Abstract

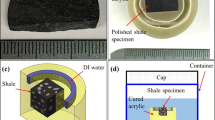

Based on the analyses of mineralogical compositions by X-ray diffraction and microstructure by optical microscopy, the Young’ modulus and hardness of a claystone were characterized by the nano-indentation technique and homogenization method. Three distinct microstructural zones are identified in the claystone: clay matrix, a composite matrix of clay and small mineral grains and imbedded quartz grains. The elastic modulus and hardness of different zones were determined by nano-indentation testing. Based on the statistical analysis of nano-indentation results, the spatial mappings and frequency distributions of elastic modulus and hardness of the different zones were obtained. The elastic moduli of main constituent phases of the claystone are then estimated from the nano-indentation tests. These values were further used for the determination of the macroscopic elastic modulus of the claystone using two different homogenization schemes: the dilute scheme and Mori–Tanaka scheme. The predicted values by the homogenization schemes are compared with experimental data obtained from conventional uniaxial compression tests.

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm FJ (2016) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation—EDX analysis. Acta Geotech 11:559–572

Abedi S, Slim M, Ulm F-J (2016) Nanomechanics of organic-rich shales: the role of thermal maturity and organic matter content on texture. Acta Geotech 11:775–787

Abou-Chakra Guery A, Cormery F, Shao JF, Kondo D (2010) A comparative micromechanical analysis of the effective properties of a geomaterial: effect of mineralogical compositions. Comput Geotech 37:585–593

Auvray C, Arnold G, Armand G (2015) Experimental study of elastic properties of different constitutions of partially saturated argillite using nanoindentation tests. Eng Geol 191:61–70

Auvray C, Lafrance N, Bartier D (2016) Elastic modulus of claystone evaluated by nano-/micro-indentation tests and meso-pression tests. J Rock Mech Geotech Eng 2:1–8

Bandini A, Berry P, Bempoard E, Sebastiani M (2012) Effects of intra-crystalline microcracks on the mechanical behavior of a marble under indentation. Int J Rock Mech Ming Sci 54:47–55

Bennett KC, Berla LA, Nix WD, Borja RI (2015) Instrumented nanoindentation and 3D mechanistic modeling of a shale at multiple scales. Acta Geotech 10:1–14

Bokko C, Ulm F-J (2008) The nano-mechanical morphology of shale. Mech Mater 40:318–337

Bokko CP, Gathier B, Ortega JA, Ulm F-J, Borge L, Abousleiman YN (2011) the nanogranular origin of friction and cohesion in shale—a strength homogenization approach to interpretation of nanoindentation results. Int J Numer Anal Methods Geomech 35:1854–1876

Constantinides G, Ulm FJ (2007) The granular nature of C–S–H. J Mech Phys Solids 55:64–90

Constantinides G, Ravi Chandran KS, Ulm FJ, Van Vlietet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng 430:189–202

Daphalapurkar NP, Wang F, Fu B, Lu H, Komanduri R (2011) Determination of mechanical properties of sand grains by nanoindentation. Exp Mech 51:719–728

Deirieh A, Ortega JA, Ulm F-J, Abousleiman Y (2012) Nanochemomechaical assessment of shale: a coupled WDS-indentation analysis. Acta Geotech 7:271–295

Donnelly E, Baker SP, Boskey AL, van der Meulen MCH (2006) Effects of surface roughness and maximum load on the mechanical properties of cancellous bone measured by Nanoindentation. J Biomed Mater Res A 77:426–435

Han Y, Abousleiman YN, Hull KL, Al-Muntasheri GA (2017) Numerical modeling of elastic spherical contact for Mohr–Coulomb type failures in micro-geomaterials. Exp Mech 57(7):1091–1105

Hodzic A, Kalyanasundaram S, Kim JK, Lowe AE, Stachurski ZH (2001) Application of nano-indentation, nano-scratch and single fibre tests in investigation of interphases in composite materials. Micron 32(8):765–775

Homand F, Shao JF, Giraud A, Auvray C (2006) Petrofabric and mechanical properties of mudstone. Earth Planet Sci 338:882–911

Hu DW, Zhang F, Shao JF, Gatmiri B (2014) Influences of mineralogy and water content on the mechanical properties of argillite. Rock Mech Rock Eng 47:157–166

Kumar V, Sondergeld CH, Rai CS (2012) Nano to macro mechanical characterization of shale, SPE paper 159804, presented in SPE annual technical conference and exhibition, San Antonio Texas, 8–10 October 2012

Lebon P, Mouroux B (1999) Knowledge of the three French underground laboratory sites. Eng Geol 52(3–4):251–256

Lee SH, Wang S, Pharr GM, Xu H (2007) Evaluation of interphase properties in a cellulose fiber-reinforced polypropylene composite by nano-indentation and finite element analysis. Compos A Appl Sci Manuf 38(6):1517–1524

Leite MH, Ferland F (2001) Determination of unconfined compressive strength and Young’s modulus of porous materials by indentation tests. Eng Geol 59:267–280

Magnet V, Auvray C, Francius G, Giraud A (2011) Determination of the matrix indentation modulus of Meuse/Haute-Marne argillite. Appl Clay Sci 52:266–269

Miller M, Bobko C, Vandamme M (2008) Surface roughness criteria for cement paste nanoindentation. Cem Concr Res 38:467–476

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall Mater 42:597–629

Paula OD, Pervukhina M, Gurevich B, Lebedev M, Martyniuk M, Delle Piane C (2010) Estimation of carbonate elastic properties from nanoindentation experiments to reduce uncertainties in reservoir modelling, Aseg Extended Abstracts 2010, Geophysical Conference. Australian Society of Exploration Geophysicists (ASEG), pp 618–625

Robinet J (2008) Minéralogie, porosité et diffusion des solutés dans l’argilite du Callovo-Oxfordien de bure (Meuse/Haute Marne, France) de l’échelle centimétrique à micrométrique. Thèse de Doctorat, Université de Poitiers, France

Shen WQ, Shao JF (2016) An incremental micro-macro model for porous geomaterials with double porosity and inclusion. Int J Plast 83:37–54

Shen WQ, Kondo D, Dormieux L, Shao JF (2013) A closed-form three scale model for ductile rocks with a plastically compressible porous matrix. Mech Mater 59:73–86

Sondergeld C, Rai CS (2013) Nanoindentation studies on shales. In: 47th US rock mechanics/geomechanics symposium, San Francisco, CA, USA, 23–26

Zaoui A (2002) Continuum micromechanics: survey. J Eng Mech ASCE 128(8):808–816

Zhang TH (2013) Micro/nano-mechanical testing technology. Science Press, Beijing

Zhang F, Xie SY, Hu DW, Shao JF, Gatmiri B (2012) Effect of water content and structural anisotropy on mechanical property of claystone. Appl Clay Sci 69:79–86

Zhang F, Hu DW, Xie SY, Shao JF (2014) Influences of temperature and water content on mechanical property of argillite. Eur J Environ Civil Eng 18:173–189

Zhu WZ, Hughes JJ, Bicanic N, Pearce CJ (2007) Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater Charact 58:1189–1198

Acknowledgements

This study has been jointly supported by the National Science Foundation of China (Grant Numbers 51579093 and 51479193) as well as the National Program on Key Basic Research Projects of China (Grant Number 2015CB057905).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, F., Guo, H., Hu, D. et al. Characterization of the mechanical properties of a claystone by nano-indentation and homogenization. Acta Geotech. 13, 1395–1404 (2018). https://doi.org/10.1007/s11440-018-0691-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-018-0691-0