Abstract

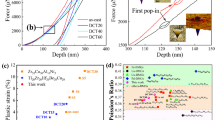

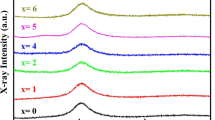

Little is known about the mechanical properties of bulk metallic glassy alloys (BMGs) after cryogenic treatment. In this study, the effects of cryogenic treatment (CT) on the microstructural transition and the mechanical properties of Cu-based bulk metallic glass (BMG) were studied. The results showed that submicron AlCu2Zr and Cu5Zr phases can precipitate from the Cu-Zr-Ag-Al matrix after 192 h CT. The formation of these nanometer-sized crystalline phases substantially enhanced the mechanical properties of the bulk amorphous alloy. The micro-hardness and the compressive strength were found to increase respectively from 501 HV and 1510 MPa to 595 HV and 1910 MPa after cryogenic treatment. CT is a promising approach to strengthening metal glasses.

Similar content being viewed by others

References

Johnson W L. Bulk amorphous metal-An emerging engineering material. JOM, 2002, 54(3): 40–43

Liu X J, Chen G L, Hou H Y, et al. Atomistic mechanism for nanocrystallization of metallic glasses. Acta Mater, 2008, 56(12): 2760–2769

Das J, Tang M B, Kim K B, et al. “Work-hardenable” ductile bulk metallic glass. Phys Rev Lett, 2005, 94(20): 205501

Inoue A, Zhang W, Zhang T, et al. High-strength Cu-based bulk glassy alloys in Cu-Zr-Ti and Cu-Hf-Ti ternary systems. Acta Mater, 2001, 49: 2645–2652

Inoue A, Zhang W. Formation, thermal stability and mechanical properties of Cu-Zr-Al bulk glassy alloys. Mater Trans, 2002, 43: 2921–2925

Wang Q, Qiang J B, Wang Y M, et al. Formation and optimization of Cu-based Cu-Zr-Al bulk metallic glasses. Mater Sci Forum, 2005, 3381: 475–479

Inoue A, Zhang W, Zhang T, et al. Cu-based bulk glassy alloys with high tensile strength of over 2000 MPa. J Non-Cry Solids, 2002, 304: 200–209

Wang H R, Teng X Y, Shi Z Q, et al. Study on microstructure and crystallization of amorphous Cu56Zr44 alloy by means of isothermal annealing. Acta Phys Sin, 2001, 50(11): 2192–2197

Zhang W, Zhang Q S, Qin C L, et al. Synthesis and properties of Cu-Zr-Ag-Al glassy alloys with high glass-forming ability. Mater Sci Eng B, 2008, 148: 92–96

Yao K F, Zang C Q. Fe-based bulk metallic glass with high plasticity. Appl Phys Lett, 2007, 90: 061901

Hajlaoui K, Yavari A R, Das J, et al. Ductilization of BMGs by optimization of nanoparticle dispersion. J Alloys Compd, 2007, 434–435: 6–9

Kawashima A, Zeng Y Q, Fukuhara M, et al. Mechanical properties of a Ni60Pd20P17B3 bulk glassy alloy at cryogenic temperatures. Mater Sci Eng A, 2008, 498: 475–481

Kawashima A, Zeng Y Q, Xie G Q, et al. Microstructure in a Ni60Pd20P17B3 bulk metallic glass compressively fractured at cryogenic temperature. Mater Sci Eng A, 2010, 528: 391–396

Ma G Z, Chen D, Jiang Y, et al. Cryogenic treatment-induced martensitic transformation in Cu-Zr-Al bulk metallic glass composite. Intermetallics, 2010, 18: 1254–1257

Wang K, Chen M W, Pan D, et al. Plastic deformation energy of bulk metallic glasses. Mater Sci Eng B, 2008, 148: 101–104

Oh J C, Ohkubo T, Kim Y C, et al. Phase separation in Cu43Zr43Al7-Ag7 bulk metallic glass. Scripta Mater, 2005, 53: 165–169

Degtyareva V F, Porsch F, Ponyatovskiian E G, et al. Structural investigations of the amorphous alloy Al30Ge70 under high pressure. Phys Rev B, 1996, 53: 8337–8339

Sun L L, Wang W K, He D W, et al. Reversible phase transition between amorphous and crystalline in Zr41.2Ti13.8Cu12.5Ni10Be22.5 under high pressure at room temperature. Appl Phys Lett, 2000, 76: 2874–2876

Zhang X Y, Zhang J W, Wang W K. Effect of pressure on the microstructure of α-Fe/Sm2(Fe, Si)17Cx nanocomposite magnets. J Appl Phys, 2001, 89: 477–481

Porter D A, Easterling K E. Phase Transformations in Metals and Alloys. New York: Van Nostrand-Reinhold, 1981. 263

Pauly S, Liu G, Wang G, et al. Microstructural heterogeneities governing the deformation of Cu47.5Zr47.5Al5 bulk metallic glass composites. Acta Mater, 2009, 57: 5445–5453

Das J, Paulya S, Bostrom M, et al. Designing bulk metallic glass and glass matrix composites in martensitic alloys. J Alloys Compd, 2009, 483: 97–101

Lu K, Wang J T. Effect of pre-annealing on crystallization kinetics of amorphous Ni-P alloys. Acta Metall Sin, 1990, 26: 316–320

Lu K, Wang J T, Dong L. In situ observation on dynamic crystallization in amorphous Ni-P alloy foil with TEM. Acta Metall Sin, 1991, 27: 108–114

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Zhang, L., Liu, J. et al. Cryogenic treatment induced hardening for Cu-Zr-Ag-Al bulk metallic glasses. Sci. China Technol. Sci. 56, 637–641 (2013). https://doi.org/10.1007/s11431-012-5107-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-5107-z