Abstract

This paper proposes an equivalent continuum model to describe the mechanical behavior of transversely isotropic rocks. In this model, the transverse isotropy of deformation and strength was achieved based on the Mohr–Coulomb and maximum tensile-stress criteria, and the damage was captured by adopting a statistical damage evolution rule. The application of the model is verified through numerical simulation of conventional triaxial tests. The model is then used to reveal the non-uniform mechanical response of the surrounding rock and the secondary lining for a tunnel situated in a weak layered rock mass. The results show that: (1) The proposed model can capture the transverse isotropy in deformation and strength of rocks, and the proposed damage formulation can represent the deterioration and degree of failure of rocks; (2) The fracturing pattern, failure strength and stress–strain curves obtained from the proposed model agree well with test results for three typical rocks with different directional variations in strength; (3) The damage distribution based on the proposed model can identify the failure of layered rock mass; and (4) The damage zones of the surrounding rock and the loads on the secondary lining after tunnel excavation show distinctly asymmetric behavior, that is, the damaged zones are concentrated in the tunnel direction normal to the weak planes, and the positive bending moment and larger axial force are parallel and vertical to the weak planes, respectively.

Similar content being viewed by others

References

Akai K (1971) The failure surface of isotropic and anisotropic rocks under multiaxial stresses. J Society Mater Sci Jpn 20(209):122–128

Abousleiman YN, Hoang SK, Liu C (2014) Anisotropic porothermoelastic solution and hydro-thermal effects on fracture width in hydraulic fracturing. Int J Numer Anal Meth Geomech 38:493–517

Ambrose J. Failure of anisotropic shales under triaxial stress conditions. Dissertation, Imperial College London, 2014.

Chen TY, Feng XT, Zhang XW, Cao WD, Fu CJ (2014) Experimental study on mechanical and anisotropic properties of black shale. Chinese J Rock Mech Eng 33(9):1772–1779 (in Chinese)

Cho JW, Kim H, Jeon SK, Min KB (2012) Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int J Rock Mech Min Sci 50:158–169

Cheng JY, Wan ZJ, Zhang YD, Li WF, Peng SS, Zhang P (2015) Experimental study on anisotropic strength and deformation behavior of a coal measure shale under room dried and water saturated conditions. Shock Vib 5:1–13

Cheng C, Li X, Qian HT (2017) Anisotropic Failure Strength of Shale with Increasing Confinement: Behaviors, Factors and Mechanism. Materials 10(11):1310

Chen ZQ, He C, Wu D, Gan LW, Xu GW, Yang WB (2018) Mechanical properties and energy damage evolution mechanism of deep-buried carbonaceous phyllite. Rock Soil Mech 39(2):445–456 (in Chinese)

Chen ZQ, He C, Xu GW, Ma GY, Wu Di. A case study on the asymmetric deformation characteristics and mechanical behavior of deep-buried tunnel in phyllite. Rock Mech Rock Eng.2019;52:4527–4545.

Chen YF, Wei K, Liu W, Hu SH, Hu R, Zhou CB (2016) Experimental characterization and micromechanical modelling of anisotropic slates. Rock Mech Rock Eng 49(9):3541–3557

Chen L, Shao JF, Huang HW (2010) Coupled elastoplastic damage modeling of anisotropic rocks. Comp Geotech 37:187–194

Crawford BR, DeDontney NL, Alramahi B, Ottesen S. Shear strength anisotropy in fine-grained rocks. In: 46th US rock mechanics/geomechanics symposium, Chicago, IL, USA, 2012.

Cui L, Zheng JJ, Dong YK, Zhang B, Wang A (2017) Prediction of critical strains and critical support pressures for circular tunnel excavated in strain-softening rock mass. Eng Geol 224:43–61

Deng HF, Wang W, Li JL, Zhang YC, Zhang XJ (2018) Experimental study on anisotropic characteristics of bedded sandstone. Chinese J Rock Mech Eng 37(1):112–120 (in Chinese)

Debecker B (2008) Influence of planar heterogeneities on the fracture behavior of rock. Katholieke Universiteit Leuven, Leuven

Duan K, Kwok CY (2015) Discrete element modeling of anisotropic rock under Brazilian test conditions. Int J Rock Mech Min Sci 78:46–56

Everitt RA, Lajtai EZ (2014) The influence of rock fabric on excavation damage in the Lac du Bonnett granite. Int J Rock Mech Min Sci 41:1277–1303

Fahimifar A (2004) Strength and deformation properties of a schist rock in Isfahan. IJST-T Civ Eng 28:619–622

Gao K, Meguid MA, Chouinard LE (2020) On the role of pre-existing discontinuities on the micromechanical behavior of confined rock samples: a numerical study. Acta Geotech. https://doi.org/10.1007/s11440-020-01037-0(0123456789(),-volV)(0123456789,-().volV)

Hao XJ, Feng XT, Li SJ. Study on the anisotropy of mechanical properties of slate. 13th International Congress of Rock Mechanics, Montreal, Canada, 2015.

Hong GB, Chen M, Lu YH, Jin Y (2018) Study on the anisotropic characteristic of deep shale in southern Sichuan basin and their impacts on fracturing pressure. Petroleum Drill Tech 46:78–85

He B, Xie LZ, Li FX, Zhao P, Zhang Y (2017) Anisotropic mechanism and characteristics of deformation and failure of Longmaxi shale. SCIENTIA SINICA Phys, Mechanica & Astronomica 47(11):1–12 (in Chinese)

Ismael M, Konietzky H (2019) Constitutive model for inherent anisotropic rocks: Ubiquitous joint model based on the Hoek-Brown failure criterion. Comput Geotech 105:99–109

Itasca consulting group Inc. Particle flow code in 2 dimensions user’s guide. 2008; Minneapolis, Minnesota.

Itasca consulting group Inc. Universal discrete element code in 2 dimensions user’s guide. 2005; Minneapolis, Minnesota.

Itasca Consulting Group Inc. FLAC3D User’s Manual (version 3.0). 2005; Minneapolis, USA.

Jin ZF, Li WX, Jin CR, Hambleton J, Cusatis G (2018) Anisotropic elastic, strength, and fracture properties of Marcellus shale. Int J Rock Mech Min 109:124–137

Katsuki D, Gutierrez M (2011) Viscoelastic damage model for asphalt concrete. Acta Geotech 6:231–241

Kim H, Cho JW, Song I, Min KB (2012) Anisotropy of elastic moduli, P-wave velocities, and thermal conductivities of Asan Gneiss, Boryeong Shale, and Yeoncheon Schist in Korea. Eng Geol 148:68–77

Kumar J. Engineering behavior of anisotropic rocks. Dissertation, IIT Roorkee, Indian, 2006.

Lee YK, Pietruszczak S (2008) A new numerical procedure for elasto-plastic analysis of a circular opening excavated in a strain-softening rock mass. Tunn Undergr Space Technol 15:187–213

Lekhnitskii SG (1981) Theory of Elasticity of an Anisotropic Body. Mir Publishers, Moscow

Lisjak A, Grasselli G, Vietor T (2014) Continuum-discontinuum analysis of failure mechanisms around unsupported circular excavations in anisotropic clay shales. Int J Rock Mech Min Sci 65:96–115

Nasseri MHB, Rao KS, Ramamurthy T (2003) Anisotropic strength and deformational behavior of Himalayan schist. Int J Rock Mech Min 40(1):3–23

Niandou H, Shao JF, Henry JP, Fourmaintraux D (1997) Laboratory investigation of the mechanical behavior of Tournemire shale. Int J Rock Mech Min 34(1):3–16

Park B, Min KB (2015) Bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int J Rock Mech Min Sci 76:243–255

Peng JW, Zeng FT, Li CH, Miao SJ. Experimental study of anisotropy and mechanical property of quartz sandstone. Rock Soil Mech. 2017; 38(supp):103–112. (in Chinese)

Peng J, Cai M, Rong G, Yao MD, Jiang QH, Zhou CB (2017) Determination of confinement and plastic strain dependent post-peak strength of intact rocks. Eng Geol 218:187–196

Przecherski P, Pietruszczak S (2020) On specification of conditions at failure in interbedded sedimentary rock mass. Acta Geotech 15:365–374

Pouragha M, Wan R, Eghbalian M (2019) Critical plane analysis for interpreting experimental results on anisotropic rocks. Acta Geotech 14:1215–1225

Ramamurthy T. Strength and modulus responses of anisotropic rocks. In: Hudson JA, editor. Comprehensive rock engineering, vol. 1. Fundamentals. Oxford: Pergamon Press, 1993:313–329.

Saeidi O, Vaneghi RG, Rasouli V, Gholami R (2013) A modified empirical criterion for strength of transversely anisotropic rocks with metamorphic origin. B Eng Geol Environ 72(2):257–269

Shi H. Laboratory tests and constitutive modeling on the anisotropic properties of soft sedimentary rock. Dissertation, Chang An University, China, 2017. (in Chinese)

Song I, Suh M (2014) Effects of foliation and microcracks on ultrasonic anisotropy in retrograde ultramafic and metamorphic rocks at shallow depths. J Appl Geophys 109:27–35

Su XQ, Nguyen S, Haghighat E, Pietruszczak S, Labrie D, Barnichon JD, Abdi H (2009) Characterizing the mechanical behaviour ofthe Tournemire argillite. In: Norris S, Bruno J, Van Geet M, Verhoef E (eds) Radioactive Waste Confinement: Clays in Natural and Engineered Barriers. Geological Society, London, p 443

Tan X, Konietzky H, Fruhwirt T, Dan DQ (2015) Brazilian tests on transversely isotropic rocks: laboratory testing and numerical simulations. Rock Mech Rock Eng 48:1341–1351

Tien YM, Kuo MC (2001) A failure criterion for transversely isotropic rocks. Int J Rock Mech Min 38(3):399–412

Wang SL, Yin XT, Tang H, Ge XR (2010) A new approach for analyzing circular tunnel in strain-softening rock masses. Int J Rock Mech Min Sci 47:170–178

Weibull GW (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Wu SC, Xu XL (2016) A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech Rock Eng 49(5):1813–1830

Xia L, Zeng Y (2018) Parametric study of smooth joint parameters on the mechanical behavior of transversely isotropic rocks and research on calibration method. Comput Geotech 98:1–7

Xie N, Zhu QZ, Xu LH, Shao JF (2011) A micromechanics-based elastoplastic damage model for quasi-brittle rocks. Comput Geotech 38:970–977

Xu GW, He C, Su A, Chen ZQ (2018) Experimental investigation of the anisotropic mechanical behavior of phyllite under triaxial compression. Int J Rock Mech Min 104:100–112

Xu GW, He C, Chen ZQ (2019) Mechanical behavior of transversely isotropic rocks with non-continuous planar fabrics under compression tests. Comput Geotech 115:103175

Xu DP, Feng XT, Chen DF, Zhang CQ, Fan QX (2017) Constitutive representation and damage degree index for the layered rock mass excavation response in underground openings. Tunn Undergr Space Technol 64:133–145

Yang SQ, Yin PF, Huang YH, Cheng JL (2019) Strength, deformability and X-ray micro-CT observations of transversely isotropic composite rock under different confining pressures. Eng Fract Mech 214:1–20

Zeng QD, Yao J, Shao JF (2018) Numerical study of hydraulic fracture propagation accounting for rock anisotropy. J Pet Sci Eng 160:422–432

Zhang XM (2010) Experimental study on anisotropic strength properties of sandstone. Electron J Geotech Eng 15:1325–1335

Zhou YY, Feng XT, Xu DP, Fan QX (2017) An enhanced equivalent continuum model for layered rock mass incorporating bedding structure and stress dependence. Int J Rock Mech Min Sci 97:75–98

Acknowledgements

The research presented in this paper was supported by the U.S. Department of Transportation (DOT) under Grant No. 69A3551747118. The opinions expressed in this paper are those of the authors and not of the funding agencies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix I: Formulation of stiffness matrix in the global coordinate

The stiffness matrix in the global coordinate \([C]\) is expressed as

where \([Q]\) is the transformation matrix defined as follows:

where li, mi and ni (i = 1,2,3) are the directional cosines of axis x’, y’ and z’, respectively. The matrix of directional cosines [R] is

where α and β are the dip direction and dip angle of weak planes, respectively.

Thus, final form of the stiffness matrix [C] is:

where the elements of matrix [C] can be calculated based on Eqs. 4, I.2 and I.3.

Appendix II: implementation of the proposed constitutive model in FLAC 3D

The three-dimensional explicit finite difference implementation of the proposed model are outlined in this Appendix.

-

1.

Deformations of the rock matrix

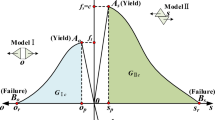

The function h(σ1, σ3) = 0, which is represented by the diagonal between the strength envelopes of fs = 0 and ft = 0 in the principal stress plane (Fig.

Determination of yielding type: a definition of h and domains used in determining yield type of the rock matrix; b definition of hj and the domains used in determining yield type of the weak planes (after Itasca [26])

18a), is defined to determine the model of yielding of rock matrix:

where

If the stress state falls within domain 1, then shear failure occurs, and the new stress is revised using the flow rule derived from gs. If the stress falls within domain 2, then tensile failure occurs, and the new stress is re-calculated adopting the flow rule derived from gt.

For shear failure, partial differentiation of Eq. 8 with damage yields

Thus, the expressions of the new stress are

where

For tensile failure, partial differentiation of Eq. 9 with damage gives

Thus, the expressions of the new stress are

where

-

2.

Deformations of the weak planes

The function hj(σ1, σ3) = 0, which is represented by the diagonal between the strength envelope of fjs = 0 and fjt = 0 in the principal stress plane (Fig. 18b), is defined:

where

If the stress falls within domain 1, then shear failure occurs, and the new stress is revised using the flow rule derived from gjs. If the stress falls within domain 2, then tensile failure occurs, and the new stress is re-calculated adopting the flow rule derived from gjt.

For shear failure, partial differentiation of Eq. 12 yields

Thus, the expressions of the new stress are

where

For tensile failure, partial differentiation of Eq. 13 gives

Thus, the expressions of the new and updated stresses are

where

The flowchart of the implementation of the proposed model is shown in Fig.

19. The main steps are as follows:

-

1.

Assume that the rock behaves elastically, and the trial stresses in global coordinate are initially obtained.

-

2.

Judge the yielding state of the rock matrix element based on the M-C criterion and modify its stress and strain if it yields. In addition, the plastic parameters of the element will be updated based on the damage evolutional law.

-

3.

Convert the stress tensor from the global coordinate to the local coordinate and judge the yielding state of the weak plane element based on the M-C criterion and modify its stress and strain if it yields. In addition, the plastic parameters of the element will be updated based on the damage evolutional law.

-

4.

Steps 1–3 are repeated until convergence of calculation is reached.

Rights and permissions

About this article

Cite this article

Xu, G., Gutierrez, M., He, C. et al. Modeling of the effects of weakness planes in rock masses on the stability of tunnels using an equivalent continuum and damage model. Acta Geotech. 16, 2143–2164 (2021). https://doi.org/10.1007/s11440-020-01087-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01087-4