Abstract

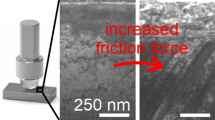

The deformation mechanism of CoCrNi alloy with high density of annealing twins was studied by in situ transmission electron microscopy. Dislocation transmission and reflection at the twin boundary were observed during in situ loading. We characterized these reaction processes by combining TEM, dislocation theory and crystallography of twin. Twin boundary not only strengthens the material by impeding the motion of dislocation, but also acts as dislocation source to produce large of slip bands. These processes generate large of slip bands to accommodate the plastic deformation or strengthening material.

Similar content being viewed by others

References

Miracle D B, Senkov O N. A critical review of high entropy alloys and related concepts. Acta Mater, 2017, 122: 448–511

Miao J, Slone C E, Smith T M, et al. The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy. Acta Mater, 2017, 132: 35–48

Tong Y, Jin K, Bei H, et al. Local lattice distortion in NiCoCr, Fe-CoNiCr and FeCoNiCrMn concentrated alloys investigated by synchrotron X-ray diffraction. Mater Des, 2018, 155: 1–7

Deng H W, Xie Z M, Zhao B L, et al. Tailoring mechanical properties of a CoCrNi medium-entropy alloy by controlling nanotwin-HCP lamellae and annealing twins. Mater Sci Eng-A, 2019, 744: 241–246

Ma Y, Yuan F, Yang M, et al. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures. Acta Mater, 2018, 148: 407–418

Yang M, Yan D, Yuan F, et al. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength. Proc Natl Acad Sci USA, 2018, 115: 7224–7229

Gludovatz B, Hohenwarter A, Catoor D, et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 2014, 345: 1153–1158

Sathiyamoorthi P, Moon J, Bae J W, et al. Superior cryogenic tensile properties of ultrafine-grained CoCrNi medium-entropy alloy produced by high-pressure torsion and annealing. Scripta Mater, 2019, 163: 152–156

Gludovatz B, Hohenwarter A, Thurston K V S, et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat Commun, 2016, 7: 10602

Ding Q, Fu X, Chen D, et al. Real-time nanoscale observation of deformation mechanisms in CrCoNi-based medium- to high-entropy alloys at cryogenic temperatures. Mater Today, 2019, 25: 21–27

Laplanche G, Kostka A, Reinhart C, et al. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to highentropy CrMnFeCoNi. Acta Mater, 2017, 128: 292–303

Huang H, Li X, Dong Z, et al. Critical stress for twinning nucleation in CrCoNi-based medium and high entropy alloys. Acta Mater, 2018, 149: 388–396

Zhang Z, Sheng H, Wang Z, et al. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat Commun, 2017, 8: 14390

Agustianingrum M P, Yoshida S, Tsuji N, et al. Effect of aluminum addition on solid solution strengthening in CoCrNi medium-entropy alloy. J Alloys Compd, 2019, 781: 866–872

Dan Sathiaraj G, Skrotzki W, Pukenas A, et al. Effect of annealing on the microstructure and texture of cold rolled CrCoNi medium-entropy alloy. Intermetallics, 2018, 101: 87–98

Zhao Y L, Yang T, Tong Y, et al. Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater, 2017, 138: 72–82

Wu W, Guo L, Guo B, et al. Altered microstructural evolution and mechanical properties of CoCrFeNiMo0.15 high-entropy alloy by cryogenic rolling. Mater Sci Eng-A, 2019, 759: 574–582

Lu K, Lu L, Suresh S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science, 2009, 324: 349–352

Lu L, Chen X, Huang X, et al. Revealing the maximum strength in nanotwinned copper. Science, 2009, 323: 607–610

Lu L, Shen Y, Chen X, et al. Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304: 422–426

Pan Q, Zhou H, Lu Q, et al. Asymmetric cyclic response of tensile predeformed Cu with highly oriented nanoscale twins. Acta Mater, 2019, 175: 477–486

Fan C, Xie D, Li J, et al. 9R phase enabled superior radiation stability of nanotwinned Cu alloys via in situ radiation at elevated temperature. Acta Mater, 2019, 167: 248–256

Zhang Y F, Xue S, Li Q, et al. Microstructure and mechanical behavior of nanotwinned AlTi alloys with 9R phase. Scripta Mater, 2018, 148: 5–9

Zheng S, Beyerlein I J, Carpenter J S, et al. High-strength and thermally stable bulk nanolayered composites due to twin-induced interfaces. Nat Commun, 2013, 4: 1696

Zheng X, Zheng S, Wang J, et al. Twinning and sequential kinking in lamellar Ti-6Al-4V alloy. Acta Mater, 2019, 181: 479–490

Zheng S, Zhang R, Huang R, et al. Structure and energetics of nanotwins in cubic boron nitrides. Appl Phys Lett, 2016, 109: 081901

Sutton A. Grain-boundary structure. Int Met Rev, 1984, 29: 377–404

Hirth J P. Defect structures in grain boundaries. Acta Metall, 1974, 22: 1023–1031

Hirth J P, Pond R C, Hoagland R G, et al. Interface defects, reference spaces and the Frank-Bilby equation. Prog Mater Sci, 2013, 58: 749–823

Tschopp M A, Mcdowell D L. Asymmetric tilt grain boundary structure and energy in copper and aluminium. Philos Mag, 2007, 87: 3871–3892

Li Q, Xue S, Wang J, et al. High-strength nanotwinned Al alloys with 9R phase. Adv Mater, 2018, 30: 1704629

Wang J. Atomistic simulations of dislocation pileup: Grain boundaries interaction. JOM, 2015, 67: 1515–1525

de Koning M, Kurtz R J, Bulatov V V, et al. Modeling of dislocationgrain boundary interactions in FCC metals. J Nucl Mater, 2003, 323: 281–289

Shen Z, Wagoner R H, Clark W A T. Dislocation and grain boundary interactions in metals. Acta Metall, 1988, 36: 3231–3242

Liang Y, Yang X, Gong M, et al. Interactions between dislocations and three-dimensional annealing twins in face centered cubic metals. Comput Mater Sci, 2019, 161: 371–378

Ni S, Wang Y B, Liao X Z, et al. The effect of dislocation density on the interactions between dislocations and twin boundaries in nanocrystalline materials. Acta Mater, 2012, 60: 3181–3189

Zhu Y T, Wu X L, Liao X Z, et al. Dislocation-twin interactions in nanocrystalline fcc metals. Acta Mater, 2011, 59: 812–821

Wu Z X, Zhang Y W, Srolovitz D J. Dislocation-twin interaction mechanisms for ultrahigh strength and ductility in nanotwinned metals. Acta Mater, 2009, 57: 4508–4518

Malyar N V, Micha J S, Dehm G, et al. Dislocation-twin boundary interaction in small scale Cu bi-crystals loaded in different crystallographic directions. Acta Mater, 2017, 129: 91–97

Xu S, Xiong L, Chen Y, et al. Sequential slip transfer of mixedcharacter dislocations across Σ3 coherent twin boundary in FCC metals: A concurrent atomistic-continuum study. npj Comput Mater, 2016, 2: 15016

Jin Z H, Gumbsch P, Ma E, et al. The interaction mechanism of screw dislocations with coherent twin boundaries in different face-centred cubic metals. Scripta Mater, 2006, 54: 1163–1168

Jin Z H, Gumbsch P, Albe K, et al. Interactions between non-screw lattice dislocations and coherent twin boundaries in face-centered cubic metals. Acta Mater, 2008, 56: 1126–1135

Wang J, Huang H. Novel deformation mechanism of twinned nanowires. Appl Phys Lett, 2006, 88: 203112

Ming K, Bi X, Wang J. Microstructures and deformation mechanisms of Cr26Mn20Fe20Co20Ni14 alloys. Mater Charact, 2017, 134: 194–201

Liang Y, Yang X, Gong M, et al. Slip transmission for dislocations across incoherent twin boundary. Scripta Mater, 2019, 166: 39–43

Cao A J, Wei Y G, Mao S X. Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries. Appl Phys Lett, 2007, 90: 151909

Sun J, Fang L, Sun K, et al. Direct observation of dislocations originating from perfect twin boundaries. Scripta Mater, 2011, 65: 501–504

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51571046 and 51421001), the Fundamental Research Funds for the Central Universities (Grant No. 2018CDJDCL0019), and the “111”Project (Grant No. B16007) by the Ministry of Education and the State Administration of Foreign Experts Affairs of China.

Rights and permissions

About this article

Cite this article

Liang, Y., Yang, X., Ming, K. et al. In situ observation of transmission and reflection of dislocations at twin boundary in CoCrNi alloys. Sci. China Technol. Sci. 64, 407–413 (2021). https://doi.org/10.1007/s11431-019-1517-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-019-1517-8