Abstract

As electronic devices continue to evolve toward miniaturization and integration, traditional thermal interface materials (TIMs) are no longer able to meet the ever-tougher thermal management challenges. Owing to their high thermal conductivity and excellent conformability within a highly confined space, liquid metals have great potential for advanced thermal management in various cutting-edge devices and have become a key candidate for next-generation high-performance TIMs. In addition to already known materials, such as liquid metal alloy TIMs, particle-filled liquid metal TIMs, and liquid metal-filled TIMs, more TIMs are still being developed. This review presents a systematic classification of the liquid metal TIMs developed thus far, interprets the fundamental mechanisms underlying material innovation and in-situ heat transfer enhancement, and comparatively evaluates their respective advantages and shortcomings. Subsequently, a series of representative theoretical models for characterizing the thermal conductivities of composites are summarized, and the limits of the thermal conductivity of liquid metal TIMs are predicted to guide practical R&D efforts. To address the urgent need for higher-performance TIMs to overcome future thermal management challenges of electronic devices, a roadmap is outlined for the development of high-performance liquid metal TIMs, and a strategy for running these technologies is demonstrated.

Similar content being viewed by others

References

Liu J. Micro/Nano Scale Heat Transfer (in Chinese). Beijing: Science Press, 2001. 6–25

Li M, Li L, Hou X, et al. Synergistic effect of carbon fiber and graphite on reducing thermal resistance of thermal interface materials. Compos Sci Tech, 2021, 212: 108883

Liu J. Advanced Liquid Metal Cooling for Chip, Device and System (in Chinese). Shanghai: Shanghai Scientific & Technical Publishers, 2020. 2–4

Hansson J, Nilsson T M J, Ye L, et al. Novel nanostructured thermal interface materials: A review. Int Mater Rev, 2018, 63: 22–45

Hansson J, Zandén C, Ye L, et al. Review of current progress of thermal interface materials for electronics thermal management applications. In: Proceedings of 2016 IEEE 16th International Conference on Nanotechnology (IEEE-NANO). Sendai, 2016. 371–374

Bahru R, Zamri M F M A, Shamsuddin A H, et al. A review of thermal interface material fabrication method toward enhancing heat dissipation. Int J Energy Res, 2021, 45: 3548–3568

Chung D D L. Thermal interface materials. J Mater Eng Performance, 2001, 10: 56–59

Deng Y, Zhang M, Jiang Y, et al. Two-stage multichannel liquid-metal cooling system for thermal management of high-heat-flux-density chip array. Energy Convers Manage, 2022, 259: 115591

Yang X H, Liu J. Advances in liquid metal science and technology in chip cooling and thermal management. Adv Heat Transfer, 2018, 50: 187–300

Khoshmanesh K, Tang S Y, Zhu J Y, et al. Liquid metal enabled microfluidics. Lab Chip, 2017, 17: 974–993

Gui L, Gao M, Ye Z, et al. Liquid Metal Microfluidics (in Chinese). Shanghai: Shanghai Scientific & Technical Publishers, 2021

Wang X, Liu J. Recent advancements in liquid metal flexible printed electronics: Properties, technologies, and applications. Micromachines, 2016, 7: 206

Hao X P, Li C Y, Zhang C W, et al. Self-shaping soft electronics based on patterned hydrogel with stencil-printed liquid metal. Adv Funct Mater, 2021, 31: 2105481

Gao Y, Li H, Liu J. Direct writing of flexible electronics through room temperature liquid metal ink. PLoS ONE, 2012, 7: e45485

Majidi C. Fluid-like soft machines with liquid metal. Matter, 2021, 4: 336–337

Yan J, Lu Y, Chen G, et al. Advances in liquid metals for biomedical applications. Chem Soc Rev, 2018, 47: 2518–2533

Lim T, Kim M, Akbarian A, et al. Conductive polymer enabled biostable liquid metal electrodes for bioelectronic applications. Adv Healthcare Mater, 2022, 11: 2102382

Gao W, Wang Y, Wang Q, et al. Liquid metal biomaterials for biomedical imaging. J Mater Chem B, 2022, 10: 829–842

Xie W, Allioux F M, Ou J Z, et al. Gallium-based liquid metal particles for therapeutics. Trends Biotechnol, 2021, 39: 624–640

Zheng Y, He Z, Gao Y, et al. Direct desktop printed-circuits-on-paper flexible electronics. Sci Rep, 2013, 3: 1786

Liu J, Wang L. Liquid Metal 3D Printing: Principles and Applications (in Chinese). Shanghai: Shanghai Scientific & Technical Publishers, 2019

Wang L, Liu J. Liquid phase 3D printing for quickly manufacturing conductive metal objects with low melting point alloy ink. Sci China Tech Sci, 2014, 57: 1721–1728

Guo S, Wang P, Zhang J, et al. Flexible liquid metal coil prepared for electromagnetic energy harvesting and wireless charging. Front Energy, 2019, 13: 474–482

Li P, Liu J. Harvesting low grade heat to generate electricity with thermosyphon effect of room temperature liquid metal. Appl Phys Lett, 2011, 99: 094106

Liu J, Sheng L, He Z Z. Liquid Metal Soft Machines: Principles and Applications. Singapore: Springer, 2019. 15–18

Liu J, Yi L T. Liquid Metal Biomaterials. Singapore: Springer, 2018. 7–105

Yu L J. Experimental study on liquid metal remote cooling method for high power density LEDs (in Chinese). Dissertation for the Doctoral Degree. Beijing: Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, 2015. 27

Zhang X D. Thermo-hydrodynamic characteristic of room temperature liquid metal driven by electromagnetic field and its applications (in Chinese). Dissertation for the Doctoral Degree. Beijing: Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, 2021. 44

Morley N B, Burris J, Cadwallader L C, et al. GaInSn usage in the research laboratory. Rev Sci Instruments, 2008, 79: 056107

Shamberger P J, Bruno N M. Review of metallic phase change materials for high heat flux transient thermal management applications. Appl Energy, 2020, 258: 113955

Fu J, Zhang C, Liu T, et al. Room temperature liquid metal: Its melting point, dominating mechanism and applications. Front Energy, 2020, 14: 81–104

Fan L W, Wu Y Y, Xiao Y Q, et al. Transient performance of a thermal energy storage-based heat sink using a liquid metal as the phase change material. Appl Thermal Eng, 2016, 109: 746–750

Yang X H, Tan S C, Ding Y J, et al. Experimental and numerical investigation of low melting point metal based PCM heat sink with internal fins. Int Commun Heat Mass Transfer, 2017, 87: 118–124

Zhou K, Tang Z, Lu Y, et al. Composition, microstructure, phase constitution and fundamental physicochemical properties of low-melting-point multi-component eutectic alloys. J Mater Sci Tech, 2017, 33: 131–154

Ge H, Li H, Mei S, et al. Low melting point liquid metal as a new class of phase change material: An emerging frontier in energy area. Renew Sustain Energy Rev, 2013, 21: 331–346

Deng Y, Liu J. Heat spreader based on room-temperature liquid metal. J Thermal Sci Eng Appl, 2012, 4: 024501

Huang Y L, Chung C K, Lin C F, et al. LTD PKG. (Liquid thermal dissipation package) technology. In: Proceedings of 2019 14th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT). Taipei, 2019. 146–149

Li T, Lv Y G, Liu J, et al. A powerful way of cooling computer chip using liquid metal with low melting point as the cooling fluid. Forsch Ingenieurwes, 2006, 70: 243–251

Xiang X, Liu W, Fan A. Comparison between the cooling performances of micro-jet impingement systems using liquid metal and water as coolants for high power electronics. Int J Thermal Sci, 2021, 173: 107375

Zhang X D, Yang X H, Zhou Y X, et al. Experimental investigation of galinstan based minichannel cooling for high heat flux and large heat power thermal management. Energy Convers Manage, 2019, 185: 248–258

Roy C K, Bhavnani S, Hamilton M C, et al. Accelerated aging and thermal cycling of low melting temperature alloys as wet thermal interface materials. MicroElectron Reliability, 2015, 55: 2698–2704

Gao Y, Liu J. Gallium-based thermal interface material with high compliance and wettability. Appl Phys A, 2012, 107: 701–708

Deng Y G, Liu J. Corrosion development between liquid gallium and four typical metal substrates used in chip cooling device. Appl Phys A, 2009, 95: 907–915

Zhao L, Liu H, Chen X, et al. Liquid metal nano/micro-channels as thermal interface materials for efficient energy saving. J Mater Chem C, 2018, 6: 10611–10617

Furman B, Iyengar M K, Lauro P A, et al. Heat dissipation assembly for chip cooling, includes heat sink(s), chip(s), and low melt solder(s) positioned between chip and heat sink. U.S. Patent, US2008265404-A1; US7898076-B2, 2008-10-30

Gao Y X, Liu J, Wang X P, et al. Investigation on the performance of gallium based liquid metal thermal interface materials. J Eng Thermophys, 2017, 38: 1077–1081

Huang Y L, Chung C K, Lin C F, et al. Highly thermal dissipation for large HPC package using liquid metal materials. In: Proceedings of 2021 IEEE 71st Electronic Components and Technology Conference (ECTC). San Diego, 2021. 1102–1108

Ndieguene A, Albert P, Fortin C, et al. Eternal packages: Liquid metal flip chip devices. In: Proceedings of 2016 IEEE 66th Electronic Components and Technology Conference (ECTC). Las Vegas, 2016. 580–587

Ji Y, Yan H, Xiao X, et al. Excellent thermal performance of gallium-based liquid metal alloy as thermal interface material between aluminum substrates. Appl Thermal Eng, 2020, 166: 114649

Stagon S, Blaser N, Bevill G, et al. Nanoscale barrier layers to enable the use of gallium-based thermal interface materials with aluminum. J Materi Eng Perform, 2020, 29: 5132–5138

Yan H, Zhang W, Qian F, et al. Wettability and thermal performance of Ga62.5In21.5Sn16 liquid metal alloy on W-coated Cu substrates with varying film thickness. Int J Thermal Sci, 2022, 172: 107333

Yan H, Yan J, Zhao G. Heat transfer of liquid metal alloy on copper plate deposited with film of different surface free energy. Chin Phys B, 2019, 28: 114401

Yan H, Ji Y, Yan J. Effect of metal buffer layer on the thermal interface performance of liquid metal alloy on copper plate. J Mater Sci-Mater Electron, 2019, 30: 15766–15771

Wang X, Li H, Yao R, et al. Thermal contact resistance optimization of press-pack IGBT device based on liquid metal thermal interface material. IEEE Trans Power Electron, 2022, 37: 5411–5421

Wang Q Y, Cai C L, Deng Z S. Experimental investigation on the heat dissipation performance of bismuth-based alloy thermal conductive sheet. Mater Sci Forum, 2021, 1035: 655–662

Huang K, Qiu W, Ou M, et al. An anti-leakage liquid metal thermal interface material. RSC Adv, 2020, 10: 18824–18829

Nguena E, Danovitch D, Sylvestre J, et al. Gallium liquid metal embrittlement of tin-based solder alloys. Metall Mater Trans A, 2020, 51: 6222–6233

Nguena E, Danovitch D, Sylvestre J, et al. A kinetic study of liquid gallium diffusion in a tin-based solder alloy and its role in solder embrittlement. J Mater Sci, 2021, 56: 7129–7141

Xia Z, Shi Y, Chen Z. Evaluation on the characteristics of tin-silver-bismuth solder. J Materi Eng Perform, 2002, 11: 107–111

Muhamad M, Masri M N, Nazeri M, et al. The effect of bismuth addition on Sn−Ag−Cu lead-free solder properties: A short review. IOP Conf Ser-Earth Environ Sci, 2020, 596: 012007

Liu J, Rottman P, Dutta S, et al. Next generation materials for thermal interface and high density energy storage applications via liquid phase sintering. In: Proceedings of 2009 11th Electronics Packaging Technology Conference. Singapore, 2009. 506–511

Ma K Q, Liu J. Nano liquid-metal fluid as ultimate coolant. Phys Lett A, 2007, 361: 252–256

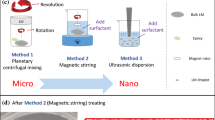

Kong W, Wang Z, Wang M, et al. Oxide-mediated formation of chemically stable tungsten-liquid metal mixtures for enhanced thermal interfaces. Adv Mater, 2019, 31: 1904309

Kong W, Wang Z, Casey N, et al. High thermal conductivity in multiphase liquid metal and silicon carbide soft composites. Adv Mater Inter, 2021, 8: 2100069

Wang H, Xing W, Chen S, et al. Liquid metal composites with enhanced thermal conductivity and stability using molecular thermal linker. Adv Mater, 2021, 33: 2103104

Hong S J, Suryanarayana C. Mechanism of low-temperature θ-CuGa2 phase formation in Cu-Ga alloys by mechanical alloying. J Appl Phys, 2004, 96: 6120–6126

Ralphs M I, Kemme N, Vartak P B, et al. In situ alloying of thermally conductive polymer composites by combining liquid and solid metal microadditives. ACS Appl Mater Interfaces, 2018, 10: 2083–2092

Parekh D P, Fancher C M, Mohammed M G, et al. Liquid-solid mixtures of Ga metal infused with Cu microparticles and nanoparticles for microscale and nanoscale patterning of solid metals at room temperature. ACS Appl Nano Mater, 2020, 3: 12064–12070

Li G, Ji Y L, Sun Y Q, et al. Experimental investigation on the thermal performance of liquid metal filled with copper particles as thermal interface material (in Chinese). J Xi’an Jiaotong Univ, 2016, 50: 61–65, 73

Li G, Ji Y L, Wu M K, et al. Highly conductive thermal paste of liquid metal alloy dispersed with copper particles. Washington DC: American Society of Mechanical Engineers, 2016. 7374

Tang J, Zhao X, Li J, et al. Gallium-based liquid metal amalgams: Transitional-state metallic mixtures (TransM2ixes) with enhanced and tunable electrical, thermal, and mechanical properties. ACS Appl Mater Interfaces, 2017, 9: 35977–35987

Ki S, Shim J, Oh S, et al. Gallium-based liquid metal alloy incorporating oxide-free copper nanoparticle clusters for high-performance thermal interface materials. Int J Heat Mass Transfer, 2021, 170: 121012

Ki S, Shim J, Oh S, et al. Rapid enhancement of thermal conductivity by incorporating oxide-free copper nanoparticle clusters for highly conductive liquid metal-based thermal interface materials. In: Proceedings of 2021 IEEE 71st Electronic Components and Technology Conference (ECTC). San Diego, 2021. 601–606

Deng Z S, Liu J. Liquid Metal Based Advanced Chip Cooling Technologies (in Chinese). Shanghai: Shanghai Scientific & Technical Publishers, 2020. 130–146

Xing W, Wang H, Chen S, et al. Gallium-based liquid metal composites with enhanced thermal and electrical performance enabled by structural engineering of filler. Adv Eng Mater, 2022, 24: 2101678

Wang X, Yao W, Guo R, et al. Soft and moldable Mg-doped liquid metal for conformable skin tumor photothermal therapy. Adv Healthcare Mater, 2018, 7: 1800318

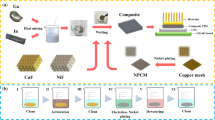

Lin Z, Liu H, Li Q, et al. High thermal conductivity liquid metal pad for heat dissipation in electronic devices. Appl Phys A, 2018, 124: 368

Fang X X, Zheng X L, Li G, et al. Study of heat transfer characteristics of liquid metal reinforced interface by steady-state method. Cryogenics, 2020, 48–53

Ma X F, Li G, Zheng X L, et al. Thermal property enhancement of liquid metal used as thermal interface material by mixing magnetic particles. In: Proceedings of the ASME 2019 6th International Conference on Micro/Nanoscale Heat and Mass Transfer. Dalian, American Society of Mechanical Engineers, 2019. 4155

Lu Y, Yu D, Dong H, et al. Dynamic leakage-free liquid metals. Adv Funct Mater, 2023, 33: 2210961

Lyon R N E. Liquid-Metals Handbook. Washington: U.S. Government Printing Office, 1952. 170–171

Ouyang Y, Bai L, Tian H, et al. Recent progress of thermal conductive ploymer composites: Al2O3 fillers, properties and applications. Compos Part A-Appl Sci Manufacturing, 2022, 152: 106685

Yu H, Li L, Kido T, et al. Thermal and insulating properties of epoxy/aluminum nitride composites used for thermal interface material. J Appl Polym Sci, 2012, 124: 669–677

Hwang Y, Kim M, Kim J. Effect of Al2O3 coverage on SiC particles for electrically insulated polymer composites with high thermal conductivity. RSC Adv, 2014, 4: 17015–17021

Luo X, Zhang Y, Zandén C, et al. Novel thermal interface materials: Boron nitride nanofiber and indium composites for electronics heat dissipation applications. J Mater Sci-Mater Electron, 2014, 25: 2333–2338

Lupoi R, Lupton T, Jenkins R, et al. Direct manufacturing of diamond composite coatings onto silicon wafers and heat transfer performance. CIRP Ann, 2018, 67: 185–188

Ping L, Hou P X, Liu C, et al. Vertically aligned carbon nanotube arrays as a thermal interface material. APL Mater, 2019, 7: 020902

Sun P, Liu B, You Z, et al. Graphene/copper nanoparticles as thermal interface materials. ACS Appl Nano Mater, 2022, 5: 3450–3457

Zhao L, Chu S, Chen X, et al. Efficient heat conducting liquid metal/CNT pads with thermal interface materials. Bull Mater Sci, 2019, 42: 192

Park Y G, Min H, Kim H, et al. Three-dimensional, high-resolution printing of carbon nanotube/liquid metal composites with mechanical and electrical reinforcement. Nano Lett, 2019, 19: 4866–4872

Wei S, Yu Z F, Zhou L J, et al. Investigation on enhancing the thermal conductance of gallium-based thermal interface materials using chromium-coated diamond particles. J Mater Sci-Mater Electron, 2019, 30: 7194–7202

Xing W, Chen S, Wang H, et al. Construction of 3D conductive network in liquid gallium with enhanced thermal and electrical performance. Adv Mater Technologies, 2021, 7: 2100970

Wang C, Gong Y, Cunning B V, et al. A general approach to composites containing nonmetallic fillers and liquid gallium. Sci Adv, 2021, 7: eabe3767

Gao J, Yan Q, Tan X, et al. Surface modification using polydopamine-coated liquid metal nanocapsules for improving performance of graphene paper-based thermal interface materials. Nanomaterials, 2021, 11: 1236

Zheng J, Li X, Xing W, et al. Paste-like recyclable Ga liquid metal phase change composites loaded with miscible Ga2O3 particles for transient cooling of portable electronics. Appl Thermal Eng, 2022, 213: 118766

Mei S, Gao Y, Deng Z, et al. Thermally conductive and highly electrically resistive grease through homogeneously dispersing liquid metal droplets inside methyl silicone oil. J Electron Packaging, 2014, 136: 011009

Mei S F, Gao Y X, Deng Z S, et al. Experimental investigation on the heat dissipation performance of liquid metal filled thermal grease. J Eng Thermophys, 2015, 36: 624–626

Fan P, Sun Z, Wang Y, et al. Nano liquid metal for the preparation of a thermally conductive and electrically insulating material with high stability. RSC Adv, 2018, 8: 16232–16242

Uppal A, Ralphs M, Kong W, et al. Pressure-activated thermal transport via oxide shell rupture in liquid metal capsule beds. ACS Appl Mater Interfaces, 2020, 12: 2625–2633

Uppal A, Kong W, Rana A, et al. Enhancing thermal transport in silicone composites via bridging liquid metal fillers with reactive metal co-fillers and matrix viscosity tuning. ACS Appl Mater Interfaces, 2021, 13: 43348–43355

Shah N U H, Kong W, Casey N, et al. Gallium oxide-stabilized oil in liquid metal emulsions. Soft Matter, 2021, 17: 8269–8275

Jeong S H, Chen S, Huo J, et al. Mechanically stretchable and electrically insulating thermal elastomer composite by liquid alloy droplet embedment. Sci Rep, 2015, 5: 18257

Zhu L, Chen Y, Shang W, et al. Anisotropic liquid metal-elastomer composites. J Mater Chem C, 2019, 7: 10166–10172

Bartlett M D, Kazem N, Powell-Palm M J, et al. High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proc Natl Acad Sci USA, 2017, 114: 2143–2148

Liu H, Liu H, Lin Z, et al. AlN/Ga-based liquid metal/PDMS ternary thermal grease for heat dissipation in electronic devices. Rare Metal Mater Eng, 2018, 47: 2668–2674

Ge X, Zhang J, Zhang G, et al. Low melting-point alloy-boron nitride nanosheet composites for thermal management. ACS Appl Nano Mater, 2020, 3: 3494–3502

Ralphs M, Kong W, Wang R Y, et al. Thermal conductivity enhancement of soft polymer composites through magnetically induced percolation and particle-particle contact engineering. Adv Mater Interfaces, 2019, 6: 1801857

Li J, Ma Q, Gao S, et al. Liquid bridge: liquid metal bridging spherical BN largely enhances the thermal conductivity and mechanical properties of thermal interface materials. J Mater Chem C, 2022, 10: 6736–6743

Jia X, Liu B, Li S, et al. High-performance non-silicone thermal interface materials based on tunable size and polymorphic liquid metal inclusions. J Mater Sci, 2022, 57: 11026–11045

Hua Q Y, Yu G Y, Hong W Y R, et al. Stretchable thermal interface material with both thermal conduction and self-healing functions based on liquid metal/polysulfide rubber. Polymer Mater Sci Eng, 2021, 37: 153–161

Liu C, Xu H, Yang J, et al. Temperature adjustable thermal conductivity and thermal contact resistance for liquid metal/paraffin/olefin block copolymer interface material. Int J Thermal Sci, 2022, 179: 107679

Guo C, Li Y, Xu J H, et al. A thermally conductive interface material with tremendous and reversible surface adhesion promises durable cross-interface heat conduction. Mater Horiz, 2022, 9: 1690–1699

Chen P, Ge X, Zhang Z, et al. Silicone-based thermally conductive gel fabrication via hybridization of low-melting-point alloy-hexagonal boron nitride-graphene oxide. Nanomaterials, 2023, 13: 490

Garnett J C M, Larmor J. Colours in metal glasses and in metallic films. Proc R Soc Lond, 1904, 73: 443–445

Hasselman D P H, Johnson L F. Effective thermal conductivity of composites with interfacial thermal barrier resistance. J Composite Mater, 1987, 21: 508–515

Bruggeman D A G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann Phys, 1935, 416: 636–664

Wang B X, Zhou L P, Peng X F. A fractal model for predicting the effective thermal conductivity of liquid with suspension of nanoparticles. Int J Heat Mass Transfer, 2003, 46: 2665–2672

Prasher R. Thermal interface materials: Historical perspective, status, and future directions. Proc IEEE, 2006, 94: 1571–1586

Shen M X, Cui Y X, He J, et al. Thermal conductivity model of filled polymer composites. Int J Miner Metall Mater, 2011, 18: 623–631

Chu K, Jia C, Tian W, et al. Thermal conductivity of spark plasma sintering consolidated SiCp/Al composites containing pores: Numerical study and experimental validation. Compos Part A-Appl Sci Manufacturing, 2010, 41: 161–167

Bhatt H, Donaldson K Y, Hasselman D P H, et al. Role of the interfacial thermal barrier in the effective thermal diffusivity/conductivity of SiC-fiber-reinforced reaction-bonded silicon nitride. J Am Ceramic Soc, 1990, 73: 312–316

Benveniste Y. Effective thermal conductivity of composites with a thermal contact resistance between the constituents: Nondilute case. J Appl Phys, 1987, 61: 2840–2843

Nan C W, Birringer R, Clarke D R, et al. Effective thermal conductivity of particulate composites with interfacial thermal resistance. J Appl Phys, 1997, 81: 6692–6699

Felske J D. Effective thermal conductivity of composite spheres in a continuous medium with contact resistance. Int J Heat Mass Transfer, 2004, 47: 3453–3461

Landauer R. Electrical conductivity in inhomogeneous media. In: Proceedings of AIP Conference. Columbus, 1978. 2–45

Every A G, Tzou Y, Hasselman D P H, et al. The effect of particle size on the thermal conductivity of ZnS/diamond composites. Acta Metall Mater, 1992, 40: 123–129

Vysotsky V V, Roldughin V I. Aggregate structure and percolation properties of metal-filled polymer films. Colloids Surfs A-Physicochem Eng Aspects, 1999, 160: 171–180

Wang J J, Yi X S. Effects of interfacial thermal barrier resistance and particle shape and size on the thermal conductivity of AlN/PI composites. Compos Sci Tech, 2004, 64: 1623–1628

Tavangar R, Molina J M, Weber L. Assessing predictive schemes for thermal conductivity against diamond-reinforced silver matrix composites at intermediate phase contrast. Scripta Mater, 2007, 56: 357–360

Chiew C, Malakooti M H. A double inclusion model for liquid metal polymer composites. Compos Sci Tech, 2021, 208: 108752

Jung J, Jeong S H, Hjort K, et al. Investigation of thermal conductivity for liquid metal composites using the micromechanics-based mean-field homogenization theory. Soft Matter, 2020, 16: 5840–5847

Zhang X D, Zhang Z T, Wang H Z, et al. Thermal interface materials with high thermal conductivity and low young’s modulus using a solid-liquid metal codoping strategy. ACS Appl Mater Interfaces, 2023, 15: 3534–3542

Ji Y, Li G, Chang C, et al. Investigation on carbon nanotubes as thermal interface material bonded with liquid metal alloy. J Heat Transfer, 2015, 137: 091017

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Deng, Z. Roadmap towards new generation liquid metal thermal interface materials. Sci. China Technol. Sci. 66, 1530–1550 (2023). https://doi.org/10.1007/s11431-023-2379-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2379-6