Abstract

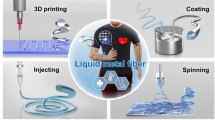

The smart clothes emerge as a new generation of garments developed in the scientific and industrial communities, gaining increasing attention due to the real-time responses to exterior environments or stimuli. Owing to the unique merits of liquid metal (LM) such as excellent fluidity, high conductivity and intrinsic stretchability in ambient environment, LM-based smart textiles are widely applied in chemical sensors, wearable electronics and stretchable devices. This review is dedicated to summarizing different preparation methods and functions of LM-based textiles (LMTs) for smart clothes, which consists of the design principles, the fabrication strategies, the working mechanism of LMTs, and the tremendous applications sorted by the features of LM. Typical methods of the synthesis to build LMTs are divided into two domains classified by spatial arrangement. One strategy is the exterior decoration with LM, while the other is interior encapsulation of LM. Moreover, the primary applications of LMT-based smart clothes have been illustrated through the utilization of the properties of LM matrix. The categorization of LMTs aims to facilitate further investigation and research in the future development of LM-based smart clothes. Finally, future prospects and opportunities of LMT-based smart clothes are discussed in this area.

Similar content being viewed by others

References

Wang H, Li R, Cao Y, et al. Liquid metal fibers. Adv Fiber Mater, 2022, 4: 987–1004

Zhu M, Kikutani T, Liu T, et al. Fiber changes our life. Adv Fiber Mater, 2019, 1: 1–2

Lin R, Kim H J, Achavananthadith S, et al. Digitally-embroidered liquid metal electronic textiles for wearable wireless systems. Nat Commun, 2022, 13: 2190

Song J, Chen S, Sun L, et al. Mechanically and electronically robust transparent organohydrogel fibers. Adv Mater, 2020, 32: 1906994

Wang C, Li X, Gao E, et al. Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv Mater, 2016, 28: 6640–6648

Lai M F, Huang C H, Lou C W, et al. Effects of different structures on the functional and mechanical properties of elastic knitted fabrics. J Textile Institute, 2022, 113: 332–340

Weng W, Chen P, He S, et al. Smart electronic textiles. Angew Chem Int Ed, 2016, 55: 6140–6169

Shi J, Liu S, Zhang L, et al. Smart textile-integrated microelectronic systems for wearable applications. Adv Mater, 2019, 32: 1901958

Lee J, Kwon H, Seo J, et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv Mater, 2015, 27: 2433–2439

Luo Y, Li Y, Sharma P, et al. Learning human-environment interactions using conformal tactile textiles. Nat Electron, 2021, 4: 193–201

Zhang L, Liu Z, Wu X, et al. A highly efficient self-healing elastomer with unprecedented mechanical properties. Adv Mater, 2019, 31: 1901402

Shi X, Zuo Y, Zhai P, et al. Large-area display textiles integrated with functional systems. Nature, 2021, 591: 240–245

Wang L, Zhang F, Liu Y, et al. Shape memory polymer fibers: Materials, structures, and applications. Adv Fiber Mater, 2022, 4: 5–23

Tonazzini A, Mintchev S, Schubert B, et al. Variable stiffness fiber with self-healing capability. Adv Mater, 2016, 28: 10142–10148

Wang Y, Niu W, Lo C, et al. Interactively full-color changeable electronic fiber sensor with high stretchability and rapid response. Adv Funct Mater, 2020, 30: 2000356

Lin R, Kim H J, Achavananthadith S, et al. Wireless battery-free body sensor networks using near-field-enabled clothing. Nat Commun, 2020, 11: 444

Persson N K, Martinez J G, Zhong Y, et al. Actuating textiles: Next generation of smart textiles. Adv Mater Technol, 2018, 3: 1700397

Guan Y, Agra-Kooijman D M, Fu S, et al. Responsive liquid-crystalclad fibers for advanced textiles and wearable sensors. Adv Mater, 2019, 31: 1902168

Jia T, Wang Y, Dou Y, et al. Moisture sensitive smart yarns and textiles from self-balanced silk fiber muscles. Adv Funct Mater, 2019, 29: 1808241

Shi Q, Sun J, Hou C, et al. Advanced functional fiber and smart textile. Adv Fiber Mater, 2022, 1: 3–31

Ma W, Zhang Y, Pan S, et al. Smart fibers for energy conversion and storage. Chem Soc Rev, 2021, 50: 7009–7061

Ghahremani Honarvar M, Latifi M. Overview of wearable electronics and smart textiles. J Textile Institute, 2017, 108: 631–652

Li X, Chen S, Peng Y, et al. Materials, preparation strategies, and wearable sensor applications of conductive fibers: A review. Sensors, 2022, 22: 3028

Liu H, Li Q, Bu Y, et al. Stretchable conductive nonwoven fabrics with self-cleaning capability for tunable wearable strain sensor. Nano Energy, 2019, 66: 104143

Wong Y C, Ang B C, Haseeb A S M A, et al. Conducting polymers as chemiresistive gas sensing materials: A Review. J Electrochem Soc, 2020, 167: 037503

Zhou J, Xu X, Xin Y, et al. Coaxial thermoplastic elastomer-wrapped carbon nanotube fibers for deformable and wearable strain sensors. Adv Funct Mater, 2018, 28: 1705591

Lima R M A P, Alcaraz-Espinoza J J, da Silva Jr. F A G, et al. Multifunctional wearable electronic textiles using cotton fibers with polypyrrole and carbon nanotubes. ACS Appl Mater Interfaces, 2018, 10: 13783–13795

Ou M, Qiu W, Huang K, et al. Ultrastretchable liquid metal electrical conductors built-in cloth fiber networks for wearable electronics. ACS Appl Mater Interfaces, 2019, 12: 7673–7678

Liu H, Xin Y, Lou Y, et al. Liquid metal gradient fibers with reversible thermal programmability. Mater Horiz, 2020, 7: 2141–2149

Leber A, Dong C, Chandran R, et al. Soft and stretchable liquid metal transmission lines as distributed probes of multimodal deformations. Nat Electron, 2020, 3: 316–326

Bartlett M D, Kazem N, Powell-Palm M J, et al. High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proc Natl Acad Sci USA, 2017, 114: 2143–2148

Chen G, Wang H, Guo R, et al. Superelastic EGaIn composite fibers sustaining 500% tensile strain with superior electrical conductivity for wearable electronics. ACS Appl Mater Interfaces, 2020, 12: 6112–6118

Zhu S, So J H, Mays R, et al. Ultrastretchable fibers with metallic conductivity using a liquid metal alloy core. Adv Funct Mater, 2013, 23: 2308–2314

Li H, Liu J. Revolutionizing heat transport enhancement with liquid metals: Proposal of a new industry of water-free heat exchangers. Front Energy, 2011, 5: 20–42

Wang H, Wang C, Jian M, et al. Superelastic wire-shaped supercapacitor sustaining 850% tensile strain based on carbon nanotube@graphene fiber. Nano Res, 2018, 11: 2347–2356

Guo R, Wang H, Chen G, et al. Smart semiliquid metal fibers with designed mechanical properties for room temperature stimulus response and liquid welding. Appl Mater Today, 2020, 20: 100738

Lin Y, Gordon O, Khan M R, et al. Vacuum filling of complex microchannels with liquid metal. Lab Chip, 2017, 17: 3043–3050

Cooper C B, Arutselvan K, Liu Y, et al. Stretchable capacitive sensors of torsion, strain, and touch using double helix liquid metal fibers. Adv Funct Mater, 2017, 27: 1605630

Yu Y, Guo J, Ma B, et al. Liquid metal-integrated ultra-elastic conductive microfibers from microfluidics for wearable electronics. Sci Bull, 2020, 65: 1752–1759

Gao Y, Li H, Liu J. Direct writing of flexible electronics through room temperature liquid metal ink. PLoS ONE, 2012, 7: e45485

Zheng L, Zhu M, Wu B, et al. Conductance-stable liquid metal sheath-core microfibers for stretchy smart fabrics and self-powered sensing. Sci Adv, 2021, 7: eabg4041

Sha Z, Boyer C, Li G, et al. Electrospun liquid metal/PVDF-HFP nanofiber membranes with exceptional triboelectric performance. Nano Energy, 2022, 92: 106713

Gui H, Tan S C, Wang Q, et al. Spraying printing of liquid metal electronics on various clothes to compose wearable functional device. Sci China Tech Sci, 2017, 60: 306–316

Yang Y, Sun N, Wen Z, et al. Liquid-metal-based super-stretchable and structure-designable triboelectric nanogenerator for wearable electronics. ACS Nano, 2018, 12: 2027–2034

Guo R, Wang H, Sun X, et al. Semiliquid metal enabled highly conductive wearable electronics for smart fabrics. ACS Appl Mater Interfaces, 2019, 11: 30019–30027

Ma Z, Huang Q, Xu Q, et al. Permeable superelastic liquid-metal fibre mat enables biocompatible and monolithic stretchable electronics. Nat Mater, 2021, 20: 859–868

Das P, Ganguly S, Perelshtein I, et al. Acoustic green synthesis of graphene-gallium nanoparticles and PEDOT:PSS hybrid coating for textile to mitigate electromagnetic radiation pollution. ACS Appl Nano Mater, 2022, 5: 1644–1655

Zhao X, Xu S, Liu J. Surface tension of liquid metal: Role, mechanism and application. Front Energy, 2017, 11: 535–567

Wang H, Yao Y, He Z, et al. A highly stretchable liquid metal polymer as reversible transitional insulator and conductor. Adv Mater, 2019, 31: 1901337

Majidi C, Alizadeh K, Ohm Y, et al. Liquid metal polymer composites: From printed stretchable circuits to soft actuators. Flex Print Electron, 2022, 7: 013002

Xin Y, Peng H, Xu J, et al. Ultrauniform embedded liquid metal in sulfur polymers for recyclable, conductive, and self-healable materials. Adv Funct Mater, 2019, 29: 1808989

Wei S, Yin R, Tang T, et al. Gas-permeable, irritation-free, transparent hydrogel contact lens devices with metal-coated nanofiber mesh for eye interfacing. ACS Nano, 2019, 13: 7920–7929

Du W, Nie J, Ren Z, et al. Inflammation-free and gas-permeable on-skin triboelectric nanogenerator using soluble nanofibers. Nano Energy, 2018, 51: 260–269

Qi X, Zhao H, Wang L, et al. Underwater sensing and warming E-textiles with reversible liquid metal electronics. Chem Eng J, 2022, 437: 135382

Eaker C B, Dickey M D. Liquid metal actuation by electrical control of interfacial tension. Appl Phys Rev, 2016, 3: 031103

Khondoker M A H, Sameoto D. Fabrication methods and applications of microstructured gallium based liquid metal alloys. Smart Mater Struct, 2016, 25: 093001

Lai Y C, Lu H W, Wu H M, et al. Elastic multifunctional liquid-metal fibers for harvesting mechanical and electromagnetic energy and as self-powered sensors. Adv Energy Mater, 2021, 11: 2100411

Yao Y, Wang H, Yang X, et al. E-BiInSn enhanced rigidity alterable artificial bandage. In: Proceedings of the 2018 40th Annual international conference of the IEEE engineering in medicine and biology society (EMBC). Honolulu, 2018. 2873–2876

Hu J, Meng H, Li G, et al. A review of stimuli-responsive polymers for smart textile applications. Smart Mater Struct, 2012, 21: 053001

Duwez P, Willens R H, Klement Jr. W. Metastable electron compound in Ag-Ge alloys. J Appl Phys, 1960, 31: 1137

Kazem N, Hellebrekers T, Majidi C. Soft multifunctional composites and emulsions with liquid metals. Adv Mater, 2017, 29: 1605985

Dickey M D. Stretchable and soft electronics using liquid metals. Adv Mater, 2017, 29: 1606425

Zhang J, Sheng L, Liu J. Synthetically chemical-electrical mechanism for controlling large scale reversible deformation of liquid metal objects. Sci Rep, 2014, 4: 7116

Daeneke T, Khoshmanesh K, Mahmood N, et al. Liquid metals: fundamentals and applications in chemistry. Chem Soc Rev, 2018, 47: 4073–4111

Lide D R. CRC Handbook of Chemistry and Physics. Boca Raton: CRC Press, 2004

Hohman J N, Kim M, Wadsworth G A, et al. Directing substrate morphology via self-assembly: Ligand-mediated scission of galliumindium microspheres to the nanoscale. Nano Lett, 2011, 11: 5104–5110

Chechetka S A, Yu Y, Zhen X, et al. Light-driven liquid metal nanotransformers for biomedical theranostics. Nat Commun, 2017, 8: 15432

Lu Y, Hu Q, Lin Y, et al. Transformable liquid-metal nanomedicine. Nat Commun, 2015, 6: 10066

Yan J, Lu Y, Chen G, et al. Advances in liquid metals for biomedical applications. Chem Soc Rev, 2018, 47: 2518–2533

Tang S Y, Khoshmanesh K, Sivan V, et al. Liquid metal enabled pump. Proc Natl Acad Sci USA, 2014, 111: 3304–3309

Park Y G, Lee G Y, Jang J, et al. Liquid metal-based soft electronics for wearable healthcare. Adv Healthcare Mater, 2021, 10: 2002280

Ma K, Liu J. Liquid metal cooling in thermal management of computer chips. Front Energy Power Eng China, 2007, 1: 384–402

Wang X, Guo R, Liu J. Liquid metal based soft robotics: Materials, designs, and applications. Adv Mater Technol, 2018, 4: 1800549

Guo R, Sun X, Yao S, et al. Semi-liquid-metal-(Ni-EGaIn)-based ultraconformable electronic tattoo. Adv Mater Technol, 2019, 4: 1900183

Xiang S, Liu D, Jiang C, et al. Liquid-metal-based dynamic thermoregulating and self-powered electronic skin. Adv Funct Mater, 2021, 31: 2100940

Zhang M, Zhang P, Zhang C, et al. Porous and anisotropic liquid metal composites with tunable reflection ratio for low-temperature electromagnetic interference shielding. Appl Mater Today, 2020, 19: 100612

Kim M, Brown D K, Brand O. Nanofabrication for all-soft and high-density electronic devices based on liquid metal. Nat Commun, 2020, 11: 1002

Zavabeti A, Ou J Z, Carey B J, et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science, 2017, 358: 332–335

Liu T, Sen P, Kim C J. Characterization of nontoxic liquid-metal alloy Galinstan for applications in microdevices. J Microelectromech Syst, 2012, 21: 443–450

Xu Q, Oudalov N, Guo Q, et al. Effect of oxidation on the mechanical properties of liquid gallium and eutectic gallium-indium. Phys Fluids, 2012, 24: 063101

Chang H, Zhang P, Guo R, et al. Recoverable liquid metal paste with reversible rheological characteristic for electronics printing. ACS Appl Mater Interfaces, 2020, 12: 14125–14135

Tang J, Zhao X, Li J, et al. Liquid metal phagocytosis: Intermetallic wetting induced particle internalization. Adv Sci, 2017, 4: 1700024

Xiao Y, Ding Y, Lei J, et al. Bubble-induced in situ property modulation of liquid metal. Adv Mater Interfaces, 2021, 8: 2002204

Li F, Shu J, Zhang L, et al. Liquid metal droplet robot. Appl Mater Today, 2020, 19: 100597

Kong W, Wang Z, Wang M, et al. Oxide-mediated formation of chemically stable tungsten-liquid metal mixtures for enhanced thermal interfaces. Adv Mater, 2019, 31: 1904309

Carle F, Bai K, Casara J, et al. Development of magnetic liquid metal suspensions for magnetohydrodynamics. Phys Rev Fluids, 2017, 2: 013301

Li X, Li M, Shou Q, et al. Liquid metal initiator of ring-opening polymerization: self-capsulation into thermal/photomoldable powder for multifunctional composites. Adv Mater, 2020, 32: 2003553

Ren L, Zhuang J, Casillas G, et al. Nanodroplets for stretchable superconducting circuits. Adv Funct Mater, 2016, 26: 8111–8118

Zhang J, Yao Y, Sheng L, et al. Self-fueled biomimetic liquid metal Mollusk. Adv Mater, 2015, 27: 2648–2655

Taccardi N, Grabau M, Debuschewitz J, et al. Gallium-rich Pd-Ga phases as supported liquid metal catalysts. Nat Chem, 2017, 9: 862–867

Torelli D A, Francis S A, Crompton J C, et al. Nickel-gallium-catalyzed electrochemical reduction of CO2 to highly reduced products at low overpotentials. ACS Catal, 2016, 6: 2100–2104

Zhang W, Ou J Z, Tang S Y, et al. Liquid metal/metal oxide frameworks. Adv Funct Mater, 2014, 24: 3799–3807

Pan Z W, Dai Z R, Ma C, et al. Molten gallium as a catalyst for the large-scale growth of highly aligned silica nanowires. J Am Chem Soc, 2002, 124: 1817–1822

Ding G, Zhu Y, Wang S, et al. Chemical vapor deposition of graphene on liquid metal catalysts. Carbon, 2013, 53: 321–326

Chen S, Yang X, Cui Y, et al. Self-growing and serpentine locomotion of liquid metal induced by copper ions. ACS Appl Mater Interfaces, 2018, 10: 22889–22895

Liang S T, Wang H Z, Liu J. Progress, mechanisms and applications of liquid-metal catalyst systems. Chem Eur J, 2018, 24: 17616–17626

Khan H, Mahmood N, Zavabeti A, et al. Liquid metal-based synthesis of high performance monolayer SnS piezoelectric nanogenerators. Nat Commun, 2020, 11: 3449

Ren L, Xu X, Du Y, et al. Liquid metals and their hybrids as stimulus-responsive smart materials. Mater Today, 2020, 34: 92–114

Liu H, Xia J, Zhang N, et al. Solid-liquid phase transition induced electrocatalytic switching from hydrogen evolution to highly selective CO2 reduction. Nat Catal, 2021, 4: 202–211

Handschuh-Wang S, Stadler F J, Zhou X. Critical review on the physical properties of gallium-based liquid metals and selected pathways for their alteration. J Phys Chem C, 2021, 125: 20113–20142

Ye Z, Lum G Z, Song S, et al. Phase change of gallium enables highly reversible and switchable adhesion. Adv Mater, 2016, 28: 5088–5092

Yuan B, Zhao C, Sun X, et al. Liquid-metal-enhanced wire mesh as a stiffness variable material for making soft robotics. Adv Eng Mater, 2019, 21: 1900530

Byun S H, Sim J Y, Zhou Z, et al. Mechanically transformative electronics, sensors, and implantable devices. Sci Adv, 2019, 5: eaay0418

Wen X, Wang B, Huang S, et al. Flexible, multifunctional neural probe with liquid metal enabled, ultra-large tunable stiffness for deep-brain chemical sensing and agent delivery. Biosens Bioelectron, 2019, 131: 37–45

Chang B S, Tutika R, Cutinho J, et al. Mechanically triggered composite stiffness tuning through thermodynamic relaxation (ST3R). Mater Horiz, 2018, 5: 416–422

Rich S, Jang S H, Park Y L, et al. Liquid metal-conductive thermoplastic elastomer integration for low-voltage stiffness tuning. Adv Mater Technol, 2017, 2: 1700179

Wang L, Yang Y, Chen Y, et al. Controllable and reversible tuning of material rigidity for robot applications. Mater Today, 2018, 21: 563–576

Bhuyan P, Wei Y, Sin D, et al. Soft and stretchable liquid metal composites with shape memory and healable conductivity. ACS Appl Mater Interfaces, 2021, 13: 28916–28924

Park S, Thangavel G, Parida K, et al. A stretchable and self-healing energy storage device based on mechanically and electrically restorative liquid-metal particles and carboxylated polyurethane composites. Adv Mater, 2019, 31: 1805536

Wu Y, Fang Z, Wu W, et al. Tuning flexibility-rigidity conversion of liquid metal/polyurethane composites by phase transition for potential shape memory application. Adv Eng Mater, 2021, 23: 2100372

Liu J, Yi L. Liquid Metal Biomaterials. Berlin: Springer, 2018

Sun X, Yuan B, Sheng L, et al. Liquid metal enabled injectable biomedical technologies and applications. Appl Mater Today, 2020, 20: 100722

Lu Y, Lin Y, Chen Z, et al. Enhanced endosomal escape by light-fueled liquid-metal transformer. Nano Lett, 2017, 17: 2138–2145

Duan M, Ren Y, Sun X, et al. EGaIn fiber enabled highly flexible supercapacitors. ACS Omega, 2021, 6: 24444–24449

Zhang W, Naidu B S, Ou J Z, et al. Liquid metal/metal oxide frameworks with incorporated Ga2O3 for photocatalysis. ACS Appl Mater Interfaces, 2015, 7: 1943–1948

Ladd C, So J H, Muth J, et al. 3D printing of free standing liquid metal microstructures. Adv Mater, 2013, 25: 5081–5085

Boley J W, White E L, Kramer R K. Mechanically sintered gallium-indium nanoparticles. Adv Mater, 2015, 27: 2355–2360

Guo R, Yao S, Sun X, et al. Semi-liquid metal and adhesion-selection enabled rolling and transfer (SMART) printing: A general method towards fast fabrication of flexible electronics. Sci China Mater, 2019, 62: 982–994

Cui Y, Ding Y, Xu S, et al. Liquid metal corrosion effects on conventional metallic alloys exposed to eutectic gallium-indium alloy under various temperature states. Int J Thermophys, 2018, 39: 113

Gao Y, Liu J. Gallium-based thermal interface material with high compliance and wettability. Appl Phys A, 2012, 107: 701–708

Guo R, Zhen Y, Huang X, et al. Spatially selective adhesion enabled transfer printing of liquid metal for 3D electronic circuits. Appl Mater Today, 2021, 25: 101236

Jia L C, Jia X X, Sun W J, et al. Stretchable liquid metal-based conductive textile for electromagnetic interference shielding. ACS Appl Mater Interfaces, 2020, 12: 53230–53238

Wang M, Ma C, Uzabakiriho P C, et al. Stencil printing of liquid metal upon electrospun nanofibers enables high-performance flexible electronics. ACS Nano, 2021, 15: 19364–19376

Wang L, Liu J. Printing low-melting-point alloy ink to directly make a solidified circuit or functional device with a heating pen. Proc R Soc A, 2014, 470: 20140609

Buchanan C, Gardner L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng Struct, 2019, 180: 332–348

Wu P, Fu J, Xu Y, et al. Liquid metal microgels for three-dimensional printing of smart electronic clothes. ACS Appl Mater Interfaces, 2022, 14: 13458–13467

Park Y G, An H S, Kim J Y, et al. High-resolution, reconfigurable printing of liquid metals with three-dimensional structures. Sci Adv, 2019, 5: eaay2844

Zhang Q, Zheng Y, Liu J. Direct writing of electronics based on alloy and metal (DREAM) ink: A newly emerging area and its impact on energy, environment and health sciences. Front Energy, 2012, 6: 311–340

Haake A, Tutika R, Schloer G M, et al. On-demand programming of liquid metal-composite microstructures through direct ink write 3D printing. Adv Mater, 2022, 34: 2200182

Votzke C, Daalkhaijav U, Menguc Y, et al. 3D-printed liquid metal interconnects for stretchable electronics. IEEE Sens J, 2019, 19: 3832–3840

Yu Y, Liu F, Liu J. Direct 3D printing of low melting point alloy via adhesion mechanism. Rapid Prototyping J, 2017, 23: 642–650

Wang L, Liu J. Advances in the development of liquid metal-based printed electronic inks. Front Mater, 2019, 6: 303

Dickey M D, Chiechi R C, Larsen R J, et al. Eutectic gallium-indium (EGaIn): A liquid metal alloy for the formation of stable structures in microchannels at room temperature. Adv Funct Mater, 2008, 18: 1097–1104

Hu Y, Zhuo H, Zhang Y, et al. Graphene oxide encapsulating liquid metal to toughen hydrogel. Adv Funct Mater, 2021, 31: 2106761

Saborio M G, Cai S, Tang J, et al. Liquid metal droplet and graphene co-fillers for electrically conductive flexible composites. Small, 2020, 16: 1903753

Zhang W, Wu B, Sun S, et al. Skin-like mechanoresponsive self-healing ionic elastomer from supramolecular zwitterionic network. Nat Commun, 2021, 12: 4082

Choi S, Park J, Hyun W, et al. Stretchable heater using ligand-exchanged silver nanowire nanocomposite for wearable articular thermotherapy. ACS Nano, 2015, 9: 6626–6633

Qiu Q, Zhu M, Li Z, et al. Highly flexible, breathable, tailorable and washable power generation fabrics for wearable electronics. Nano Energy, 2019, 58: 750–758

Wu C, Kim T W, Li F, et al. Wearable electricity generators fabricated utilizing transparent electronic textiles based on polyester/Ag nanowires/graphene core-shell nanocomposites. ACS Nano, 2016, 10: 6449–6457

Deng F, Nguyen Q K, Zhang P. Multifunctional liquid metal lattice materials through hybrid design and manufacturing. Additive Manufacturing, 2020, 33: 101117

Wang H, Chen S, Li H, et al. A liquid gripper based on phase transitional metallic ferrofluid. Adv Funct Mater, 2021, 31: 2100274

Yu D, Liao Y, Song Y, et al. A super-stretchable liquid metal foamed elastomer for tunable control of electromagnetic waves and thermal transport. Adv Sci, 2020, 7: 2000177

Wang H, Chen S, Zhu X, et al. Phase transition science and engineering of gallium-based liquid metal. Matter, 2022, 5: 2054–2085

Peng Y, Liu H, Xin Y, et al. Rheological conductor from liquid metal-polymer composites. Matter, 2021, 4: 3001–3014

Xin Y, Gao T, Xu J, et al. Transient electrically driven stiffness-changing materials from liquid metal polymer composites. ACS Appl Mater Interfaces, 2021, 13: 50392–50400

Deng Y, Liu J. Flexible mechanical joint as human exoskeleton using low-melting-point alloy. J Med Devices, 2014, 8: 044506

Liu H, Xin Y, Bisoyi H K, et al. Stimuli-driven insulator-conductor transition in a flexible polymer composite enabled by biphasic liquid metal. Adv Mater, 2021, 33: 2104634

Wu Y, Zhen R, Liu H, et al. Liquid metal fiber composed of a tubular channel as a high-performance strain sensor. J Mater Chem C, 2017, 5: 12483–12491

Yuan B, Zhao C, Sun X, et al. Lightweight liquid metal entity. Adv Funct Mater, 2020, 30: 1910709

Wang L, Fu J, Zhao F, et al. Pressure sensing of liquid metal-based fiber arrays. AIP Adv, 2021, 11: 035322

Dong C, Leber A, Das Gupta T, et al. High-efficiency super-elastic liquid metal based triboelectric fibers and textiles. Nat Commun, 2020, 11: 3537

Kim T, Kim D, Lee B J, et al. Soft and deformable sensors based on liquid metals. Sensors, 2019, 19: 4250

Kim K, Choi J, Jeong Y, et al. Highly sensitive and wearable liquid metal-based pressure sensor for health monitoring applications: Integration of a 3D-printed microbump array with the microchannel. Adv Healthcare Mater, 2019, 8: 1900978

Furse C, Chung Y C, Lo C, et al. A critical comparison of reflectometry methods for location of wiring faults. Smart Struct Syst, 2006, 2: 25–46

Zhou Z, Jiao T, Zhao P, et al. Development of a distributed crack sensor using coaxial cable. Sensors, 2016, 16: 1198

Dominauskas A, Heider D, Gillespie J W. Electric time-domain reflectometry applied to measurement of rock mass deformation. Int J Rock Mech Min Sci Geomech Abstr, 1988, 25: 287–297

Zadan M, Chiew C, Majidi C, et al. Liquid metal architectures for soft and wearable energy harvesting devices. Multifunct Mater, 2021, 4: 012001

Yang Y, Han J, Huang J, et al. Stretchable energy-harvesting tactile interactive interface with liquid-metal-nanoparticle-based electrodes. Adv Funct Mater, 2020, 30: 1909652

Wang K, Jiang K, Chung B, et al. Lithium-antimony-lead liquid metal battery for grid-level energy storage. Nature, 2014, 514: 348–350

Kim H, Boysen D A, Newhouse J M, et al. Liquid metal batteries: Past, present, and future. Chem Rev, 2013, 113: 2075–2099

Li H, Yin H, Wang K, et al. Liquid metal electrodes for energy storage batteries. Adv Energy Mater, 2016, 6: 1600483

Guo X, Zhang L, Ding Y, et al. Room-temperature liquid metal and alloy systems for energy storage applications. Energy Environ Sci, 2019, 12: 2605–2619

Liu G, Kim J Y, Wang M, et al. Soft, highly elastic, and discharge-current-controllable eutectic gallium-indium liquid metal-air battery operated at room temperature. Adv Energy Mater, 2018, 8: 1703652

Guo X, Ding Y, Xue L, et al. A self-healing room-temperature liquid-metal anode for alkali-ion batteries. Adv Funct Mater, 2018, 28: 1804649

Liu J, Yang, Y, Deng Z. A fabric composite composed of liquid metal. PRC Patent, CN201010219755.2, 2013-08-21

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12072054 and 22201223), and Natural Science Foundation of Hubei, China (Grant No. 2022CFA023).

Rights and permissions

About this article

Cite this article

Bie, B., Xu, W. & Lv, Y. Liquid metal-based textiles for smart clothes. Sci. China Technol. Sci. 66, 1511–1529 (2023). https://doi.org/10.1007/s11431-022-2266-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2266-3