Abstract

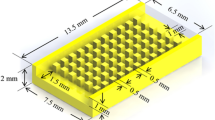

A model of non-uniform height rectangular fin, in which the variation of base’s thickness and width are taken into account, is established in this paper. The dimensionless maximum thermal resistance (DMTR) and the dimensionless equivalent thermal resistance (DETR) defined based on the entransy dissipation rate (EDR) are taken as performance evaluation indexes. According to constructal theory, the variations of the two indexes with the geometric parameters of the fin are analyzed by using a finite-volume computational fluid dynamics code, the effects of the fin-material fraction on the two indexes are analyzed. It is found that the two indexes decrease monotonically as the ratio between the front height and the back height of the fin increases subjected to the non-uniform height rectangular fin. When the model is reduced to the uniform height fin, the two indexes increase first and then decrease with increase in the ratio between the height of the fin and the fin space. The fin-material fraction has no effect on the change rule of the two indexes with the ratio between the height of the fin and the fin space. The sensitivity of the DETR to the geometric parameters of the fin is higher than that of the DMTR to the geometric parameters. The results obtained herein can provide some theoretical support for the thermal design of rectangular fins.

Similar content being viewed by others

References

Garimella S V, Joshi Y K, Bar-Cohen A, et al. Thermal challenges in next generation electronic systems: Summary of panel presentations and discussions. IEEE T Compon Pack T, 2002, 25: 569–575

Garimella S V, Fleischer A S, Murthy J Y, et al. Thermal challenges in next-generation electronic systems. IEEE T Compon Pack Tech, 2008, 31: 801–815

Liu S, Yang J H, Gan Z Y, et al. Structural optimization of a microjet based cooling system for high power LEDs. Int J Therm Sci, 2008, 27: 1086–1095

Dirker J, Meyer J P. Topology optimization for an internal heat-conduction cooling scheme in a square domain for high heat flux applications. J Heat Trans-T ASME, 2013, 135: 111010

Sharma C S, Tiwari M K, Zimmermann S, et al. Energy efficient hotspot-targeted embedded liquid cooling of electronics. Appl Energy, 2015, 138: 414–422

Naphon P, Wiriyasart S, Wongwises S. Thermal cooling enhancement techniques for electronic components. Int Commun Heat Mass, 2015, 61: 140–145

Bejan A. Shape and Structure, from Engineering to Nature. Cambridge: Cambridge University Press, 2000

Bejan A, Lorente S, Miguel A F, et al. Along with Constructal Theory. Switzerland: University of Lausanne, 2006

Bejan A, Lorente S. Design with Constructal Theory. New York: John Wiley & Sons, 2008

Rocha L A O. Convection in Channels and Porous Media: Analysis, Optimization, and Constructal Design. Saarbrücken: VDM Verlag Dr Mueller Aktiengesellschaft & Co. KG, 2009

Lorenzini G, Moretti S, Bejan A. Fin Shape Thermal Optimization Using Bejan’s Constructal Theory. Williston: Morgan & Claypool Publishers, 2011

Chen L G. Progress in study on constructal theory and its application. Sci China Tech Sci, 2012, 55: 802–820

Bejan A, Zane P J. Design in Nature. New York: Doubleeday, 2012

Rocha L A O, Lorente S, Bejan A. Constructal Law and the Unifying Principle of Design. Berlin: Springer, 2013

Bejan A, Lorente S. Constructal law of design and evolution: Physics, biology, technology, and society. J Appl Phys, 2013, 113: 151301

Bejan A. Constructal law: Optimization as design evolution. J Heat Trans-T ASME, 2015, 137: 61003

Bejan A. Street network theory of organization in nature. J Adv Transport, 1996, 30: 85–107

Bejan A. Constructal-theory network of conducting paths for cooling a heat generating volume. J Heat Trans-T ASME, 1997, 40: 799–816

Alebrahim A, Bejan A. Constructal trees of circular fins for conductive and convective heat transfer. Int J Heat Mass Transf, 1999, 42: 3585–3597

Almogbel M, Bejan A. Cylindrical trees of pin fins. Int J Heat Mass Transf, 2000, 43: 4285–4297

Xie G N, Song Y, Asadi M, et al. Optimization of pin-fins for a heat exchanger by entropy generation minimization and constructal law. J Heat Trans-T ASME, 2015, 137: 61901

Bejan A, Almogbel M. Constructal T-shaped fins. Int J Heat Mass Transf, 2000, 43: 2101–2115

Lorenzini G, Biserni C, Correa R L, et al. Constructal design of T-shaped assemblies of fins cooling a cylindrical solid body. Int J Therm Sci, 2014, 83: 96–103

Lorenzini G, Rocha L A O. Constructal design of Y-shaped assembly of fins. Int J Heat Mass Transf, 2006, 49: 4552–4557

Xie Z H, Chen L G, Sun F R. Constructal optimization of twice level Y-shaped assemblies of fins by taking maximum thermal resistance minimization as objective. Sci China Tech Sci, 2010, 53: 2756–2764

Lorenzini G, Moretti S. Bejan’s constructal theory and overall performance assessment: The global optimization for heat exchanging finned modules. Therm Sci, 2014, 18: 339–348

Lorenzini G, Rocha L A O. Constructal design of T-Y assembly of fins for an optimized heat removal. Int J Heat Mass Transf, 2009, 52: 1458–1463

Lorenzini G, Corrêa R L, Santos E D D, et al. Constructal design of complex assembly of fins. J Heat Trans-T ASME, 2011, 133: 81902

Guo Z Y, Zhu H Y, Liang X G. Entransy—A physical quantity describing heat transfer ability. Int J Heat Mass Transf, 2007, 50: 2545–2556

Guo Z Y, Cheng X G, Xia Z Z. Least dissipation principle of heat transport potential capacity and its application in heat conduction optimization. Chin Sci Bull, 2003, 48: 406–410

Cheng X T, Liang X G, Xu X H. Microscopic expression of entransy (in Chinese). Acta Phys Sin, 2011, 60: 60512

Cheng X T, Xu X H, Liang X G. Principles of potential entransy in generalized flow (in Chinese). Acta Phys Sin, 2011, 60: 118103

Cheng X T, Dong Y, Liang X G. Potential entransy and potential entransy decrease principle (in Chinese). Acta Phys Sin, 2011, 60: 114402

Feng H J, Chen L G, Xie Z H, et al. Thermal insulation constructal optimization for steel rolling reheating furnace wall based on entransy dissipation extremum principle. Sci China Tech Sci, 2012, 55: 3322–3333

Xie Z H. Multi-objective Constructal Optimizations for Three Classes of Heat Transfer Structures (in Chinese). Wuhan: Naval University of Engineering, 2010

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization the problem of constracting “disc-point” cooling channels (in Chinese). Acta Phys Sin, 2013, 62: 134703

Chen Q, Wang M, Pan N, et al. Optimization principles for convective heat transfer. Energy, 2009, 34: 1199–1206

Song W M, Meng J A, Li Z X. Optimization of flue gas turbulent heat transfer with condensation in a tube. Chin Sci Bull, 2011, 56: 263–268

Jia H, Liu Z C, Liu W, et al. Convective heat transfer optimization based on minimum entransy dissipation in the circular tube. Int J Heat Mass Transf, 2014, 73: 124–129

Liu X B, Wang M, Meng J A, et al. Minimum entransy dissipation principle for the optimization of transport networks. Int J Nonlin Sci Num, 2010, 11: 113–120

Xia S J, Chen L G, Sun F R. Entransy dissipation minimization for one-way isothermal mass transfer processes with a generalized mass transfer law. Sci Iran Chem Chem Eng, 2012, 19: 1616–1625

Xia S J, Chen L G, Sun F R. Entransy dissipation minimization for liquid-solid phase change processes. Sci China Tech Sci, 2010, 53: 960–968

Wang H R, Wu H Y. Application of minimum thermal resistance principle in optimization for melting process with multiple PCMs (in Chinese). Chin Sci Bull, 2015, 60: 3377–3385

Xu M T, Cheng L, Guo J F. An application of entransy dissipation theory to heat exchanger design (in Chinese). J Engng Thermophys, 2009, 30: 2090–2092

Li X F, Guo J F, Xu M T, et al. Entransy dissipation minimization for optimization of heat exchanger design. Chin Sci Bull, 2011, 56: 2174–2178

Guo J F, Xu M T. The application of entransy dissipation theory in optimization design of heat exchanger. Appl Therm Eng, 2012, 36: 227235

Xia S J, Chen L G, Ge Y L, et al. Influence of heat leakage on entransy dissipation minimization of heat exchanger (in Chinese). Acta Phys Sin, 2014, 63: 20505

Xia S J, Chen L G, Sun F R. Entransy dissipation minimization for a class of one-way isothermal mass transfer processes. Sci China Tech Sci, 2011, 54: 352–361

Yuan F, Chen Q. Optimization criteria for the performance of heat and mass transfer in indirect evaporative cooling systems. Chin Sci Bull, 2012, 57: 687–693

Zhou B, Cheng X T, Wang W H, et al. Entransy analyses of thermal processes with variable thermophysical properties. Int J Heat Mass Transf, 2015, 90: 1244–1254

Cheng X T, Liang X G. Entransy, entransy dissipation and entransy loss for analyses of heat transfer and heat-work conversion processes. J Therm Sci Tech, 2013, 8: 337–352

Wang W, Cheng X, Liang X. Analyses of the endoreversible Carnot cycle with entropy theory and entransy theory. Chin Phys B, 2013, 22: 110506

Yang A B, Chen L G, Xia S J, et al. The optimal configuration of reciprocating engine based on maximum entransy loss. Chin Sci Bull, 2014, 59: 2031–2038

Li T, Fu W, Zhu J. An integrated optimization for organic Rankine cycle based on entransy theory and thermodynamics. Energy, 2014, 72: 561–573

Zhu Y, Hu Z, Zhou Y, et al. Applicability of entropy, entransy and exergy analyses to the optimization of the organic Rankine cycle. Energy Conv Manag, 2014, 88: 267–276

Wang W, Cheng X, Liang X. T-Q diagram analyses and entransy optimization of the organic flash cycle (OFC). Sci China Tech Sci, 2015, 58: 630–637

Kim K H, Kim K. Comparative analyses of energy-exergy-entransy for the optimization of heat-work conversion in power generation systems. Int J Heat Mass Transf, 2015, 84: 80–90

Ahmadi M H, Ahmadi M A, Pourfayaz F, et al. Thermodynamic analysis and multi-objective optimization of performance of solar dish Stirling engine by the centrality of entransy and entropy generation. Int J Electr Power Energy, 2016, 78: 88–95

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy optimizations for insulation layer of steel rolling reheating furnace wall with convective and radiative boundary conditions. Chin Sci Bull, 2014, 59: 2470–2477

Feng H J, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization for variable cross-section insulation layer of the steel rolling reheating furnace wall. Int Commun Heat Mass, 2014, 52: 26–32

Feng H J, Chen L G, Xie Z H, et al. Constructal optimization of variable cross-section insulation layer of steel rolling reheating furnace wall based on entransy theory (in Chinese). Acta Phys Sin, 2015, 64: 054402

Liu X, Chen L G, Feng H J, et al. Constructal design for blast furnace wall based on the entransy theory. Appl Therm Eng, 2016, 100: 798–804

Chen L G. Progress in entransy theory and its applications. Chin Sci Bull, 2012, 57: 4404–4426

Zhao T, Chen Q. Macroscopic physical meaning of entransy and its application (in Chinese). Acta Phys Sin, 2013, 62: 234401

Chen Q, Liang X G, Guo Z Y. Entransy theory for the optimization of heat transfer: A review and update. Int J Heat Mass Transf, 2013, 63: 65–81

Chen L G. Progress in optimization of mass transfer processes based on mass entransy dissipation extremum principle. Sci China Tech Sci, 2014, 57: 2305–2327

Cheng X T, Liang X G. Entransy: Its physical basis, applications and limitations. Chin Sci Bull, 2014, 59: 5309–5323

Cheng X T, Liang X G. Work entransy and its applications. Sci China Tech Sci, 2015, 58: 2097–2103

Zhou L, Liu Y. Optimization of horizontal plate fin heat sink in natural convection for electronics cooling by simulated annealing algorithm. Adv Mater Res, 2014, 1022: 91–95

Cheng X T, Zhang Q Z, Xu X H, et al. Optimization of fin geometry in heat convection with entransy theory. Chin Phys B, 2013, 22: 20503

Yang A B, Chen L G, Xie Z H, et al. Comparative study on constructal optimizations of rectangular fins heat sink based on entransy dissipation rate minimization and maximum thermal resistance minimization (in Chinese). Acta Phys Sin, 2015, 64: 204401

Xie Z H, Chen L G, Sun F R. Comparative study on constructal optimizations of T-shaped fin based on entransy dissipation rate minimization and maximum thermal resistance minimization. Sci China Tech Sci, 2011, 54: 1249–1258

Chen L G, Xiao Q H, Xie Z H, et al. T-shaped assembly of fins with constructal entransy dissipation rate minimization. Int Commun Heat Mass, 2012, 39: 1556–1562

Xiao Q H, Chen L G, Xie Z H, et al. Constructal entransy dissipation rate minimization for Y-shaped assembly of fins (in Chinese). J Engng Thermophys, 2012, 33: 1465–1470

Chen L, Xiao Q, Xie Z, et al. Constructal entransy dissipation rate minimization for tree-shaped assembly of fins. Int J Heat Mass Transf, 2013, 67: 506–513

Feng H J, Chen L G, Xie Z H, et al. Constructal optimization of complex fin with convective heat transfer based on entransy dissipation rate minimization (in Chinese). Acta Phys Sin, 2015, 64: 34701

Das B, Giri A. Second law analysis of an array of vertical platefinned heat sink undergoing mixed convection. Int Commun Heat Mass, 2014, 56: 42–49

Taji S G, Parishwad G V, Sane N K. Enhanced performance of horizontal rectangular fin array heat sink using assisting mode of mixed convection. Int J Heat Mass Transf, 2014, 72: 250–259

Zhou J H, Yang C X, Zhang L N. Minimizing the entropy generation rate of the plate-finned heat sinks using computational fluid and combined optimization. Appl Therm Eng, 2009, 29: 1872–1879

Zhang X H, Liu D W. Optimum geometric arrangement of vertical rectangular fin arrays in natural convection. Energy Conv Manage, 2010, 51: 2449–2456

Baskaya S, Sivrioglu M, Ozek M. Parametric study of natural convection heat transfer from horizontal rectangular fin arrays. Int J Therm Sci, 2000, 39: 797–805

Chen H, Lai S, Haung L. Investigation of heat transfer characteristics in plate-fin heat sink. Appl Therm Eng, 2013, 50: 352–360

Morega M, Bejan A. Plate fins with variable thickness and height for air-cooled electronic modules. Int J Heat Mass Transf, 1994, 37: 433–445

Kim D K. Thermal optimization of plate-fin heat sinks with fins of variable thickness under natural convection. Int J Heat Mass Transf, 2012, 55: 752–761

Chen Q. Irreversibility and Optimization of Convective Transport Processes (in Chinese). Beijing: Tsinghua University, 2008

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, A., Chen, L., Xie, Z. et al. Thermal performance analysis of non-uniform height rectangular fin based on constructal theory and entransy theory. Sci. China Technol. Sci. 59, 1882–1891 (2016). https://doi.org/10.1007/s11431-016-0081-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-0081-6