Abstract

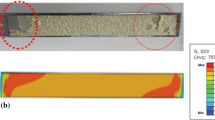

Metal foams are typically subjected to quasi-static or dynamic shear-compression combined loading in applications such as energy absorbers and structure protectors. The yield behavior of a metal foam under dynamic and quasi-static shear-compression combined loadings is investigated in this study. First, quasi-static and dynamic compression-shear combined tests at different loading angles are conducted using a universal testing machine and a rotatable Hopkinson bar system, respectively. Shear deformation reduces the plateau stress as the loading angle increases. Subsequently, the yield modes of the metal foam under combined loadings are investigated. Only one yield band occurs under a combined loading with large loading angles (mode I), whereas several yield bands occur under a combined loading with small loading angles (mode II). Finally, the yield surface plot of metal foam indicates significant enhancement in terms of normal stress and shear stress under dynamic loading. Quasi-static and dynamic phenomenological yield criteria for a shear-normal stress space are established to provide a brief and precise prediction of the behavior of metal foam under quasi-static and dynamic combined loadings.

Similar content being viewed by others

References

Gibson L J, Ashby M F. Cellular Solids: Structure and Properties. Cambridge: Cambridge University Press, 1997

Tan P J, Reid S R, Harrigan J J, et al. Dynamic compressive strength properties of aluminium foams. Part I—Experimental data and observations. J Mech Phys Solids, 2005, 53: 2174–2205

Tan P J, Reid S R, Harrigan J J, et al. Dynamic compressive strength properties of aluminium foams. Part II—‘Shock’ theory and comparison with experimental data and numerical models. J Mech Phys Solids, 2005, 53: 2206–2230

Radford D D, Deshpande V S, Fleck N A. The use of metal foam projectiles to simulate shock loading on a structure. Int J Impact Eng, 2005, 31: 1152–1171

Idris M I, Vodenitcharova T, Hoffman M. Mechanical behaviour and energy absorption of closed-cell aluminium foam panels in uniaxial compression. Mater Sci Eng-A, 2009, 517: 37–45

Cui L, Kiernan S, Gilchrist M D. Designing the energy absorption capacity of functionally graded foam materials. Mater Sci Eng-A, 2009, 507: 215–225

Sun Y, Li Q M. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int J Impact Eng, 2018, 112: 74–115

Cao X, Xiao D, Li Y, et al. Dynamic compressive behavior of a modified additively manufactured rhombic dodecahedron 316L stainless steel lattice structure. Thin-Walled Struct, 2020, 148: 106586

Sridhar I, Fleck N A. The multiaxial yield behaviour of an aluminium alloy foam. J Mater Sci, 2005, 40: 4005–4008

Deshpande V S, Fleck N A. Multi-axial yield behaviour of polymer foams. Acta Mater, 2001, 49: 1859–1866

Doyoyo M, Wierzbicki T. Experimental studies on the yield behavior of ductile and brittle aluminum foams. Int J Plast, 2003, 19: 1195–1214

Zhou Z, Wang Z, Zhao L, et al. Uniaxial and biaxial failure behaviors of aluminum alloy foams. Compos Part B-Eng, 2014, 61: 340–349

Ruan D, Lu G, Ong L, et al. Triaxial compression of aluminium foams. Compos Sci Tech, 2007, 67: 1218–1234

Combaz E, Bacciarini C, Charvet R, et al. Multiaxial yield behaviour of Al replicated foam. J Mech Phys Solids, 2011, 59: 1777–1793

Combaz E, Bacciarini C, Charvet R, et al. Yield surface of polyurethane and aluminium replicated foam. Acta Mater, 2010, 58: 5168–5183

Ashab A, Ruan D, Lu G, et al. Quasi-static and dynamic experiments of aluminum honeycombs under combined compression-shear loading. Mater Des, 2016, 97: 183–194

Kossa A. A new biaxial compression fixture for polymeric foams. Polym Testing, 2015, 45: 47–51

Duan Y, Liu Z, Zhao X, et al. Crushing behavior of honeycomb vs. foam under combined shear-compression loading. Int J Impact Eng, 2020, 146: 103696

Hou B, Wang Y, Sun T F, et al. On the quasi-static and impact responses of aluminum honeycomb under combined shear-compression. Int J Impact Eng, 2019, 131: 190–199

Miller R E. A continuum plasticity model for the constitutive and indentation behaviour of foamed metals. Int J Mech Sci, 2000, 42: 729–754

Shen J, Lu G, Ruan D. Compressive behaviour of closed-cell aluminium foams at high strain rates. Compos Part B-Eng, 2010, 41: 678–685

Hou B, Xiao R, Sun T F, et al. A new testing method for the dynamic response of soft cellular materials under combined shear-compression. Int J Mech Sci, 2019, 159: 306–314

Luo G, Xue P, Li L, et al. Experimental and theoretical investigation on dynamic properties of metal foam. Int J Appl Mech, 2016, 08: 1650025

Zheng Z, Wang C, Yu J, et al. Dynamic stress-strain states for metal foams using a 3D cellular model. J Mech Phys Solids, 2014, 72: 93–114

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11672248 and 12072288), the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University, and the Fundamental Research Funds for the Central Universities, CHD. The authors also highly acknowledge Professor LU GuoXing for his kind support on the experiment.

Rights and permissions

About this article

Cite this article

Luo, G., Xue, P. & Li, Y. Experimental investigation on the yield behavior of metal foam under shear-compression combined loading. Sci. China Technol. Sci. 64, 1412–1422 (2021). https://doi.org/10.1007/s11431-020-1786-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1786-6