Abstract

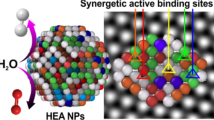

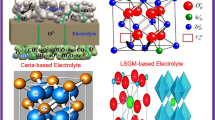

Carbon-neutral technologies are critical to ensure a stable future climate. Currently, low-melting-point liquid metals are emerging rapidly as important energy materials with significant potential to contribute to carbon neutrality. The advantages of gallium- and bismuth-based liquid metals, such as their high fluidity, low melting point, high thermal/electrical conductivity, unique chemical properties, non-flammability, and nontoxic characteristics, render them highly attractive for the development of advanced carbon-neutral technologies. Although their significance in both academia and industry has increased gradually, to the best of our knowledge, a systematic monograph of liquid-metal materials, mechanisms, and technologies toward carbon neutrality is not yet available. Therefore, we presented a comprehensive review of low-melting-point liquid metals for carbon neutrality. First, liquid-metal materials, including fluids, pastes, solids, and their composites were introduced. Subsequently, the mechanisms of liquid-metal technologies used to achieve carbon neutrality were interpreted. Finally, typical liquid-metal applications of carbon neutrality in the power, industry, transport, and building sectors were presented. Both the fundamental mechanisms and promising technologies were elaborated upon, and the critical assessment criteria for carbon-neutral technologies were discussed. The scientific and technical challenges and future perspectives in these areas were also highlighted.

Similar content being viewed by others

References

Spalding M D, Brown B E. Warm-water coral reefs and climate change. Science, 2015, 350: 769–771

Matthews H D, Wynes S. Current global efforts are insufficient to limit warming to 1.5°C. Science, 2022, 376: 1404–1409

Hoegh-Guldberg O, Jacob D, Taylor M, et al. The human imperative of stabilizing global climate change at 1.5°C. Science, 2019, 365: 1263

Zurek M, Hebinck A, Selomane O. Climate change and the urgency to transform food systems. Science, 2022, 376: 1416–1421

International Energy Agency. An energy sector roadmap to carbon neutrality in China. IEA, 2021. License: CC BY 4.0 IEA

Liu Z, Deng Z, He G, et al. Challenges and opportunities for carbon neutrality in China. Nat Rev Earth Environ, 2022, 3: 141–155

Deng Y, Li J. E. E. Emerging roles of liquid metals in carbon neutrality. Front Energy, 2022, 16: 393–396

Deng Y G, Liu J. Liquid Metals for Advanced Energy Applications. New York: AIP Publishing, 2022

Liu J. Advanced Liquid Metal Cooling for Chip, Device and System. Shanghai: Shanghai Science & Technology Press, 2020

Zuraiqi K, Zavabeti A, Allioux F M, et al. Liquid metals in catalysis for energy applications. Joule, 2020, 4: 2290–2321

Wang X, Lu C, Rao W. Liquid metal-based thermal interface materials with a high thermal conductivity for electronic cooling and bioheat-transfer applications. Appl Therm Eng, 2021, 192: 116937

Wang H, Chen S, Zhu X, et al. Phase transition science and engineering of gallium-based liquid metal. Matter, 2022, 5: 2054–2085

Liu J, Zhou Y X. A computer chip cooling method which uses low melting point metal and its alloys as the cooling fluid (in Chinese). China Patent. CN2131419, 2002

Ma K Q, Liu J. Heat-driven liquid metal cooling device for the thermal management of a computer chip. J Phys D-Appl Phys, 2007, 40: 4722–4729

Deng Y G, Liu J, Zhou Y X. Liquid metal based mini/micro channel cooling device. In: Proceedings of the ASME 2009 7th International Conference on Nanochannels, Microchannels, and Minichannels. Pohang, 2009. 253–259

Deng Y, Liu J. Design of practical liquid metal cooling device for heat dissipation of high performance CPUs. J Electron Packag, 2010, 132: 031009

Dai D, Zhou Y, Liu J. Liquid metal based thermoelectric generation system for waste heat recovery. Renew Energy, 2011, 36: 3530–3536

Deng Y, Liu J. An experimental investigation of liquid metal thermal joint. Energy Conv Manag, 2012, 56: 152–156

Zhang Q, Liu J. Nano liquid metal as an emerging functional material in energy management, conversion and storage. Nano Energy, 2013, 2: 863–872

Yang X H, Liu J. Advances in liquid metal science and technology in chip cooling and thermal management. Adv Heat Transfer, 2018, 50: 187–300

Ji Y, Li G, Chang C, et al. Investigation on carbon nanotubes as thermal interface material bonded with liquid metal alloy. J Heat Transfer, 2015, 137: 091017

Chen S, Deng Z, Liu J. High performance liquid metal thermal interface materials. Nanotechnology, 2021, 32: 092001

Ge H, Liu J. Phase change effect of low melting point metal for an automatic cooling of USB flash memory. Front Energy, 2012, 6: 207–209

Ge H, Liu J. Keeping smartphones cool with gallium phase change material. J Heat Transfer, 2013, 135: 054503

Huang T, Gao Q, Liu D, et al. Preparation of Al−Ga−In−Sn−Bi quinary alloy and its hydrogen production via water splitting. Int J Hydrog Energy, 2015, 40: 2354–2362

Tan S C, Gui H, Yang X H, et al. Comparative study on activation of aluminum with four liquid metals to generate hydrogen in alkaline solution. Int J Hydrog Energy, 2016, 41: 22663–22667

Weier T, Bund A, El-Mofid W, et al. Liquid metal batteries-materials selection and fluid dynamics. In: Proceedings of the Final LIMTECH Colloquium and International Symposium on Liquid Metal Technologies. Dresden, 2017. 012013

Zhang S, Liu Y, Fan Q, et al. Liquid metal batteries for future energy storage. Energy Environ Sci, 2021, 14: 4177–4202

Tajima H, Ogihara H, Yoshida-Hirahara M, et al. Methane conversion on cobalt-added liquid-metal indium catalysts. New J Chem, 2020, 44: 17198–17202

Tsakonas C, Dimitropoulos M, Manikas A C, et al. Growth and in situ characterization of 2D materials by chemical vapour deposition on liquid metal catalysts: A review. Nanoscale, 2021, 13: 3346–3373

Deng Y, Liu J. A liquid metal cooling system for the thermal management of high power LEDs. Int Commun Heat Mass Transfer, 2010, 37: 788–791

Li P, Liu J. Self-driven electronic cooling based on thermosyphon effect of room temperature liquid metal. J Electron Packag, 2011, 133: 041009

Song S, Shen W, Wang J, et al. Experimental study on laminar convective heat transfer of microencapsulated phase change material slurry using liquid metal with low melting point as carrying fluid. Int J Heat Mass Transfer, 2014, 73: 21–28

Tan S C, Zhou Y X, Wang L, et al. Electrically driven chip cooling device using hybrid coolants of liquid metal and aqueous solution. Sci China Technol Sci, 2016, 59: 301–308

Yang X H, Tan S C, Ding Y J, et al. Flow and thermal modeling and optimization of micro/mini-channel heat sink. Appl Therm Eng, 2017, 117: 289–296

Kim H, Boysen D A, Newhouse J M, et al. Liquid metal batteries: Past, present, and future. Chem Rev, 2013, 113: 2075–2099

Kelley D H, Weier T. Fluid mechanics of liquid metal batteries. Appl Mech Rev, 2018, 70: 020801

Ding Y, Guo X, Yu G. Next-generation liquid metal batteries based on the chemistry of fusible alloys. ACS Cent Sci, 2020, 6: 1355–1366

Guo X, Ding Y, Yu G. Anode materials: Design principles and applications of next-generation high-energy-density batteries based on liquid metals (Adv. Mater. 29/2021). Adv Mater, 2021, 33: 2170226

Wang K, Hu J, Chen T, et al. A high-performance room-temperature Li‖Ga-Sn liquid metal battery for grid energy storage. Energy Tech, 2021, 9: 2100330

Miner A, Ghoshal U. Cooling of high-power-density microdevices using liquid metal coolants. Appl Phys Lett, 2004, 85: 506–508

Deng Y, Liu J. Heat spreader based on room-temperature liquid metal. J Therm Sci Eng Appl, 2012, 4: 024501

Deng Y, Liu J. Optimization and evaluation of a high-performance liquid metal CPU cooling product. IEEE Trans Compon Packag Manufact Technol, 2013, 3: 1171–1177

Li P, Liu J, Zhou Y. Design of a self-driven liquid metal cooling device for heat dissipation of hot chips in a closed cabinet. J Therm Sci Eng Appl, 2014, 6: 8

Xiang X, Yang J, Fan A, et al. A comparison between cooling performances of water-based and gallium-based micro-channel heat sinks with the same dimensions. Appl Therm Eng, 2018, 137: 1–10

Armbrüster M, Kovnir K, Behrens M, et al. Pd-Ga intermetallic compounds as highly selective semihydrogenation catalysts. J Am Chem Soc, 2010, 132: 14745–14747

Collins S E, Delgado J J, Mira C, et al. The role of Pd-Ga bimetallic particles in the bifunctional mechanism of selective methanol synthesis via CO2 hydrogenation on a Pd/Ga2O3 catalyst. J Catal, 2012, 292: 90–98

Liang S T, Wang H Z, Liu J. Progress, mechanisms and applications of liquid-metal catalyst systems. Chem Eur J, 2018, 24: 17616–17626

Sun H, Guo W, Liu J, et al. Supported rhodium liquid metal catalysts for the hydroformylation of olefins. Appl Organomet Chem, 2018, 32: e4555

Saedi M, de Voogd J M, Sjardin A, et al. Development of a reactor for the in situ monitoring of 2D materials growth on liquid metal catalysts, using synchrotron X-ray scattering, Raman spectroscopy, and optical microscopy. Rev Sci Instrum, 2020, 91: 013907

Wang L, Liu J. Liquid metal material genome: Initiation of a new research track towards discovery of advanced energy materials. Front Energy, 2013, 7: 317–332

Wang H, Yuan B, Liang S, et al. PLUS-M: A porous liquid-metal enabled ubiquitous soft material. Mater Horiz, 2018, 5: 222–229

Liu J, Wang L. Principle and Application of Liquid Metal 3D Printing Technology (in Chinese). Shanghai: Shanghai Science & Technology Press, 2019

Liu J, Wang Q. Liquid Metal Printed Electronics (in Chinese). Shanghai: Shanghai Science & Technology Press, 2019

Chen G, Wang H, Guo R, et al. Superelastic EGaIn composite fibers sustaining 500% tensile strain with superior electrical conductivity for wearable electronics. ACS Appl Mater Interfaces, 2020, 12: 6112–6118

Wang Q, Yu Y, Liu J. Preparations, characteristics and applications of the functional liquid metal materials. Adv Eng Mater, 2018, 20: 1700781

Wang X, Guo R, Liu J. Liquid metal based soft robotics: Materials, designs, and applications. Adv Mater Technol, 2018, 4: 1800549

Zhang M, Yao S, Rao W, et al. Transformable soft liquid metal micro/nanomaterials. Mater Sci Eng-R-Rep, 2019, 138: 1–35

Chen S, Wang H Z, Zhao R Q, et al. Liquid metal composites. Matter, 2020, 2: 1446–1480

Yuan B, Zhao C, Sun X, et al. Lightweight liquid metal entity. Adv Funct Mater, 2020, 30: 1910709

Fu J H, Liu T Y, Cui Y, et al. Interfacial engineering of room temperature liquid metals. Adv Mater Interfaces, 2021, 8: 2001936

Gao J, Ye J, Chen S, et al. Liquid metal foaming via decomposition agents. ACS Appl Mater Interfaces, 2021, 13: 17093–17103

Tang S Y, Tabor C, Kalantar-Zadeh K, et al. Gallium liquid metal: The devil’s elixir. Annu Rev Mater Res, 2021, 51: 381–408

Wang H, Chen S, Yuan B, et al. Liquid metal transformable machines. Acc Mater Res, 2021, 2: 1227–1238

Wang H, Chen S, Li H, et al. A liquid gripper based on phase transitional metallic ferrofluid. Adv Funct Mater, 2021, 31: 2100274

Zhang X D, Liu J. Perspective on liquid metal enabled space science and technology. Sci China Tech Sci, 2020, 63: 1127–1140

Deng Y G, Liu J. Corrosion development between liquid gallium and four typical metal substrates used in chip cooling device. Appl Phys A, 2009, 95: 907–915

Gao Y, Liu J. Gallium-based thermal interface material with high compliance and wettability. Appl Phys A, 2012, 107: 701–708

Roy C K, Bhavnani S, Hamilton M C, et al. Investigation into the application of low melting temperature alloys as wet thermal interface materials. Int J Heat Mass Transfer, 2015, 85: 996–1002

Ki S, Shim J, Oh S, et al. Gallium-based liquid metal alloy incorporating oxide-free copper nanoparticle clusters for high-performance thermal interface materials. Int J Heat Mass Transfer, 2021, 170: 121012

Yang X H, Tan S C, Ding Y J, et al. Experimental and numerical investigation of low melting point metal based PCM heat sink with internal fins. Int Commun Heat Mass Transfer, 2017, 87: 118–124

Yang X H, Tan S C, He Z Z, et al. Evaluation and optimization of low melting point metal PCM heat sink against ultra-high thermal shock. Appl Therm Eng, 2017, 119: 34–41

Wang H, Peng Y, Peng H, et al. Fluidic phase-change materials with continuous latent heat from theoretically tunable ternary metals for efficient thermal management. Proc Natl Acad Sci USA, 2022, 119: e2200223119

Sola A C, Broch Gösser M, Ramírez de la Piscina P, et al. Promoter effect of Ga in Pt/Ga-TiO2 catalysts for the photo-production of H2 from aqueous solutions of ethanol. Catal Today, 2017, 287: 85–90

Bartlett M D, Kazem N, Powell-Palm M J, et al. High thermal conductivity in soft elastomers with elongated liquid metal inclusions. Proc Natl Acad Sci USA, 2017, 114: 2143–2148

Ma K Q, Liu J. Nano liquid-metal fluid as ultimate coolant. Phys Lett A, 2007, 361: 252–256

Zhang J, Guo R, Liu J. Self-propelled liquid metal motors steered by a magnetic or electrical field for drug delivery. J Mater Chem B, 2016, 4: 5349–5357

Guo R, Sun X, Yuan B, et al. Magnetic liquid metal (Fe-EGaIn) based multifunctional electronics for remote self-healing materials, degradable electronics, and thermal transfer printing. Adv Sci, 2019, 6: 1901478

Lu Y, Yu D, Dong H, et al. Magnetically tightened form-stable phase change materials with modular assembly and geometric conformality features. Nat Commun, 2022, 13: 1397

Liu G L, Liu J. Convective cooling of compact electronic devices via liquid metals with low melting points. J Heat Transfer, 2021, 143: 050801

Qian Z Y. The Thermophysical Properties of the Low Melting Point Alloy (in Chinese). Beijing: Science Press, 1985

Deng Z S, Liu J. Advanced Liquid Metal Chip Cooling Technology. Shanghai: Shanghai Science & Technology Press, 2020

Wetzel T, Pacio J, Marocco L, et al. Liquid metal technology for concentrated solar power systems: Contributions by the German research program. AIMS Energy, 2014, 2: 89–98

Zhang X D, Yang X H, Zhou Y X, et al. Experimental investigation of galinstan based minichannel cooling for high heat flux and large heat power thermal management. Energy Convers Manage, 2019, 185: 248–258

Xing Z, Fu J, Chen S, et al. Perspective on gallium-based room temperature liquid metal batteries. Front Energy, 2022, 16: 23–48

Kim H, Boysen D A, Ouchi T, et al. Calcium-bismuth electrodes for large-scale energy storage (liquid metal batteries). J Power Sources, 2013, 241: 239–248

Ning X, Phadke S, Chung B, et al. Self-healing Li-Bi liquid metal battery for grid-scale energy storage. J Power Sources, 2014, 275: 370–376

Ouchi T, Kim H, Ning X, et al. Calcium-antimony alloys as electrodes for liquid metal batteries. J Electrochem Soc, 2014, 161: A1898–A1904

Li H, Yin H, Wang K, et al. Liquid metal electrodes for energy storage batteries. Adv Energy Mater, 2016, 6: 1600483

Li Z H, Zhu F F, Li H M, et al. Research progresses of liquid metal batteries (in Chinese). Energy Stor Sci Technol, 2017, 6: 981–989

Li Q, Du B D, Gao J Y, et al. Room-temperature printing of ultrathin quasi-2D GaN semiconductor via liquid metal gallium surface confined nitridation reaction. Adv Mater Technol, 2022, 7: 2200733

Zavabeti A, Ou J Z, Carey B J, et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science, 2017, 358: 332–335

Upham D C, Agarwal V, Khechfe A, et al. Catalytic molten metals for the direct conversion of methane to hydrogen and separable carbon. Science, 2017, 358: 917–921

Esrafilzadeh D, Zavabeti A, Jalili R, et al. Room temperature CO2 reduction to solid carbon species on liquid metals featuring atomically thin ceria interfaces. Nat Commun, 2019, 10: 865

Deng Y G, Liu J, Zhou Y X. Study on liquid metal cooling of photovoltaic cell. In: Proceedings of the Inaugural US-EU-China Thermophysics Conference-Renewable Energy. Beijing, 2009

Van-Kessel T G, Martin Y C, Sandstrom R L, et al. Extending photovoltaic operation beyond 2000 suns using a liquid metal thermal interface with passive cooling. In: Proceedings of the 33rd IEEE Photovoltaic Specialists Conference. San Diego, 2008

Deng Y, Zhang M, Jiang Y, et al. Two-stage multichannel liquid-metal cooling system for thermal management of high-heat-flux-density chip array. Energy Convers Manage, 2022, 259: 115591

Deng Y, Jiang Y, Liu J. Liquid metal technology in solar power generation—Basics and applications. Sol Energy Mater Sol Cells, 2021, 222: 110925

Deng Y, Jiang Y, Liu J. Low-melting-point liquid metal convective heat transfer: A review. Appl Therm Eng, 2021, 193: 117021

Bradwell D J, Kim H, Sirk A H C, et al. Magnesium-antimony liquid metal battery for stationary energy storage. J Am Chem Soc, 2012, 134: 1895–1897

Wang K, Jiang K, Chung B, et al. Lithium-antimony-lead liquid metal battery for grid-level energy storage. Nature, 2014, 514: 348–350

Li H, Wang K, Cheng S, et al. High performance liquid metal battery with environmentally friendly antimony-tin positive electrode. ACS Appl Mater Interfaces, 2016, 8: 12830–12835

Chang H, Guo R, Sun Z, et al. Direct writing and repairable paper flexible electronics using nickel-liquid metal ink. Adv Mater Interfaces, 2018, 5: 1800571

Wang J, Chen L, Wu N, et al. Uniform graphene on liquid metal by chemical vapour deposition at reduced temperature. Carbon, 2016, 96: 799–804

Messalea K A, Carey B J, Jannat A, et al. Bi2O3 monolayers from elemental liquid bismuth. Nanoscale, 2018, 10: 15615–15623

Li Q, Lin J, Liu T Y, et al. Gas-mediated liquid metal printing toward large-scale 2D semiconductors and ultraviolet photodetector. NPJ 2D Mater Appl, 2021, 5: 36

Xu S, Liu J. Metal-based direct hydrogen generation as unconventional high density energy. Front Energy, 2018, 13: 27–53

Xu S, Zhao X, Liu J. Liquid metal activated aluminum-water reaction for direct hydrogen generation at room temperature. Renew Sustain Energy Rev, 2018, 92: 17–37

Dupiano P, Stamatis D, Dreizin E L. Hydrogen production by re-acting water with mechanically milled composite aluminum-metal oxide powders. Int J Hydrog Energy, 2011, 36: 4781–4791

Ilyukhina A V, Kravchenko O V, Bulychev B M, et al. Mechanochemical activation of aluminum with gallams for hydrogen evolution from water. Int J Hydrog Energy, 2010, 35: 1905–1910

Ziebarth J T, Woodall J M, Kramer R A, et al. Liquid phase-enabled reaction of Al−Ga and Al−Ga−In−Sn alloys with water. Int J Hydrog Energy, 2011, 36: 5271–5279

Zhong Y, Guo Q, Li L, et al. Heat transfer improvement of Wood’s alloy using compressed expanded natural graphite for thermal energy storage. Sol Energy Mater Sol Cells, 2012, 100: 263–267

Hosseinzadeh M, Sardarabadi M, Passandideh-Fard M. Energy and exergy analysis of nanofluid based photovoltaic thermal system integrated with phase change material. Energy, 2018, 147: 636–647

Mei S, Gao Y, Deng Z, et al. Thermally conductive and highly electrically resistive grease through homogeneously dispersing liquid metal droplets inside methyl silicone oil. J Electron Packag, 2014, 136: 011009

Li G, Ji Y, Zhang Q, et al. Thermal performance of liquid metal alloy with graphene addition as thermal interface material. J Heat Transfer, 2016, 138: 080911

Tang J, Zhao X, Li J, et al. Gallium-based liquid metal amalgams: Transitional-state metallic mixtures (TransM2 ixes) with enhanced and tunable electrical, thermal, and mechanical properties. ACS Appl Mater Interfaces, 2017, 9: 35977–35987

Lin Z, Liu H, Li Q, et al. High thermal conductivity liquid metal pad for heat dissipation in electronic devices. Appl Phys A, 2018, 124: 368

Kong W, Wang Z, Wang M, et al. Oxide-mediated formation of chemically stable tungsten-liquid metal mixtures for enhanced thermal interfaces. Adv Mater, 2019, 31: 1904309

Huang K, Qiu W, Ou M, et al. An anti-leakage liquid metal thermal interface material. RSC Adv, 2020, 10: 18824–18829

Ji Y, Yan H, Xiao X, et al. Excellent thermal performance of gallium-based liquid metal alloy as thermal interface material between aluminum substrates. Appl Therm Eng, 2020, 166: 114649

Qiu W, Ou M, Huang K, et al. Multilayer graphite-Ga68.5In21.5Sn10 composites as highly thermal conductive and low-cost material. Energy Technol, 2020, 8: 2000240

Deng Y, Jiang Y. High-performance, safe, and reliable soft-metal thermal pad for thermal management of electronics. Appl Therm Eng, 2021, 199: 117555

Cui T, Xuan Y, Yin E, et al. Experimental investigation on potential of a concentrated photovoltaic-thermoelectric system with phase change materials. Energy, 2017, 122: 94–102

Liu L, Chen J, Qu Y, et al. Preparation and thermal properties of low melting point alloy/expanded graphite composite phase change materials used in solar water storage system. Sol Energy Mater Sol Cells, 2019, 201: 110112

Tang J, Tang J, Mayyas M, et al. Liquid-metal-enabled mechanical-energy-induced CO2 conversion. Adv Mater, 2022, 34: 2105789

Ding Y, Guo X, Qian Y, et al. Room-temperature all-liquid-metal batteries based on fusible alloys with regulated interfacial chemistry and wetting. Adv Mater, 2020, 32: 2002577

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Beijing Institute of Technology Research Fund Program for Young Scholars and the 2020 Collaborative Education Project of the Ministry of Education by Beijing DREAMInk Technologies Co., Ltd. (Grant No. 202101049002).

Rights and permissions

About this article

Cite this article

Deng, Y., E, E., Li, J. et al. Materials, fundamentals, and technologies of liquid metals toward carbon neutrality. Sci. China Technol. Sci. 66, 1576–1594 (2023). https://doi.org/10.1007/s11431-022-2239-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2239-9