Abstract

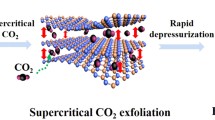

Two-dimensional (2D) boron nitride nanosheet (BNNS) is promising in polymer-based thermal management materials (TMMs) by pre-constructing three-dimensional (3D) thermally conductive skeleton, but it yet suffers from the challenges of high-effective exfoliation and affinitive compatibility with matrix. In this work, we developed a one-step exfoliation and deprotonation approach by the high-effective ball milling technique to prepare aramid nanofiber (ANF)/BNNS suspension. Under the strong collision/shear effect of ball-milling, micron-level hBN sheets were exfoliated into smaller and thinner BNNS with edge functional groups, meanwhile, poly-p-phenylene terephthalamide (PPTA) fibers were split into ANF by dissociating the intermolecular hydrogen bonds. More importantly, both the exfoliation and deprotonation could be accelerated by each other to achieve a 100% yield of ANF/BNNS suspension with strong hydrogen/covalent bonding interactions between them. Subsequently, the prepared ANF/BNNS suspension was used to construct 3D vertically aligned ANF/BNNS skeleton by the unidirectional freezing method. The obtained epoxy-based composite (EP/ANF/BNNS) revealed excellent thermal conductivity of 2.41 Wm−1 K−1 at 14.9 vol% BNNS loading due to the vertically oriented heat conduction paths and low interfacial thermal resistance in the skeleton. Moreover, EP/ANF/BNNS composite showed high thermal stability and extraordinary fire retardancy with dramatically decreased heat release rate (265 W g−1) and total heat release (20.6 kJ g−1). Therefore, this work demonstrates a high-efficient one-step ball-milling exfoliation and deprotonation technique for preparing ANF/BNNS suspension, which reveals an enormous potential in preparing advanced TMMs by constructing 3D thermally conductive skeletons.

Similar content being viewed by others

References

Zhang F, Feng Y, Feng W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater Sci Eng-R-Rep, 2020, 142: 100580

Ruan K, Yan H, Zhang S, et al. In-situ fabrication of hetero-structured fillers to significantly enhance thermal conductivities of silicone rubber composite films. Compos Sci Tech, 2021, 210: 108799

Ma T, Zhao Y, Ruan K, et al. Highly thermal conductivities, excellent mechanical robustness and flexibility, and outstanding thermal stabilities of aramid nanofiber composite papers with nacre-mimetic layered structures. ACS Appl Mater Interfaces, 2020, 12: 1677–1686

Xu X, Chen J, Zhou J, et al. Thermal conductivity of polymers and their nanocomposites. Adv Mater, 2018, 30: 1705544

Chen J, Wei H, Bao H, et al. Millefeuille-inspired thermally conductive polymer nanocomposites with overlapping BN nanosheets for thermal management applications. ACS Appl Mater Interfaces, 2019, 11: 31402–31410

Burger N, Laachachi A, Ferriol M, et al. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog Polym Sci, 2016, 61: 1–28

Ruan K, Zhong X, Shi X, et al. Liquid crystal epoxy resins with high intrinsic thermal conductivities and their composites: A mini-review. Mater Today Phys, 2021, 20: 100456

Chen J, Huang X, Sun B, et al. Vertically aligned and interconnected boron nitride nanosheets for advanced flexible nanocomposite thermal interface materials. ACS Appl Mater Interfaces, 2017, 9: 30909–30917

Zeng X, Ye L, Yu S, et al. Artificial nacre-like papers based on noncovalent functionalized boron nitride nanosheets with excellent mechanical and thermally conductive properties. Nanoscale, 2015, 7: 6774–6781

Guo H, Zhao H, Niu H, et al. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano, 2021, 15: 6917–6928

Yao Y, Sun J, Zeng X, et al. Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small, 2018, 14: 1704044

Yao Y, Ye Z, Huang F, et al. Achieving significant thermal conductivity enhancement via an ice-templated and sintered BN-SIC skeleton. ACS Appl Mater Interfaces, 2020, 12: 2892–2902

Lu H, Liang F, Gou J. Nanopaper enabled shape-memory nanocomposite with vertically aligned nickel nanostrand: Controlled synthesis and electrical actuation. Soft Matter, 2011, 7: 7416–7423

Zhu K, Xue P, Cheng G, et al. Thermo-managing and flame-retardant scaffolds suppressing dendritic growth and polysulfide shuttling toward high-safety lithium-sulfur batteries. Energy Storage Mater, 2021, 43: 130–142

Wang X, Wu P. 3D vertically aligned BNNS network with long-range continuous channels for achieving a highly thermally conductive composite. ACS Appl Mater Interfaces, 2019, 11: 28943–28952

Han J, Du G, Gao W, et al. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv Funct Mater, 2019, 29: 1900412

Guo Y, Ruan K, Shi X, et al. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos Sci Tech, 2020, 193: 108134

Feng Y, Han G, Wang B, et al. Multiple synergistic effects of graphene-based hybrid and hexagonal born nitride in enhancing thermal conductivity and flame retardancy of epoxy. Chem Eng J, 2020, 379: 122402

Guerra V, Wan C, McNally T. Thermal conductivity of 2D nanostructured boron nitride (BN) and its composites with polymers. Prog Mater Sci, 2019, 100: 170–186

Wu L, Wu K, Lei C, et al. Surface modifications of boron nitride nanosheets for poly(vinylidene fluoride) based film capacitors: Advantages of edge-hydroxylation. J Mater Chem A, 2019, 7: 7664–7674

Jiang F, Cui S, Song N, et al. Hydrogen bond-regulated boron nitride network structures for improved thermal conductive property of polyamide-imide composites. ACS Appl Mater Interfaces, 2018, 10: 16812–16821

Yan Q, Dai W, Gao J, et al. Ultrahigh-aspect-ratio boron nitride nanosheets leading to superhigh in-plane thermal conductivity of foldable heat spreader. ACS Nano, 2021, 15: 6489–6498

Chen S, Xu R, Liu J, et al. Simultaneous production and functionalization of boron nitride nanosheets by sugar-assisted mechanochemical exfoliation. Adv Mater, 2019, 31: 1804810

Niu L, Coleman J N, Zhang H, et al. Production of two-dimensional nanomaterials via liquid-based direct exfoliation. Small, 2016, 12: 272–293

Yang G, Zhang X, Pan D, et al. Highly thermal conductive poly(vinyl alcohol) composites with oriented hybrid networks: Silver nanowire bridged boron nitride nanoplatelets. ACS Appl Mater Interfaces, 2021, 13: 32286–32294

Hu B, Zhang W, Guo H, et al. Nacre-mimetic elastomer composites with synergistic alignments of boron nitride/graphene oxide towards high through-plane thermal conductivity. Compos Part A-Appl Sci Manuf, 2022, 156: 106891

Ma J, Shang T, Ren L, et al. Through-plane assembly of carbon fibers into 3D skeleton achieving enhanced thermal conductivity of a thermal interface material. Chem Eng J, 2020, 380: 122550

Luo S, Xiang T, Dong J, et al. A double crosslinking mxene/cellulose nanofiber layered film for improving mechanical properties and stable electromagnetic interference shielding performance. J Mater Sci Tech, 2022, 129: 127–134

Chen J, Huang X, Zhu Y, et al. Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability. Adv Funct Mater, 2017, 27: 1604754

Hu P, Lyu J, Fu C, et al. Multifunctional aramid nanofiber/carbon nanotube hybrid aerogel films. ACS Nano, 2020, 14: 688–697

Liu Z, Lyu J, Fang D, et al. Nanofibrous Kevlar aerogel threads for thermal insulation in harsh environments. ACS Nano, 2019, 13: 5703–5711

Zhu J, Yang M, Emre A, et al. Branched aramid nanofibers. Angew Chem Int Ed, 2017, 56: 11744–11748

Zhang X, Wang A, Zhou X, et al. Fabrication of aramid nanofiber-wrapped graphene fibers by coaxial spinning. Carbon, 2020, 165: 340–348

Ma Z, Kang S, Ma J, et al. High-performance and rapid-response electrical heaters based on ultraflexible, heat-resistant, and mechanically strong aramid nanofiber/Ag nanowire nanocomposite papers. ACS Nano, 2019, 13: 7578–7590

Han Y, Ruan K, Gu J. Janus (BNNS/ANF)−(AgNWs/ANF) thermal conductivity composite films with superior electromagnetic interference shielding and joule heating performances. Nano Res, 2022, 15: 4747–4755

Wu K, Wang J, Liu D, et al. Highly thermoconductive, thermostable, and super-flexible film by engineering 1D rigid rod-like aramid nanofiber/2D boron nitride nanosheets. Adv Mater, 2020, 32: 1906939

Patel A, Wilcox K, Li Z, et al. High modulus, thermally stable, and self-extinguishing aramid nanofiber separators. ACS Appl Mater Interfaces, 2020, 12: 25756–25766

Lei C, Zhang Y, Liu D, et al. Metal-level robust, folding endurance, and highly temperature-stable mxene-based film with engineered aramid nanofiber for extreme-condition electromagnetic interference shielding applications. ACS Appl Mater Interfaces, 2020, 12: 26485–26495

Wang A, Zhang X, Chen F, et al. Aramid nanofiber framework supporting graphene nanoplate via wet-spinning for a high-performance filament. Carbon, 2021, 179: 655–665

Yang B, Wang L, Zhang M, et al. Fabrication, applications, and prospects of aramid nanofiber. Adv Funct Mater, 2020, 30: 2000186

Yang M, Cao K, Sui L, et al. Dispersions of aramid nanofibers: A new nanoscale building block. ACS Nano, 2011, 5: 6945–6954

Chen H J, Bai Q Y, Liu M C, et al. Ultrafast, cost-effective and scaled-up recycling of aramid products into aramid nanofibers: Mechanism, upcycling, closed-loop recycling. Green Chem, 2021, 23: 7646–7658

Yang B, Zhang M, Lu Z, et al. From poly(p-phenylene terephthalamide) broken paper: High-performance aramid nanofibers and their application in electrical insulating nanomaterials with enhanced properties. ACS Sustain Chem Eng, 2018, 6: 8954–8963

Bai Y, Zhang J, Wang Y, et al. Ball milling of hexagonal boron nitride microflakes in ammonia fluoride solution gives fluorinated nanosheets that serve as effective water-dispersible lubricant additives. ACS Appl Nano Mater, 2019, 2: 3187–3195

Deepika A, Li L H, Glushenkov A M, et al. High-efficient production of boron nitride nanosheets via an optimized ball milling process for lubrication in oil. Sci Rep, 2014, 4: 7288

Han G, Zhao X, Feng Y, et al. Highly flame-retardant epoxy-based thermal conductive composites with functionalized boron nitride nanosheets exfoliated by one-step ball milling. Chem Eng J, 2021, 407: 127099

Lei W, Mochalin V N, Liu D, et al. Boron nitride colloidal solutions, ultralight aerogels and freestanding membranes through one-step exfoliation and functionalization. Nat Commun, 2015, 6: 8849

Lee D, Lee B, Park K H, et al. Scalable exfoliation process for highly soluble boron nitride nanoplatelets by hydroxide-assisted ball milling. Nano Lett, 2015, 15: 1238–1244

Li X, Hao X, Zhao M, et al. Exfoliation of hexagonal boron nitride by molten hydroxides. Adv Mater, 2013, 25: 2200–2204

Lin Y, Williams T V, Xu T B, et al. Aqueous dispersions of few-layered and monolayered hexagonal boron nitride nanosheets from sonication-assisted hydrolysis: Critical role of water. J Phys Chem C, 2011, 115: 2679–2685

Han G, Zhang D, Kong C, et al. Flexible, thermostable and flame-resistant epoxy-based thermally conductive layered films with aligned ionic liquid-wrapped boron nitride nanosheets via cyclic layer-by-layer blade-casting. Chem Eng J, 2022, 437: 135482

Zeng H, Wu J, Pei H, et al. Highly thermally conductive yet mechanically robust composites with nacre-mimetic structure prepared by evaporation-induced self-assembly approach. Chem Eng J, 2021, 405: 126865

Foygel M, Morris R D, Anez D, et al. Theoretical and computational studies of carbon nanotube composites and suspensions: Electrical and thermal conductivity. Phys Rev B, 2005, 71: 104201

Feng Y, He C, Wen Y, et al. Superior flame retardancy and smoke suppression of epoxy-based composites with phosphorus/nitrogen co-doped graphene. J Hazard Mater, 2018, 346: 140–151

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Key R&D Program of China (Grant No. 2019YFA0706802), the National Natural Science Foundation of China (Grant Nos. 51903223 and 12072325), the Natural Science Foundation of Henan Province (Grant No. 222300420541), and the Key Technologies R&D Program of Henan Province (Grant No. 212102210302).

Supporting Information

The supporting information is available online at tech.scichina.com and link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Supporting Information

11431_2022_2168_MOESM1_ESM.pdf

One-step exfoliation and deprotonation of ANF/BNNS suspension for constructing 3D vertically aligned skeleton in epoxy-based thermal management composites

Rights and permissions

About this article

Cite this article

Han, G., Xue, P., Cai, Z. et al. One-step exfoliation and deprotonation of ANF/BNNS suspension for constructing 3D vertically aligned skeleton in epoxy-based thermal management composites. Sci. China Technol. Sci. 65, 2675–2686 (2022). https://doi.org/10.1007/s11431-022-2168-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2168-3