://doi.org/10.1007/s11440-019-00849-z

Long M (2001) Database for retaining wall and ground movements due to deep excavations. J Geotech Geoenviron 127(3):203–224. https://doi.org/10.1061/(Asce)1090-0241(2001)127:3(203)

Loveridge F, Cecinato F (2016) Thermal performance of thermoactive continuous flight auger piles. Environ Geotech-J 3(4):265–279. https://doi.org/10.1680/jenge.15.00023

Loveridge F, McCartney JS, Narsilio GA, Sanchez M (2020) Energy geostructures: a review of analysis approaches, in situ testing and model scale experiments. Geomech Energy Environ 22:100173. https://doi.org/10.1016/j.gete.2019.100173

Madabhushi G (2014) Centrifuge modelling for civil engineers. CRC Press, Boca Raton

Makasis N, Narsilio GA (2020) Energy diaphragm wall thermal design: the effects of pipe configuration and spacing. Renew Energy 154:476–487. https://doi.org/10.1016/j.renene.2020.02.112

Makasis N, Narsilio GA (2021) Investigating the thermal performance of energy soldier pile walls. Geomech Energy Environ. https://doi.org/10.1016/j.gete.2021.100242

Makasis N, Narsilio GA, Bidarmaghz A, Johnston IW, Zhong Y (2020) The importance of boundary conditions on the modelling of energy retaining walls. Comput Geotech 120:103399. https://doi.org/10.1016/j.compgeo.2019.103399

McCartney JS, Murphy KD (2017) Investigation of potential dragdown/uplift effects on energy piles. Geomech Energy Envir 10:21–28. https://doi.org/10.1016/j.gete.2017.03.001

Montalti L (2015) 3D modelling of bored pile installation effects and long term monitoring of a propped retaining wall, Ph.D. thesis, School of Civil Engineering and the Environment, University of Southampton, Southampton

Mimouni T, Laloui L (2015) Behaviour of a group of energy piles. Can Geotech J 52(12):1913–1929. https://doi.org/10.1139/cgj-2014-0403

Munsi A (2020) Crossrail Plans to Transform Tottenham Court Road and West End Approved. Crossrail. https://www.crossrail.co.uk/news/articles/crossrail-plans-to-transform-tottenham-court-road-west-end-approved