Abstract

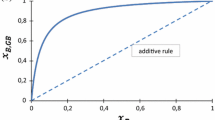

A modified theoretical model is proposed to predict the grain boundary segregation of impurity atoms during high temperature plastic deformation. The model is based on the supersaturated vacancy-impurity complex created by plastic deformation and involves quasi-thermodynamics and kinetics. Model predictions are made for phosphorus grain boundary segregation during plastic deformation in ferrite steel. The results reveal that phosphorus segregates at grain boundaries during plastic deformation. At a given temperature, under a certain strain rate the segregation increases with increasing deformation amount until reaching a steady value, and at the same deformation amount it increases with increasing strain rate. The predicted results are compared with the available experimental values, indicating that there is a reasonable agreement between the theoretical predictions and the experimental observations.

Similar content being viewed by others

References

Mintz B. The influence of composition on the hot ductility of steels and to the problem of transverse cracking. ISIJ Int, 1999, 39: 833–855

Guo A M, Wang Y H, Shen D D, et al. Influence of phosphorus on the hot ductility of 2.25CrMo steel. Mater Sci Technol, 2003, 19: 1553–1556

Song S H, Yuan Z X, Jia J, et al. The role of tin in the hot ductility deterioration of a low-carbon steel. Metall Mater Trans A, 2003, 34A: 1611–1616

Matsuoka H, Osawa K, Ono M, et al. Influence of Cu and Sn on hot ductility of steels with various C content. ISIJ Int, 1997, 37: 255–262

Mclean D. Grain Boundaries in Metals. London: Oxford University Press, 1957

Faulkner R G. Non-equilibrium grain-boundary segregation in austenitic alloys. J Mater Sci, 1981, 16: 373–383

Xu T D. A model for intergranular segregation/dilution induced by applied stress. J Mater Sci, 2000, 35: 5621–5628

Faulkner R G, Song S H, Flewitt P E J, et al. Grain boundary segregation under neutron irradiation in dilute alloys. J Nucl Mater, 1998, 255: 189–209

Nachtrab W T, Chou Y T. Grain boundary segregation of copper, tin and antimony in C-Mn steels at 900°C. J Mater Sci, 1984, 19: 2136–2144

Song S H, Zhang Q, Weng L Q. Deformation-induced non-equilibrium grain boundary segregation in dilute alloys. Mater Sci Eng A, 2008, 473: 226–232

He X L, Chu Y Y, Jonas J J. The grain boundary segregation of boron during isothermal holding. Acta Metall, 1989, 37: 2905–2916

Militzer M, Sun W P, Jonas J J. Modelling the effect of deformation-induced vacancies on segregation and precipitation. Acta Metall Mater, 1994, 42: 133–141

Zehetbauer M J, Steiner G, Schafler E, et al. Deformation induced vacancies with severe plastic deformation: Measurements and modelling. Mater Sci Forum, 2006, 503–504: 57–64

Lindgren L E, Domkin K, Hansson S. Dislocations, vacancies and solute diffusion in physical based plasticity model for AISI 316L. Mech Mater, 2008, 40: 907–919

Murty K, Detemple K, Kanert O, et al. In-situ nuclear magnetic resonance investigation of strain, temperature, and strain-rate variations of deformation-induced vacancy concentration in aluminum. Metall Mater Trans A, 1998, 29: 153–159

Williams T M, Stoneham A M, Harries D R. The segregation of boron to grain boundaries in solution-treated Type 316 austenitic stainless steel. Metal Sci, 1976, 10: 14–19

Xu T D, Song S H. A kinetic model of non-equilibrium grainboundary segregation. Acta Metall, 1989, 37: 2499–2506

Chen X M, Song S H. Unpublished work. Shenzhen Graduate School, Harbin Institute of Technology, Shenzhen, China

Xu T D, Cheng B Y. Kinetics of non-equilibrium grain-boundary segregation. Prog Mater Sci, 2004, 49: 109–208

Laasraoui A, Jonas J J. Prediction of steel flow stresses at high temperatures and strain rates. Metall Mater Trans A, 1991, 22A: 1545–1558

Bailey J E, Hirsch P B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos Mag A, 1960, 5: 485–497

Chen X M, Song S H. Plastic deformation-induced phosphorus segregation to ferrite grain boundaries in an interstitial free steel. Mater Sci Eng A, 2010, 527: 7580–7584

Latella B A, Humphries S R. Young’s modulus of a 2.25Cr-1Mo steel at elevated temperature. Scr Mater, 2004, 51: 635–639

Zehetbauer M, Mikulowski B. Deformation induced vacancies and work hardening of metals. Arch Metall, 2001, 46: 65–80

Vincent E, Becquart C S, Domain C. Solute interaction with point defects in α-Fe during thermal ageing: A combined ab initio and atomic kinetic Monte Carlo approach. J Nucl Mater, 2006, 351: 88–99

Faulkner R G, Song S H, Flewitt P E J. Determination of impurity-point defect binding energies in alloys. Mater Sci Technol, 1996, 12: 904–910

Song S H, Faulkner R G, Flewitt P E J. Quenching and tempering induced molybdenum segregation to grain boundaries in a 2.25Cr1Mo steel. Mater Sci Eng A, 2000, 281: 23–27

Song S H, Weng L Q. Diffusion of solute-vacancy complexes in alloys. Mater Sci Technol, 2005, 21: 305–310

Yoshie A, Morikawa H, Onoe Y, et al. Formulation of static recrystallization of austenite in hot rolling process of steel plate. Trans ISIJ, 1987, 27: 425–431

Lejcek P. Grain Boundary segregation in Metals. Berlin Heidelberg: Springer, 2010

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Song, S. Modelling of grain boundary impurity segregation during high temperature plastic deformation. Sci. China Phys. Mech. Astron. 54, 872–877 (2011). https://doi.org/10.1007/s11433-011-4311-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-011-4311-3