Abstract

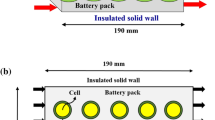

The Li-ion battery is widely used in power tools, energy storage systems, and electric vehicles. In reality, battery thermal management is essential to control the battery temperature within a specific temperature range. Although research has shown that preheating the battery at low temperatures on cold days can improve output performance significantly, few efforts have been made to study the preheating method in-depth As a result, this research proposes two preheating designs for cylindrical batteries with supercooled phase change materials: Single- and dual-phase change material (PCM) designs. A mathematical model is developed to analyze the effect of the PCM layer’s height, thickness, and mass on the preheating effect for seven candidate PCMs with high supercooling degrees. Furthermore, the economic efficiency of the single-PCM design with different PCMs is compared. In addition, the optimal ratio of the PCMs’ height for the dual-PCM design is investigated. Eventually, the improvement of the battery’s output performance is discussed. The results reveal that the proposed designs can effectively preheat the battery with a temperature rise higher than 10°C. The single-PCM design using LiNO3·3H2O shows the best preheating ability, while CH3COONa·3H2O is the most economical. Although the dual-PCM design cannot outperform the single-PCM design, it can preheat the battery twice and show better flexibility. Compared with the battery without preheating, a 26650-format battery with the single-PCM design can prolong the operating time by 38.8 min and save the electric quantity by 2.1 A h; while they are by 42.8 min and 2.3 A h with the dual-PCM design.

Similar content being viewed by others

References

Pesaran A, Santhanagopalan S, Kim G H. Addressing the impact of temperature extremes on large format Li-ion batteries for vehicle applications (Presentation). United States, 2013-05-01, 2013

Pesaran A A. Battery thermal models for hybrid vehicle simulations. J Power Sources, 2002, 110: 377–382

Bibin C, Vijayaram M, Suriya V, et al. A review on thermal issues in Li-ion battery and recent advancements in battery thermal management system. Mater Today-Proc, 2020, 33: 116–128

Wang Q, Ping P, Zhao X, et al. Thermal runaway caused fire and explosion of lithium ion battery. J Power Sources, 2012, 208: 210–224

Lin X, Zhang X. Research progress of phase change storage material on power battery thermal management. Energy Tech, 2021, 9: 2000940

Kim S W, Talluri T, Angani A, et al. Improve performance of the lithium polymer battery module Part 1: Heat transfer enhancement on Li-pouch battery with PCM in hot soaking. In: Proceedings of the 2020 IEEE 2nd International Conference on Architecture, Construction, Environment and Hydraulics (ICACEH). Hsinchu, Taiwan, China, 2020. 87–89

Ma S, Jiang M, Tao P, et al. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog Nat Sci-Mater Int, 2018, 28: 653–666

Bing B, Zheng L, Li X, et al. Discharge performance and charge-discharge heat generation characteristics of aging batteries (in Chinese). Energy Storage Sci Technol, 2022, 11: 679–689

Aris A M, Shabani B. An experimental study of a lithium ion cell operation at low temperature conditions. Energy Procedia, 2017, 110: 128–135

Sun M, Liu T, Li M, et al. A deep supercooling eutectic phase change material for low-temperature battery thermal management. J Energy Storage, 2022, 50: 104240

Safari A, Saidur R, Sulaiman F A, et al. A review on supercooling of phase change materials in thermal energy storage systems. Renew Sustain Energy Rev, 2017, 70: 905–919

Bayern Z. Storage technology issues and opportunities. In: Proceedings of the Committee on Energy Research and Technology (International Energy Agency), International Low-Carbon Energy Technology Platform, Strategic and Cross-Cutting Workshop “Energy Storage-Issues and Opportunities”. Paris, 2011

Ling Z, Wen X, Zhang Z, et al. Thermal management performance of phase change materials with different thermal conductivities for Li-ion battery packs operated at low temperatures. Energy, 2018, 144: 977–983

Ghadbeigi L, Day B, Lundgren K, et al. Cold temperature performance of phase change material based battery thermal management systems. Energy Rep, 2018, 4: 303–307

Ling Z, Wen X, Zhang Z, et al. Warming-up effects of phase change materials on lithium-ion batteries operated at low temperatures. Energy Technol, 2016, 4: 1071–1076

Zhang J, Liu H, Zheng M, et al. Numerical study on a preheating method for lithium-ion batteries under cold weather conditions using phase change materials coupled with heat films. J Energy Storage, 2022, 47: 103651

He F, Li X, Zhang G, et al. Experimental investigation of thermal management system for lithium ion batteries module with coupling effect by heat sheets and phase change materials. Int J Energy Res, 2018, 42: 3279–3288

Zhu T, Min H, Yu Y, et al. An optimized energy management strategy for preheating vehicle-mounted Li-ion batteries at subzero temperatures. Energies, 2017, 10: 243

Ling Z, Luo M, Song J, et al. A fast-heat battery system using the heat released from detonated supercooled phase change materials. Energy, 2021, 219: 119496

Yuan K, Zhou Y, Sun W, et al. A polymer-coated calcium chloride hexahydrate/expanded graphite composite phase change material with enhanced thermal reliability and good applicability. Compos Sci Tech, 2018, 156: 78–86

Lane G A. Solar Heat Storage: Latent Heat Materials, Vol II—Technology. Chicago: CRC Press, 1986

Shamberger P J, Reid T. Thermophysical properties of lithium nitrate trihydrate from (253 to 353) K. J Chem Eng Data, 2012, 57: 1404–1411

Zalba B, Marin J M, Cabeza L F, et al. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl Thermal Eng, 2003, 23: 251–283

Sharma A, Tyagi V V, Chen C R, et al. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev, 2009, 13: 318–345

Pacák P. Crystal growth from a calcium nitrate tetrahydrate melt. Kristall und Technik, 1980, 15: 523–529

Günther E. Sononucleation of inorganic phase change materials. Dissertation of Doctoral Degree. München: Technische Universität München, 2011

Hirschey J R, Kumar N, Turnaoglu T, et al. Review of low-cost organic and inorganic phase change materials with phase change temperature between 0°C and 65°C. In: International High Performance Buildings Conference at 2020 Herrick Conferences. West Lafayette, 2021

https://www.nwmissouri.edu/naturalsciences/sds/p/Pyrophosphate%20tetrasodium%20decahydrate.pdf. Available online (accessed on 2022.07.27)

Purohit B K, Sistla V S. Inorganic salt hydrate for thermal energy storage application: A review. Energy Storage, 2021, 3: e212

Hirschey J, Gluesenkamp K R, Mallow A, et al. Review of inorganic salt hydrates with phase change temperature in range of 5 to 60° C and material cost comparison with common waxes. In: International High Performance Buildings Conference. West Lafayette, 2018

Luo C, Su Q, Mi W. Thermophysical properties and application of LiNO3-H2O working fluid. Int J Refrig, 2013, 36: 1689–1700

Yim C, Choi K, Kim J, et al. A study of heat transfer characteristics of PCM in a latent heat storage tank (cubic type). Solar Energy, 1995, 15: 15–27

Sádovská G, Honcová P, Pilař R, et al. Calorimetric study of calcium nitrate tetrahydrate and magnesium nitrate hexahydrate. J Therm Anal Calorim, 2016, 124: 539–546

Beaupere N, Soupremanien U, Zalewski L. Nucleation triggering methods in supercooled phase change materials (PCM), a review. Thermochim Acta, 2018, 670: 184–201

Fang G, Zhang W, Yu M, et al. Research progress of phase change energy storage materials CH3COONa·3H2O (in Chinese). New Chem Mater, 2021, 49: 16–20

https://www.chemicalbook.com/ProductIndex.aspx. Available online (accessed on 2022.07.27)

Cao F, Zheng Y, Chen C H, et al. Thermal energy storage with tunable melting point phase change materials. In: Proceedings of the International Heat Transfer Conference. Digital Library, 2018

Fang Z, Maode L. Study on temperature rise effect of cylindrical lithium-ion battery (in Chinese). Power Technol, 2011, 35: 1061–1062, 1068

Jiang G. Preparation of high thermal conductivity composite phase change materials and application research on thermal management of power batteries (in Chinese). Dissertation of Doctrol Degree. Nanchang: Nanchang University, 2017

Geem Z W, Noh J S. Parameter estimation for a proton exchange membrane fuel cell model using GRG technique. Fuel Cells, 2016, 16: 640–645

Niu X, Tian J, Zhao F, et al. Estimation of SOC of Li-ion battery under different ambient temperature (in Chinese). First Battery Bimonthly, 2021, 51: 342–345

Zhan S, Tang N, Wang J. Research on SOC estimation method of LiFePO4 battery (in Chinese). Chin J Power Sources, 2015, 39: 1620–1622

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51821004, 51876061) and the Interdisciplinary Innovation Program of North China Electric Power University.

Rights and permissions

About this article

Cite this article

Fang, X., Nong, X., Liao, Z. et al. A novel preheating method for the Li-ion battery using supercooled phase change materials. Sci. China Technol. Sci. 66, 193–203 (2023). https://doi.org/10.1007/s11431-022-2209-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2209-9