Abstract

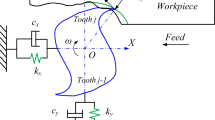

This paper focuses on the development of an efficient semi-analytical solution of chatter stability in milling based on the spectral method for integral equations. The time-periodic dynamics of the milling process taking the regenerative effect into account is formulated as a delayed differential equation with time-periodic coefficients, and then reformulated as a form of integral equation. On the basis of one tooth period being divided into a series of subintervals, the barycentric Lagrange interpolation polynomials are employed to approximate the state term and the delay term in the integral equation, respectively, while the Gaussian quadrature method is utilized to approximate the integral term. Thereafter, the Floquet transition matrix within the tooth period is constructed to predict the chatter stability according to Floquet theory. Experimental-validated one-degree-of-freedom and two-degree-of-freedom milling examples are used to verify the proposed algorithm, and compared with existing algorithms, it has the advantages of high rate of convergence and high computational efficiency.

Similar content being viewed by others

References

Budak E. Analytical models for high performance milling. Part I: Cutting forces, structural deformations and tolerance integrity. Int J Mach Tools Manuf, 2006, 46(12–13): 1478–1488

Budak E. Analytical models for high performance milling. Part II: Process dynamics and stability. Int J Mach Tools Manuf, 2006, 46(12–13): 1489v1499

Altintas Y, Merdol S D. Virtual high performance milling. CIRP Ann-Manuf Technol, 2007, 56(1): 81–84

Wiercigroch M, Budak E. Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos Trans R Soc A-Math Phys Eng Sci, 2001, 359(1781): 663–693

Altintas Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and Cnc Design. Cambridge: Cambridge University Press, 2000

Altintas Y, Weck M. Chatter stability of metal cutting and grinding. CIRP Ann-Manuf Technol, 2004, 53(2): 619–642

Altintas Y, Stépán G, Merdol D, et al. Chatter stability of milling in frequency and discrete time domain. CIRP J Manuf Sci Technol, 2008, 1(1): 35–44

Tlusty J, Ismail F. Basic non-linearity in machining chatter. CIRP Ann-Manuf Technol, 1981, 30(1): 299–304

Smith S, Tlusty J. Efficient simulation programs for chatter in milling. CIRP Ann-Manuf Technol, 1993, 42(1): 463–466

Campomanes M L, Altintas Y. An improved time domain simulation for dynamic milling at small radial immersions. J Manuf Sci Eng-Trans ASME, 2003, 125(3): 416–422

Li Z, Liu Q. Solution and analysis of chatter stability for end milling in the time-domain. Chin J Aeronaut, 2008, 21(2): 169–178

Altintas Y, Budak E. Analytical prediction of stability lobes in milling. CIRP Ann-Manuf Technol, 1995, 44(1): 357–362

Budak E, Altintas Y. Analytical prediction of chatter stability in milling-Part I: General formulation. J Dyn Syst Meas Control-Trans ASME, 1998, 120(1): 22–30

Merdol S D, Altintas Y. Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng-Trans ASME, 2004, 126(3): 459–466

Altintas Y. Analytical prediction of three dimensional chatter stability in milling. JSME Int J Ser C-Mech Syst Mach Elem Manuf, 2001, 44(3): 717–723

Ko J H, Altintas Y. Dynamics and stability of plunge milling operations. J Manuf Sci Eng-Trans ASME, 2007, 129(1): 32–40

Kardes N, Altintas Y. Mechanics and dynamics of the circular milling process. J Manuf Sci Eng-Trans ASME, 2007, 129(1): 21–31

Ozturk E, Budak E. Dynamics and stability of five-axis ball-end milling. J Manuf Sci Eng-Trans ASME, 2010, 132(2): 021003

Bayly P V, Halley J E, Mann B P, et al. Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng-Trans ASME, 2003, 125(2): 220–225

Mann B P, Bayly P V, Davies M A, et al. Limit cycles, bifurcations, and accuracy of the milling process. J Sound Vibr, 2004, 277(1–2): 31–48

Mann B P, Young K A, Schmitz T L, et al. Simultaneous stability and surface location error predictions in milling. J Manuf Sci Eng-Trans ASME, 2005, 127(3): 446–453

Mann B P, Edes B T, Easley S J, et al. Chatter vibration and surface location error prediction for helical end mills. Int J Mach Tools Manuf, 2008, 48(3–4): 350–361

Insperger T, Stépán G. Semi-discretization method for delayed systems. Int J Numer Methods Eng, 2002, 55(5): 503–518

Insperger T, Stépán G. Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Eng, 2004, 61(1): 117–141

Insperger T, Stépán G, Turi J. On the higher-order semi-discretizations for periodic delayed systems. J Sound Vibr, 2008, 313(1–2): 334–341

Insperger T, Mann B P, Stepan G, et al. Stability of up-milling and down-milling, Part 1: Alternative analytical methods. Int J Mach Tools Manuf, 2003, 43(1): 25–34

Mann B P, Insperger T, Bayly P V, et al. Stability of up-milling and down-milling, Part 2: Experimental verification. Int J Mach Tools Manuf, 2003, 43(1): 35–40

Long X H, Balachandran B, Mann B P. Dynamics of milling processes with variable time delays. Nonlinear Dyn, 2007, 47(1–3): 49–63

Long X H, Balachandran B. Stability analysis for milling process. Nonlinear Dyn, 2007, 49(3): 349–359

Sims N D, Mann B, Huyanan S. Analytical prediction of chatter stability for variable pitch and variable helix milling tools. J Sound Vibr, 2008, 317(3-5): 664–686

Seguy S, Insperger T, Arnaud L, et al. On the stability of high-speed milling with spindle speed variation. Int J Adv Manuf Technol, 2010, 48(9–12): 883–895

Wan M, Zhang W H, Dang J W, et al. A unified stability prediction method for milling process with multiple delays. Int J Mach Tools Manuf, 2010, 50(1): 29–41

Olgac N, Sipahi R. A unique methodology for chatter stability mapping in simultaneous machining. J Manuf Sci Eng-Trans ASME, 2005, 127(4): 791–800

Butcher E A, Ma H, Bueler E, et al. Stability of linear time-periodic delay-differential equations via chebyshev polynomials. Int J Numer Methods Eng, 2004, 59(7): 895–922

Butcher E A, Bobrenkov O A, Bueler E, et al. Analysis of milling stability by the chebyshev collocation method: Algorithm and optimal stable immersion levels. J Computat Nonlinear Dyn, 2009, 4(3): 031003

Ding Y, Zhu L, Zhang X, et al. A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf, 2010, 50(5): 502–509

Ding Y, Zhu L, Zhang X, et al. On a Numerical method for simultaneous prediction of stability and surface location error in low radial immersion milling. J Dyn Syst Meas Control-Trans ASME, 2011, 133(2): 024503

Insperger T. Full-discretization and semi-discretization for milling stability prediction: Some comments. Int J Mach Tools Manuf, 2010, 50(7): 658–662

Ding Y, Zhu L, Zhang X, et al. Numerical integration method for prediction of milling stability. J Manuf Sci Eng-Trans ASME, 2011, 133(3): 031005

Ding Y, Zhu L, Zhang X, et al. Spectral method for prediction of chatter stability in low radial immersion milling. Proceedings-IEEE International Conference on Robotics and Automation, 2011, Shanghai, China. 4359–4363

Tang T, Xu X, Cheng J. On spectral methods for volterra integral equations and the convergence analysis. J Comput Math, 2008, 26(6): 825–837

Ali I, Brunner H, Tang T. Spectral methods for pantograph-type differential and integral equations with multiple delays. Frontiers Math China, 2009, 4(1): 49–61

Khasawneh F A, Mann B P. A Spectral Element Approach for the Stability of Delay Systems. Int J Numer Methods Eng, 2011, 87(6): 566–592

Trefethen L N. Spectral Methods in Matlab, Society for Industrial and Applied Mathematics, Philadelphia, 2000

Yang W Y, Cao W, Chung T S, et al. Applied Numerical Methods Using Matlab. Hoboken, N.J.: Wiley-Interscience, 2005

Berrut J P, Trefethen L N. Barycentric lagrange interpolation. SIAM Rev, 2004, 46(3): 501–517

Farkas M. Periodic Motions. New York: Springer-Verlag, 1994

Henninger C, Eberhard P. Improving the computational efficiency and accuracy of the semi-discretization method for periodic delay-differential equations. Eur J Mech A-Solids, 2008, 27(6): 975–985

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (I): Third-order approximation of tool envelope surface. Sci China Tech Sci, 2010, 53(7): 1904–1912

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (II): Tool positioning strategy. Sci China Tech Sci, 2010, 53(8): 2190–2197

Ye T, Xiong C H, Xiong Y L, et al. Kinematics constrained five-axis tool path planning for high material removal rate. Sci China Tech Sci, 2011, 54: 3155–3165

Mao X Y, Liu H Q, Li B. Time-frequency analysis and the detecting method research on the milling force token signal in the spindle current signal. Sci China Ser E-Tech Sci, 2009, 52: 2810–2813

Liu H Q, Chen Q H, Li B, et al. On-line chatter detection using servo motor current signal in turning. Sci China Tech Sci, 2011, 54: 3119–3129

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, Y., Zhu, L., Zhang, X. et al. Milling stability analysis using the spectral method. Sci. China Technol. Sci. 54, 3130–3136 (2011). https://doi.org/10.1007/s11431-011-4611-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4611-x