Abstract

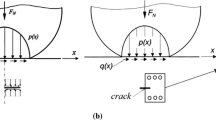

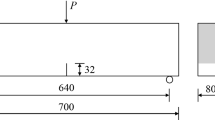

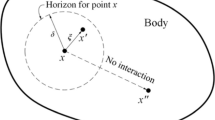

Mixed-mode I-II crack-based fatigue crack propagation (FCPI-II) usually occurs in engineering structures; however, no theoretical formula or effective compliance test methods have been established for FCPI-II to date. For mixed-mode I-II flawed components, based on the principle of mean-value energy equivalence, we propose a theoretical method to describe the relationship between material elastic parameters, geometrical dimensions, load (or displacement), and energy. Based on the maximum circumferential stress criterion, we propose a uniform compliance model for compact tensile shear (CTS) specimens with horizontal cracks deflecting and propagating (flat-folding propagation) under different loading angles, geometries, and materials. Along with an innovative design of the fixture of CTS specimens used for FCPI-II tests, we develop a new compliance-based testing method for FCPI-II. For the 30Cr2Ni4MoV rotor steel, the FCP rates of mode I, mode II, and mixed-mode I-II cracks were obtained via FCP tests using compact tension, Arcan, and CTS specimens, respectively. The obtained da/dN versus ΔJ curves of the FCP rates are close. The loading angle α and dimensionless initial crack length a0/W demonstrated negligible effects on the FCP rates. Hence, the FCP rates of mode I crack can be used to predict the residual life of structural crack propagation.

Similar content being viewed by others

References

Richard H A. Specimens for investigating biaxial fracture and fatigue processes. In: Biaxial and Multiaxial Fatigue (EGF 3). Hoboken: John Wiley & Sons, Inc., 1989. 217–228

Mahanty D K, Maiti S K. Experimental and finite element studies on mode I and mixed mode (I and II) stable crack growth—I. Experimental. Eng Fract Mech, 1990, 37: 1237–1250

Buzzard R J, Gross B, Srawley J E. Mode II fatigue crack growth specimen development. In: Proceedings of National Symposium on Fracture Mechanics. Albany, 1983. 329–346

Otsuka A, Tohgo K, Matsuyama H. Fatigue crack initiation and growth under mixed mode loading in aluminum alloys 2017-T3 and 7075-T6. Eng Fract Mech, 1987, 28: 721–732

Richard H A, Benitz K. A loading device for the creation of mixed mode in fracture mechanics. Int J Fract, 1983, 22: R55–R58

Richard H A. Fracture Mechanical Predictions for Cracks with Superimposed Normal and Shear Loading. Düsseldorf: VDI-Verlag, 1985

Heirani H, Farhangdoost K. Mixed mode I/II fatigue crack growth under tensile or compressive far-field loading. Mater Res Express, 2017, 4: 116505

Heirani H, Farhangdoost K. Effect of compressive mode I on the mixed mode I/II fatigue crack growth rate of 42CrMo4. J Materi Eng Perform, 2018, 27: 138–146

Kim J K, Kim C S. Fatigue crack growth behavior of rail steel under mode I and mixed mode loadings. Mater Sci Eng-A, 2002, 338: 191–201

Peixoto D F C, de Castro P M S T. Mixed mode fatigue crack propagation in a railway wheel steel. Procedia Struct Integrity, 2016, 1: 150–157

Arcan M, Hashin Z, Voloshin A. A method to produce uniform plane-stress states with applications to fiber-reinforced materials. Exp Mech, 1978, 18: 141–146

Erdogan F, Sih G C. On the crack extension in plates under plane loading and transverse shear. J Basic Eng, 1963, 85: 519–525

Richard H A, Fulland M, Sander M. Theoretical crack path prediction. Fat Frac Eng Mat Struct, 2005, 28: 3–12

Richard H A, Schöllmann M, Fulland M, et al. Experimental and numerical simulation of mixed mode crack growth. In: Proceedings of the 6th International Conference on Biaxial/multiaxial Fatigue & Fracture. Lisbon, 2001. 623–30

Guo Y, Li Q. Material configurational forces applied to mixed mode crack propagation. Theor Appl Fract Mech, 2017, 89: 147–157

Eshelby J D. The elastic energy-momentum tensor. J Elasticity, 1975, 5: 321–335

Chen H, Cai L. Theoretical model for predicting uniaxial stress-strain relation by dual conical indentation based on equivalent energy principle. Acta Mater, 2016, 121: 181–189

Chen H, Cai L. Unified elastoplastic model based on a strain energy equivalence principle. Appl Math Model, 2017, 52: 664–671

Chen H, Cai L. An elastoplastic energy model for predicting the deformation behaviors of various structural components. Appl Math Model, 2019, 68: 405–421

Qi S, Cai L X, Bao C, et al. Analytical theory for fatigue crack propagation rates of mixed-mode I–II cracks and its application. Int J Fatigue, 2019, 119: 150–159

Rice J R. A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech, 1968, 35: 379–386

Tanaka K. Fatigue crack propagation from a crack inclined to the cyclic tensile axis. Eng Fract Mech, 1974, 6: 493–507

Shih C F. Elastic-plastic analysis of combined mode crack problems. Dissertation for Doctoral Degree. Cambridge: Harvard University. 1973. 1–3

Irwin G R. Analysis of stresses and strains near the end of a crack traversing a plate. J Appl Mech, 1957, 24: 361–364

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Key Research and Development Program of China (Grant No. 2017YFB0702200), the National Natural Science Foundation of China (Grant No. 11872320), and the Policy Guidance Program of Jiangsu Province (Grant No. BZ2020057).

Rights and permissions

About this article

Cite this article

Qi, S., Xiang, W., Cai, L. et al. Compliance-based testing method for fatigue crack propagation rates of mixed-mode I–II cracks. Sci. China Technol. Sci. 64, 2577–2585 (2021). https://doi.org/10.1007/s11431-020-1872-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1872-8