Abstract

Discrete randomly distributed fibers are commonly used to improve the engineering characteristics of the soil and thus soil properties such as shear strength, compressibility, density, and hydraulic conductivity. Most studies have so far focused on describing the behavior of soils containing randomly distributed fibers under dried or saturated conditions. However, the water table may seasonally fluctuate, thus generating unsaturated soil conditions. Therefore, a better understanding of the hydro-mechanical properties of unsaturated improved soils is of high necessity. In this research, the shear strength parameters of fine-grained soils were evaluated using the biaxial device available at Ruhr Universität Bochum. The applied device was modified to test unsaturated fine-grained soils with various degrees of saturation using axis translation and vapor equilibrium techniques. The experiments were conducted on fine soils containing 0, 0.5, and 1% fiber contents under a wide range of matric suctions. The ductile behavior was more noticeable in samples with lower suctions and higher straw contents. Furthermore, the shear strength of both unreinforced and reinforced fine-grained soils considerably increased by an increase in the suction. Finally, shear band inclination increased by the suction while decreasing by straw content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Discrete randomly distributed fibers are typically applied for improving the engineering characteristics of the soil, and consequently, the soil properties such as shear strength, density, compressibility, and hydraulic conductivity. One of the main advantages of using the above-mentioned fibers is the maintenance of strength isotropy and the absence of the potential planes of weakness that can develop in soils with oriented reinforcement [36, 55]. Moreover, when local cracks appear in a specimen, some fibers crossing these cracks are responsible for the tension in the soil by the fiber-soil connection, which effectively impedes further development of cracks and thus changes the failure mode of the reinforced specimens to a more ductile one with a less distinct failure plane. An increase in the fiber content leads to a greater number of failure surfaces, and surface orientations are regular with a higher angle with respect to the horizontal line. This behavior suggests that increasing the fiber inclusion (i.e., the number of filaments per unit volume) makes the soil more homogenous and isotropic [59]. Freilich et al. [30] showed that the axial deformation of the unreinforced specimen resulted in the development of a failure plane, while reinforced specimens tended to bulge, indicating an increase in the ductility of the soil–fiber mixture.

Tang et al. [81] investigated the micromechanical interaction between soil particles and reinforcing polypropylene fibers. They concluded that the interfacial shear resistance of the fiber-reinforced soil depends primarily on the rearrangement resistance of soil particles, the effective interface contact area (the area through which the soil is connected to the fiber, which is normally less than the surface area of the fiber), fiber surface roughness, and soil composition. In addition, Jamellodin et al. [45] observed that fibers connected a group of particles in a unitary coherent matrix, leading to an increase in the strength properties of the soil.

The scanning electron microscopy (SEM) photographs of [80] also indicated that the bond strength and friction at the interface seem to be the dominant mechanisms controlling reinforcement benefits. Accordingly, the fiber surface is attached by many clay minerals which contribute to bond strength and friction between the fiber and the soil matrix. Likewise, Jacob et al. [44] found that the adhesion between the fiber and the composite matrix was a major factor in determining the response of the interface and its integrity under stress. The interfacial shear strength was a critical factor that controlled the toughness and mechanical properties of composite materials. Similarly, Tang et al. [80] indicated that the distributed discrete fibers act as a spatial three-dimensional network to interlock soil grains and help grains to restrict the displacement. As expected, this bonding network will reduce the liquid limit of the soil as [43] reported for bentonite.

Many researchers have used natural or artificial fibers (e.g., polypropylene, polyester, polyethylene, and glass fibers) to improve various mechanical properties of the sandy soil (e.g., [1, 5, 46, 51, 56, 84, 86]). Previous investigations have also shown that the strength of the reinforced soil increases by an increase in the fiber content, aspect ratio, and friction between the soil and the fiber (e.g., [1, 6, 7, 21, 22, 31, 38, 45, 48, 57, 63, 68, 69, 71, 80]). Most published studies in the field of soil reinforcement have generally proved that the strength and stiffness of the soil improved by fiber reinforcement (e.g., [10, 11, 14, 18, 26, 33, 37, 38, 38, 47, 49, 57, 58, 60, 63, 70, 70, 72,73,74, 79, 80]). The experiments also demonstrated an increase in \(q_\mathrm{{peak}}\) (maximum deviatoric stress) in reinforced soils in comparison with unreinforced soils [12, 16, 17, 22, 26, 34, 61, 65, 80].

Based on the results of some studies, soils represent an increase in the cohesion intercept and the friction angle by an increase in the fiber content up to a certain amount of fiber content (e.g., [3, 11, 21, 24, 50, 62, 69, 75, 76, 78, 89]). Natural fibers can be considered as an eco-friendly alternative for soil improvement and may originate from the stem, leaf, seed, fruit, wood, cereal straw, and the other remains of plants. However, some aspects influence the durability and performance of natural fibers, including the part of the plant that is the origin of the fiber, the age of the plant, and the fiber treatment method [35].

Qu and Sun [71] reported the reinforcing effect of the wheat straw fiber on the strength behavior of Shanghai clayey soil, and Li et al. [52] verified the feasibility of combining SH-treated (i.e., modified polyvinyl alcohol) wheat straw fiber reinforcement with lime stabilization to improve the properties of the saline soil. They found that SH filled the pores evenly distributed on the characteristic cross-sectional honeycomb pattern of the wheat straw, thus improving the water resistance and tensile strength of the wheat straw fiber. Consoli et al. [15] added the randomly distributed fibers to the cemented soil, conducted triaxial compression tests on the mixture, and concluded that the fiber reinforcement increased both the peak and residual strength and changed the brittle behavior of this soil to a more ductile one.

The slope of critical state line M is a function of the fiber content of the reinforced soil [85]. It was reported that the inclusion of a small number of wheat straw fibers into the lime-stabilized soil could improve the intensity of the strain-softening behavior associated with pure lime stabilization.

Wei et al. [87] showed that the strength of the reinforced inshore saline soil with the wheat straw and lime is higher than that of the soil with lime only. The strength of the reinforced soil is maximal when the fiber content is 0.25%, and the optimum length of the reinforcing element is 10 mm (50 mm in diameter of the specimen).

Although the traditional soil mechanics idealizes geomaterials as being either in a dry or fully water-saturated state, there is a zone between the ground surface and the groundwater table, where the soil is in an unsaturated state. This zone is affected by environmental changes during wetting and drying seasons through precipitation and evaporation or evapotranspiration, respectively. Fredlund and Morgenstern [27] described the stress state in an unsaturated soil using two independent normal stress variables of the net normal stress \(\sigma _\mathrm{{net}} = \sigma _t - u_\mathrm{a}\) and the matric suction \(\psi = u_\mathrm{a}-u_\mathrm{w}\) with the total stress \(\sigma _\mathrm{t}\), pore water pressure \(u_\mathrm{w}\), and pore air pressure \(u_\mathrm{a}\). The influence of the water content on the stress state in an unsaturated soil is basically considered by means of the matric suction, which is applicable for describing the mechanical behavior of partially saturated soils. The water content is related to the matric suction via the Soil Water Characteristic Curve (SWCC). SWCC is one of the most useful characteristics in unsaturated soil mechanics and related to many geotechnical and hydro-mechanical properties of a soil, including hydraulic conductivity, effective stress, and volume changes [28, 29, 82] and [83]. This concept is widely used to capture the effect of the water content on the behavior of soils located in the unsaturated or vadose zone. However, how water content affects the behavior of random natural reinforced soils is still questionable and of interest of research.

In the present study, series of biaxial shear strength tests were conducted on materials with 0, 0.5, and 1% fiber content with suctions varying from 0 (the saturated condition) to 55,000 kPa in order to investigate the shear strength parameters of the unsaturated reinforced clay under a plane strain condition. Other experimental programs were performed to determine the basic properties and the SWCC of the applied materials in addition to biaxial tests. The SWCCs of the used materials are shown in Figs. 4 and 5 in the form of the void ratio and the degree of saturation versus suction.

2 Experimental program

2.1 Material

The applied materials in this study were soil–straw mixtures with different dosages. The host soil itself was a composite of kaolin, a calcium-type bentonite (Calcigel), silt, and sand. The physical characteristics of the adopted mixture were determined in accordance with the DIN standard. The adopted soil has a liquid limit of 20.5%, plasticity limit of 12.5%, plasticity index of 8%, and the specific gravity of 2.67. Table 1 presents the liquid limit and specific gravity of this material reinforced with straw fibers. This soil is classified as low-plasticity clay in the unified system. Figure 1a, b shows the grain size distribution and the Atterberg limits of the applied material in the Casagrande chart, respectively.

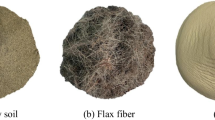

Unlike most studies on the fiber reinforcement of the soils, the selected fiber for reinforcement in this research is a natural fiber, typical wheat straw (Fig. 2a), which is available worldwide and is a non-hazardous by-product of agriculture. The reason for choosing the wheat straw fiber as the reinforcing element was its affordable price, abundance, relatively high tensile strength compared to other natural fibers, environmental protection (avoiding burning in the field that pollutes air), and the like. Therefore, it is advised to use wheat straw fiber as the primary reinforcement and an alternative low-cost material for soil reinforcement. The dosage of the straw in this research varied from 0 to 1%.

The applied straw samples in this study were collected at the harvest time from the wheat farms of the North Rhine-Westphalia, Germany. Most straw filaments were pressed and flattened or opened during the packing process. The straw stems keeping original cylindrical shapes were discarded and not used in the tests. The width and thickness of straw pieces were in the range of 4–8 mm and 0.5–1.2 mm, respectively. The specific gravity of the adopted straw was 1.68. For the biaxial shear strength analyses of this study, the fibers were cut to the lengths of 1–3 cm.

Although there are neither standardized testing procedures nor systematic reviews for testing herbaceous stems [77], many studies have attempted to analyze the physical and mechanical properties of the wheat straw (e.g., [9, 39, 88], and other citations in this section), among others, on tensile and shear strength which are of interest in the present study. For example, Hornsby et al. [41], Panthapulakkal et al. [66], and Pickering et al. [67] pointed out that a large standard deviation was observed in the strength and modulus of wheat straw fibers due to the large variation in the strength properties of fibers, which is expected for natural fibers. Likewise, Esehaghbeygi et al. [25] and Chandio et al. [13] reported a significant increase in the shear strength of the wheat straw in relation to the location (height) of the sample in the stalk. Moreover, O’Dogherty et al. [64] found the same trend for tensile strength. Similarly, Du and Wang [23] stated that the maturity of the wheat plant affects the shear strength and Young’s modulus of straw filaments. Young’s modulus significantly increased by increasing maturity up to the harvest time. However, fibers are collected at the harvest time thus with the maximum strength in typical applications. Additionally, Galedar et al. [32] concluded that tensile strength increases by an increase in the fiber area (alfalfa fibers). O’Dogherty et al. [64] reported the tensile strength varying from 22.7 to 31.2 MPa for the moisture content range of 8–22% without observing a consistent trend. Conversely, Limpiti [53] reported tensile strength to be in the range of 32.5–37.8 MPa for the moisture range between 10 and 65%. In addition, Du and Wang [23] demonstrated the tensile of the wheat fiber to be in the range of 30.4–52.6 MPa.

2.2 Adopted device and applying suction

The adopted biaxial apparatus in this study for measuring the plane strain shear strength of the unsaturated material was developed by [2] in Bauhaus Universität-Weimar, in cooperation with APS GmbH (Wille Geotechnik), Germany (Fig. 3a, b). The rectangular (prismatic) soil specimen of this test had a height of 120 mm, a width of 100 mm, and thickness of 40 mm. The high slenderness ratio was chosen to allow the free formation of the shear band without reflecting on the end plates.

a Schematic setup of biaxial apparatus, b a photograph of the device without the outer cell [2], c schematic setup of applying suction via ATT, and d schematic setup of applying suction via VET (these figures are not scaled)

To measure volumetric changes for unsaturated samples, a so-called double-wall technique was implemented, in which the sample was mounted inside two concentric cylindrical cells. In this system, both inner and outer cells were pressurized by the same value of pressure during the test. After calibration, theoretically, no volume change (expansion or contraction) was expected from the inner cell and the transport of the observed water inside the inner cell during the test was assumed to be the volumetric change of the tested soil specimen.

The sample was covered with a prismatic membrane fixed and sealed to the bottom platen and the top cap (Fig. 2b) through which air and water pressures were controlled completely. The deformation was restricted (\(\epsilon _2=0\)) along the long dimension of the cross-section by two immovable side steel platens (i.e., the specimen had a constant width of 100 mm). The loading system consisted of a loading frame, outer and inner pistons, and a load cell with the maximum capacities of 50 kN installed above the outer piston and below the horizontal beam of the frame. All produced data during the test (from the load cell, pressure transducers, displacement transducers, and volume change indicators) were automatically accumulated to the computer using data logging software. The device was designed to apply suction via the Axis Translation Technique (ATT) up to 100 kPa, but in this study, the applied suction increased to 55,000 kPa using the Vapor Equilibrium Technique (VET) with small modifications.

The soil mixture was thoroughly mixed and blended with 1.25\(\times\)LL water content to reach a soft and uniform slurry mud. To have a good distribution of water in all parts of the sample, the mud was left for 2 days and then poured into the molds for drying. After drying in the laboratory atmosphere, the samples were placed in the oven for 2 days to reach the maximum dry condition. Then, the samples were subjected to controlled humidities to absorb moisture and reach the designed suction for the test. All samples were tested in the imbibition path of the SWCC. Regarding the applied clayey material in this study, the establishment of suction equilibrium took a long time. To accelerate the process, first, the samples got the determined suctions out of the biaxial device and the above-mentioned setup procedure was conducted after the occurrence of the equilibrium condition. For this purpose, the samples were directly placed in desiccators with certain salt solutions for suctions in the VET range. The equilibrium occurred when the weights of the samples reached a constant value. After equilibrium, the applied suction by the solution was checked again by the chilled mirror in order to assure suction values. Regarding the wetting path of the SWCC for suctions in the ATT range, the samples received water to reach the designed water content and its corresponding suction.

The same suction was applied to the sample after the placement of the sample in the device and termination of the equipment setup. The applied suctions had a wide range from 80 to 55,000 kPa. The ATT (Fig. 3c) and VET (Fig. 3d) methods were used for 80 and 400 kPa, as well as 3000, 9500, and 55,000 kPa, respectively. The porous and ceramic discs were considered to apply pore-air and pore-water pressures (\(u_\mathrm{a}\) and \(u_\mathrm{w}\)) to the soil specimen. These discs were fixed to the metal plate. Metal plates can be simply replaced with other plates equipped with ceramic discs with higher air entry values, enabling the application of higher values of the matric suction and thus testing the unsaturated soil in a wide range of matric suctions. In this research, 100 and 500 kPa ceramic discs were used based on the above-mentioned purpose. Several studies have also utilized the VET method for controlling the total suction in the unsaturated oedometer and triaxial tests (e.g., [4, 8, 20, 54]). For controlling higher suctions in the biaxial device, the vapor produced from salt solutions with the given molalities of various salts was circulated over the sample. The top and bottom metal plates with four porous discs were used, and saturated tests were also performed by the same metal plates.

This condition was kept constant for 3 days before shearing. The specimens were axially compressed by 0.002 mm/min (i.e., the strain rate of \(1.6 \times 10^{-5} \%/\text {min}\)). The low strain rate is vital for ensuring the dissipation of the induced pore pressures during the compression stage [28]. As shown in this section, the shrinkage and swelling of the studied materials highly rely on the straw content and the sample preparation method. Samples with a higher dosage of straw were conduced to a greater void ratio. Considering that swelling occurs in the wetting path, samples with the same straw content had higher void ratios in the lower suction. This phenomenon can be clearly observed in Fig. 4. Table 2 presents the void ratios of samples with different straw contents and suctions. Figure 5 shows the degree of saturation of samples versus suction for drying and wetting paths, SWCC curves.

3 Results and discussion

3.1 Effect of straw fibers on shear strength

Figure 6a–d illustrates the deviatoric stress (\(\sigma _\mathrm{d}\)) and volumetric behavior (\(\epsilon _\mathrm{v}\)) plotted against the axial strain (\(\epsilon _1\)) under saturated conditions with 50 and 150 kPa confining pressures (\(\sigma _3\)). As shown, under any confined stress, samples with more fiber contents required higher axial strains to reach the failure. The deviatoric stress at failure also increased by an increase in the fiber content. The volumetric behavior of samples approved that fiber inclusion can make the failure more ductile, which is in line with the findings of many researchers (e.g., [10, 11, 26, 59, 80, 90]).

Effect of fibers content on: a deviator stress versus shear strain at \(\sigma _3=50\) kPa, b deviator stress versus shear strain at \(\sigma _3=150\) kPa, c volumetric strain versus shear strain at \(\sigma _3=50\) kPa, and d volumetric strain versus shear strain at \(\sigma _3=150\) kPa all under a saturated condition (positive and negative volumetric strains show contraction and expansion respectively)

The effect of fiber reinforcement is more pronounced when the strain in any strength test is increasing, implying that fibers, if mobilized, play a role in load bearing. The contribution of fiber reinforcement is more effective after a certain level of shear strain, which is in agreement with the results of [40] and [22]. At extremely small strains, the inclusion of fiber reinforcement does not influence the initial stiffness and the elastic shear modulus.

3.2 Shear strength of unsaturated soils

Figure 7a–c and d–f depicts the deviator stress and the volumetric strain versus the axial strain for unreinforced materials under three levels of cell pressure (50, 100, and 150 kPa) for saturated and unsaturated conditions with five different suctions (80, 400, 3000, 9500, and 55,000 kPa), respectively. The initial void ratio for each sample is provided in Table 2. The suctions of samples were applied using methods explained in Sect. 2.2. Based on the results, stiffness, peak deviator stress, and consequently, the shear strength increased by an increase in the suction. The material behaves softer if the suction is lower. However, the strain at the failure point decreased by an increase in the suction. The post-peak drop had a direct relation with the value of the suction. The same tendency can be found for specimens under the cell pressures of 100 and 150 kPa.

Figures 8 and 9 show the deviator stress and the volumetric strain versus the axial strain for materials containing 0, 0.5, and 1% fiber content for saturated and unsaturated conditions with five different suctions (80, 400, 3000, 9500, and 55,000 kPa) under the cell pressures of 50 and 150 kPa, respectively. As depicted in Figs. 8 and 9 , all samples (irrespective of fiber content and suction) represented contraction in the first phase of shearing and then the volumetric behavior changed its trend and dilation started slightly before failure. The same trend was observed for all conditions (cell pressures: 50, 100, and 150 kPa and materials with 0\(\%\), 0.5\(\%\), and 1\(\%\) straw content). The maximum contraction increased by an increase in the suction although it decreased by any further increase in the suction after a certain suction (mostly around 400 kPa). The maximum contraction was affected by the degree of saturation and straw inclusion. Reinforcement increased the void ratio; therefore, a greater contraction was expected for higher straw contents, which was observed in samples with suctions lower than the Air Entry Value (AEV) because soft materials and ductile failure allowed the movement of particles over each other and contraction could freely take place and maximum contraction was a direct function of the straw content. However, straw content did not represent a meaningful effect on the maximum contraction for suctions higher than AEV. This can be due to the rigidity of samples which limits the displacement of grains independent of the fiber content.

The AEV of the soil (Fig. 5) was around 600 kPa for all tested fiber contents. As depicted in Fig. 10, shear strength decreased for suctions higher than AEV (i.e., 3000, 9500, and 55,000 kPa) as fiber content demonstrated an increase. (The saturated condition is represented by suction = 1 kPa) This is due to an inverse relation between fiber content and the dry density of materials (Table 2). Based on the above-mentioned findings, reinforcement played no role in increasing the strength because failure occurred at the extremely small strain in high suctions. However, as illustrated in Fig. 10, fiber inclusion increased the shear strength in suctions lower than AEV (0, 80, and 400 kPa). The weak bonding between clay particles and straw filaments allowed the movement of fibers among the soil matrix. The mobilized filaments contributed to carrying the load and caused an increase in the shear strength.

3.3 Shear band inclination

Suction and straw inclusion affected the mobilized shear band inclination. As much as the ductility of the sample increases, a lower angle is expected for the shear band. Based on the obtained data (Fig. 11), by an increase in the suction, a greater angle was obtained for the shear band to the horizontal axis increasing around 15\(^{\circ }\) to 20\(^{\circ }\) over the range of a suction between 0 and 55,000 kPa. (As shown, the saturated condition is represented by suction = 1 kPa) Cruz et al. [19] also observed a fully developed failure surface for the unsaturated silty sand under a plane strain condition with failure angles of 61\(^{\circ }\) and 65\(^{\circ }\) for suctions 50 and 100 kPa, respectively.

Additionally, the failure mode was considerably affected by fiber inclusion for the unsaturated condition. Unreinforced samples failed with a distinct and clear shear band, and upper and lower parts of the samples were mainly separated after shearing, while failure occurred in several small cracks rather than a unique crack at the same condition in reinforced samples. When local cracks appeared in a specimen, some fibers crossing these cracks were responsible for the tension in the soil by a fiber-soil connection, which effectively impeded further development of the cracks, and accordingly, changed the failure mode of the reinforced specimens to a more ductile one with less distinct failure plane. This behavior was because increasing the fiber inclusion (i.e., the number of filaments per unit volume) made the soil more homogenous and isotropic [59] and [30]. The differences in the mentioned failure mode are illustrated in Fig. 12, including three samples under the same suction and cell pressure while various fiber contents.

The results further revealed that fiber inclusion decreased the angle of the shear band (Fig. 11). As shown in Fig. 12, shear band inclinations were 69\(^{\circ }\), 68\(^{\circ }\), and 63\(^{\circ }\) for three samples with the same suction and cell pressure but straw contents equal to 0, 0.5, and 1%. Figure 13 shows how the straw filaments crossed the shear band. The void ratio of the material is a factor that affects shear band inclination. A decrease in the void ratio probably leads to a greater angle for the shear band if other conditions remain constant, indicating the reduction in the shear band inclination by an increase in the fiber content (according to Table 2).

3.4 Volumetric strain and angle of dilation

The angle of dilation (\(\psi _\mathrm{d}\)) is defined as the ratio between a volumetric strain rate and a shear strain rate. For the plane strain condition (\(\epsilon _2=0\)), this ratio can be written in terms of the principal strain rates as follows:

In this study, the angle of dilation was affected by suction and straw content. Figure 14 shows the maximum angle of dilation for all materials and conditions over the suction. (The saturated condition is demonstrated by suction = 1 kPa) Based on the result, an increase in the suction led to a general increase in the angle of dilation, which is because the failure strain considerably decreased by an increase in the suction; consequently, all volumetric strains happened after a small amount of the axial strain, increasing the fraction in Eq. 1. However, the opposite behavior was observed for the two highest suctions, in which, probably, the axial strain corresponding to the maximum volumetric strain was relatively similar.

Based on the findings (Fig. 14), the straw inclusion in nearly all suctions caused an increase in the angle of dilation. This phenomenon can be described according to the sawtooth-shape model for sliding. If we consider that sliding occurs between two rough planes represented by rigid sawtooth surfaces, the angle of dilation can be imagined more physically as the angle of teeth to the horizontal axis [42], implying that as much as the roughness (or the angle of the teeth) increases, the angle of dilation increases as well. The fiber surface was attached to the soil matrix by many clayey bridges. Fiber filaments could connect the two sides of the failure plane even after the failure providing a rough sliding plane (Fig. 13) and resulting in a higher angle of dilation.

4 Conclusion

This study analyzed the saturated and unsaturated shear strength of the unreinforced and reinforced soil with natural straw fibers under a plane strain condition. Straw fibers with different dosages (0, 0.5, and 1\(\%\)) were mixed with the soil and tested to determine the shear strength and some other initial and prerequisite parameters such as the SWCC. The following conclusions were obtained based on the test results and analyses:

-

Shrinkage reduced and samples with higher void ratios were resulted by an increase in the straw content.

-

More ductile behavior was observed for samples with lower suctions and higher straw contents.

-

The shear strength of both unreinforced and reinforced fine-grained soils considerably increased by an increase in the suction.

-

The fiber inclusion reduced the shear strength of samples with suctions higher than AEV while increasing for samples with suctions lower than AEV.

-

Shear band inclination increased with the suction, while it decreased with the straw content.

-

The maximum contraction increased by an increase in the suction although it decreased after a certain value of suction.

-

Although the straw content increased the maximum contraction for suctions lower than AEV, it did not express a meaningful effect for higher suctions.

-

The maximum angle of dilation generally increased by an increase in the suction and straw content.

References

Ahmad F, Bateni F, Azmi M (2010) Performance evaluation of silty sand reinforced with fibers. Geotext Geomembr 28:93

Alabdullah J (2010) Testing unsaturated soil for plane strain conditions: a new double-wall biaxial device. Ph.D. thesis, Bauhaus Universität Weimar, Germany

Al-Adili A, Azzam R, Spagnoli G, Schrader J (2012) Strength of soil reinforced with fiber materials (papyrus). Soil Mech Found Eng 48:241

Al-Badran Y (2011) Volumetric yielding behavior of unsaturated fine-grained soils. Ph.D. thesis, Ruhr-Universität Bochum, Germany

Al-Refeai TO (1991) Behavior of granular soils reinforced with discrete randomly oriented inclusions. Geotext Geomembr 10:319

Andersland OB, Khattak AS (1979) Shear strength of kaolinite/fiber soil mixtures. In: Proceedings of international conference on soil reinforcement, Paris, France, vol 1

Attom MF, Al-Akhras NM, Malkawi AIH (2009) Effect of fibers on the mechanical properties of clayey soil. In: Proceedings of the Institute of Civil Engineers, Geotechnical Engineering, vol 162(GES)

Blatz JA, Graham J (2003) Elastic–plastic modeling of unsaturated soil using results from a new triaxial test with controlled suction. Géotechnique 53:113

Bouasker M, Belayachi N, Hoxha D, Al-Mukhtar M (2014) Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials 7(4):3034. https://doi.org/10.3390/ma7043034

Bouhicha M, Aouissi F, Kenai S (2005) Performance of composite soil reinforced with barley straw. Cem Concrete Compos 27:617

Cai Y, Shi B, Ng CWW, Tang C (2006) Effect of polypropylene fiber and lime admixture on engineering properties of clayey soil. Eng Geol 87:230

Casagrande M, Coop M, Consoli N (2006) Behavior of a fiber-reinforced bentonite at large shear displacements. Geotech Geoenviron Eng Eng ASCE 132:1505

Chandio FA, Changying J, Tagar AA, Mari IA, Guangzhao T, Cuong DM (2013) Comparison of mechanical properties of wheat and rice straw influenced by loading rates. Afr J Biotechnol 12(10):1068

Chen CW, Loehr JE (2008) Undrained and drained triaxial tests of fiber-reinforced sand. Geotext Geomembr 25:194

Consoli CN, Prietto DM, Ulbrich LA (1998) Influence of fiber and cement addition on behavior of sandy soil. J Geotech Geoenviron Eng 124:1211

Consoli C, Prietto M, Pasa S (2002) Engineering behavior of a sand reinforced with plastic waste. J Geotech Geoenviron Eng ASCE 128:462

Consoli C, Casagrande T, Prietto M, Thome A (2003) Plate load test on fiber-reinforced soil. J Geotech Geoenviron Eng ASCE 129:951

Consoli NC, Heineck KS, Casagrande MDT, Coop MR (2007) Shear strength behavior of fiber-reinforced sand considering triaxial tests under distinct stress paths. J Geotech Geoenviron Eng ASCE 133:1466

Cruz, AJ and Hoyos, LR and Lizcano A (2012) Unsaturated Soil Response under Plane Strain Conditions Using a Servo/Suction-Controlled Biaxial Apparatus. 2nd European conference on unsaturated soils

Cuisinier O, Masrouri F (2002) In: Vulliet L, Laloui L, Schrefler B (eds) Influence of a suction cycle on the hydromechanical behaviour of a swelling soil. International workshop on environmental geomechanics, Monte Verità, Switzerland. EPFL Press, Lausanne, pp 175–180

Devi D, Jempen B (2016) Shear strength behaviour of bamboo fiber reinforced soil. Int Res J Eng Technol 3:433

Diambra A, Ibraim E, Muir Wood D, Russell A (2010) Fibre reinforced sands: experiments and modelling. Geotext Geomembr 28:238

Du DD, Wang J (2016) Research on mechanics properties of crop stalks: a review. Int J Agric Biol Eng 9(6):10

Dutta RK, Khatri VN, Gayathri V (2012) Effect of addition of treated coir fibres on the compression behaviour of clay. Jordan J Civ Eng 6:476

Esehaghbeygi A, Hoseinzadeh B, Khazaei M, Masoumi A (2009) Bending and shearing properties of wheat stem of alvand variety. World Appl Sci J 6(8):1028

Esna-ashari M, Asadi M (2008) A study on shear strength and deformation of sandy soil reinforced with tire cord wastes. In: 4th Asian regional conference on geosynthetics, Shanghai, China

Fredlund DG, Morgenstern NR (1977) Stress state variables for unsaturated soils. Geotech Div ASCE 103:447

Fredlund DG, Rahardjo H (1993) Soil mechanics for unsaturated soils. Wiley, New York

Fredlund DG, Xing A, Fredlund MD, Barbour SL (1995) The relationship of the unsaturated soil shear strength function to the soil–water characteristic curve. Can Geotech J 32:440

Freilich J, Li C, Zornberg G (2010) Effective shear strength of fiber-reinforced clays. In: 9th international conference on geosynthetics, Brazil

Freitag DR (1986) Soil randomly reinforced with fibers. J Geotech Eng 112:823

Galedar MN, Tabatabaeefar A, Jafari A, Sharifi A, Rafiee S, Mohtasebi SS (2009) Influence of moisture content, rate of loading and height regions on tensile strength of alfalfa stems. Int Agrophys 23:27

Ghavami K, Filho R, Barbosa P (1999) Behaviour of composite soil reinforced with natural fibers. Cem Concrete Compos 21:39

Ghiassian H, Poorebrahim G, Gray D (2004) Soil reinforcement with recycled carpet wastes. Waste Manag Res 22:108

Gowthaman S, Nakashima K, Kawasaki S (2018) A state-of-the-art review on soil reinforcement technology using natural plant fiber materials: past findings, present trends and future directions. MDPI/Materials 11(4):553. https://doi.org/10.3390/ma11040553

Gray DH, Maher MH (1982) Proceeding of the XIIth international conference on soil mechanics and foundation engineering, vol 1. Riode Janeiro, Brazil

Gray H, Al-Refeai T (1986) Behavior of fabric versus fiber reinforced sand. Geotech Geoenviron Eng ASCE 112:809

Gray DH, Ohashi H (1983) Mechanics of fiber reinforcement in sand. Geotech Geoenviron Eng ASCE 109:355

Hamman KD, Williamson RL, Steffler ED, Wright CT, Hess JR, Pryfogle PA (2005) Structural Analysis of Wheat Stems. In: Davison BH, Evans BR, Finkelstein M, McMillan JD (eds) Twenty-sixth symposium on biotechnology for fuels and chemicals. ABAB symposium

Heineck KS, Coop MR, Consoli NC (2005) Effect of microreinforcement of soil from very small to large shear strains. J Geotech Geoenviron Eng ASCE 131:1024

Hornsby PR, Hinrichsen E, Trivedi K (1997b) Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibers. Part II. Analysis of composite microstructure and mechanical properties. J Mater Sci 32:1009

Houlsby GT (1991) How the dilatancy of soils affects their behavior. In: Tenth European conference on soil mechanics and foundation engineering. Florance, Italy

Ikizler BS, Aytekin M, Turker E, Yavuz HI (2009) Effect of fibers on swelling characteristics of bentonite. In: 2nd International conference on new developments in soil mechanics and geotechnical engineering. Near East University, Nicosia

Jacob M, Joseph S, Pothan LA (2005) A study of advances in characterization of interfaces and fiber surfaces in lingocellulosic fiber-reinforced composites. Compos Interfaces 12:95

Jamellodin Z, Talib Z, Kolop R, Noor N (2010) The effect of oil palm fibre on strength behaviour of soil. In: 3rd SANREM conference, Kota Kinabalu, Malaysia

Jiang H, Cai Y, Liu J (2010) Engineering properties of soils reinforced by short discrete polypropylene fiber. J Mater Civ Eng 22:1315–1322

Kim T, Kim J, Lee G (2008) Mechanical behavior of lightweight soil reinforced with waste fishing net. Geotext Geomembr 26:512

Kumar A, Walia BS, Bajaj A (2007) Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. Mater Civil Eng ASCE 19:242

Kumar A, Walia BS, Mohan J (2006) Compressive strength of fiber reinforced highly compressible clay. J Constr Build Mater 20:1063

Lekha BM, Goutham S, Shankar AUR (2015) Evaluation of lateritic soil stabilized with arecanut coir for low volume pavements. Transp Geotech 2:20

Li M, Chai SX, Du HP and Wei L (2011) Deviator stress–strain characters of reinforced lime-soil with wheat straw and parameters of Duncan-Chang model. J Hebei Univ Technol 40:87

Li M, Chai SX, Zhang HY, Du HP, Wei L (2012) Feasibility of saline soil reinforced with treated wheat straw and lime. Soils Found 52:228

Limpiti S (1980) Effect of moisture content and stage of maturity on mechanical properties of wheat straw. Thai J Agric Sci 13:277

Lloret A, Villar M, Sánchez M, Gens A, Pintado X, Alonso E (2003) Mechanical behaviour of heavily compacted bentonite under high suction changes. Géotechnique 53:27

Maher MH (1988) Static and dynamic response of sands reinforced with discrete randomly distributed fibers. Ph.D. thesis, University of Michigan, USA

Maher MH, Gray DH (1990) Static response of sand reinforced with randomly distributed fibers. J Geotech Eng 116:1661

Maher H, Ho C (1994) Mechanical properties of kaolinite/fiber soil composite. Geochem Eng 120:1381

Malekzadeh M, Bilsel H (2012) Effect of polypropylene fiber on mechanical behavior of expansive soils. Electron J Geotech Eng 17:55

Marandi M, Bagheripour H, Rahgozar R, Zare H (2008) Strength and ductility of randomly distributed palm fibers reinforced silty-sand soils. Am J Appl Sci 5:209

Mesbah A, Morel JC, Walker P, Ghavami K (2004) Development of a direct tensile test for compacted earth blocks reinforced with natural fibers. Mater Civ Eng 16:95

Michalowski RL, Zhao A (1996) Failure of fiber-reinforced granular soils. Geotech Eng ASCE 122:226

Naeini SA, Sadjadi SM (2009) Effect of waste polymer materials on shear strength of unsaturated clays. 2nd International conference on new developments in soil mechanics and geotechnical engineering. Near East University, Nicosia

Nataraj MS, McManis KL (1997) Strength and deformation properties of soils reinforced with fibrillated fibers. Geosynth Int 4:65

O’Dogherty MJ, Hubert JA, Dyson J, Marshall CJ (1995) A study of the physical and mechanical properties of wheat straw. J Agric Eng Res 62:133

Ola SA (1989) Stabilization of lateritic soils by extensible fiber reinforcement. Eng Geol 26:125

Panthapulakkal S, Zereshkian A, Sain M (2006) Preparation and characterization of wheat straw fibers for reinforcing application in injection molded thermoplastic composites. Bioresour Technol 97(2):265

Pickering KL, Abdella A, Ji C, McDonald AG, Franich RA (2003) The effect of silane coupling agents on radiate pine fiber for use in thermoplastic matrix composites. Compos Part A 34:915

Prabakara J, Sridhar R (2002) Effect of random inclusion of sisal fiber on strength behavior of soil. Constr Build Mater 16:123

Pradhan PK, Kar R, Naik A (2012) Effect of random inclusion of polypropylene fibers on strength characteristics of cohesive soil. J Geotech Geol Eng 30:15

Puppala A, Musenda C (2000) Effects of fiber reinforcement on strength and volume change in expansive soils. Transp Res Rec 1736:134

Qu J, Sun Z (2015) Strength behavior of Shanghai clayey soil reinforced with wheat straw fibers. Geotech Geol Eng. https://doi.org/10.1007/s10706-015-9963-8

Ranjan G, Vasan RM, Charan HD (1996) Probabilistic analysis of randomly distributed fiber-reinforced soil. Geotech Eng 122:419

Ravishankar U, Raghavan S (2004) Indian geotechnical conference Ahmedabad, India

Santhi K, Sayida M (2009) 10th national conference on technological trends (NCTT09)

Setty S, Murthy A (1987) Behavior of fiber-reinforced Black Cotton soil. IGC (87), Bangalore, India

Setty S, Rao G (1987) Characteristics of fiber reinforced lateritic soil. IGC (87), Bangalore, India

Shah DU, Reynolds PS, Ramage MH (2017) The strength of plants: theory and experimental methods to measure the mechanical properties of stems. J Exp Bot 68:4497–4516

Sivakumar B, Vasudevan A (2008) Strength and stiffness response of coir fiber-reinforced tropical soil. J Mater Civ Eng 20:571

Tang C, Shi B, Chen W (2006) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 24:1

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25:194

Tang C, Shi B, Zhao L (2010) Interfacial shear strength of fiber reinforced soil. Geotext Geomembr 28:54

Vanapalli SK, Fredlund DG, Pufahl DE (1999) Influence of soil structure and stress history on the soil–water characteristics of a compacted till. Géotechnique 49:143

Vanapalli SK, Fredlund DG (1999) Empirical procedures to predict the shear strength of unsaturated soils. Eleventh Asian regional conference on soil mechanics and geotechnical engineering, Rotterdam

Wang P, Chai SX, Wang XY, Wei L, Li M (2011) Analysis of effect factors of heavy compaction test for wheat straw-reinforced saline soil. Rock Soil Mech 32:448

Wang Y, Guo P, Li X, Lin H, Liu Y, Yuan H (2019) Behavior of fiber-reinforced and lime-stabilized clayey soil in triaxial tests. Appl Sci 9:1

Wei HW, Yu ZH, Zou YS (2005) Shear characteristics of soil reinforced with geosynthetic material. Shuili Xuebao 36:1

Wei L, Chai SX, Cai HZ, Wang XY, Li M, Yang JW (2010) Physical and mechanical properties of wheat straw and unconfined compressive strength of inshore saline soil reinforced with wheat straw. CHN Civil Eng J 43:93

Wright CT, Pryfogle PA, Stevens NA, Steffler ED, Hess JR, Ulrich TH (2005) Biomechanics of Wheat/Barley Straw / Corn Stover. In: Davison BH, Evans BR, Finkelstein M, McMillan JD (eds) Twenty-sixth symposium on biotechnology for fuels and chemicals. ABAB symposium. Humana Press

Yadav JS, Tiwari SK (2016) Behaviour of cement stabilized treated coir fibre-reinforced clay-pond ash mixtures. J Build Eng 8:131

Yetimoglu T, Salbas O (2003) A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext Geomembr 21:103

Acknowledgements

The project was performed in the frame of a PhD thesis by Dr. Fard supervised by Professor Tom Schanz who passed away during the drafting of this paper. The authors believe that the content of the paper is in line with his scientific view on the topic. Accordingly, they would like to express their gratitude to Professor Schanz for his significant contribution to this work.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Soleimani-Fard, H., König, D. & Goudarzy, M. Plane strain shear strength of unsaturated fiber-reinforced fine-grained soils. Acta Geotech. 17, 105–118 (2022). https://doi.org/10.1007/s11440-021-01197-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01197-7